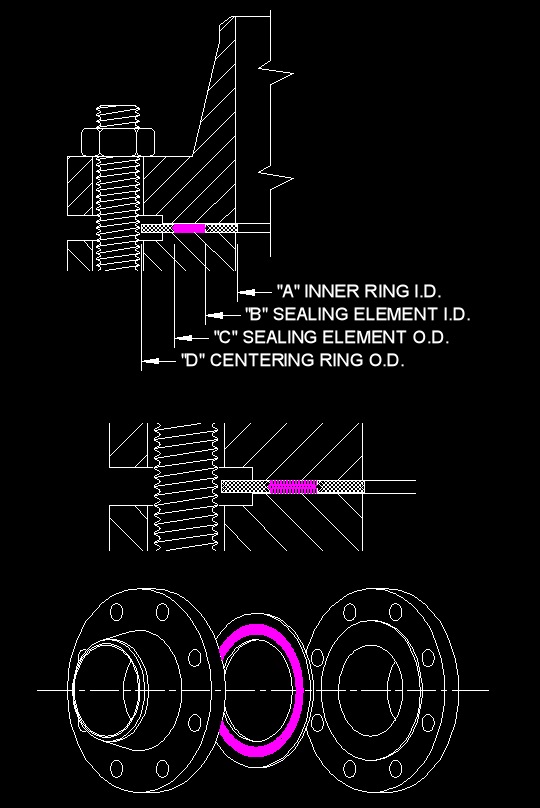

Gasket - Spiral Wound, for ANSI Class 900, B16.5 (in)

Gasket - Spiral Wound, for ANSI Class 900, B16.5 (in) | ||||

|---|---|---|---|---|

| Pipe

Size (NPS) | Inner

Ring Inside Diameter A | Sealing

Element Inside Diameter B | Sealing

Element Outside Diameter C | Outer

Ring Outside Diameter D |

| 1/2 (*) | — | 0.75 | 1.25 | 2.50 |

| 3/4 (*) | — | 1.00 | 1.56 | 2.75 |

| 1 (*) | — | 1.25 | 1.88 | 3.13 |

| 1 1/4 (*) | — | 1.56 | 2.38 | 3.50 |

| 1 1/2 (*) | — | 1.88 | 2.75 | 3.88 |

| 2 (*) | — | 2.31 | 3.38 | 5.63 |

| 2 1/2 (*) | — | 2.75 | 3.88 | 6.50 |

| 3 | 3.10 | 3.75 | 4.75 | 6.63 |

| 3 1/2 | — | 4.13 | 5.25 | 7.50 |

| 4 | 4.04 | 4.75 | 5.88 | 8.13 |

| 5 | 5.05 | 5.81 | 7.00 | 9.75 |

| 6 | 6.10 | 6.88 | 8.25 | 11.38 |

| 8 | 7.75 | 8.75 | 10.13 | 14.13 |

| 10 | 9.69 | 10.88 | 12.25 | 17.13 |

| 12 | 11.50 | 12.75 | 14.50 | 19.63 |

| 14 | 12.63 | 14.00 | 15.75 | 20.50 |

| 16 | 14.75 | 16.25 | 18.00 | 22.63 |

| 18 | 16.75 | 18.25 | 20.50 | 25.13 |

| 20 | 19.00 | 20.50 | 22.50 | 27.50 |

| 24 | 23.25 | 24.75 | 26.75 | 33.00 |

Dimensions to ASME B16.20 - Metallic Gaskets for Pipe Flanges: Ring-Joint, Spiral-Wound, and Jacketed

Dimensions to ASME B16.20 - Metallic Gaskets for Pipe Flanges: Ring-Joint, Spiral-Wound, and Jacketed- Inner rings are recommended for all graphite filled gaskets, required for all PTFE filled gaskets.

- The gasket outside diameter tolerance for NPS 1/2" through NPS 8" is ±0.03"; for NPS 10" through NPS 24", +0.06", –0.03".

- The gasket inside diameter tolerance for NPS 1/2" through NPS 8" is ±0.016"; for NPS 10" through NPS 24", ±0.03".

- The centering ring outside diameter tolerance is ±0.03".

- (*) There are no Class 900 flanges in NPS 1/2" through NPS 2 1/2" (use Class 1500), or Class 2500 flanges NPS 14" and larger.

- ASME B16.20 does not include gaskets with no internal ring dimensions for NPS 1/4" or 3 1/2" and Class 900 flanges up to NPS 2 1/2".