Clamp and Saddle Pipe Support

Clamp and saddle pipe support is a type of mechanical support used in piping systems to secure and stabilize pipes. This type of support consists of a combination of clamps and saddles that are used together to hold the pipes in place and prevent them from moving, sagging, and transfering the vertical load from a piece of pipe to another. These supports are useful for pipes that run parallel or crosses another pipe and need to be kept in a fixed position. This design can be used when access to pouring a pipe support within the foundation is not possible. This design may not be advangageous if either of the pipes experience vibration or cyclic thermal loading. Frequent expansion and contraction of the pipe could cause premature failure.

It's also important to use the same materials for saddle as the carrier pipe. Having dissimilar metals can cause galvanic corrosion and generally should be avoided. This can be accomplished one of two ways. First, a pipe clamp where the inside diameter of the clamp matches the outside diameter of the carrier pipe. Secondly, a piece of plate can be bent such that the ID of the plate matches the OD of the carrier pipe.

It should be noted that this type of design cannot and should not ever be used for a pipe guide, anchor or directional anchor. Utilization of a pipe saddle is to transfer vertical load only. When designing and installing clamp and saddle pipe supports, various factors such as pipe material, operating conditions, weight, temperature variations, and the specific layout of the piping system need to be considered. Proper engineering practices are essential to ensure the safety, reliability, and longevity of the piping system.

- See Article - Pipe Support Dont's

How Clamp and Saddle Pipe Supports Generally Work

Clamps - Clamps are used to fasten the pipe to the surface, such as a wall, structure or pipes. They are typically designed to encircle the pipe and provide a secure attachment point. Clamps come in various designs, including one-piece clamps and split clamps, which can be installed without the need to disassemble the entire pipe.

Saddles - Saddles are components that are attached to the clamps and cradle the pipe. They provide additional support and stability, ensuring that the pipe is held securely without direct contact with the clamp. Saddles are often lined with materials that prevent abrasion and damage to the pipe's surface.

Key Points about Clamp and Saddle Pipe Supports

Prevent Sagging - The clamps and saddles work together to prevent sagging of the pipe, maintaining its proper alignment and preventing issues like uneven flow or stress.

Thermal Expansion Compensation - Like other pipe supports, clamp and saddle supports can accommodate thermal expansion and contraction of pipes, preventing excessive stress on the piping system.

Vibration Damping - The support system can help dampen vibrations and noise that might be transmitted through the pipes, enhancing the overall performance and comfort of the system.

Protection - The saddle's lining helps protect the pipe's surface from damage that might be caused by the clamps or external factors.

Uniform Distribution - The use of clamps and saddles along the length of the pipe ensures that the support is distributed evenly, minimizing stress concentrations.

Clamp and Saddle Support

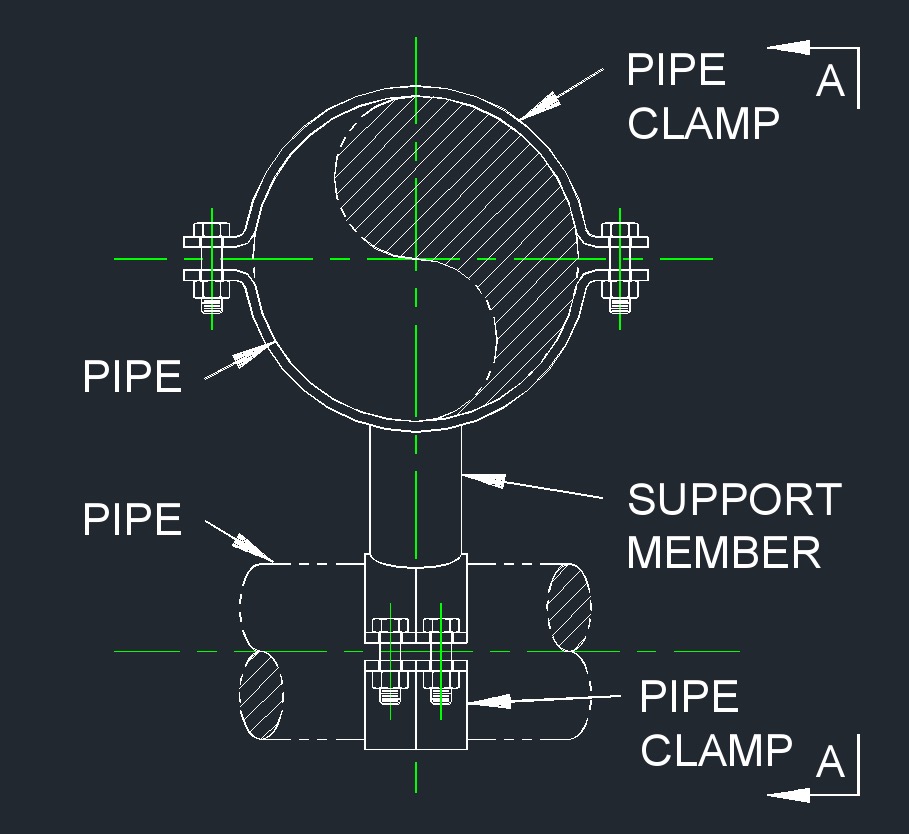

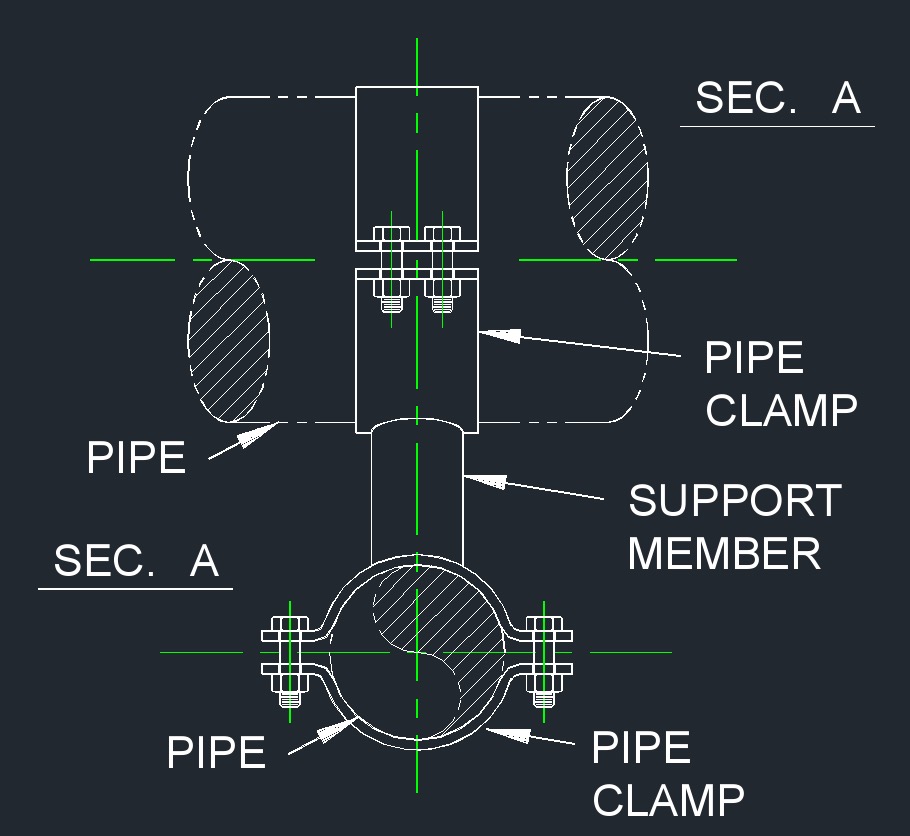

Clamp & Clamp Crossed

Clamp & Clamp Crossed

Clamp & Clamp Crossed

Clamp & Clamp Crossed

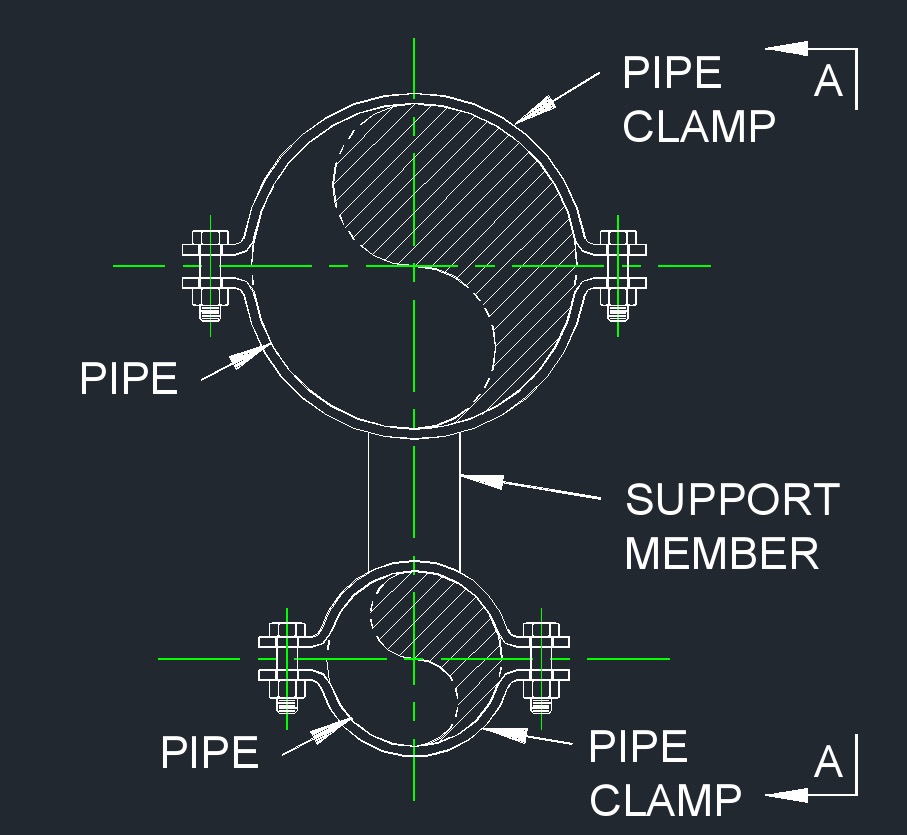

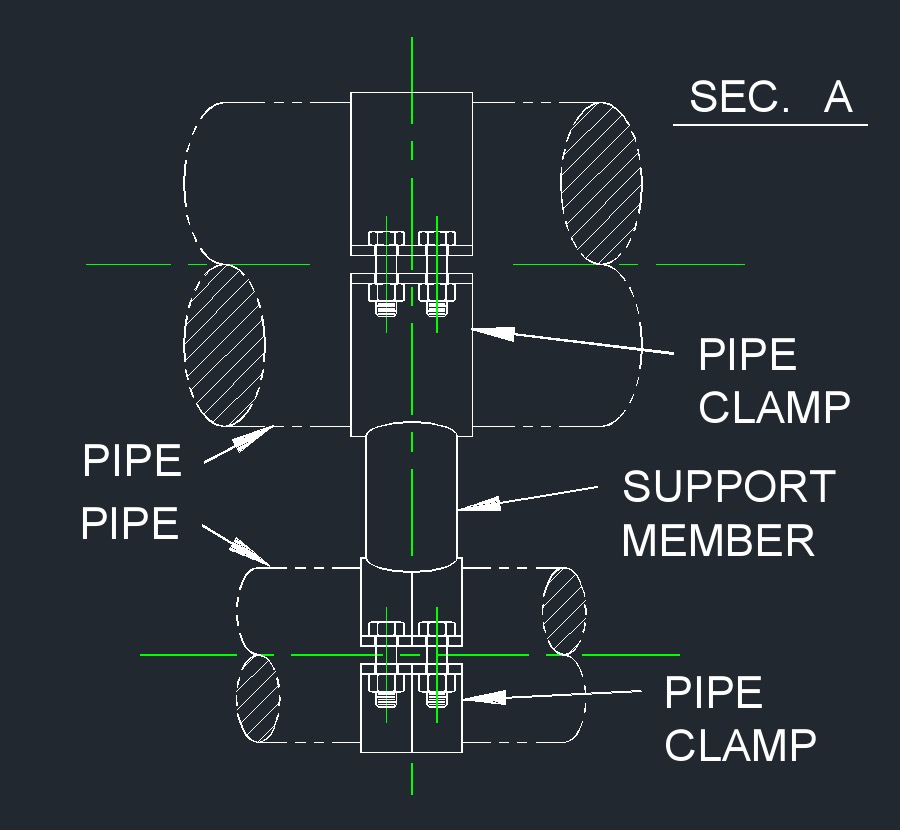

Clamp & Clamp Aligned

Clamp & Clamp Aligned

Clamp & Clamp Aligned

Clamp & Clamp Aligned

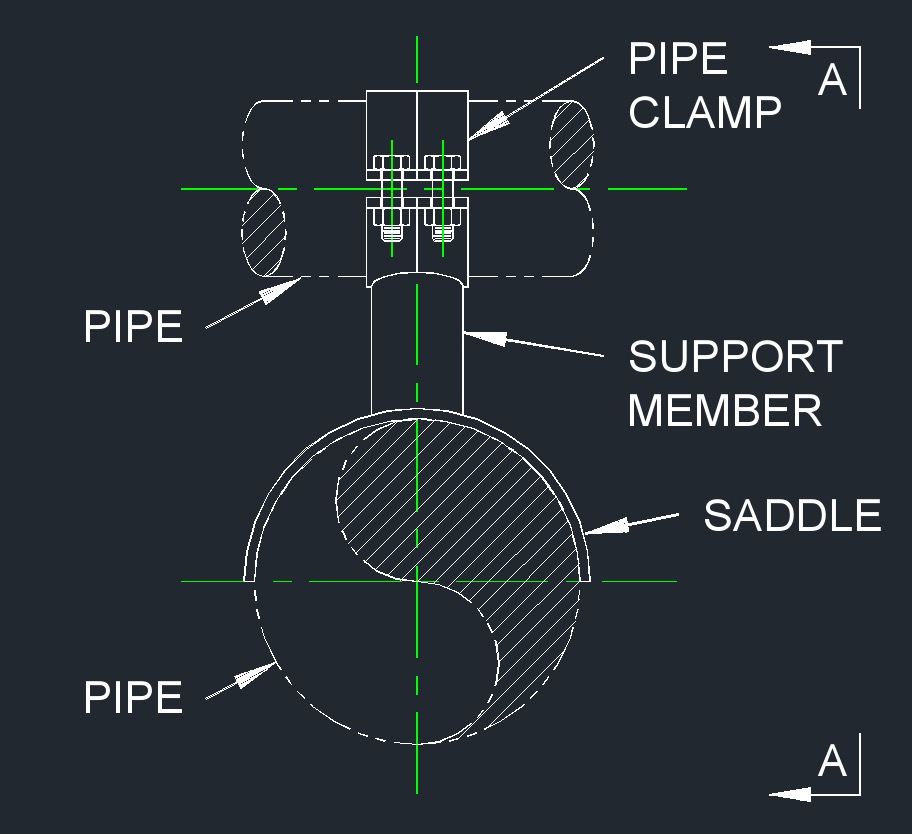

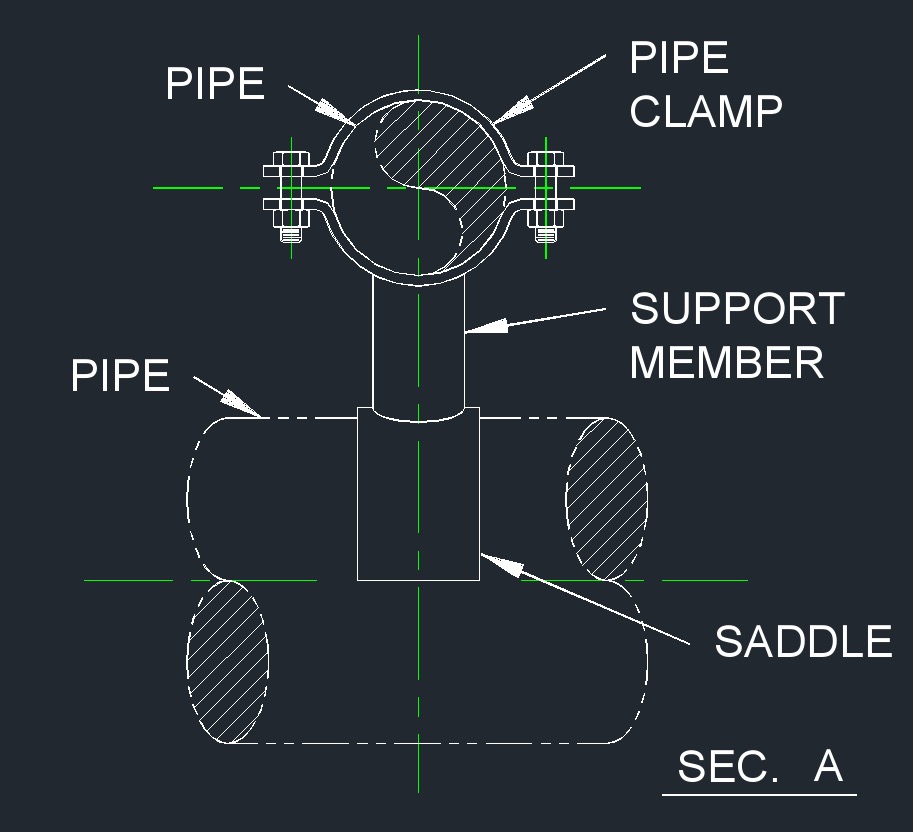

Clamp & Saddle Crossed

Clamp & Saddle Crossed

Clamp & Saddle Crossed

Clamp & Saddle Crossed

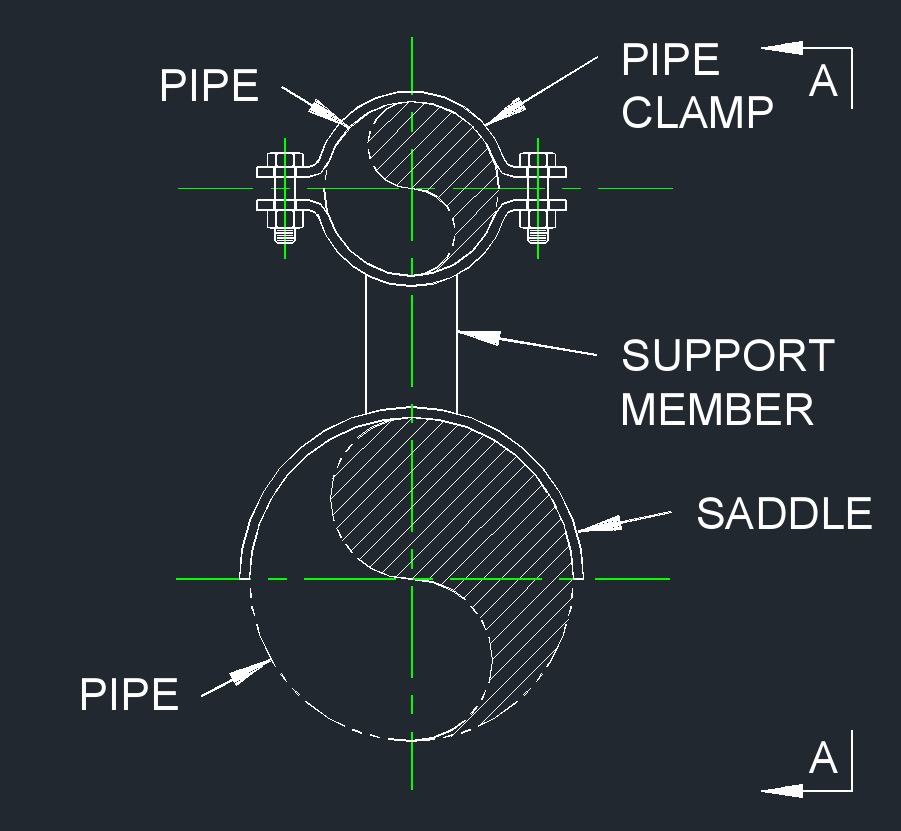

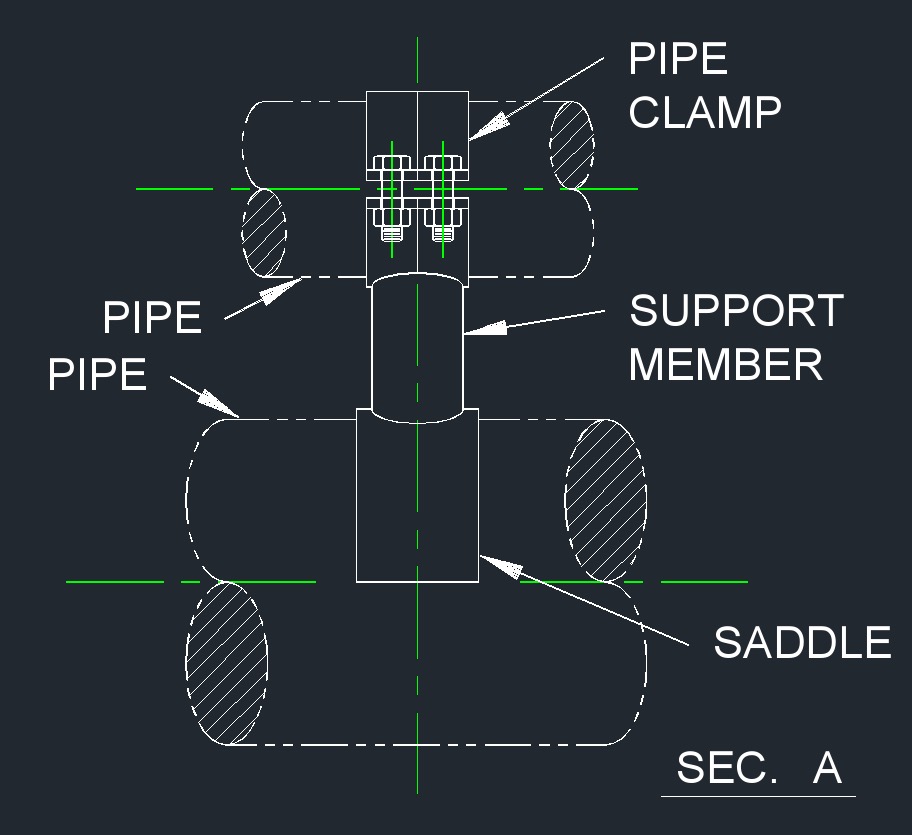

Clamp & Saddle Aligned

Clamp & Saddle Aligned

Clamp & Saddle Aligned

Clamp & Saddle Aligned