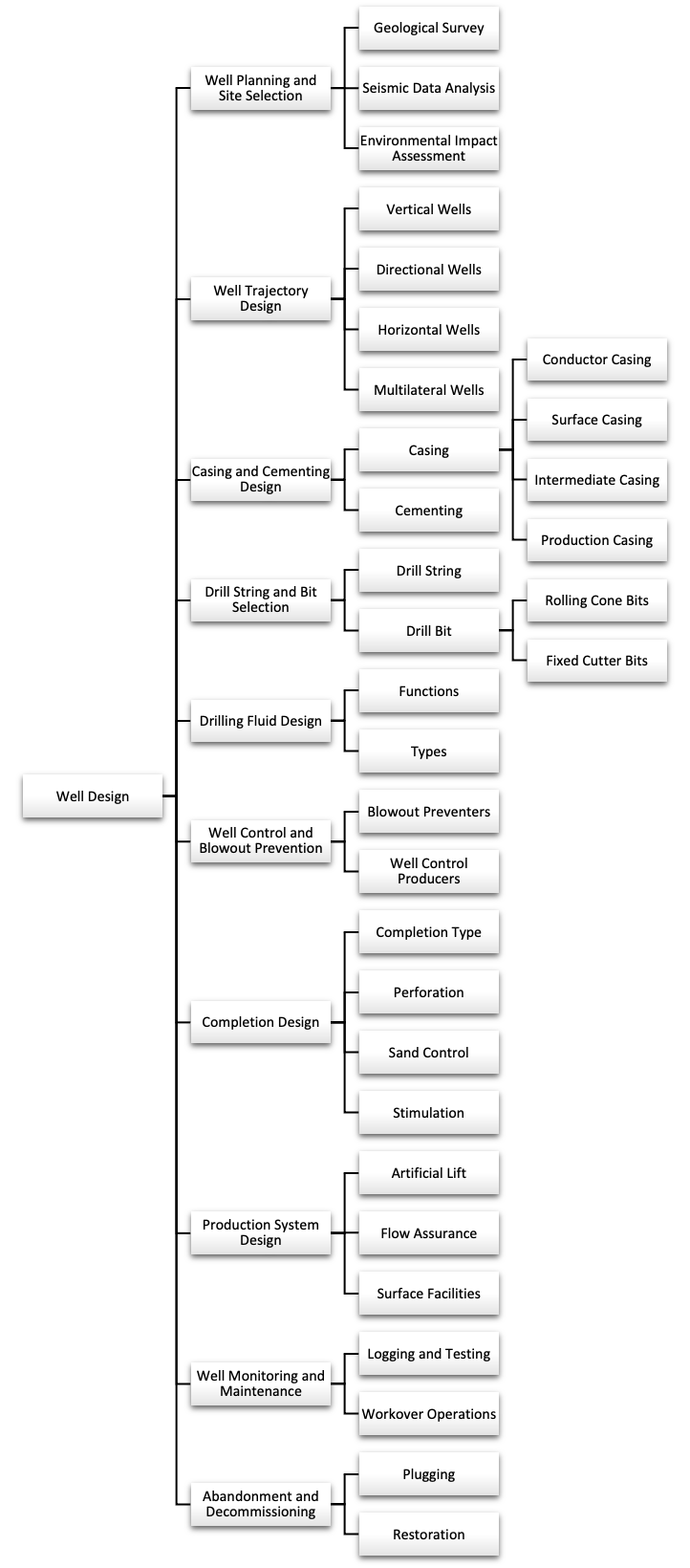

Drilling Well Design

Oil and gas well design is a complex process that involves several stages to ensure safe, efficient, and productive extraction of hydrocarbons. The design process includes various technical, environmental, and economic considerations. Below is an overview of the key components and stages of oil and gas well design.

Well Planning and Site Selection

Well Planning and Site Selection

Geological Survey - Understanding the subsurface geology to identify potential hydrocarbon reservoirs.

Seismic Data Analysis - Using seismic surveys to map underground formations.

Environmental Impact Assessment - Evaluating the environmental implications and obtaining necessary permits.

Well Trajectory Design

Vertical Wells - Drilled straight down to reach the reservoir.

Directional Wells - Include deviations from vertical to reach different parts of the reservoir.

Horizontal Wells - Extended horizontally within the reservoir to maximize contact with the hydrocarbon-bearing formation.

Multilateral Wells - Multiple wellbore branches from a single well to enhance reservoir drainage.

Casing and Cementing Design

Casing - Steel pipes installed in the wellbore to maintain well integrity, prevent collapse, and isolate different subsurface layers.

- Conductor Casing - First casing set near the surface.

- Surface Casing - Provides a foundation for blowout preventers.

- Intermediate Casing - Isolates different pressure zones.

- Production Casing - Runs through the productive formation.

Cementing - Pumping cement between the casing and the wellbore to secure the casing and prevent fluid migration.

Drill String and Bit Selection

Drill String - Comprises drill pipes, collars, and tools to transmit drilling fluid and rotate the bit.

Drill Bit - Selected based on formation hardness and wellbore design.

- Roller Cone Bits - Suitable for soft to medium-hard formations.

- Fixed Cutter Bits (PDC bits) - Used for harder formations.

Drilling Fluid Design

Functions - Removes cuttings, controls well pressure, lubricates and cools the bit, and stabilizes the wellbore.

Types - Water-based mud, oil-based mud, and synthetic-based mud.

Well Control and Blowout Prevention

Blowout Preventers (BOP) - Installed on the wellhead to control unexpected pressure surges.

Well Control Procedures - Include mud weight adjustments and kick detection protocols.

Completion Design

Completion Type - Open hole, cased hole, or liner completions.

Perforation - Creating holes in the casing to connect the wellbore with the reservoir.

Sand Control - Techniques like gravel packing or screens to prevent sand production.

Stimulation - Hydraulic fracturing or acidizing to enhance well productivity.

Production System Design

Artificial Lift - Methods like pumps or gas lift to enhance production if natural reservoir pressure is insufficient.

Flow Assurance - Ensuring steady flow of hydrocarbons to the surface, preventing blockages due to hydrates, wax, or asphaltenes.

Surface Facilities - Design of separators, storage tanks, and pipelines for handling produced fluids.

Well Monitoring and Maintenance

Logging and Testing - Monitoring well integrity and performance through various logs and tests.

Workover Operations - Interventions to repair, maintain, or enhance well productivity.

Abandonment and Decommissioning

Plugging - Sealing the well with cement plugs to prevent fluid migration.

Restoration - Restoring the site to its original condition or as per regulatory requirements.

Each stage of the well design process involves specialized engineering knowledge, regulatory compliance, and the application of advanced technologies to ensure the well is drilled safely and efficiently, with minimal environmental impact.