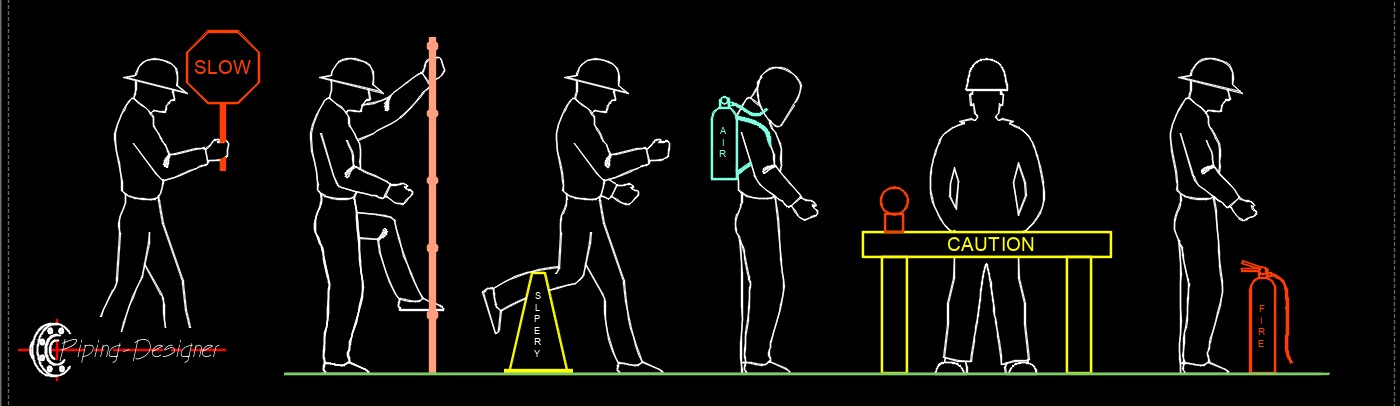

Safety Engineering

Safety, Engineering, Management and SystemsSafety engineering, abbreviated as SAF, also known as safety management or safety science, is a discipline that focuses on ensuring the safety of people, equipment, processes, and environments. It involves the application of scientific and engineering principles to identify, assess, and control potential hazards and risks in various settings. The primary goal of safety engineering is to prevent accidents, injuries, and adverse events by designing and implementing effective safety measures and controls. It encompasses a wide range of industries and sectors, including manufacturing, construction, transportation, healthcare, energy, and more.

| Engineering |

| Management and Systems Engineering |

Overall, safety engineering is a multidisciplinary field that combines engineering, science, psychology, and management principles to create safe and secure environments for individuals and society as a whole.

- See Article - Safety Glossary