Bar to Plate Welds

-

- See Article - Welded Stress and Strain Connections

- See Article - Welded Stress and Strain Connections

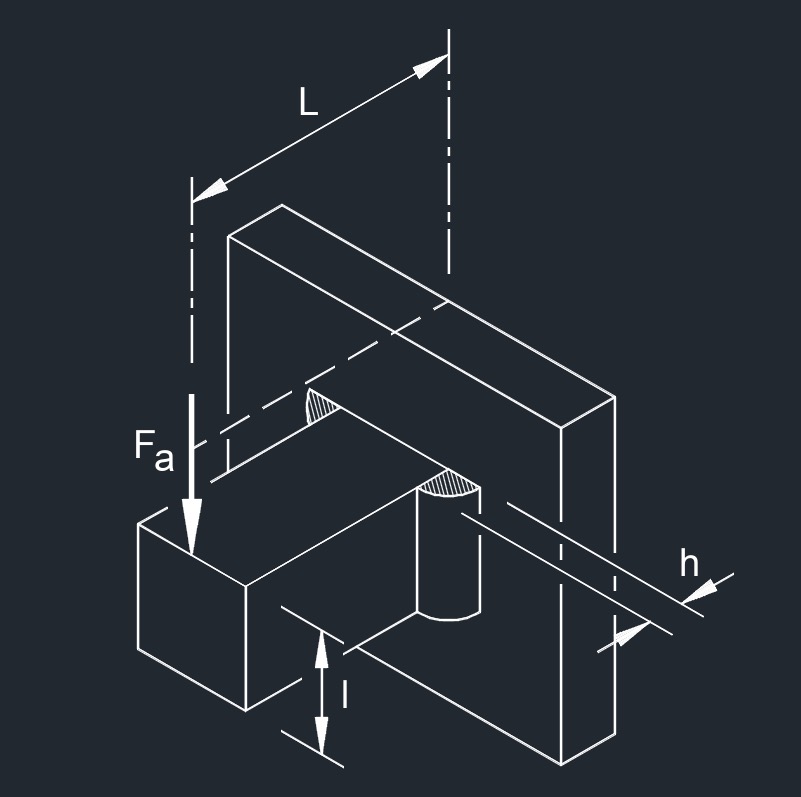

Applied Force on PJP Fillet Weld formulas

|

||

|

\( \tau \;=\; \dfrac{ 0.707 \cdot F_a }{ h \cdot L } \) \( \sigma \;=\; \dfrac{ 4.24 \cdot F_a \cdot l }{ h \cdot L } \) |

||

| Symbol | English | Metric |

| \( \tau \) (Greak symbol tau) = Shear Stress | \(lbf\;/\;in^2\) | \(Pa\) |

| \( \sigma \) (Greek symbol sigma) = Weld Stress | \(lbf\;/\;in^2\) | \(Pa\) |

| \( F_a \) = Total Applied Force | \( lbf \) | \(N\) |

| \( h \) = Plate Thickness | \( in \) | \( mm \) |

| \( L \) = Weld Length | \( in \) | \( mm \) |

| \( l \) = Bar Length | \( in \) | \( mm \) |

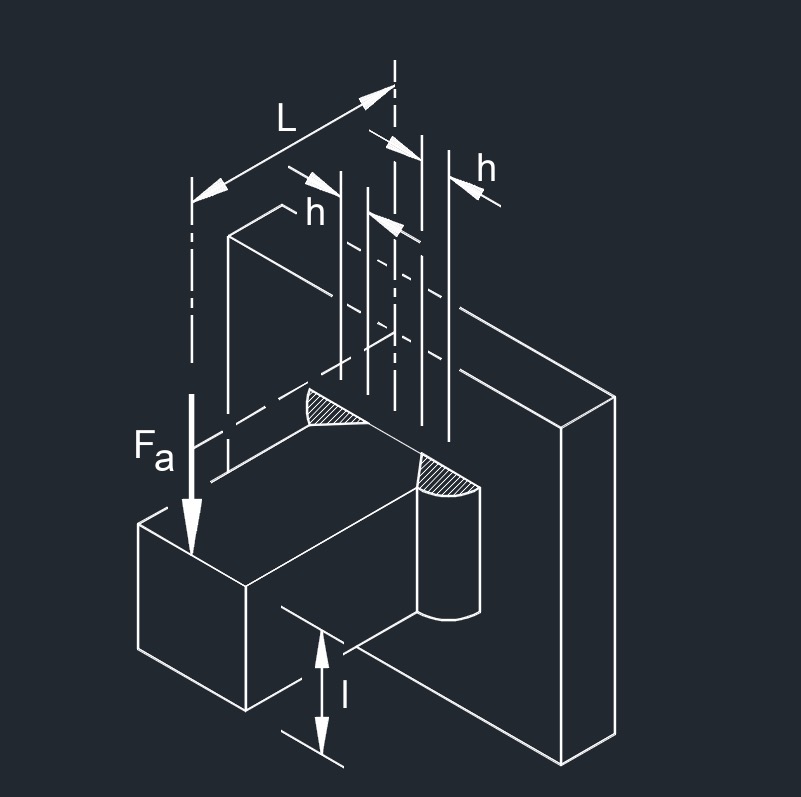

Applied Force on CJP Fillet Weld formulas

|

||

|

\( \tau \;=\; \dfrac{ F_a }{ 2 \cdot h \cdot L }\) \( \sigma \;=\; \dfrac{ 3 \cdot F_a \cdot l }{ h \cdot L^2 }\) |

||

| Symbol | English | Metric |

| \( \tau \) (Greak symbol tau) = Shear Stress | \(lbf\;/\;in^2\) | \(Pa\) |

| \( \sigma \) (Greek symbol sigma) = Weld Stress | \(lbf\;/\;in^2\) | \(Pa\) |

| \( F_a \) = Total Applied Force | \( lbf \) | \(N\) |

| \( l \) = Bar Length | \( in \) | \( mm \) |

| \( h \) = Plate Thickness | \( in \) | \( mm \) |

| \( L \) = Weld Length | \( in \) | \( mm \) |

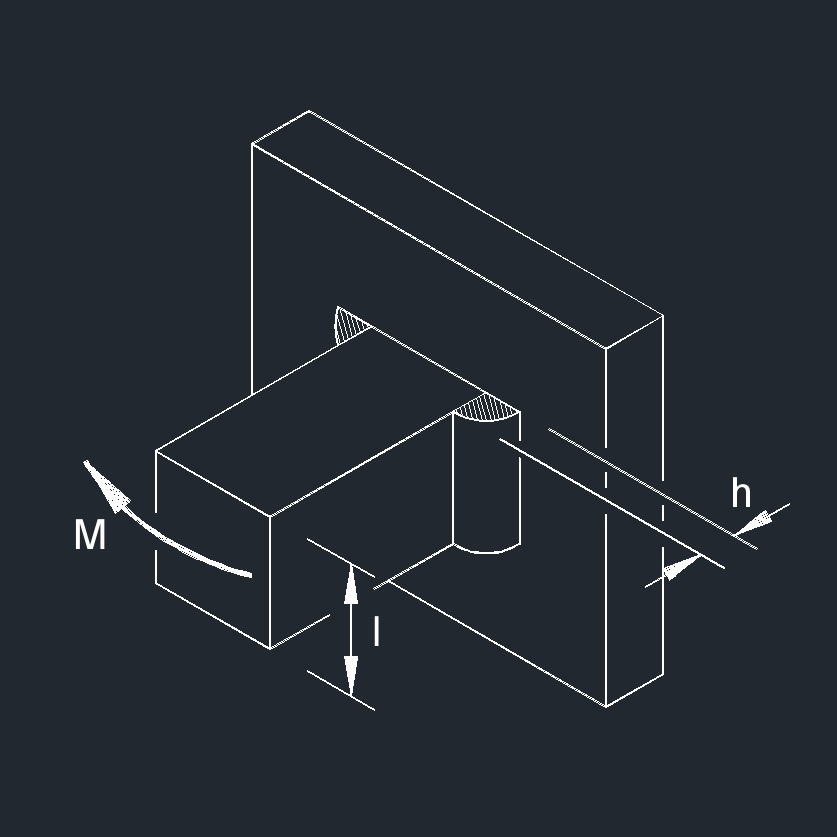

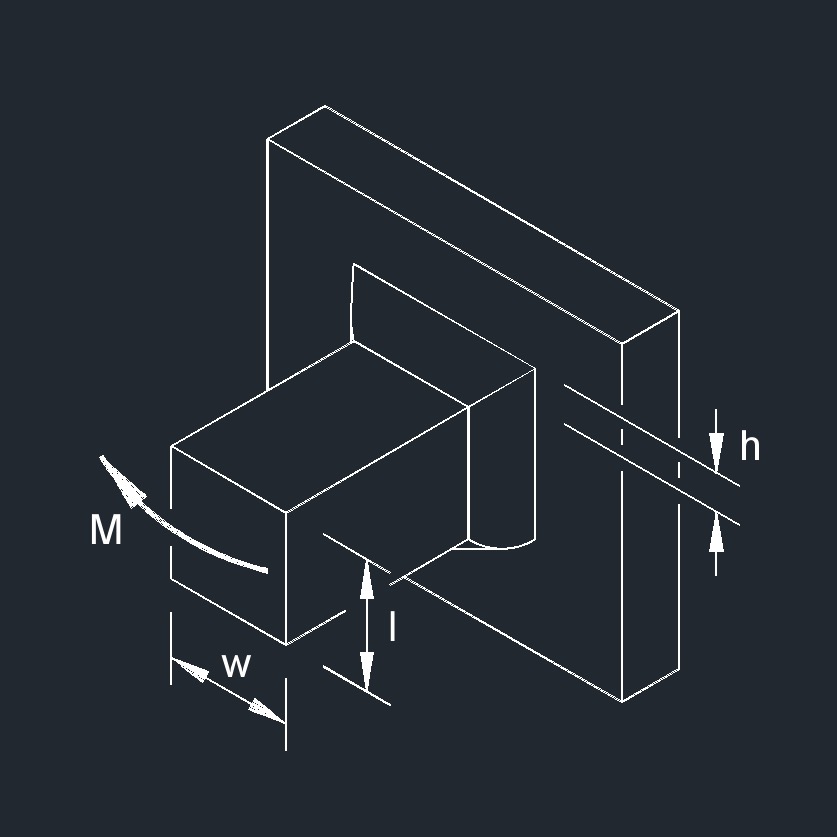

Bending Moment on PJP Fillet Weld formula

|

||

| \( \sigma \;=\; \dfrac{ 4.24 \cdot M }{ h \cdot L^2 }\) | ||

| Symbol | English | Metric |

| \( \sigma \) (Greek symbol sigma) = Weld Stress | \(lbf\;/\;in^2\) | \(Pa\) |

| \( M \) = Bending Moment | \(lbf-in\) | \(N-mm\) |

| \( h \) = Plate Thickness | \( in \) | \( mm \) |

| \( L \) = Weld Length | \( in \) | \( mm \) |

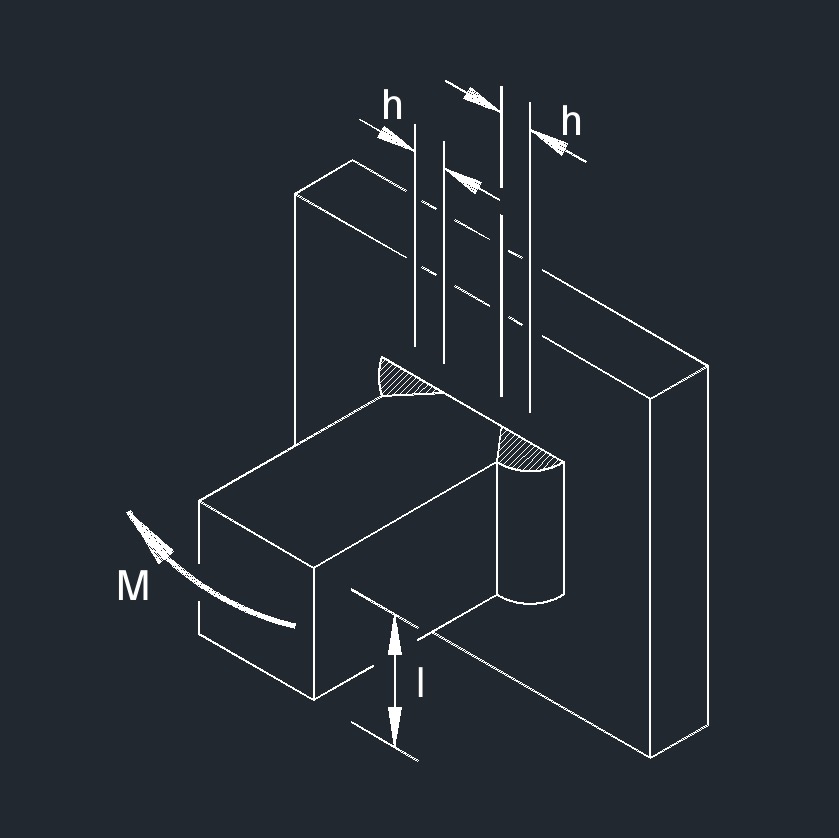

Bending Moment on CJP Fillet Weld formula

|

||

| \( \sigma \;=\; \dfrac{ 3 \cdot M }{ h \cdot L^2 }\) | ||

| Symbol | English | Metric |

| \( \sigma \) (Greek symbol sigma) = Weld Stress | \(lbf\;/\;in^2\) | \(Pa\) |

| \( M \) = Bending Moment | \(lbf-in\) | \(N-mm\) |

| \( h \) = Plate Thickness | \( in \) | \( mm \) |

| \( L \) = Weld Length | \( in \) | \( mm \) |

Bending Moment on PJP Fillet Weld All Around formula

|

||

| \( \sigma \;=\; \dfrac{ 4.24 \cdot M }{ h \cdot (\; w^2 + 3 \cdot L \cdot ( w + h ) \;) }\) | ||

| Symbol | English | Metric |

| \( \sigma \) (Greek symbol sigma) = Weld Stress | \(lbf\;/\;in^2\) | \(Pa\) |

| \( M \) = Bending Moment | \(lbf-in\) | \(N-mm\) |

| \( h \) = Weld Thickness | \( in \) | \( mm \) |

| \( w \) = Width of Bar | \( in \) | \( mm \) |

| \( L \) = Weld Length | \( in \) | \( mm \) |

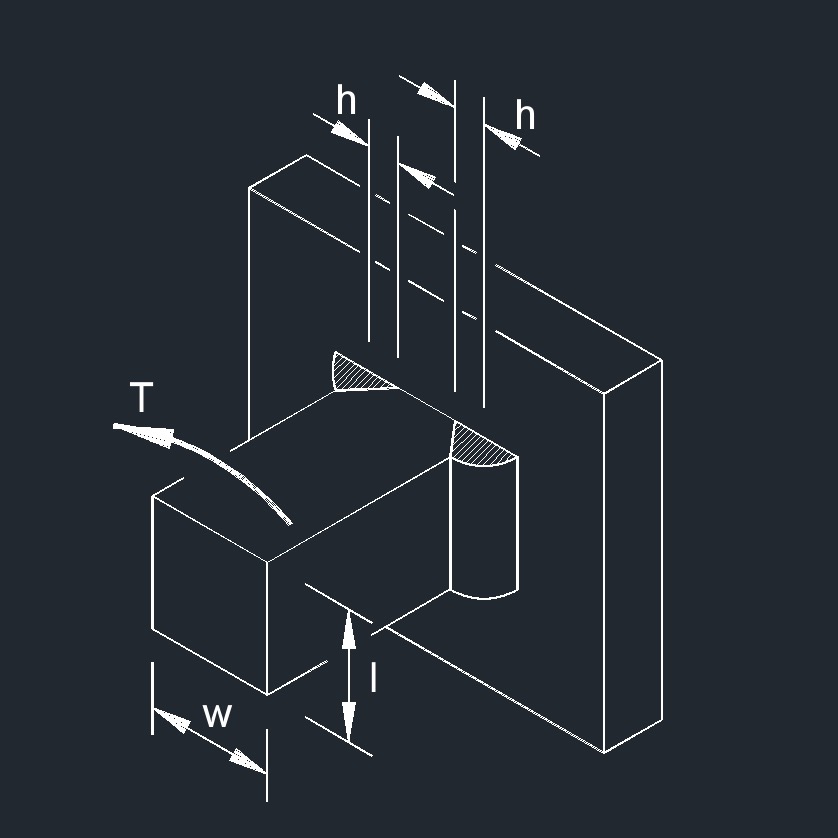

Torsion Moment on CJP Fillet Weld formula

|

||

| \( \sigma \;=\; \dfrac{ T }{ 2 \cdot ( w - h ) \cdot ( L - h ) \cdot h }\) | ||

| Symbol | English | Metric |

| \( \sigma \) (Greek symbol sigma) = Weld Stress | \(lbf\;/\;in^2\) | \(Pa\) |

| \( T \) = Torsion Moment | \(lbf-in\) | \(N-mm\) |

| \( w \) = Bar Width | \( in \) | \( mm \) |

| \( h \) = Weld Throat Thickness | \( in \) | \( mm \) |

| \( L \) = Weld Length | \( in \) | \( mm \) |