Expansion loop, also called expansion joint or thermal expansion loop, is a flexible component or arrangement used in piping systems to accommodate the expansion and contraction of pipes due to temperature changes. It allows pipes to change in length without causing excessive stress, strain, or damage to the piping system, ensuring its integrity and longevity.

When materials such as metal pipes are subjected to temperature variations, they expand when heated and contract when cooled. This thermal expansion can exert substantial forces on the piping, leading to issues like distortion, buckling, leaks, or even structural damage. An expansion loop is designed to mitigate these problems by providing a controlled and flexible area where the pipe can expand or contract. An expansion loop typically consists of a section of pipe with one or more curves, bends, or loops. These loops introduce flexibility to the piping system, allowing the pipe to elongate or shorten while the loop absorbs the resulting movement. The expansion loop can be made of materials that offer good flexibility and durability, and it's often accompanied by appropriate anchoring and guiding mechanisms to ensure proper functioning.

Expansion loops are commonly used in various industries, including HVAC, industrial process piping, and power generation. They're essential in systems where pipes are exposed to temperature fluctuations, as they prevent stresses that could otherwise lead to pipe failure or system disruption. There are different types of expansion joints, including bellows-type expansion joints, which use accordion-like structures to accommodate movement, and slip-type expansion joints, which use sliding elements to allow for movement. The choice of the right type of expansion joint depends on factors such as the operating conditions, the piping material, the temperature range, and the specific requirements of the application. Proper design, installation, and maintenance of expansion loops are critical to ensuring the safe and efficient operation of piping systems.

- See Article - Pipe Support Don's

Expansion Loop Designing

Designing an expansion loop used to accommodate thermal expansion and contraction, vibration, and other movements while maintaining the integrity of the system. Always consult with experienced engineers or specialists in expansion joint design to ensure that your specific application meets safety and performance requirements. Designing and selecting the right expansion loop can be critical to the overall reliability and efficiency of your system. Here are steps to design an expansion loop:

Understand System Requirements - Determine the specific requirements and constraints of your system. This includes factors such as temperature variations, pressure changes, pipe or duct material, and allowable movement.Calculate Expected Movements - Determine the expected thermal expansion and contraction, as well as other movements (due to vibration) that the expansion loop needs to accommodate. Consider both axial (lengthwise) and lateral (sideways) movements.

Select Expansion Loop Type - Choose the type of expansion loop that best suits your system's needs.

Determine Materials - Select materials for the expansion loop components based on the system's requirements. Consider factors like temperature, pressure, corrosion resistance, and material compatibility with the system.

Calculate Expansion Loop Dimensions - Calculate the dimensions of the expansion loop components (the bellows in a bellows expansion joint) based on the expected movements and materials used. Ensure that the loop can accommodate the required range of motion without overstressing the materials.

Factor in Safety and Codes - Ensure compliance with industry standards and codes (ASME B31.3 for piping systems) to ensure the expansion loop's safety and performance. Consider factors like allowable stresses, load ratings, and testing requirements.

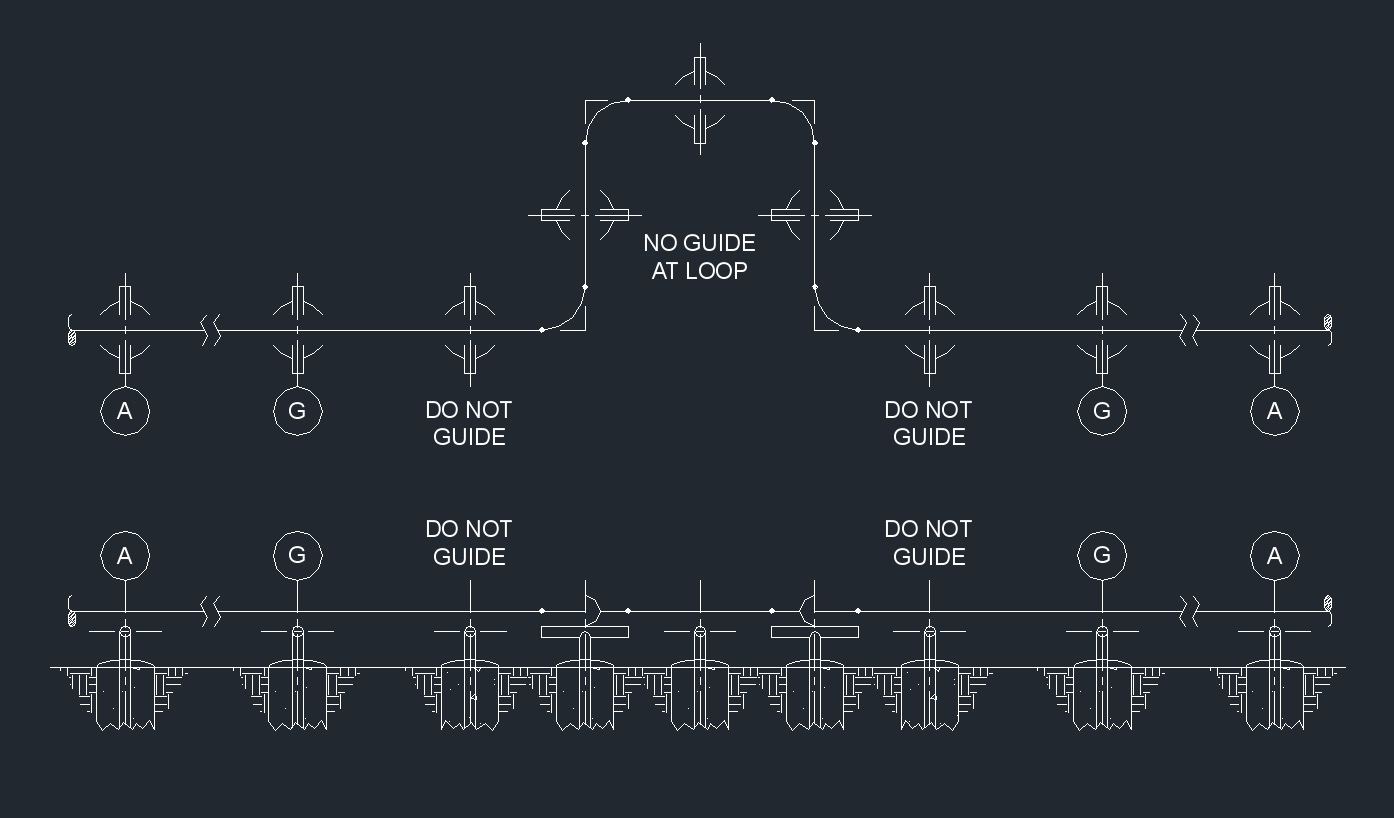

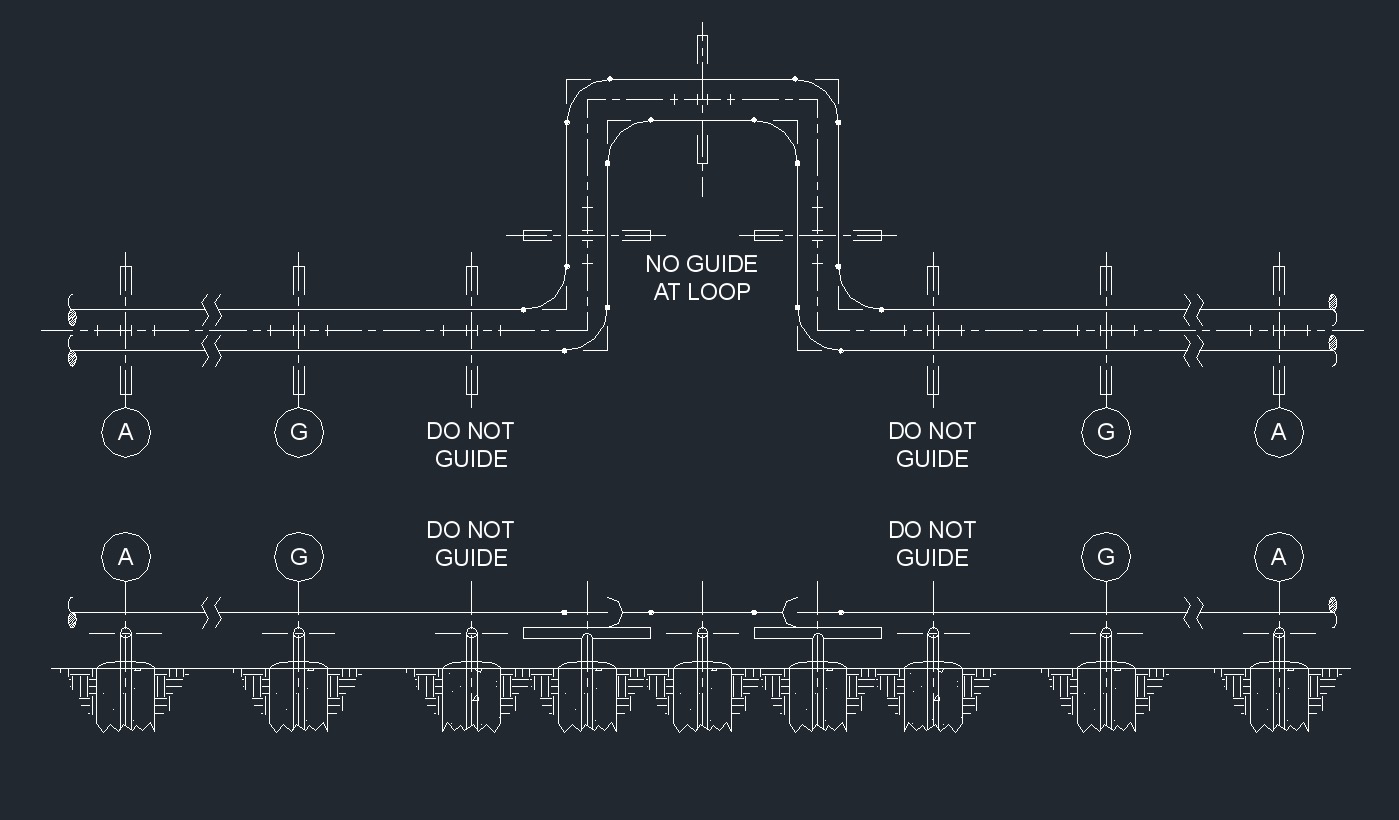

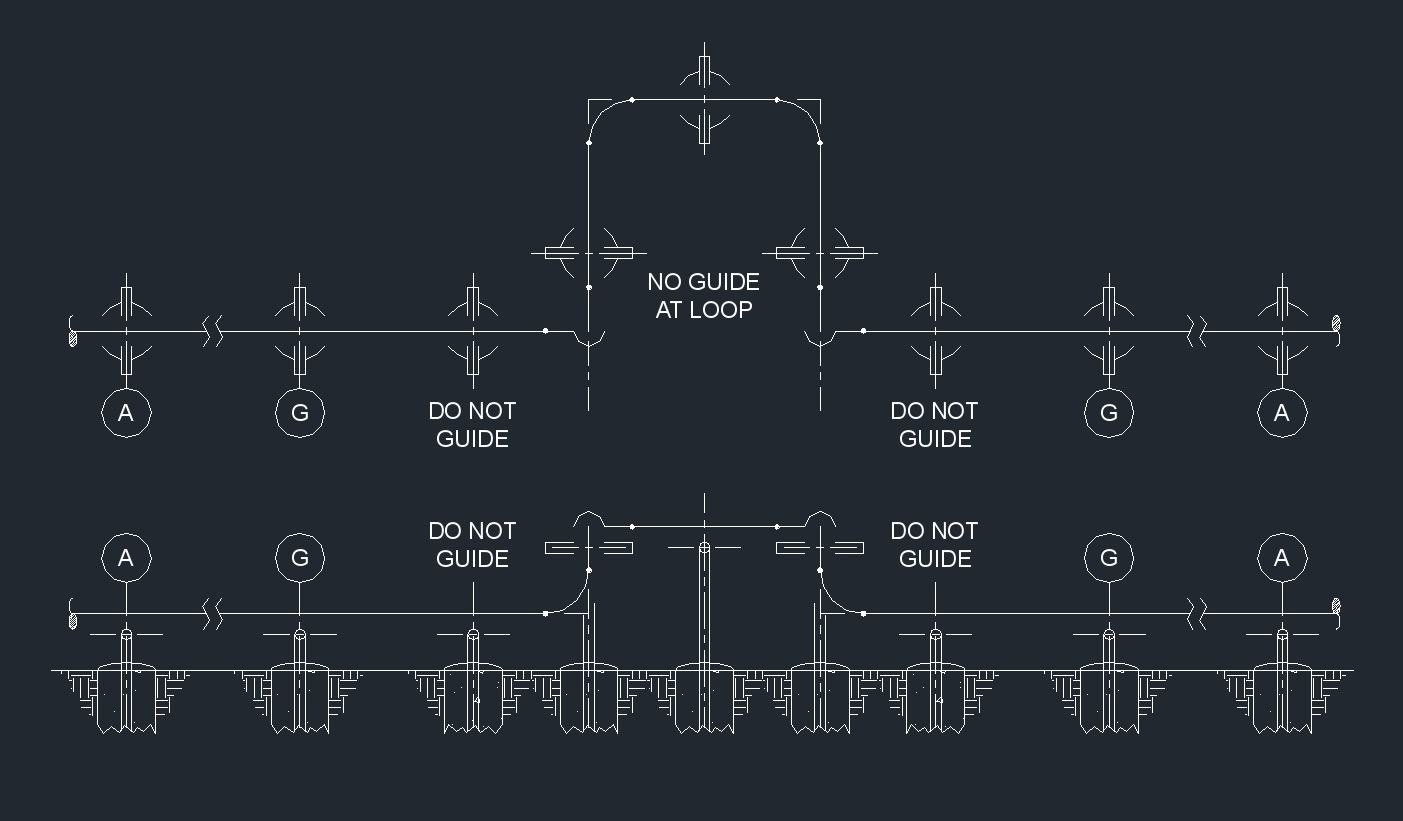

Design Support and Anchoring - Plan the supports and anchor points for the expansion loop within the system. Proper support is crucial to prevent excessive stress on the expansion joint and maintain system integrity.

Stress Analysis - Perform a stress analysis of the expansion loop and adjacent components to ensure that the design meets safety and performance criteria. Consider static and dynamic loads, as well as worst case scenarios.

Fabrication and Quality Control - Fabricate the expansion loop components with precision, adhering to the design specifications and quality control standards. Inspect and test the expansion loop for leaks, material defects, and proper functionality.

Installation and Maintenance - Follow recommended installation procedures, ensuring proper alignment and clearances. Implement a maintenance schedule to inspect the expansion loop regularly and replace it when necessary.

Documentation - Maintain thorough documentation of the expansion loop design, materials, fabrication, installation, and maintenance. This information is essential for future reference and compliance with regulations.

Consider Expansion Joint Accessories - Depending on the application, you may need additional accessories such as limit rods, control units, or protective covers to enhance the expansion loop's performance and longevity.

Expansion Loop Placement

An expansion loop is used in piping systems to accommodate the thermal expansion and contraction of pipes. These expansion loops are crucial to prevent stress and damage to the pipes, supports, and connected equipment. Proper placement of expansion loops is necessary to ensure the effective functioning of the piping system. Consulting with a qualified engineer or piping designer is often necessary to ensure that expansion loops are installed correctly in your specific application. Here are some considerations for expansion loop placement:

Location - Expansion loops should be placed at specific locations where thermal movement is expected to occur. These locations include areas where temperature fluctuations are significant, such as near hot equipment like boilers or coolers.Anchor Points - Expansion loops are typically installed between two anchor points. Anchor points are fixed locations where the pipe is secured and does not move. One end of the expansion loop is connected to an anchor point, while the other end is connected to a sliding support, which allows for movement.

Thermal Analysis - Conduct a thermal analysis of the piping system to determine the amount of thermal expansion and contraction that is expected. This analysis should consider the temperature range, material properties, and pipe length.

Design and Sizing - The size and design of the expansion loop should be selected based on the expected thermal movement. Expansion loops come in various types, including bellows, slip joints, and ball joints, each with different capabilities for movement. Properly size and select the type of expansion loop that meets the system's requirements.

Spacing - Depending on the design and temperature changes, you may need multiple expansion loops along a pipeline. The spacing between expansion loops should be determined based on the maximum allowable movement and the design of the expansion joints.

Alignment - Ensure that the expansion loop is properly aligned with the pipeline to prevent any stress on the joints. Misalignment can lead to premature failure of the expansion loop.

Supports - Use appropriate supports for the expansion loop, such as hangers, to ensure that it remains in the correct position and doesn't sag or twist.

Access - Consider accessibility for maintenance and inspection of the expansion loop. It should be easy to access for visual inspections and potential repairs.

Manufacturer Guidelines - Follow the manufacturer's guidelines and recommendations for the installation and maintenance of the specific expansion joint you are using. Different types of expansion joints may have unique requirements.

Codes and Standards - Ensure compliance with relevant industry codes and standards (ASME B31.1 for power piping or ASME B31.3 for process piping) when designing and installing expansion loops.

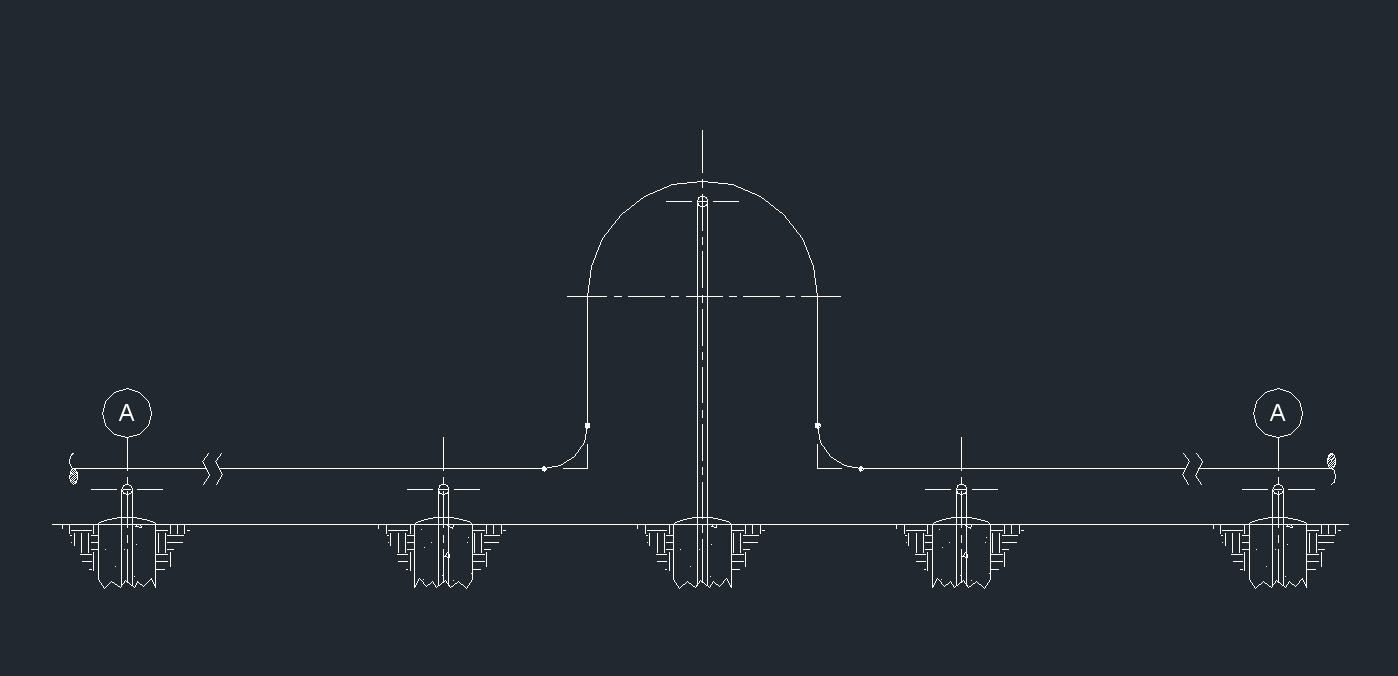

Horizontal Bend Expansion Loop

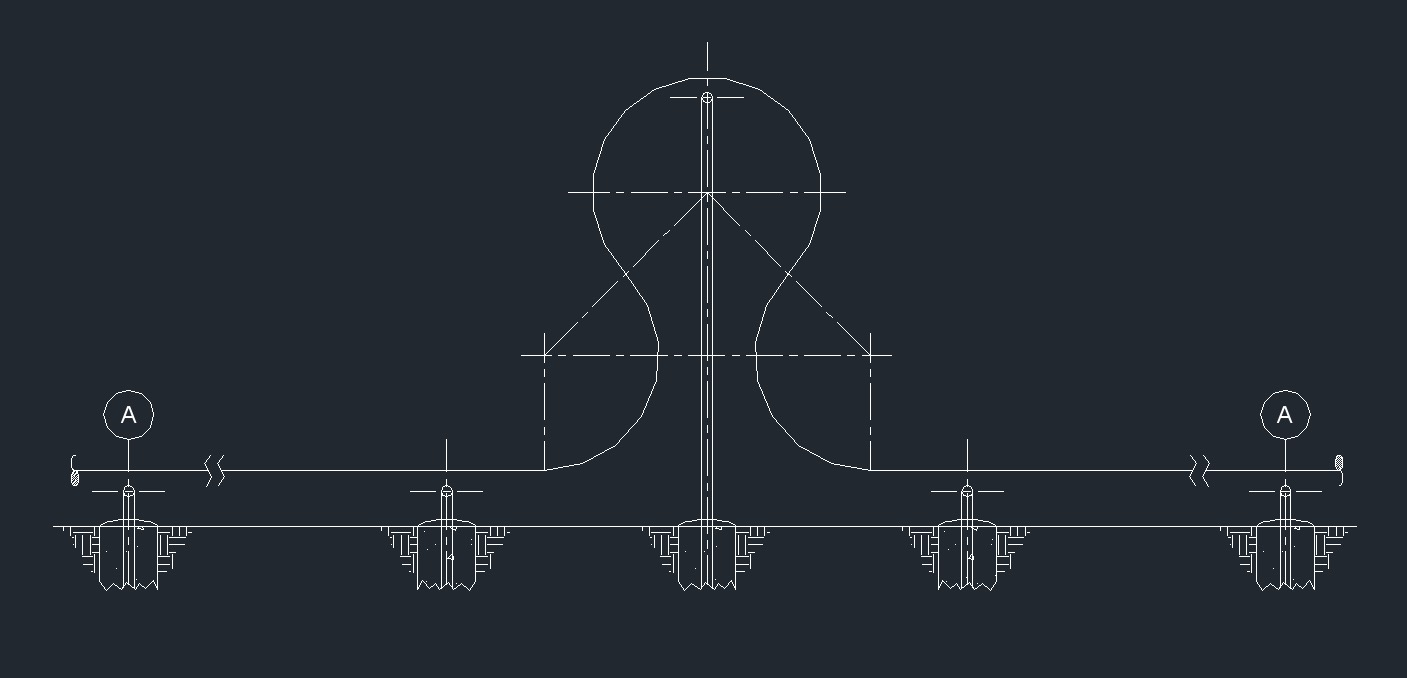

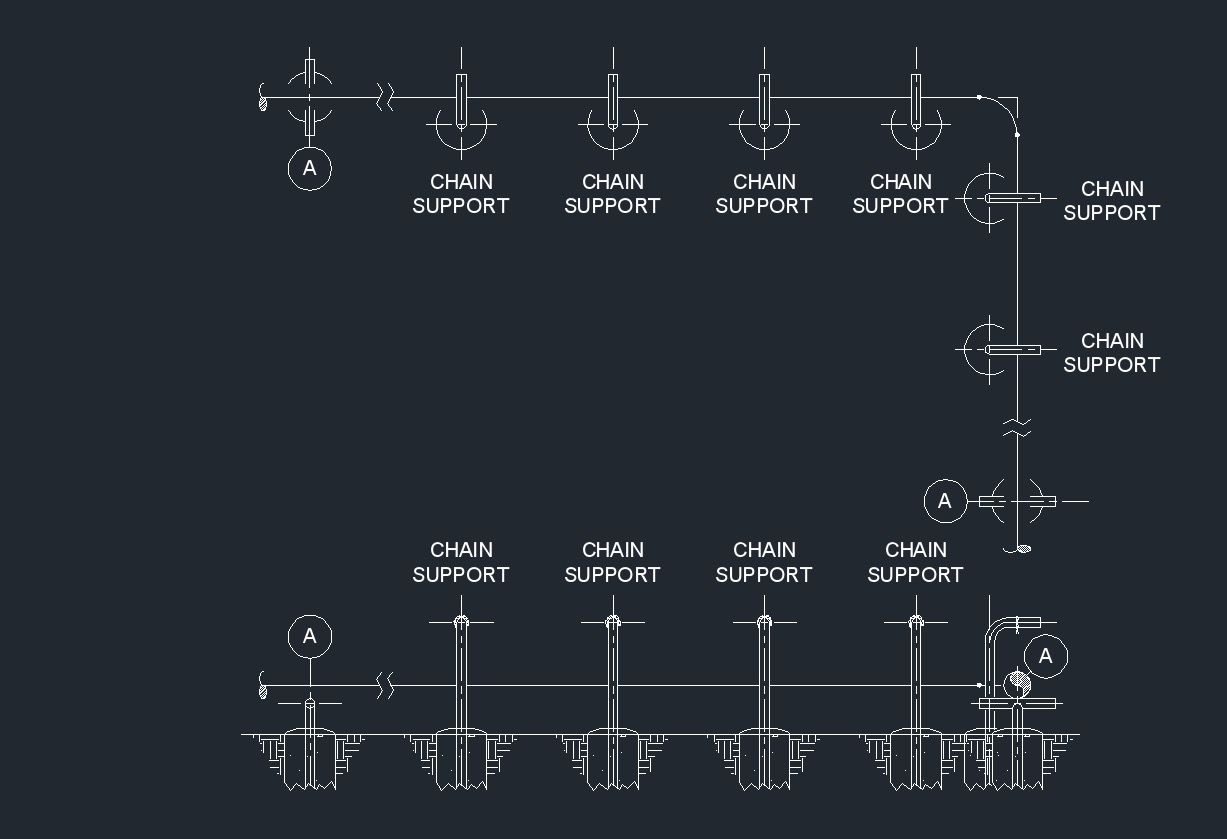

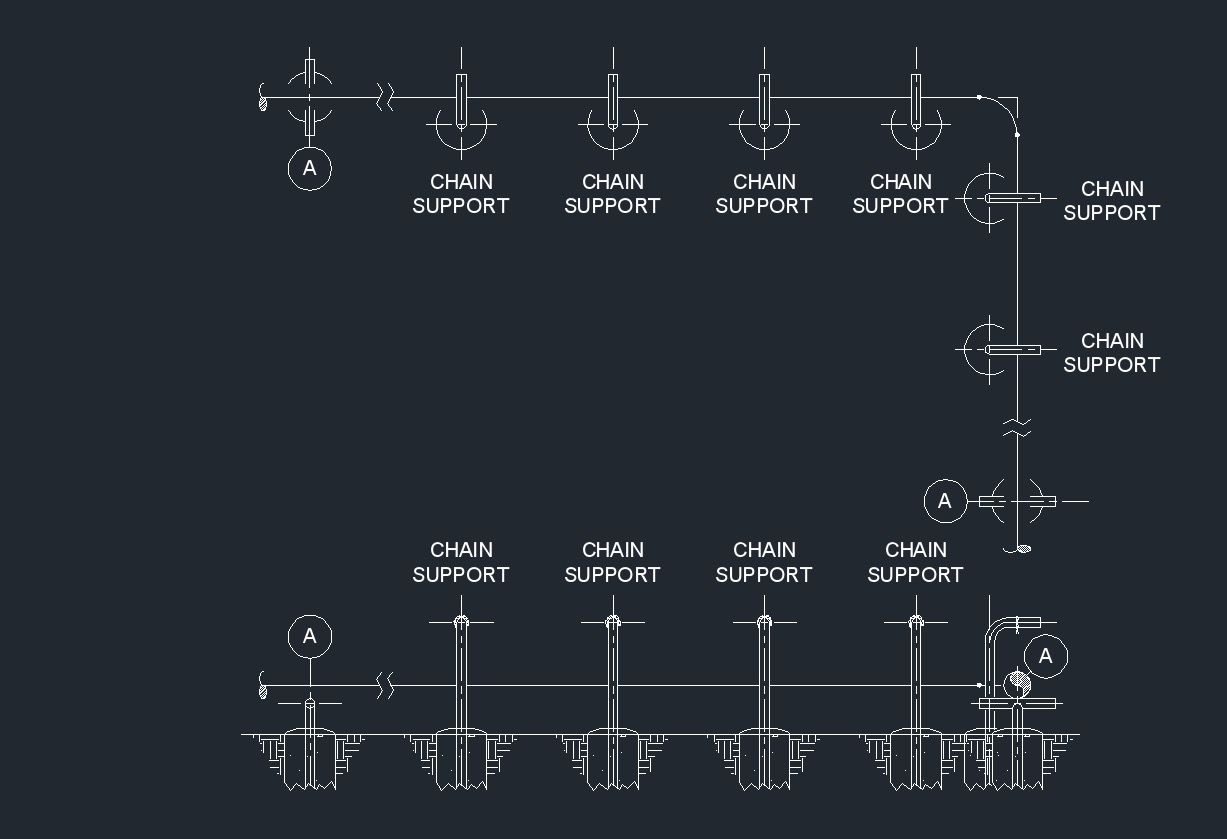

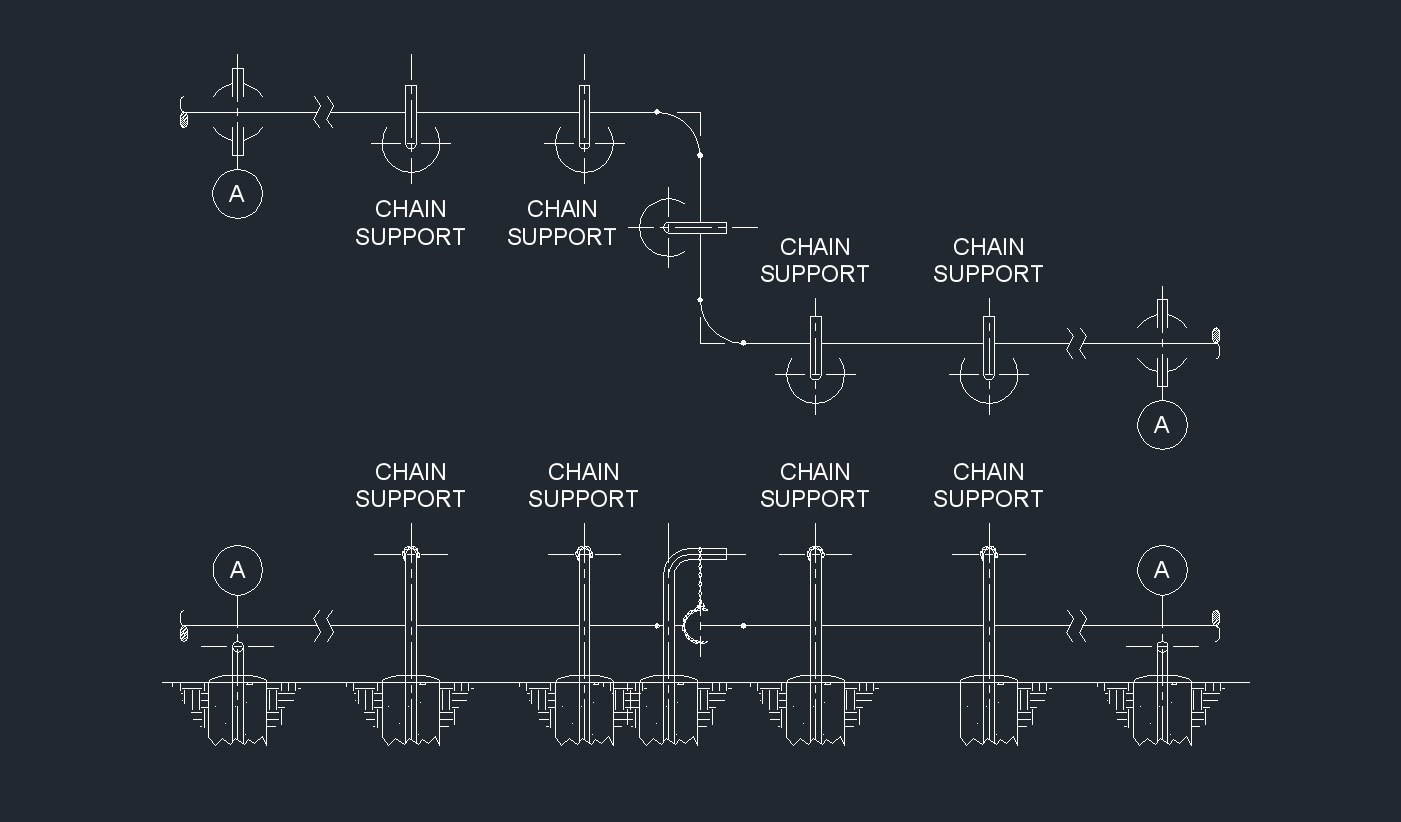

Horizontal Chain U Bend Expansion Loop

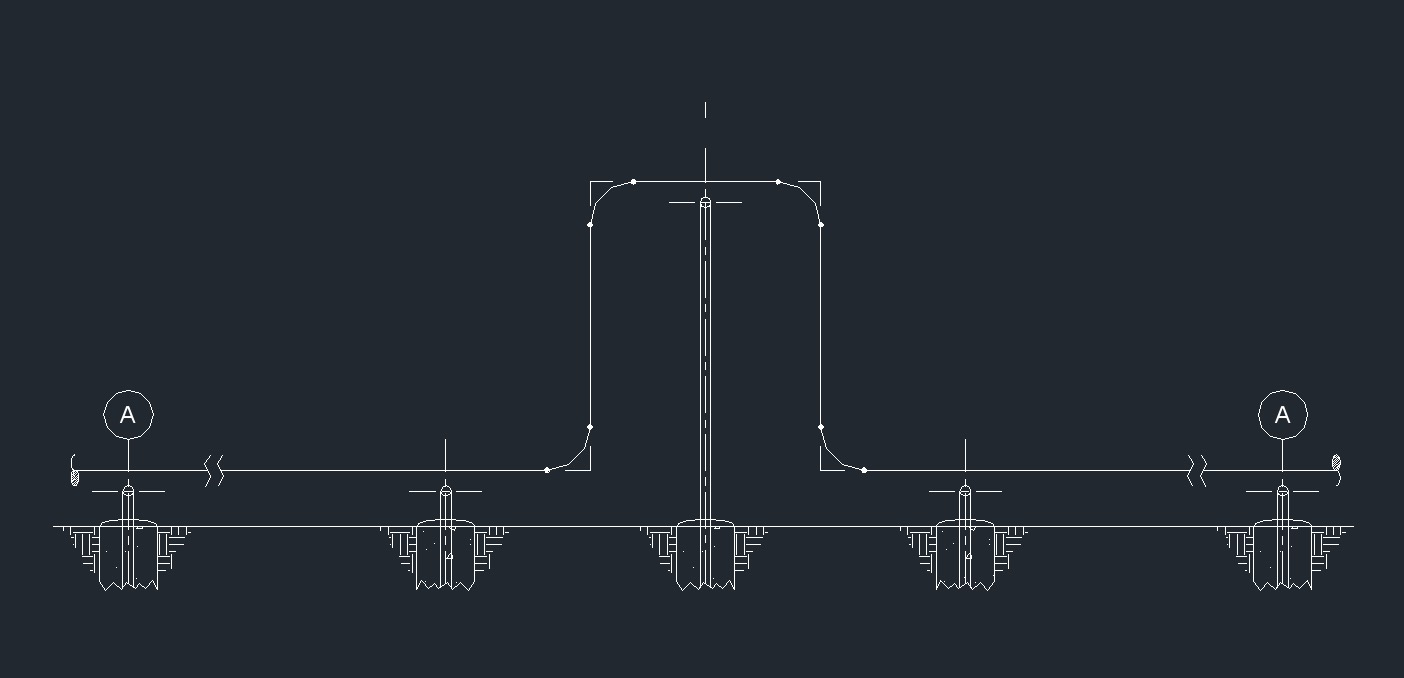

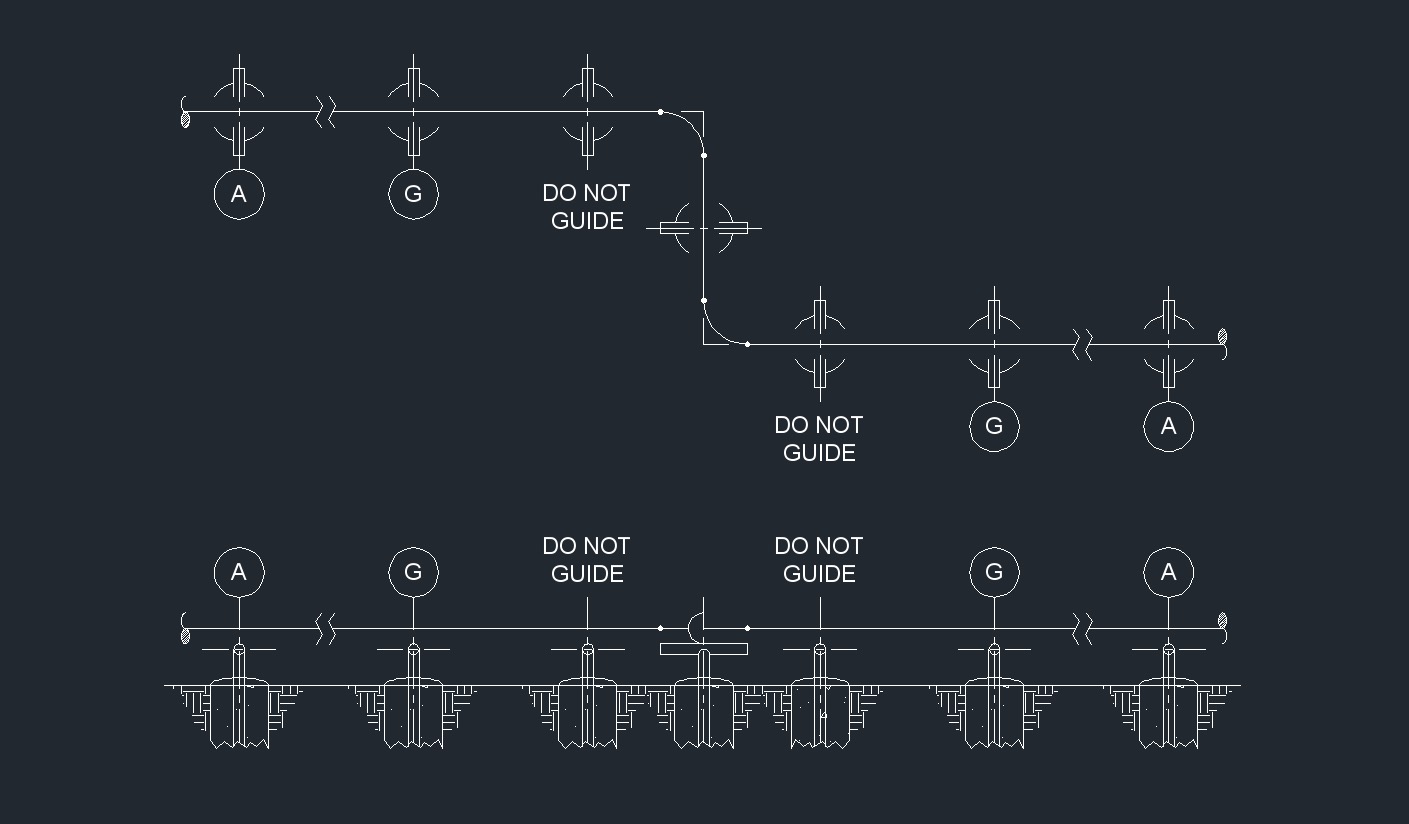

Horizontal Chain Bend Expansion Loop

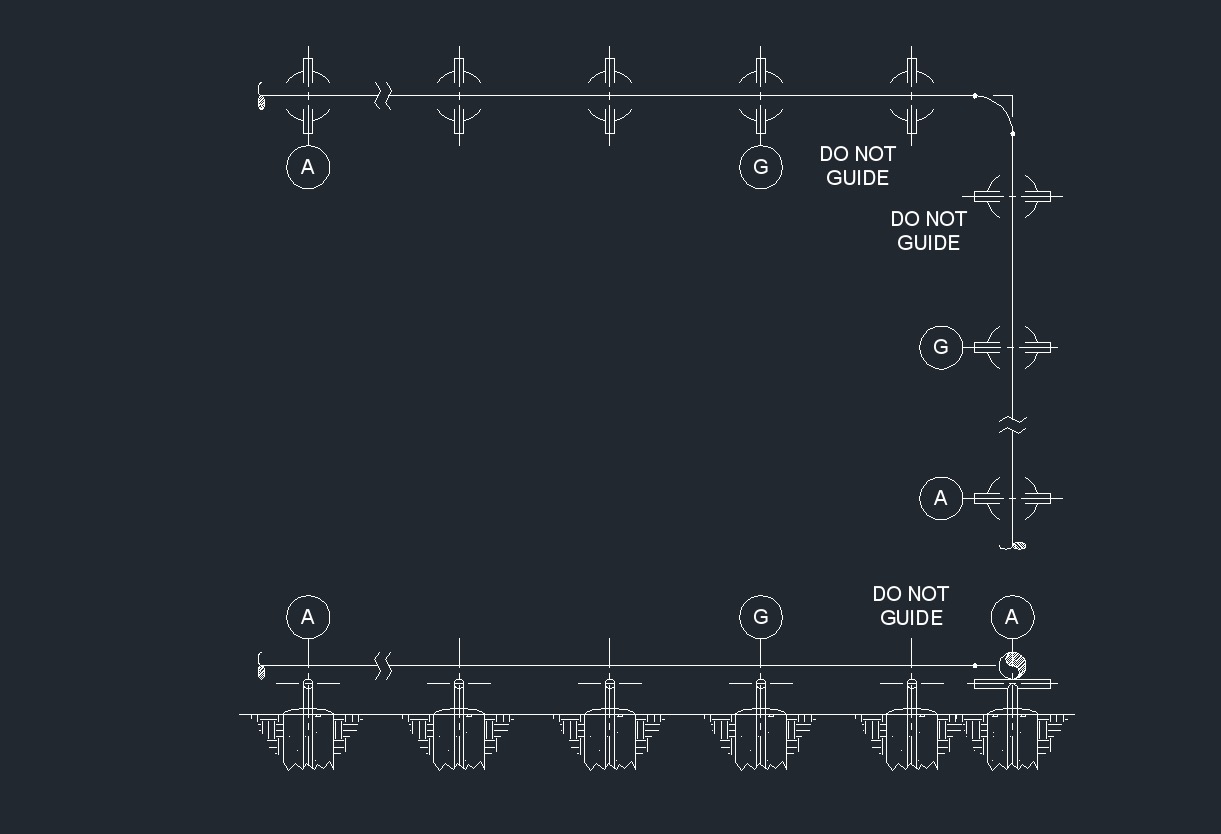

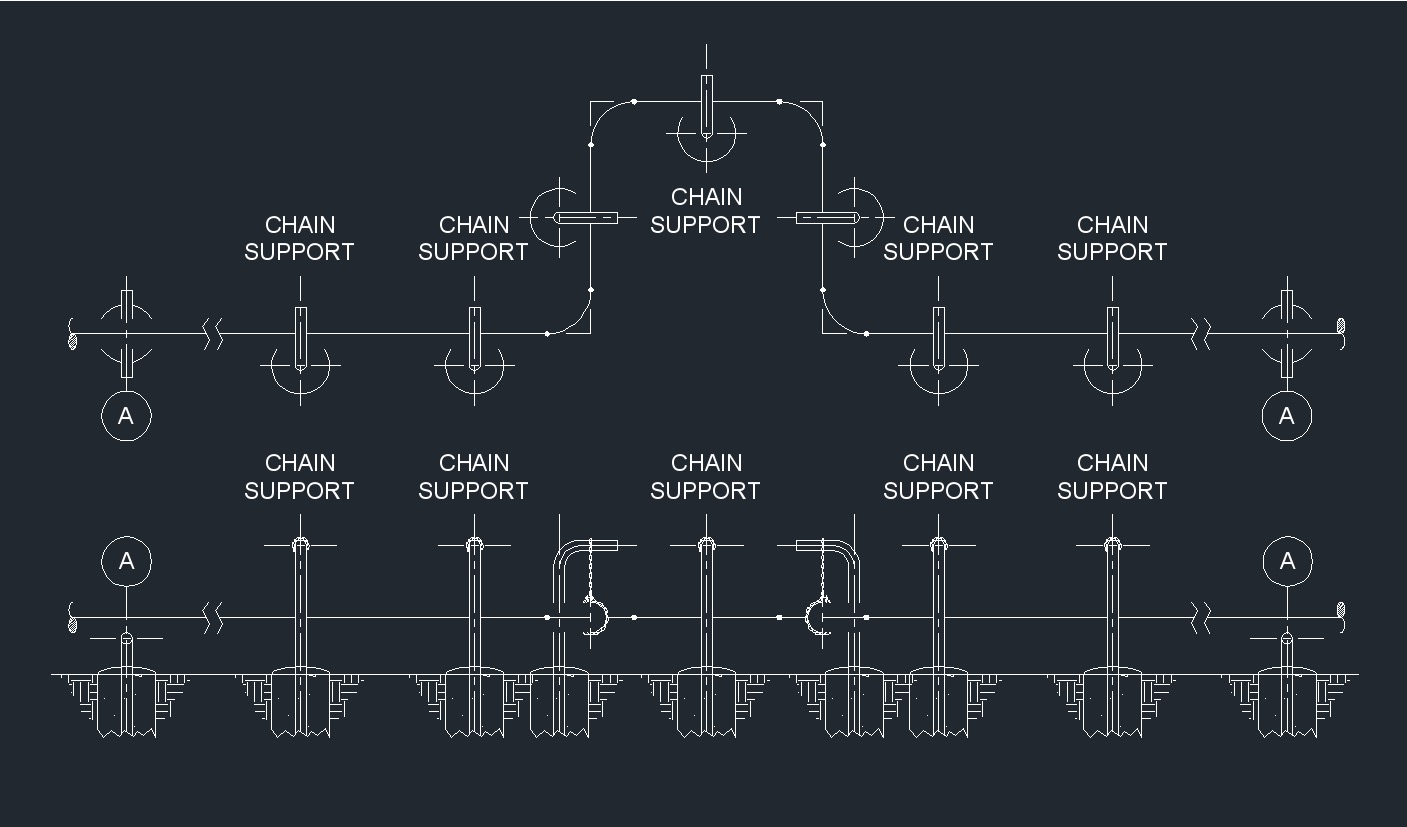

Horizontal U Bend Expansion Loop

Vertical U Bend Expansion Loop