Three Phase Separator

Three Phase Separator Index

- The Three Phases Are

- Three Phase Separator Advantages and Disadvantages

- Three Phase Separator Process

- Three Phase Separator Design Considerations

The three phases are

- Gas Phase - This phase consists of gases such as natural gas or other hydrocarbon gases. It is usually the lightest phase and occupies the upper portion of the separator.

- Liquid Phase - The liquid phase includes oil and water. Oil is usually the heavier liquid phase and settles beneath the gas phase, while water may settle at the bottom due to its density.

- Solid Phase - In some cases, there may be solid particles or solids suspended in the fluid stream. These solids can include sand, sediment, or other contaminants. The separator's design may allow for the separation and removal of these solids.

The primary purpose of a three phase separator is to separate these three phases so that they can be further processed, transported, or disposed of separately. This separation is achieved through a combination of gravity, differential density, and sometimes additional separation mechanisms such as internal baffles or coalescing elements. The separator typically has different compartments or sections for each phase, allowing for controlled separation and collection.

Three phase separators are commonly used in upstream oil and gas production facilities, refineries, chemical plants, and other industries where the separation of multiple phases from a mixed fluid stream is necessary for various purposes, including product recovery, environmental compliance, and process efficiency. The design and size of a three phase separator can vary significantly based on the specific application and the characteristics of the fluid stream being processed.

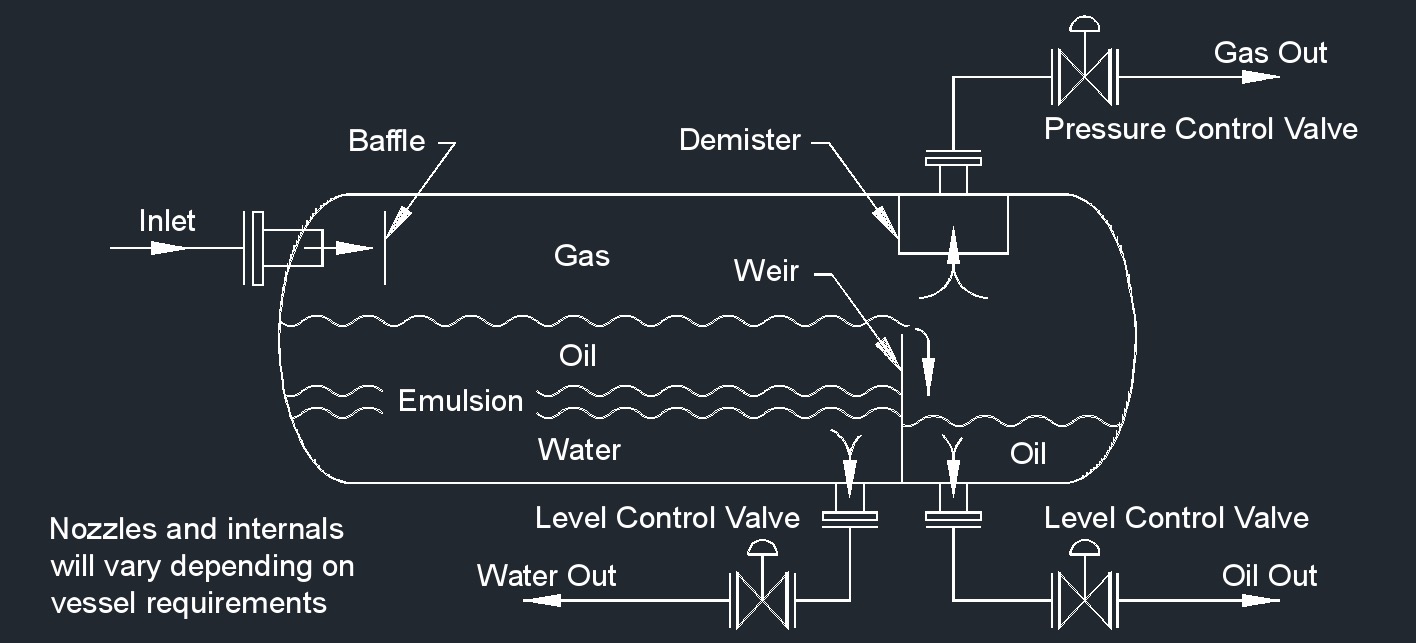

Most, if not all, production meters require conditioning of the process stream prior to measurement. The conditioning process allows for solids to drop out of the stream, entrained gas to break out of the stream or oil/water/gas separation. One tool for this is the three phase separator. Three phase separators are typically horizontal vessels that separate production fluids into separate measurable streams.

Three Phase Separator process

Here's an overview of the three phase separator process.

- Inlet - The mixture of gas, oil, and water enters the separator through an inlet pipe. This mixture typically comes from an oil well or a production facility.

- Gravity Separation - The separator takes advantage of the differences in density among the three phases. Gravity causes the heavier liquid phase (oil) to settle at the bottom of the separator, while the lighter gas phase rises to the top. This separation occurs due to the fact that gas is less dense than both oil and water.

- Water Separation - Water, being denser than oil, settles below the oil layer. The water layer is typically at the bottom of the separator, and any solid particles or sediments may also settle here.

- Internal Components - Inside the separator, various internal components such as baffles, coalescers, and weirs are used to enhance the separation process. Baffles help prevent the mixing of phases, while coalescers aid in merging tiny droplets of one phase into larger ones to facilitate separation.

- Outlet Streams -

- Gas Outlet - The gas phase is collected and exits the separator from the top, typically through a gas outlet pipe. It may contain some residual liquid droplets, which are removed through demisting devices before the gas is transported for further processing or sale.

- Oil Outlet - The separated oil phase is drawn from the bottom of the separator. It may contain some dissolved gas and residual water, which may require further treatment.

- Water Outlet - The separated water phase is usually discharged from the bottom of the separator and may still contain traces of oil and gas. It is sent for further treatment and disposal.

- Control and Monitoring - The three phase separator process is closely monitored and controlled to ensure optimal separation efficiency. Instruments and sensors measure the levels of each phase, and control systems adjust parameters such as flow rates and pressure to optimize separation performance.

The separated phases are typically further processed, with the gas sent for compression and transportation, the oil processed for refining, and the water treated to meet environmental regulations before disposal. Three phase separators are essential in the oil and gas industry to maximize production efficiency, ensure safety, and minimize environmental impact by preventing the release of hydrocarbons or contaminants into the environment.

Three Phase Separator Design Considerations

Designing a three phase separator is a crucial aspect of many industrial processes, particularly in the oil and gas industry. A three phase separator is used to separate a mixture of oil, gas, and water into their individual phases.

- Fluid Properties - Understand the properties of the fluids involved, including their densities, viscosities, and phase behavior. This information is essential for sizing and designing the separator correctly.

- Flow Rates - Determine the flow rates of the oil, gas, and water phases. These flow rates will influence the size and capacity of the separator.

- Separation Efficiency - Define the desired separation efficiency for each phase. Higher separation efficiency may require a larger separator and more advanced internals.

- Pressure and Temperature - Consider the operating pressure and temperature conditions. These factors affect the design and material selection for the separator.

- Inlet Configuration - Design the inlet configuration to promote proper phase separation. This may include using inlet devices like baffles, diverter plates, or cyclonic separators.

- Vessel Geometry - Select an appropriate vessel geometry (e.g., horizontal, vertical, or spherical) based on the available space, process requirements, and other constraints.

- Internal Components - Choose appropriate internal components, such as coalescers, demisters, and baffles, to enhance separation efficiency and prevent carryover of one phase into another.

- Retention Time - Calculate the required retention time inside the separator to allow sufficient settling of the phases. The retention time depends on fluid properties and flow rates.

- Design Codes and Standards - Ensure that the separator design complies with relevant industry standards and codes, such as ASME Boiler and Pressure Vessel Code or API (American Petroleum Institute) standards.

- Safety Considerations - Incorporate safety features like relief valves and pressure gauges to protect against overpressure and ensure safe operation.

- Material Selection - Choose materials that are compatible with the fluids and conditions inside the separator, considering factors like corrosion resistance and temperature limits.

- Level Control - Implement level control systems to maintain the desired liquid levels within the separator for effective separation.

- Gas Handling - Consider the handling and disposal of the separated gas phase, which may include compression, treatment, or flaring.

- Maintenance and Accessibility - Design the separator with ease of maintenance in mind, including access points for inspection and cleaning.

- Environmental Regulations - Ensure compliance with environmental regulations related to the discharge or treatment of separated phases, particularly water and gas.

- Cost Considerations - Balance the design choices with the overall project budget, taking into account capital and operational costs.

- Process Control - Develop a control strategy to maintain stable and efficient separator operation, possibly using level, pressure, and temperature control systems.

- Future Expansion - Consider future expansion needs and design the separator to accommodate potential changes in production rates or process conditions.

A well designed three phase separator is essential for efficient and safe separation of oil, gas, and water, which can significantly impact the overall performance and profitability of a production facility. Collaboration between process engineers, mechanical engineers, and other experts is often necessary to ensure a successful separator design.