Boiler

Heat Transfer, Heat Exchanger, Refinery A boiler, abbreviated as BLR, is a closed vessel in which water or other fluid is heated under pressure for generating steam or other hot fluids.

A boiler, abbreviated as BLR, is a closed vessel in which water or other fluid is heated under pressure for generating steam or other hot fluids.

Science Branches

|

| Science |

| Applied Science |

| Engineering |

| Mechanical Engineering |

|

When sizing a boiler you must have enough capacity to handle the maximum hourly load of the system. You should always install a boiler with future expansion in mind. More than one may be required depending how critical it is for continuous service during shutdown and maintenance. All boilers should be equipped with fully automatic controls to provide adequate safety at all times. All equipment in the system should be rated at least to the maximum allowable working pressure. Equipment and controls should meet if not exceed ASME, UA, local, state and all applicable codes.

Boilers require fresh air and ventilation and must be installed in areas where both can be attained. When in confined rooms permanent openings for air transfer should be provided. Vents and draft creating equipment may be needed to achieve proper movement. The venting system should be wired to the boiler to assure proper air when the boiler is fired up. At least two doors at a minimum are recommended for ingress and egress to insure proper safety for personnel.

Do not use galvanized pipe or fittings on any of the boiler piping: feed, steam, or water lines. A proper blowdown system must be provided for safety.

When boilers are not used for periods of time, such as seasonal or storage in freezing weather the system should be drained so not to damage the equipment.

Boiler Design Classification

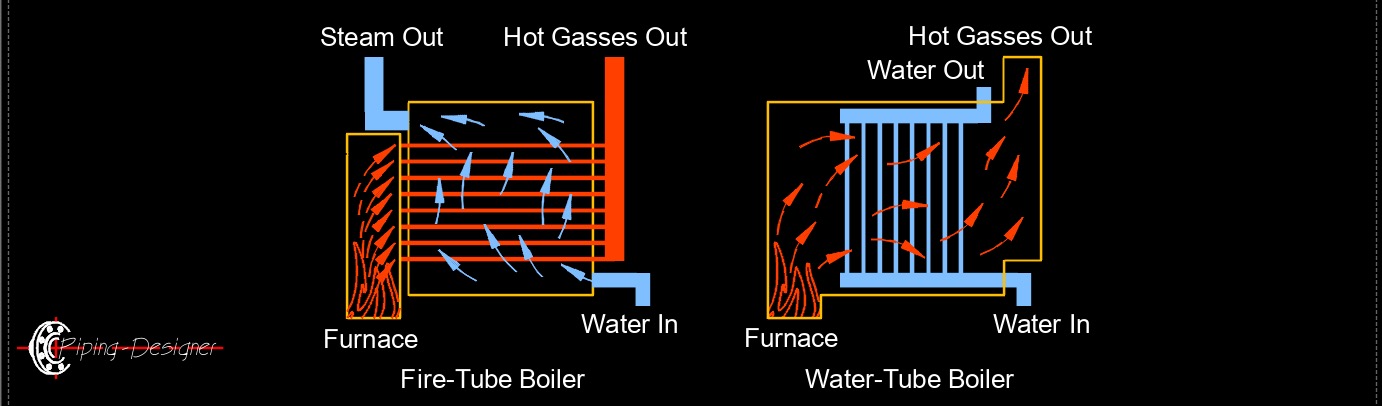

Fire-tube Boiler - In this type of boiler, gases are directed through vertical or horizontal steel tubes that are surrounded by the water for heating. The fire tube boilers have a smaller capacity and can not handle high pressures over 250 psig. This boiler can be classified by its size, steam pressure, and steam temperature. A single-drum or multi-drum boiler is determined by the number of drums it has. Most boilers have just one drum but some may have 2 or more. These boilers are used in heating applications and are frequently found in hospitals and schools as well as in industrial process applications such as food and chemical plants.

- Cochran Boiler - This is a low pressure type of boiler arranged in the vertical direction that has multi tubes. This is a modified version of a basic vertical boiler with different fire tubes that can exchange heat by convection to water. The efficiency of this boiler is much higher than the efficiency of simple vertical boiler.

- Cornish Boiler - This kind of boiler includes a plane cylindrical shell, as well as a tiny flue pipe holding the heating system, flows through it.

- Horizontal Boiler - Has a horizontally cylindrical shell that has many flue tubes arranged in a horizontal direction.

- Lancashire Boiler - This boiler is enclosed in brickwork. It consists of fire tubes surrounded by water and the fire tubes are conical towards the rear end. A brick arch is placed after the furnace in order to increase the flow of hot gases.

- Locomotive Boiler - It is a horizontal, multi-tubular, internally fired, and naturally circulated type boiler. This type of boiler is mounted horizontally in direction and has multi tubes.

- Scotch Marine Boiler - This type of boiler is different from other because of using a large number of small diameter tubes. The furnace remains a single large diameter tubes with a number of small tubes arranged above it. They connect each other with a combustion chamber. So the flow of flue gas into the pipes is from the back to the front. An enclosed smokebox covering the front of these tubes leads up to a chimney or a funnel.

- Simple Vertical Boiler - Installed in a vertical direction, and it doesn’t remain in a stationary condition, unlike other fire tube boilers. It has a low working steam pressure and is not best for high steam pressure applications.

Water-tube Boiler - The water-tube boiler is a type of boiler in which the water is present inside the tubes and fire or hot gases surround these tubes. Watertube boilers are safer by design and generally considered to last much longer than the firetube boiler. They are available in much larger sizes and recover faster than firetube boilers, can handle pressures up to 5000 psig, and have the ability to reach very high temperatures with the use of superheaters.

- Benson Boiler - A high pressure super critical water boiler in which no bubble is formed because the water is compressed at super critical pressure and it directly converts into steam.

- Babcock and Wilcox Boiler - A horizontal type drum axis, stationary, high pressure, natural circulation, solid fuel-fired water tube boiler in which coal is burned to heat the water for changing the phase into steam and later that steam is used for power generation.

- Lamont Boiler - This is a high pressure type of water tube boiler in which steams are generated from water by the burning of coal for fuel, and later that steam is used for the generation of electricity and so on.

- Loeffler Boiler - This boiler is used to evaporate the water by taking superheated steam from the superheater. In this boiler, 70% of the superheated steam is useed for the water evaporation in the evaporating drum, and 30% of the superheated steam is used to run the steam turbine.

- Yarrow Boiler - This high pressure boiler design is characteristic of the three-drum boiler. Two banks of straight water-tubes are arranged in a triangular row with a single furnace between them. A single steam drum is mounted at the top between them, with smaller water drums at the base of each bank. Circulation, both upwards and downwards, occurs within this same tube bank.

Boiler Advantages and Disadvantages | |

|---|---|

| Advantages | Disadvantages |

|

|

Boiler Design Consideration

- Acidic Corrosion - The mishandling of chemicals during acid cleaning or the boiler pH being run too low. This will passivate the carbon steel surfaces of the boiler.

- Caustic Corrosion - Caustic stress corrosion cracking is a failure affecting both carbon and austenitic steels. Corrosion and gouging occurs when alkalinity of boiler water increases.

- Crevice Corrosion - This is a localized form of corrosion usually results from a crack in the boiler that does not get good circulation to rinse away caustic corrosion.

- Galvanic Corrosion - Accelerated corrosion of a metal because of an electrical contact with a more noble metal or nonmetallic conductor in a corrosive electrolyte.

- Oxygen Corrosion - In the presence of oxygen, steel breaks down into either insoluble or soluble iron compounds. Oxygen will cause pitting in the preboiler section and in the tubes. Dissolved oxygen refers to the volume of oxygen that is contained in water. The amount of oxygen that can be held by the water depends on the water temperature, salinity, and pressure.

- Pitting Corrosion - Pitting is a localized form of corrosion. Either a local anodic point or more commonly a cathodic point, forms a small corrosion cell within the surrounding normal surface.

Boiler Standards

- API RP 535 - Burners for Fired Heaters in General Refinery Services

- API RP 573 - Inspection of Fired Boilers and Heaters

- ISO 16528-1 - Boilers and pressure vessels -- Part 1: Performance requirements

- ISO 16528-2 - Boilers and pressure vessels -- Part 2: Procedures for fulfilling the requirements of ISO 16528-1