Pipe Support Don'ts

When designing, installing, or maintaining pipe support systems, there are certain practices that should be avoided to ensure the safety, integrity, and efficiency of the piping system. To avoid these don'ts, it's crucial to involve experienced professionals and engineers when designing, selecting, installing, and maintaining pipe support systems. Adhering to best practices and industry standards will help ensure the reliability, safety, and longevity of your piping system.

Pipe Support Don'ts or Common Mistakes to Avoid

Don't Ignore Engineering Standards - Pipe support design and installation should adhere to relevant industry standards and codes. Ignoring these guidelines can lead to safety risks and system failures.

Don't Overlook Load Calculations - Failing to accurately calculate the loads and stresses that the pipe support will experience can result in inadequate support, leading to misalignment, sagging, or even failure.

Don't Neglect Thermal Expansion - Not accounting for thermal expansion and contraction can lead to stress buildup, misalignment, and potentially catastrophic failures as pipes heat up and cool down.

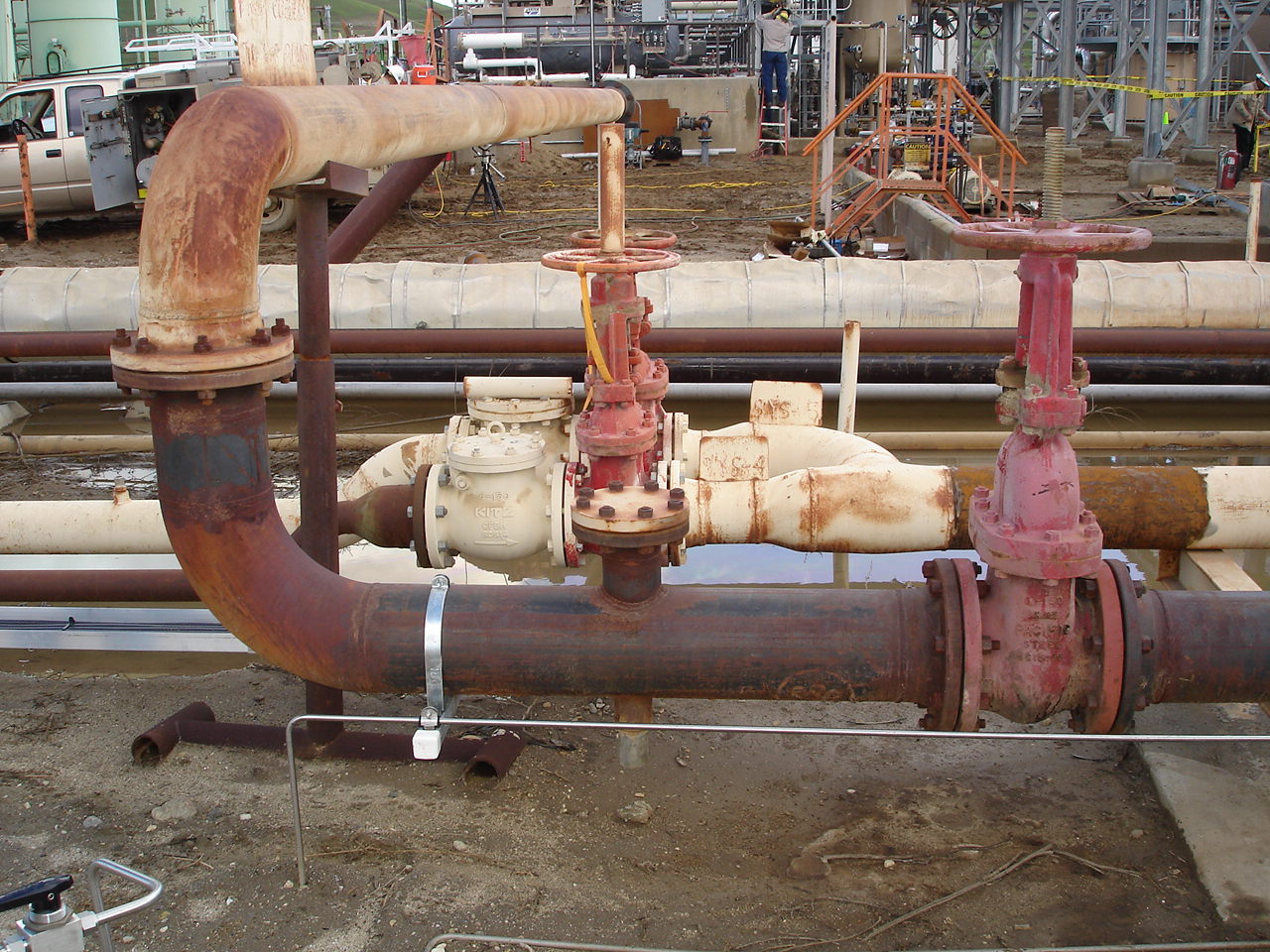

Don't Use Improper Materials - Using materials that aren't suitable for the specific application can lead to corrosion, degradation, or insufficient load-bearing capacity.

Don't Ignore Corrosion Protection - Corrosion can weaken supports over time. Neglecting proper corrosion protection measures can compromise the structural integrity of the support system.

Don't Misalign Supports - Improperly aligned supports can cause stress concentrations, misalignment of pipes, and reduced system efficiency.

Don't Over Tighten Fasteners - Over-tightening fasteners can deform components, lead to stress concentrations, and weaken the support system.

Don't Neglect Vibration and Oscillation - Failing to account for vibration or oscillation can lead to fatigue failure of components or supports over time.

Don't Skip Regular Inspections - Regular inspections are crucial to identify signs of wear, damage, or misalignment in the support system. Skipping inspections can lead to undetected issues and potential failures.

Don't Disregard Expansion Joints - Expansion joints are important components for absorbing thermal expansion. Neglecting their use can lead to excessive stress on supports and pipes.

Don't Ignore Environmental Factors - Environmental conditions such as exposure to chemicals, moisture, or extreme temperatures can impact the performance and longevity of supports.

Don't Neglect Proper Documentation - Accurate documentation of support design, installation, and maintenance is essential for future reference and compliance.

Don't Overlook Load Distribution - Proper load distribution is critical to prevent localized stress concentrations. Ensure that loads are evenly distributed across supports.

Don't Use Supports as Hangers - Pipe supports and hangers have distinct functions. Using a support as a hanger or vice versa can lead to improper load distribution and system inefficiencies.

Don't Ignore Safety - Safety should be a top priority. Improperly designed or installed supports can pose risks to personnel and the environment.