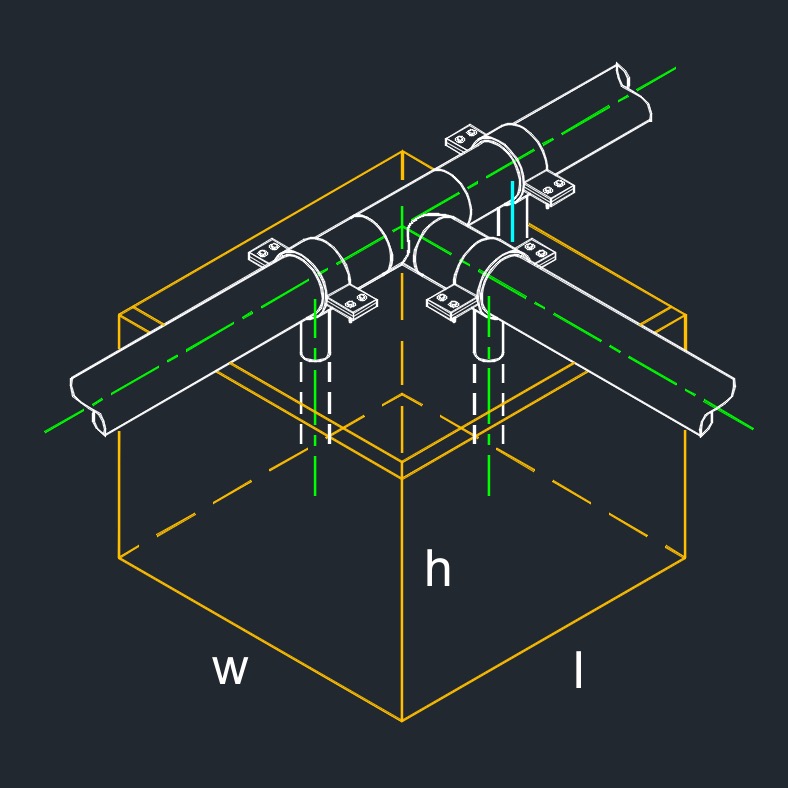

Impact Tee

An impact tee takes steam flow through the branch connection of a normal tee. Steam vapor and liquids are more or less split equally through the two outlets. Like most piping, some flow conditioning is required to ensure an even split. To ensure even splitting, impact tee design should allow for 20 pipe diameters minimum of straight run prior to a tee and 10 diameters downstream of the impact tee.

An impact tee takes steam flow through the branch connection of a normal tee. Steam vapor and liquids are more or less split equally through the two outlets. Like most piping, some flow conditioning is required to ensure an even split. To ensure even splitting, impact tee design should allow for 20 pipe diameters minimum of straight run prior to a tee and 10 diameters downstream of the impact tee.

Impact tees used for splitting flows should be anchored at the tee. Anchoring more than 5 feet or more upstream or downstream of the tee is not advised without a loop or some other stress containing/relieving device. The impact tee should be mounted as level as possible with the run portion of the tee in the horizontal plane.

Line Sizing

For good flow splitting at impact tees, the design steam velocity should be between 12 and 20 feet per second.

Outside of the tee area, the line size should be determined by standard criteria of pressure drop, allowable velocity and economics. However, the design steam velocity should be less than 50 ft/sec in order to avoid excessive pipe and fitting erosion.

Tags: Pipe Fitting Steam