Impressed Current Anode

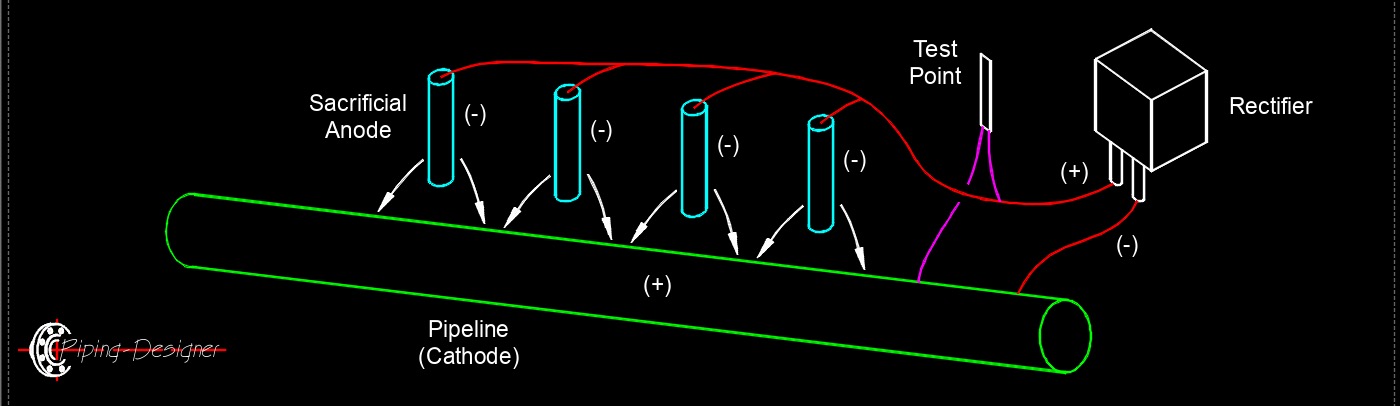

Impressed current anodes are components in impressed current cathodic protection (ICCP) systems, used to prevent corrosion in metal structures like pipelines, storage tanks, and marine vessels. Unlike sacrificial anodes, impressed current anodes are made from relatively inert, durable materials such as mixed metal oxide (MMO) coated titanium, high-silicon cast iron, graphite, or platinized titanium. These anodes are connected to an external power source, typically a rectifier, which supplies a controlled electrical current to drive electrons through the electrolyte (soil, water, or concrete) to the protected structure, keeping it cathodic and corrosion-free. Impressed current anodes are designed for long-term use and high current output, making them suitable for large or complex structures in challenging environments. Their durability and ability to deliver adjustable current make them more versatile than sacrificial anodes, though they require a power source and regular maintenance to ensure system effectiveness.

Impressed current anodes are components in impressed current cathodic protection (ICCP) systems, used to prevent corrosion in metal structures like pipelines, storage tanks, and marine vessels. Unlike sacrificial anodes, impressed current anodes are made from relatively inert, durable materials such as mixed metal oxide (MMO) coated titanium, high-silicon cast iron, graphite, or platinized titanium. These anodes are connected to an external power source, typically a rectifier, which supplies a controlled electrical current to drive electrons through the electrolyte (soil, water, or concrete) to the protected structure, keeping it cathodic and corrosion-free. Impressed current anodes are designed for long-term use and high current output, making them suitable for large or complex structures in challenging environments. Their durability and ability to deliver adjustable current make them more versatile than sacrificial anodes, though they require a power source and regular maintenance to ensure system effectiveness.

- Mixed Metal Oxide (MMO) Coated Titanium - These anodes consist of a titanium substrate coated with a thin layer of mixed metal oxides (e.g., iridium oxide, ruthenium oxide). They are highly durable, dimensionally stable, and provide excellent current distribution. Widely used in various environments, including seawater, brackish water, freshwater, carbon backfill, and concrete. They are a popular choice for long pipelines, ship hulls, and steel in concrete. Cost-effective in the long run due to their longevity and high current output per unit area.

- High Silicon Cast Iron (HSCI) - HSCI anodes are a traditional and robust choice. They offer good resistance to corrosion in various environments. Commonly used in groundbeds for pipelines and storage tanks, and in some marine applications. Can be brittle and heavy, and their consumption rate can be higher than MMO anodes in some conditions.

- Graphite - Graphite is a carbon-based material that is electrically conductive and resistant to many corrosive environments. Often used in deep well groundbeds and sometimes in freshwater or soil applications. Can be consumed over time and may require backfill to maintain good electrical contact.

- Platinum (and Platinum-Clad Niobium/Titanium) - Platinum is highly corrosion-resistant and has excellent electrochemical properties. It's often clad onto a titanium or niobium substrate to reduce cost while retaining performance. Used in specialized applications where high current density, long life, and chemical inertness are critical, such as in aggressive chemical environments or specific marine applications. High cost limits their widespread use, but their performance justifies it in certain scenarios.

- Scrap Steel - While not as efficient or long-lasting as other ICCP anode materials, scrap steel can be used as a low-cost option, particularly in certain soil environments. More common in some regions as a cost-effective solution for temporary or less critical applications. High consumption rate and requires significant material volume for effective protection.