Block Flow Diagram

A block flow diagram, abbreviated as BFD, or a block schematic diagram is a simplified representation of a Process Flow Diagram (PFD). In the design process, it is used as a first step in development of the PFD. Essentially, it is developed by taking a written problem and converting it into a graphical representation. A BFD can be used to describe an entire facility or plant (Block Flow Plant Diagram) or a specific process within a plant (Block Flow Process Diagram).

BFD is Used For

- The block flow diagram may be used to communicate to individuals with little to no knowledge of reading process diagrams. (E.g. management, environmental, health and safety (EHS) departments, government agencies, etc.)

- The first step in the development of a PFD.

- Communicate the process streams and material flows entering and exiting the process.

Unit operations or processes may be represented by rectangles or by a CAD block of the piece of equipment. Each block shows an activity, such as storage or treatment, performed on the primary streams only. Blocks are connected by straight lines and flow arrows and represent a mixture of liquids, gasses or solids moving through the facility. Similar to PFDs, a Block Flow Diagram does not show bypasses, secondary lines or line numbers.

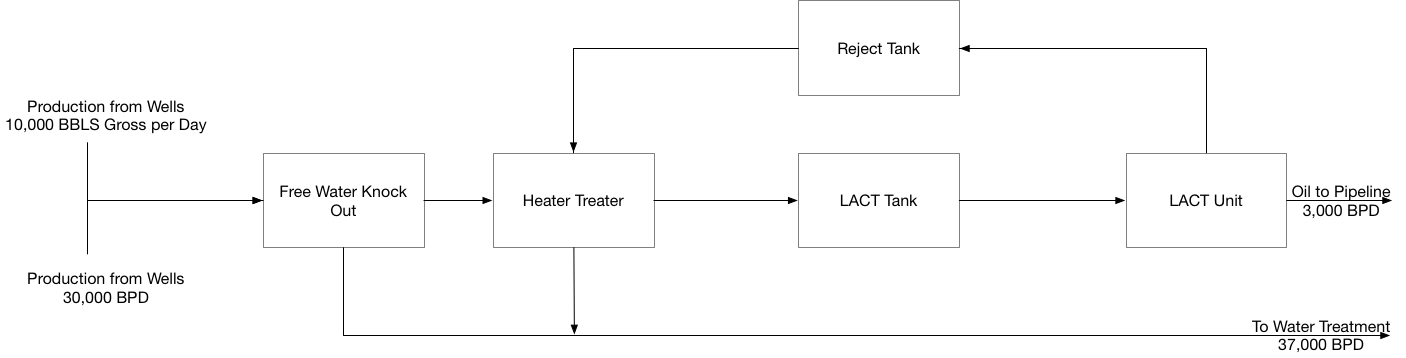

The PFD displays the relationship between major equipment in a plant facility or process and does not show details such as minor equipment items, piping materials of construction and piping sizes. An example of a BFD is shown below. Note that the process flow is easily distinguishable, contains no instrumentation or controls.

Block Flow Diagram Example - Oil Dehy Facility

Block Flow Diagram Example - Oil Dehy Facility

The BFD above shows the overall process for an oil dehydration facility. There are several process streams that are not shown on this diagram. Blanket gas and instrument air, for example, is not shown since it is not a major part of the process. Details specific to the water portion of the dehy are not shown. Generally, there will be a wash tank and ISF to remove the rest of the oil from the process stream. Since this BFD is only for the oil portion, it is not shown.

In Order to Create a Well Versed Block Flow Diagram, the Following Process is Recommended

- Place all major pieces of equipment and unit operations. When multiple pieces of equipment exist in parallel, they may be shown as a single item. The equipment need not have numbers but should show the process or operation that it conducts.

- Connect the pieces of equipment with straight primary lines and show flow arrows.

- Flow direction should always go left to right. If they cross, the horizontal line takes precedence over the vertical line.

- Light stream (gases) toward top with heavy stream (liquids and solids) toward bottom.

- Only the most critical process information needs to be supplied. This could be the name of the product or function

- If there is a chemical reaction occuring within that piece of equipment, it may be shown.

- A material balance should be provided to communicate throughput volumes.

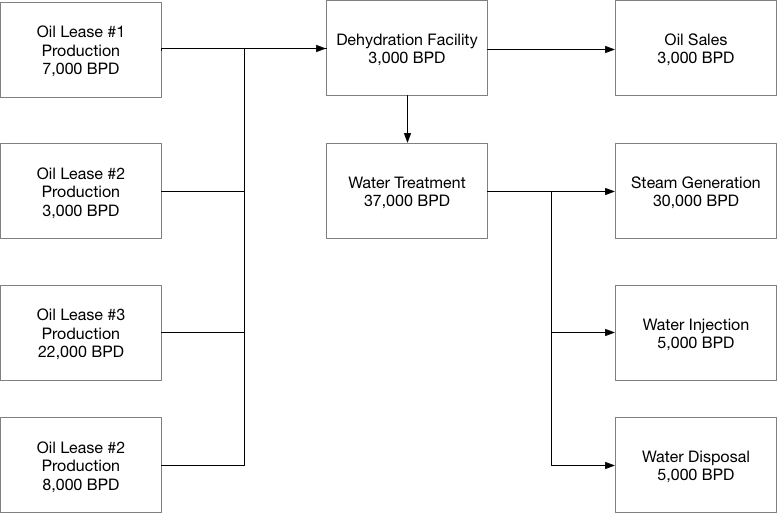

Block Flow Diagram Example 2 - Heavy Oil Field

Block Flow Diagram Example 2 - Heavy Oil Field

The diagram is an overly simplified example of different facilities and processes within a heavy oil producing oil field. This might be used to describe the integration of a new oil lease or perhaps how a facility consolidation project might affect other facilities.

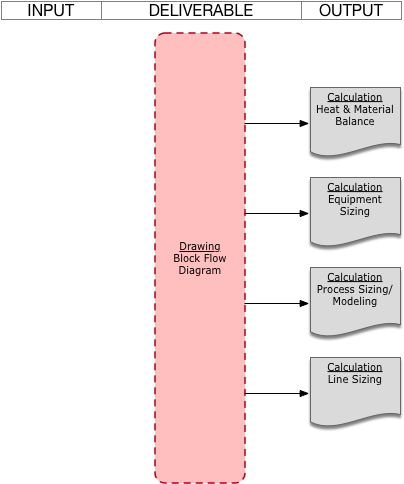

Block Flow Diagram Inputs & Outputs

Input / Output Drawing - Block Flow Diagram

Input / Output Drawing - Block Flow Diagram

In order to put together a block flow diagram, the engineer or designer needs a scope and a project. The scope defines the limits of the drawing and what should be included. No matter what the project is, assembly of the BFD follows the same process: Start with what is known (as-built conditions) and then make modifications.

Information from a BFD is used to create the building blocks of a Process Flow Diagram: Heat & Material Balance Calculations, Equipment Sizing, Process Sizing & Line Sizing.

Graphically, this is described to the left.