Steam

Steam, abbreviated as STM, is the invisible vapor (gas) when water is heated to its boiling point and passes from a liquid to a gaseous state. As water is heated and approaches its boiling point, some of the molecules attain kinetic energy enough to escape into the space above the surface of the liquid. The more the water is heated the more molecules excapes. When more molecules leave the liquid than enter the liquid, the saturation point is reached. As the temperature continues to rising it reaches superheated steam where no liquid exists. The temperature at which water boils and turns into steam depends on the pressure applied to it . At standard atmospheric pressure (1 atmosphere or 101.3 kilopascals), water boils at 100 degrees Celsius (212 degrees Fahrenheit), resulting in the formation of steam.

Steam, abbreviated as STM, is the invisible vapor (gas) when water is heated to its boiling point and passes from a liquid to a gaseous state. As water is heated and approaches its boiling point, some of the molecules attain kinetic energy enough to escape into the space above the surface of the liquid. The more the water is heated the more molecules excapes. When more molecules leave the liquid than enter the liquid, the saturation point is reached. As the temperature continues to rising it reaches superheated steam where no liquid exists. The temperature at which water boils and turns into steam depends on the pressure applied to it . At standard atmospheric pressure (1 atmosphere or 101.3 kilopascals), water boils at 100 degrees Celsius (212 degrees Fahrenheit), resulting in the formation of steam.

- See Article Links - Clean Steam, Dry Steam, Flash Steam, Plant Steam, Saturated Steam, Superheated Steam, Wet Steam, and Steam vs Vapor

Steam has several unique properties and behaviors. It occupies a greater volume than an equivalent mass of liquid water, as the gas molecules are more spread out and less densely packed. Steam is also less dense than air, making it rise and disperse quickly.

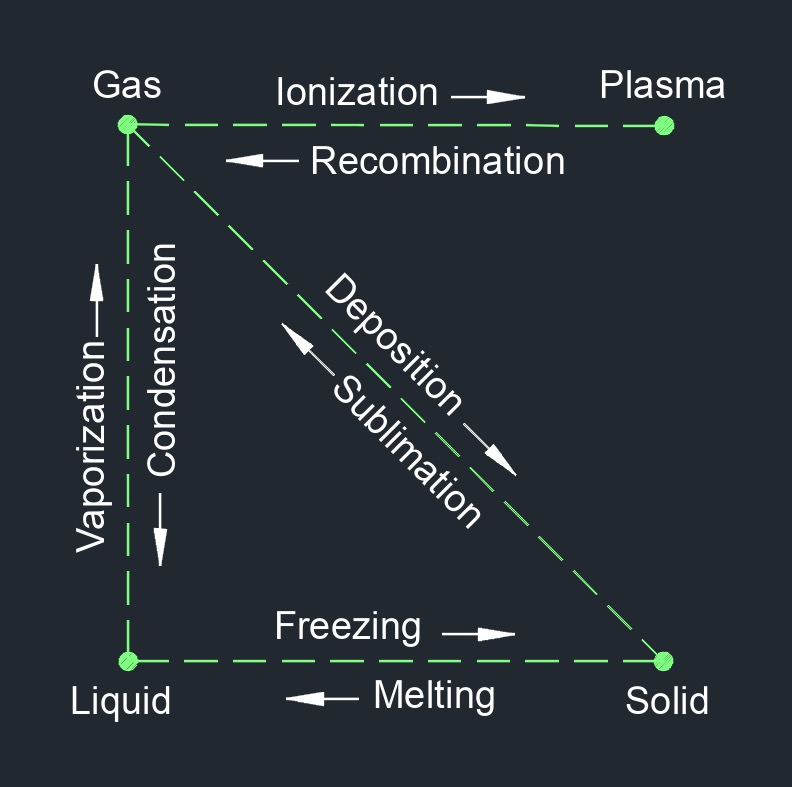

In addition to its applications in industrial processes and power generation, steam has played a crucial role in the development of thermodynamics and the study of heat transfer. Steam engines, for instance, were historically significant in powering trains and other machinery during the industrial revolution. Understanding the physics of steam involves concepts such as phase transitions, thermodynamics, heat transfer, and the behavior of gases. It has practical implications in fields like engineering, energy production, and environmental science.

Steam Tables

- Steam Saturation Properties Pressure Table

- Steam Saturation Properties Temperature Table

- Steam Superheated Vapor Properties Table

- Water Compressed Liquid Properties Table

Tags: Steam Pipe Sizing