Concrete Anchoring

Concrete anchoring is the process of securely attaching or fastening objects to concrete surfaces or structures. This is commonly done to ensure stability, safety, and durability in various construction and industrial applications. Anchoring is necessary because concrete, while strong and durable, may not always provide enough grip or structural integrity for items to be attached directly. Concrete anchors are specialized devices or techniques used to achieve this attachment. They come in various types and designs, each suited for specific applications and load bearing requirements. Proper installation of concrete anchors is crucial to ensure their effectiveness and the structural integrity of the attached items. Factors like the type of anchor, concrete condition, load requirements, and installation technique need to be considered.

It's important to follow manufacturer guidelines and specifications when selecting and installing concrete anchors. Depending on the application, factors like the depth and diameter of the drilled hole, the torque applied during installation, and the curing time of adhesives (if used) can significantly impact the strength and reliability of the anchoring system. Overall, concrete anchoring is a critical aspect of construction and maintenance that helps to ensure the safety and stability of structures and equipment attached to concrete surfaces.

- See Article - Pipe Support Dont's

Base Plate

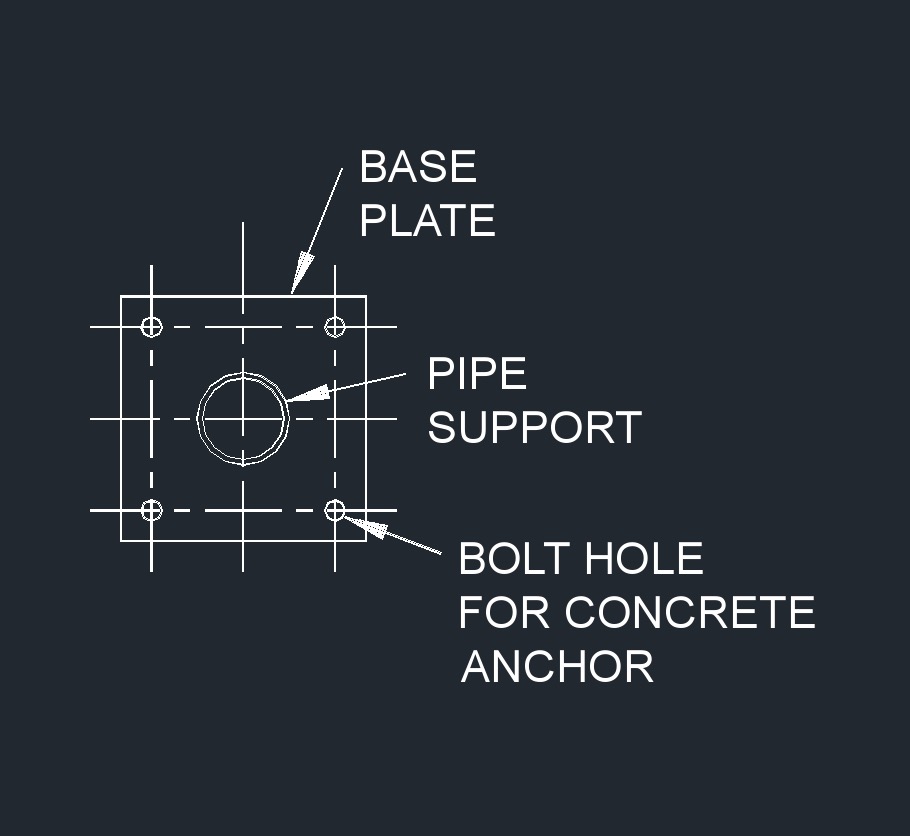

Base Plate for Pipe

Base Plate for Pipe

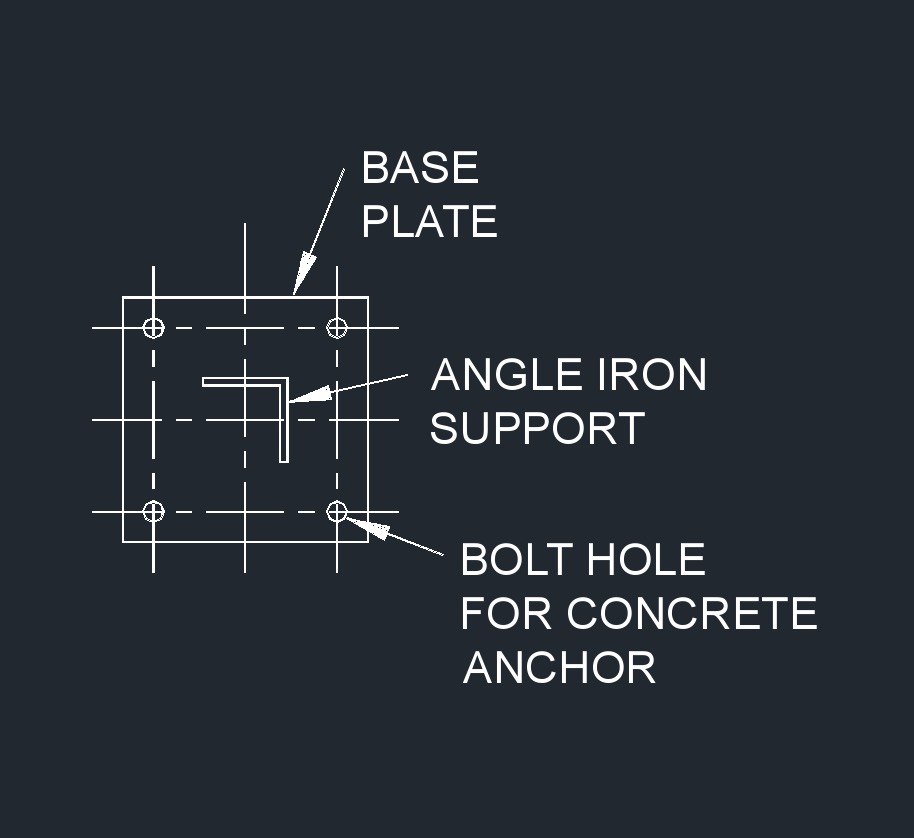

Base Plate for Angle Iron

Base Plate for Angle Iron

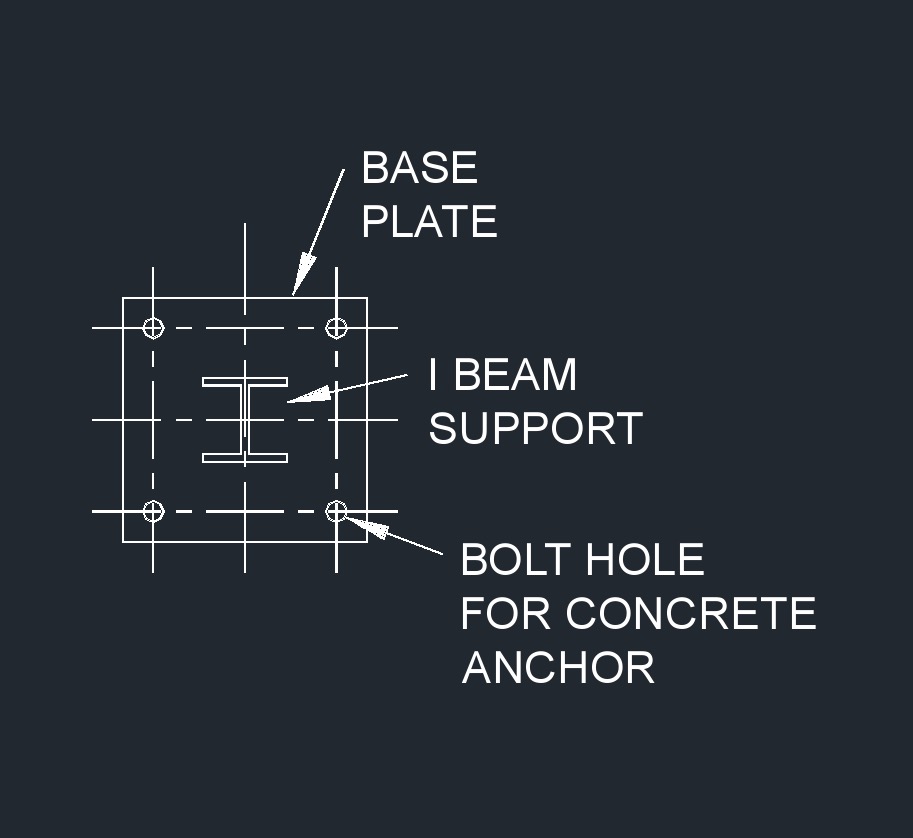

Base Plate for I Beam

Base Plate for I Beam

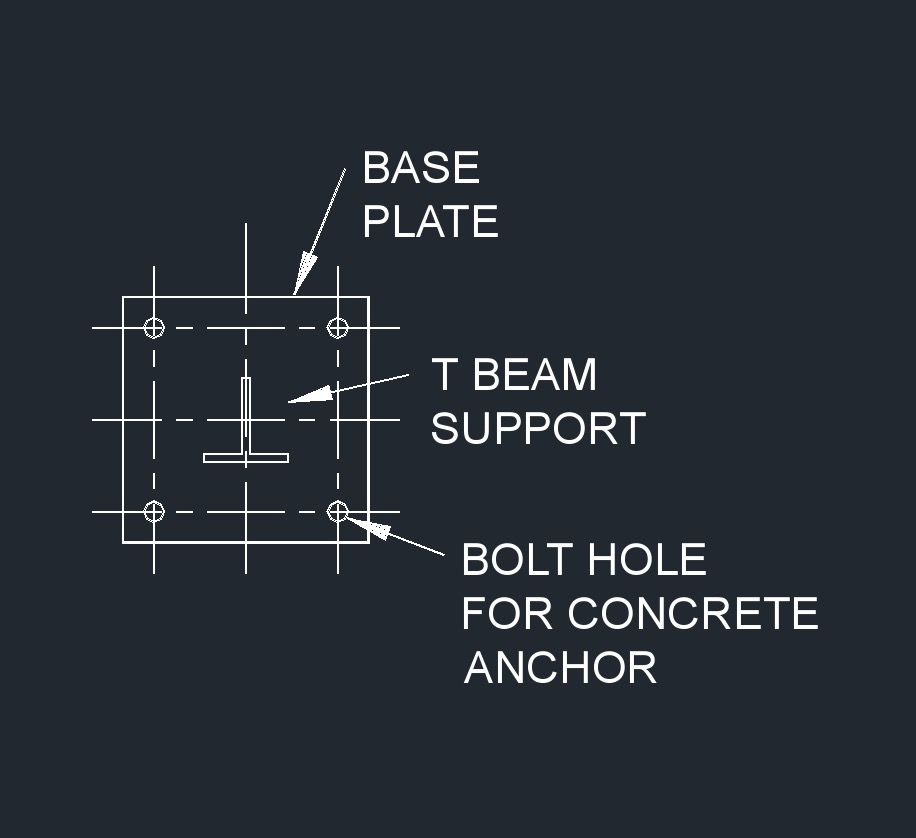

Base Plate for T Beam

Base Plate for T Beam

Concrete Anchor Bolt

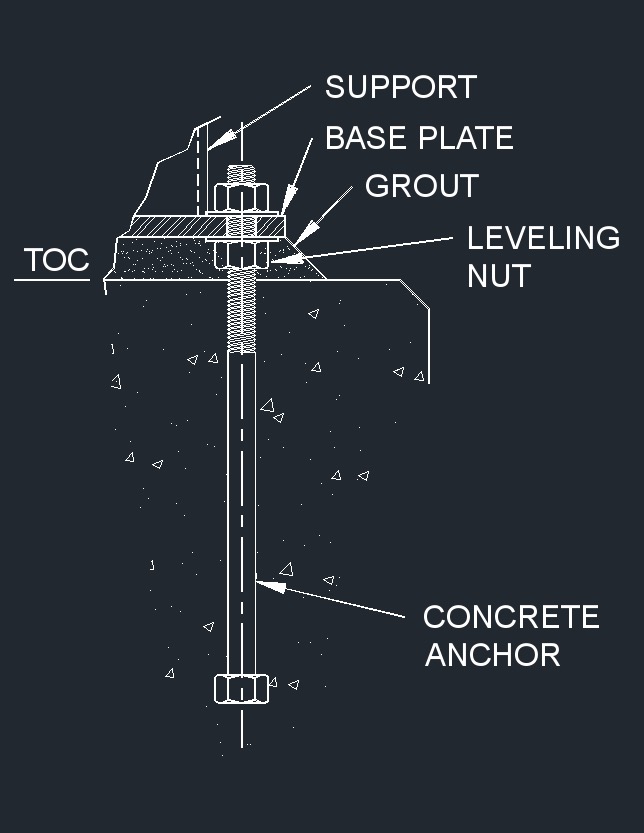

Grouting an Anchor Bolt

Grouting an Anchor Bolt

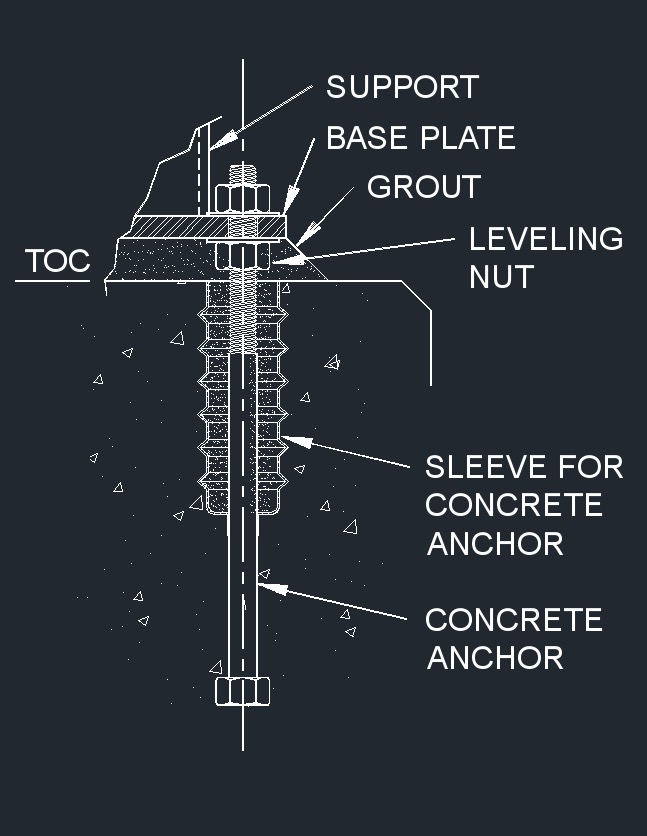

Grouting an Anchor Bolt with Sleeve

Grouting an Anchor Bolt with Sleeve

Anchor Bolt with Sleeve

Anchor Bolt with Sleeve

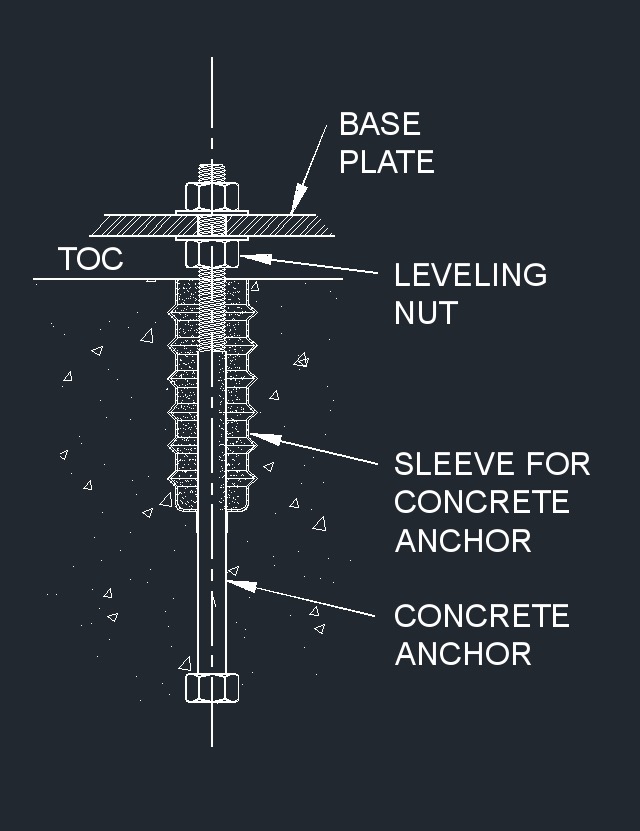

Anchor Bolt with Sleeve

Anchor Bolt with Sleeve

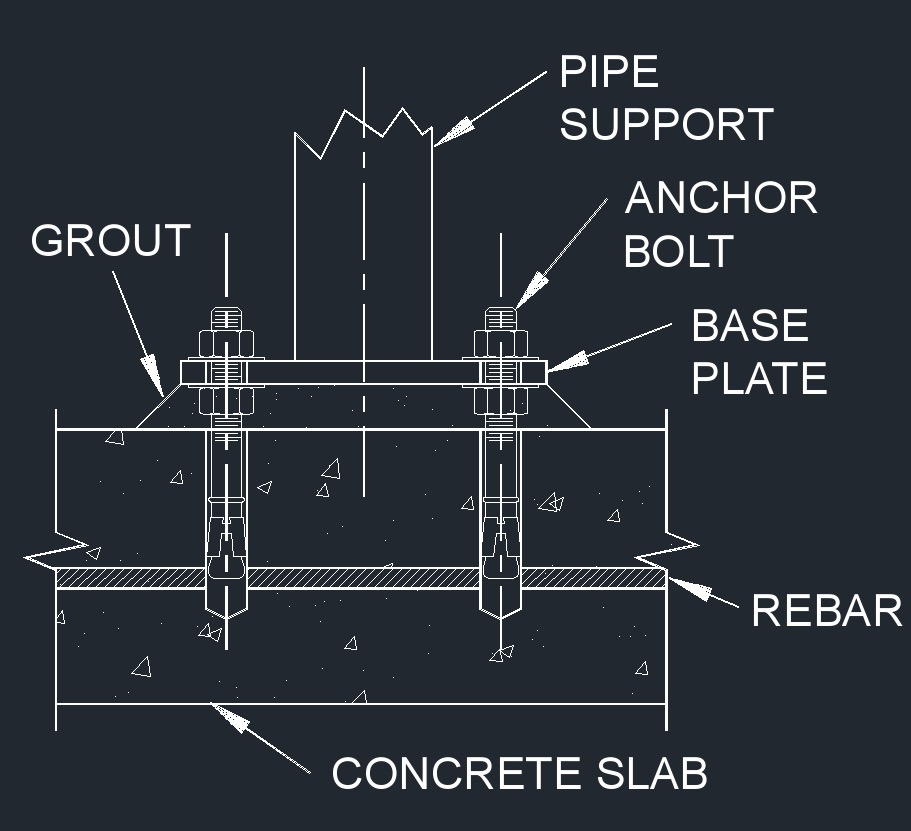

Concrete Anchoring for a Base Plate

Anchoring a Grouted Base Plate

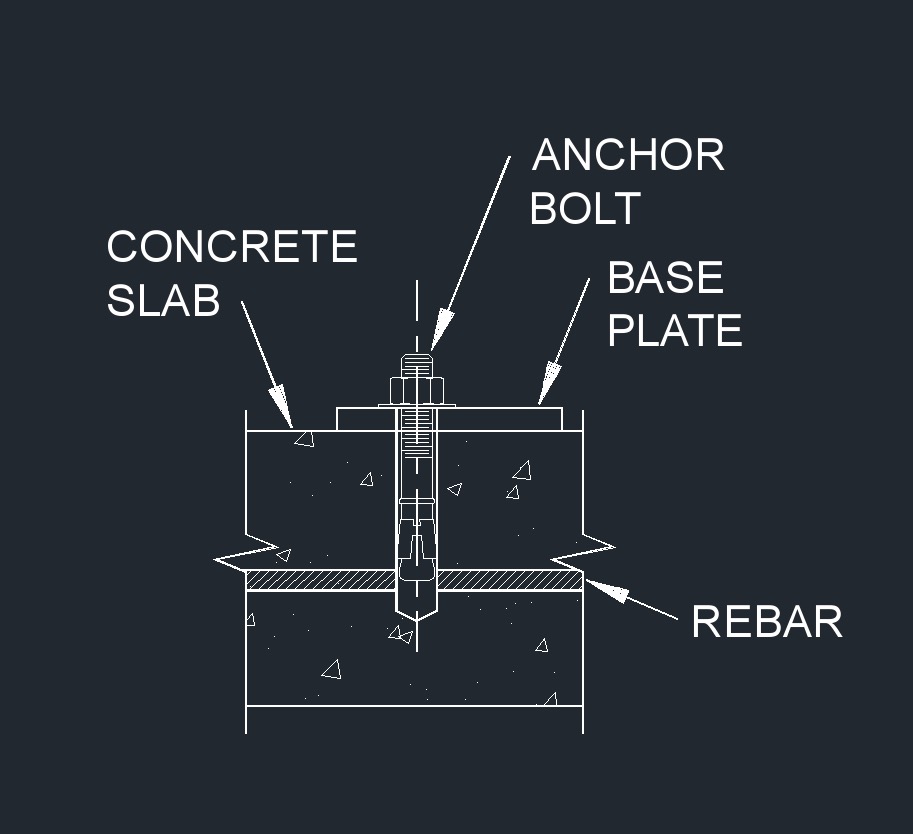

Anchoring a Grouted Base Plate Anchoring a Base Plate

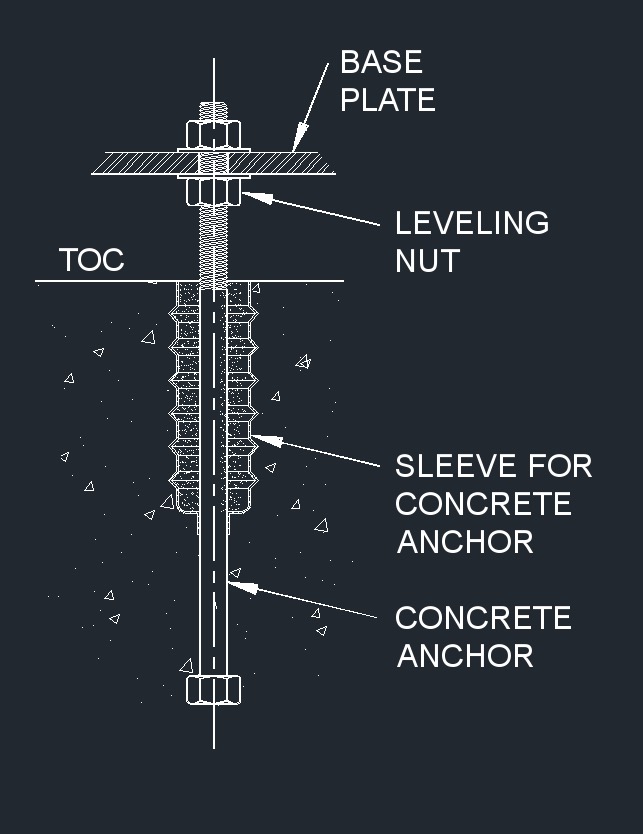

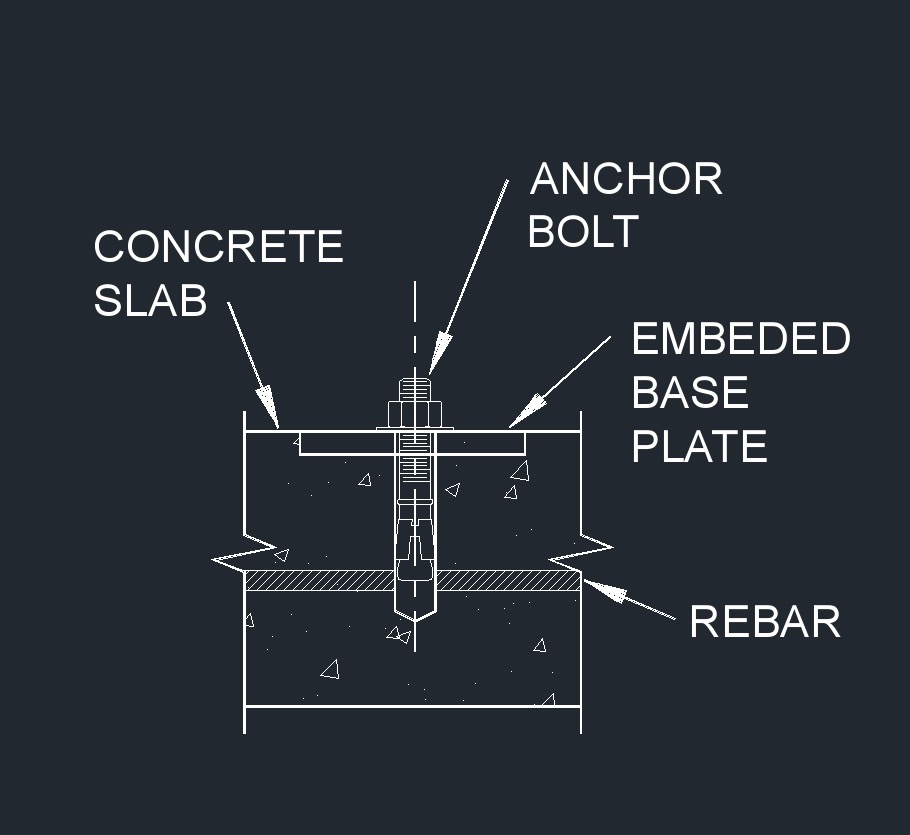

Anchoring a Base Plate Anchoring a Fixed Base Plate

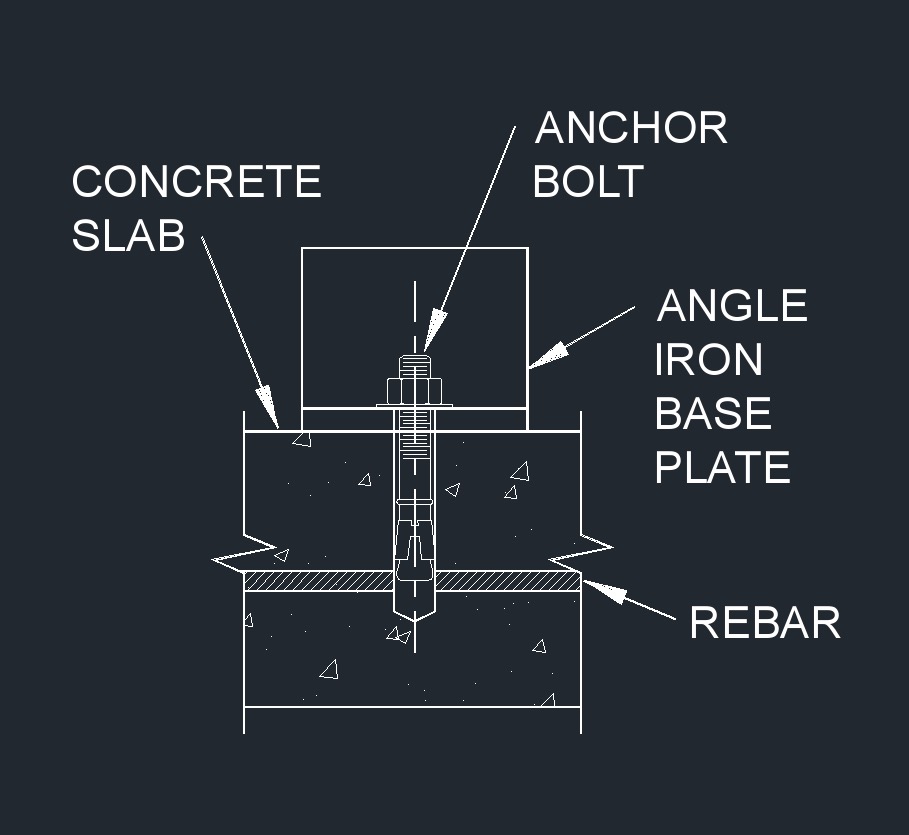

Anchoring a Fixed Base Plate Anchoring an Angle Iron

Anchoring an Angle Iron