Temporary Strainer

This photo shows a conical strainer that was installed with the cone facing downstream. After the cone was in for several hours, it begun to plug off. Note in the photo that the only available flow area is near the outside of the strainer. For this installation, no construction debris was removed from the line. The debris in the line is inherent to the process.A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. It can be installed to protect a flowmeter, pump, control or relief valves or other pieces of equipment during startup. During construction, materials may become trapped in the line. These materials could be welding slag, welding rod, pieces of wood, cigarettes, rocks, etc. Many pieces of equipment will become damaged if this debris enters it. A start up strainer is temporarily installed to keep this debris out of the equipment. After start up is completed, the startup strainer should be removed.

This photo shows a conical strainer that was installed with the cone facing downstream. After the cone was in for several hours, it begun to plug off. Note in the photo that the only available flow area is near the outside of the strainer. For this installation, no construction debris was removed from the line. The debris in the line is inherent to the process.A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. It can be installed to protect a flowmeter, pump, control or relief valves or other pieces of equipment during startup. During construction, materials may become trapped in the line. These materials could be welding slag, welding rod, pieces of wood, cigarettes, rocks, etc. Many pieces of equipment will become damaged if this debris enters it. A start up strainer is temporarily installed to keep this debris out of the equipment. After start up is completed, the startup strainer should be removed.

Temporary Strainer Design

Things to consider when sizing and designing the installation of a startup strainer are as follows:

- The materials of construction must be compatible with the process fluid.

- Design pressure and temperature of the process. If a strainer cannot withstand high temperatures or differential pressures, it could come apart and cause damage to your equipment. Will the expected pressure drop across the strainer cause the downstream operating pressure to fall below the minimum required pressure of the line? As an example, the downstream pressure should never fall below the NPSHr of a pump.

- Perforation size or screen size. The strainer should be slightly smaller than the smallest piece of debris that is expected to flow through it. If the perforations are too small, a high pressure drop could develop across the strainer and cause it to fail.

- Ability to easily remove the strainer. Consider adding a pipe support or pipe stand close to the strainer and/ or a removable spool so that the strainer can be removed easily.

- Ability to shutdown the process in order to remove the strainer. Is there a redundant piece of equipment that can be used while the strainer is being removed? Are there block valves in place to allow you to bypass the strainer?

- Installation location. Do not install a strainer immediately upstream of a piece of equipment that is sensitive to the flow regime, such as an orifice plate. If possible, install the strainer downstream.

- After the strainer has served it’s purpose and it is removed, how will the piping be configured? At the flange, the strainer is usually 1/16” and it also requires two gaskets. When the strainer is removed, how will the pipe be connected again without double or triple stacking gaskets?

- Bolt size. The addition of a start up strainer can add 1/8” to the length of the bolts. Some companies require full thread engagement when installing piping and the extra 1/8” can be added to the bolt size.

It is not designed to be a permanent fixture in the piping system. If the application requires a more permanent fixture, a basket strainer should be installed. Installation of a conical strainer can be done in one of two different ways, cone facing upstream or cone facing downstream.

Temporary Strainer Installation

There are two different methods for installing the start up strainer. According to various manufacturers of cone strainers, they can be installed with the cone facing upstream or the cone facing downstream.

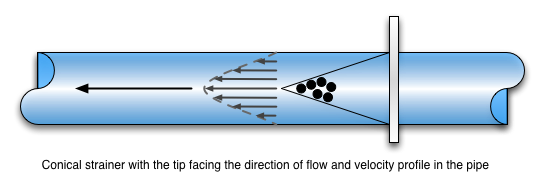

In the photo above, the cone is pointing downstream. In this orientation, debris is captured at the pointed portion of the strainer. The photo also shows a velocity profile for fully developed flow. While the flow regimes are different depending on whether or not the flow is laminar or turbulent, the general characteristics stay the same. The flow is lower near the walls of the pipe and the velocity is higher in the center of the pipe. If the cone is pointed with the tip facing downstream, debris will collect in the tip and may rip the cone apart due to heavier strain on the tip.

A reason for this orientation would be that it will be easy to remove debris since it is swept within the strainer. If this orientation is required, ensure that the strainer is reinforced to ensure its mechanical stability.

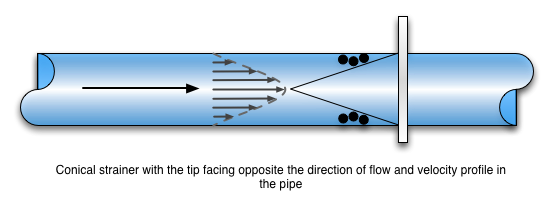

Another option for installation is pointing the cone facing upstream:

In the photo above, debris is swept to the side of the strainer. The outside to inside flow pattern is an advantage in that any plugging of the strainer will start in the outside and work it’s way in.

Temporary Strainer Advantages and Disadvantages | |

|---|---|

| Advantages | Disadvantages |

|

|