Deaerator

Deaerator removes dissolved gases mainly dissolved oxygen, carbon dioxide, and other non-condensable gases from boiler feed water to prevent corrosion of the feed water system. Oxygen causes pitting corrosion in feed water systems. Mechanical deaeration considered as a first stage process where most of the dissolved gases escap from the water. Chemical deaeration acts as a polishing process which can remove trace amount of dissolved gases by adding oxygen scavenger chemicals in to deaerator.

Deaerator removes dissolved gases mainly dissolved oxygen, carbon dioxide, and other non-condensable gases from boiler feed water to prevent corrosion of the feed water system. Oxygen causes pitting corrosion in feed water systems. Mechanical deaeration considered as a first stage process where most of the dissolved gases escap from the water. Chemical deaeration acts as a polishing process which can remove trace amount of dissolved gases by adding oxygen scavenger chemicals in to deaerator.

The design of an effective deaeration system depends upon the amount of gases to be removed and the final oxygen gas concentration desired. This depends upon the ratio of boiler feedwater makeup to returned condensate and the operating pressure of the deaerator.

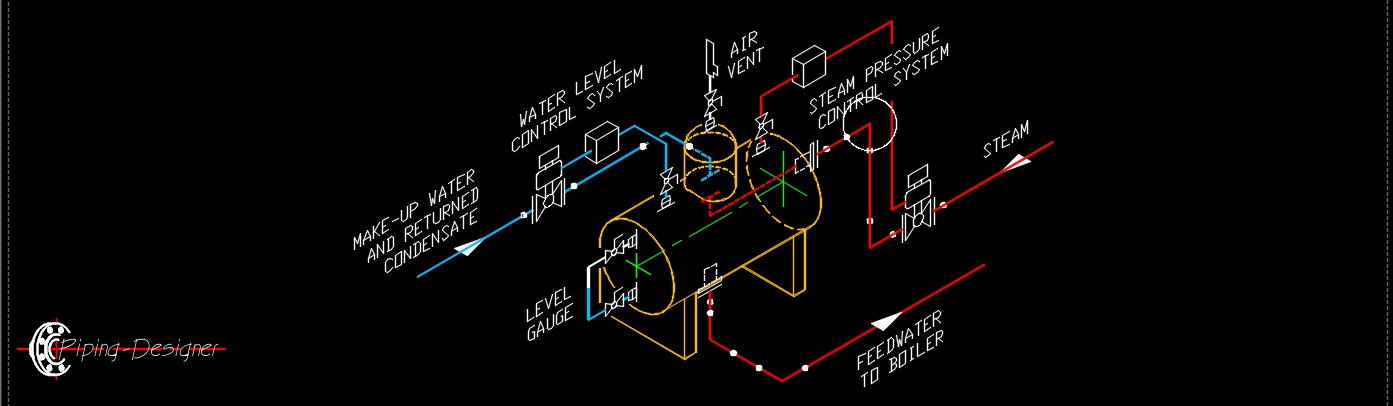

Deaerators use steam to heat the water to the full saturation temperature corresponding to the steam pressure in the deaerator and to scrub out and carry away dissolved gases. The deaerator consists of a deaeration section, a storage tank, and a vent. In the deaeration section, steam bubbles through the water, both heating and agitating it. Steam is cooled by incoming water and condensed at the vent condenser. Noncondensable gases and some steam are released through the vent.

Steam provided to the deaerator provides a stripping action and heats the mixture of returned condensate and boiler feedwater makeup to saturation temperature. Most of the steam will condense, but a small fraction must be vented to accommodate the stripping requirements. If the condensate return rate is high and the condensate pressure is high in comparison to the deaerator pressure, then very little steam is needed for heating and provisions may be made for condensing the surplus flash steam.

Deaerator Advantages and Disadvantages | |

|---|---|

| Advantages | Disadvantages |

|

|

Deaerator Design Classification

Functions of a Deaerator

Remove Dissolved Gases - The main function is to strip dissolved gases from the feedwater. Oxygen and carbon dioxide are particularly harmful as they can cause pitting and corrosion in boiler systems.

Preheat Feedwater - Deaerators also serve to preheat the feedwater before it enters the boiler. This increases the efficiency of the steam generation process and reduces thermal shock to the boiler.

Working Principle

The deaerator operates on the principle of Henry's Law, which states that the solubility of gases in a liquid decreases with increasing temperature.

In a deaerator -

- Feedwater Entry - Cold feedwater enters the deaerator and is sprayed or passed over trays where it comes into contact with steam.

- Steam Contact - The steam heats the water, reducing the solubility of dissolved gases and causing them to be released from the water.

- Gas Removal - The released gases are vented out of the deaerator, typically through a vent condenser to prevent steam loss.

- Preheated Water Collection - The now deaerated and preheated water is collected in a storage tank or sent directly to the boiler.

Inverse Solubility of Water

The principle state that increased water temperature decreases the dissolved oxygen content within the water. Thus injecting steam in deaerator increases the water temperature. The solubility of the dissolved gas reduces and also causes the gases to escape the water.

Deaerator Insulation

The deaerator section and storage tank and all piping conveying hot water or steam should be adequately insulated to prevent the condensation of steam and loss of heat.

Deaerator Pressure Fluctuations

Sudden increases in free or flash steam can cause a spike in deaerator vessel pressure, resulting in re-oxygenation of the feedwater. A dedicated pressure regulating valve should be provided to maintain the deaerator at a constant pressure.

Deaerator Steam Consumption

The deaerator steam consumption is equal to the steam required to heat incoming water to its saturation temperature, plus the amount vented with the noncondensable gases, less any flashed steam from hot condensate or steam losses through failed traps. The heat balance calculation is made with the incoming water at its lowest expected temperature. The vent rate is a function of deaerator type, size, and the amount of makeup water. The operating vent rate is at its maximum with the introduction of cold, oxygen rich makeup water.

Water Level Control

During a stable operation the water balance is maintained and controlling the source water level fluctuation is important. High level and low level alarms are provided. Low level might lead to the starvation of feed water in the pump and high level leads to water entry into steam header. An overflow drain is put in to drain the water if very high level is reached.