Steam Flow Rate through Piping

steam Flow Rate through Piping formula |

||

| \( Q_s \;=\; 3600 \cdot \pi \cdot \dfrac{ v_s }{ \upsilon } \cdot \left( \dfrac{ d }{ 24 } \right) ^2 \) | ||

| Symbol | English | Metric |

| \( Q_s \) = Steam Flow Rate | \(ft^3\;/\;sec\) | \(m^3\;/\;s\) |

| \( \pi \) = Pi | \(3.141 592 653 ...\) | \(3.141 592 653 ...\) |

| \( d \) = Pipe Inside Diameter | \(in\) | \(mm\) |

| \( \upsilon \) (Greek symbol upsilon) = Steam Specific Volume | \(ft^3\;/\;lbm\) | \(m^3\;/\;kg\) |

| \( v_s \) = Steam Velocity | \(ft\;/\;sec\) | \(m\;/\;s\) |

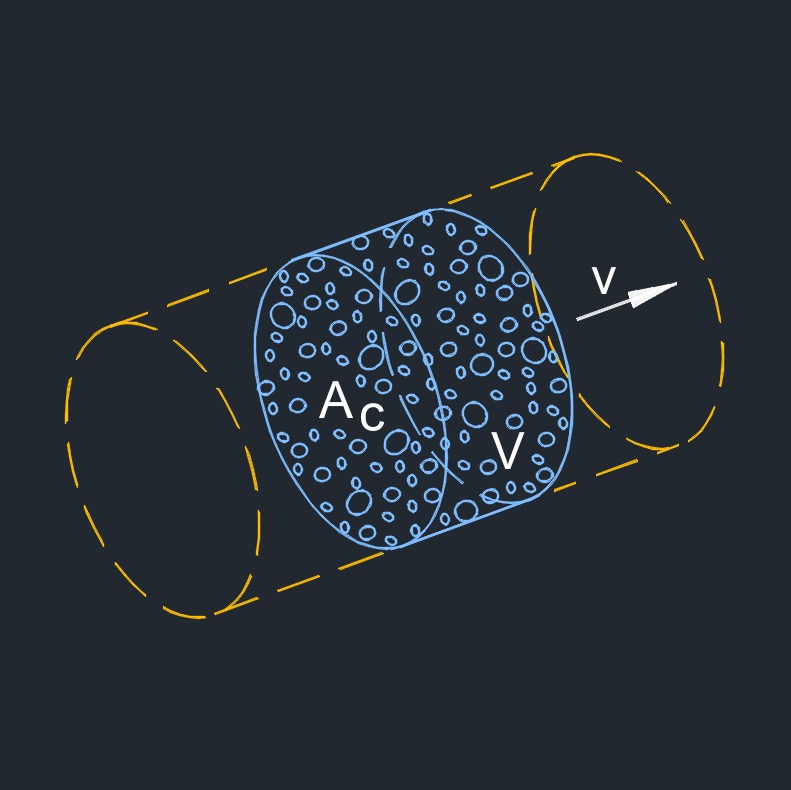

Steam flow rate through piping is the amount of steam that passes through a pipe within a specific time period. This flow rate through depends on various factors including the pipe size, the pressure and temperature of the steam, the length and configuration of the piping system, and the demand of the steam using equipment or processes.

Steam flow rate through piping is the amount of steam that passes through a pipe within a specific time period. This flow rate through depends on various factors including the pipe size, the pressure and temperature of the steam, the length and configuration of the piping system, and the demand of the steam using equipment or processes.

Calculating the steam flow rate requires consideration of these factors along with the physical properties of steam, such as its density and specific volume at the given pressure and temperature conditions. Engineers use steam tables or specialized software to accurately determine steam flow rates in piping systems for design and operational purposes.