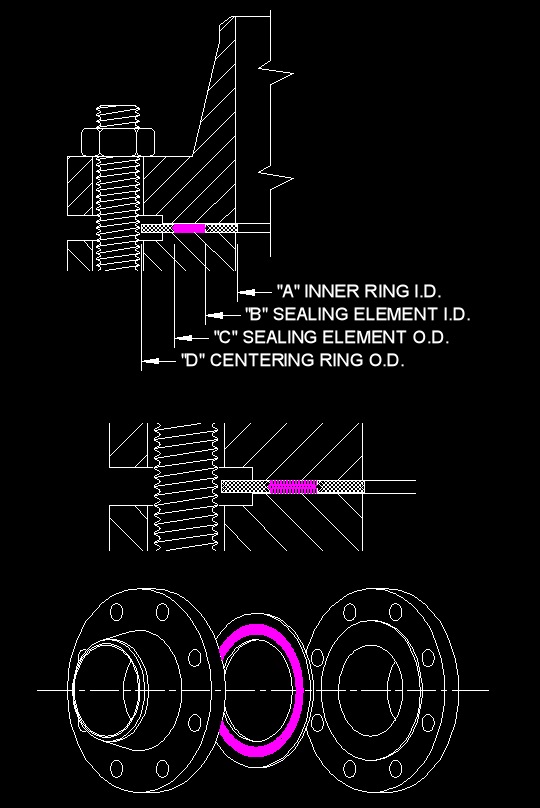

Gasket - Spiral Wound, for ANSI Class 2500, B16.5 (in)

| ||||

|---|---|---|---|---|

| Pipe

Size (NPS) | Inner

Ring Inside Diameter A | Sealing

Element Inside Diameter B | Sealing

Element Outside Diameter C | Outer

Ring Outside Diameter D |

| 1/2 | 0.56 | 0.75 | 1.25 | 2.75 |

| 3/4 | 0.81 | 1.00 | 1.56 | 3.00 |

| 1 | 1.06 | 1.25 | 1.88 | 3.38 |

| 1 1/4 | 1.31 | 1.56 | 2.38 | 4.13 |

| 1 1/2 | 1.63 | 1.88 | 2.75 | 4.63 |

| 2 | 2.06 | 2.31 | 3.38 | 5.75 |

| 2 1/2 | 2.50 | 2.75 | 3.88 | 6.63 |

| 3 | 3.10 | 3.63 | 4.75 | 7.75 |

| 4 | 3.85 (*) | 4.63 | 5.88 | 9.25 |

| 5 | 4.90 (*) | 5.63 | 7.00 | 11.00 |

| 6 | 5.80 (*) | 6.75 | 8.25 | 12.50 |

| 8 | 7.75 (*) | 8.50 | 10.13 | 15.25 |

| 10 | 9.69 (*) | 10.63 | 12.25 | 18.75 |

| 12 | 11.50 (*) | 12.50 | 14.50 | 21.63 |