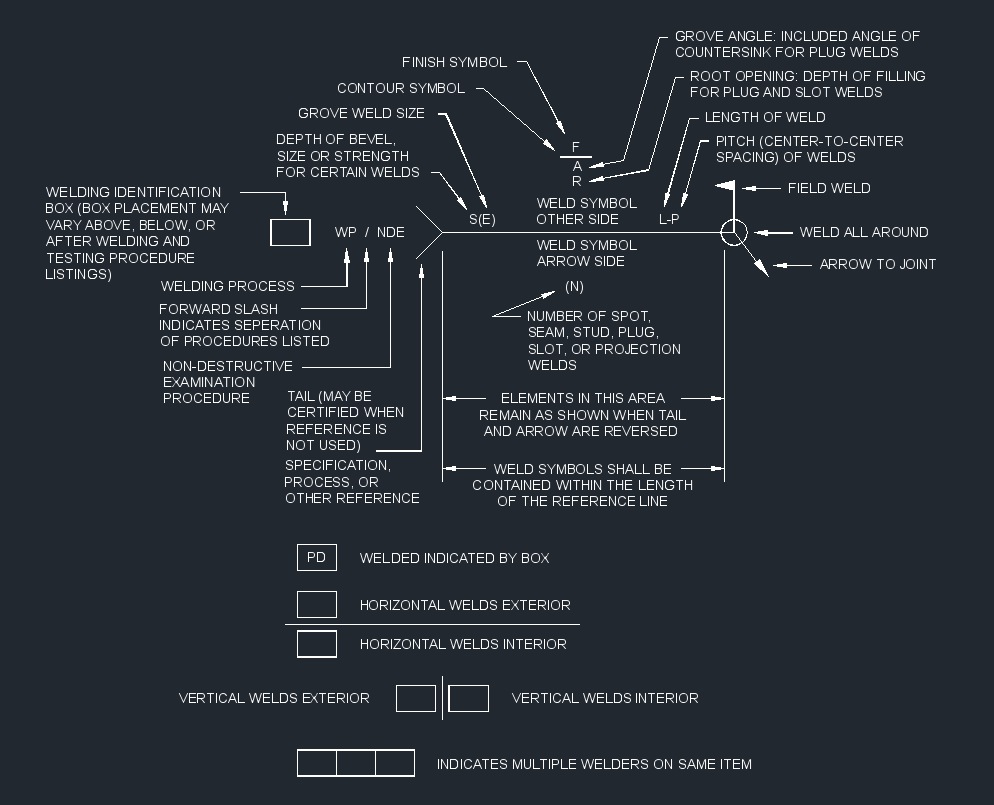

Elements of a Welding Symbol

A welding symbol is a standardized graphical representation used in welding blueprints, drawings, and documents to convey important information about the weld joint and welding process. It provides essential details to welders, inspectors, and fabricators.

Elements of a Welding Symbol

Reference Line - The horizontal line that represents the base or reference for the welding symbol. All other elements of the symbol are positioned with respect to this line.

Arrow - An arrow is attached to the reference line, indicating the location of the weld on the joint. The arrow's tail points to the joint's starting point, while the arrowhead indicates the end of the weld.

Basic Welding Symbol - A simple representation of the type of weld required. This could include symbols for various weld types, such as fillet welds, groove welds, plug welds, etc.

Dimensions and Measurements - These indicate the dimensions, sizes, and lengths of welds, such as the length of a fillet weld or the depth of a groove weld.

Welding Process - The process used for welding is often represented as an abbreviation inside the welding symbol. Common abbreviations include "SMAW" (Shielded Metal Arc Welding), "GMAW" (Gas Metal Arc Welding), and "GTAW" (Gas Tungsten Arc Welding).

Welding Symbol Tail - The tail of the welding symbol contains additional information, such as weld specification, electrode or filler material, and other relevant details.

Welding Symbol Arrow Side - Indicates which side of the joint the weld is applied to. The side where the arrow points is often labeled "arrow side" or "arrow side of joint," and the opposite side is labeled "other side" or "other side of joint."

Welding Symbol Reference Line Extension - Extensions to the reference line may be added to indicate specific details about the joint preparation, contour, or finish.

Weld Symbol Finish - Indicated by a tail or additional annotations, this provides information about the desired surface finish or contour of the weld.

Weld Symbol Supplementary Symbols - These additional symbols provide more detailed information about the weld. They might include symbols for backing, root opening, backing run, and more.

Weld Symbol Tail Specification - A note in the tail of the welding symbol specifies the welding procedure to be followed, including relevant codes and standards.

Welding Symbol Process Type - The type of welding process is often indicated by an abbreviation within the welding symbol, representing the specific method to be used.

These elements work together to provide comprehensive information about the welding requirements for a given joint. Welding symbols help ensure that welders, inspectors, and fabricators have a clear understanding of how to perform the weld correctly and meet the specified standards.