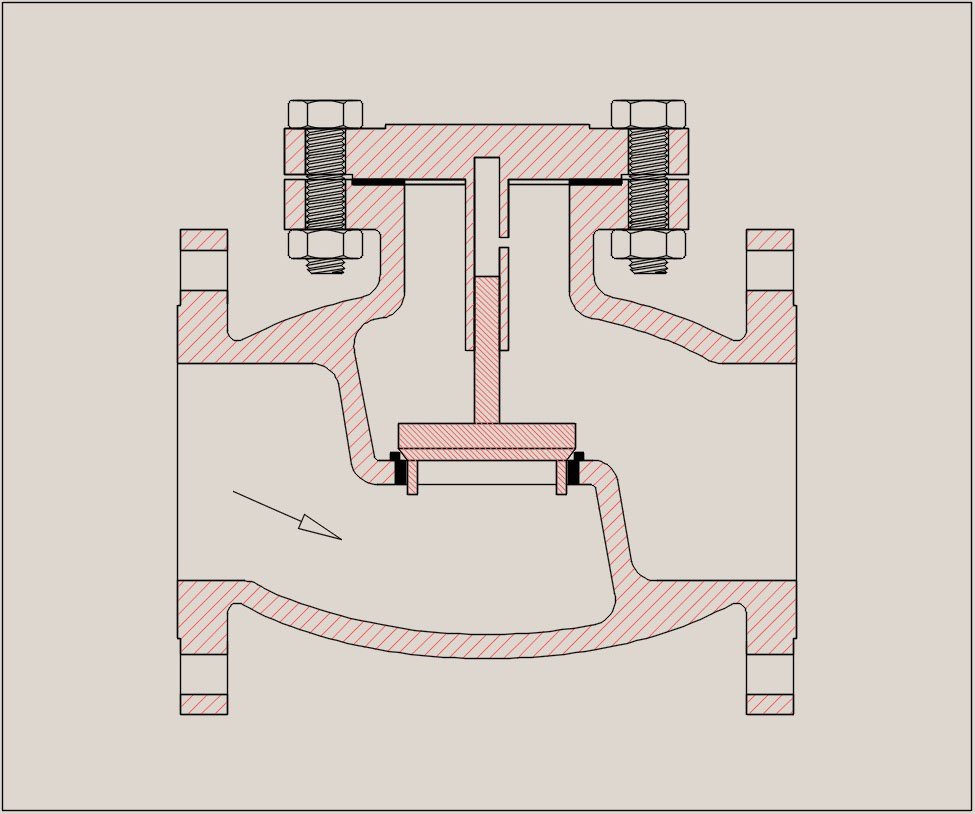

Lift Check Valve

A lift check valve is a check valve that is very much like a piston check valve where the flow lifts a disk when the valve is open. The upstream side of the lift check is under the disk and the flow flows up through the disk. The disk is guided to keep the motion to be perpendicular to the line flow direction.

A lift check valve is a check valve that is very much like a piston check valve where the flow lifts a disk when the valve is open. The upstream side of the lift check is under the disk and the flow flows up through the disk. The disk is guided to keep the motion to be perpendicular to the line flow direction.

The guide is generally bolted to the top of the valve which makes maintenance easy. The only moving part is the disk and which can be replaced easily with the valve seat through the top of the valve. It is easier to maintain than a tilt check valve.

Liquid entering this valve must change directions twice to get through the valve. This is a similar design to a globe valve and, as such, has a relatively high pressure drop across the valve. If the process is sensitive to pressure drop, this valve may not be the right valve to use.

In order to hold the valve open, the minimum flow rate can be calculated in the following way:

- \(V = j r \sqrt{v}\)

- \(V\) = liquid flow, ft/s (m/s)

- \(j\) = 40 (152.8) for bolted cap

- = 140 (534.7) for Y-pattern

- \(r\) = ratio of port diameter to inside pipe diameter

- \(v\) = specific volume of the liquid, ft3/lb (m3/N)

Lift check valves are usually used in high pressure where the velocity is high. They are often used immediately downstream of a globe valve. Additionally, due to their configuration, they usually have a more effective shutoff and tighter seal than a swing check valve.

Like the swing check and tilt check valve, the lift check must be installed such that gravity does not keep the disk open when there is zero flow. This can be overcome by adding a spring to the disk to force the check valve closed when there is no flow.

Lift Check Valve Advantages and Disadvantages | |

|---|---|

| Advantages | Disadvantages |

|

|