Barlow's Formula

Barlow's Formula |

||

|

\( p \;=\; \dfrac{ 2 \cdot S \cdot t }{ D } \) (Barlow's Formula) \( S \;=\; \dfrac{ p \cdot D }{ 2 \cdot t } \) \( t \;=\; \dfrac{ p \cdot D }{ 2 \cdot S } \) \( D \;=\; \dfrac{ 2 \cdot S \cdot t }{ p } \) |

||

| Symbol | English | Metric |

| \( p \) = Pressure | \(lbf \;/\; in^2\) | \(Pa\) |

| \( S \) = Allowable Stress | \(lbf \;/\; in^2\) | \(Pa\) |

| \( t \) = Pipe Thickness | \(in\) | \(mm\) |

| \( D \) = Pipe OD | \(in\) | \(mm\) |

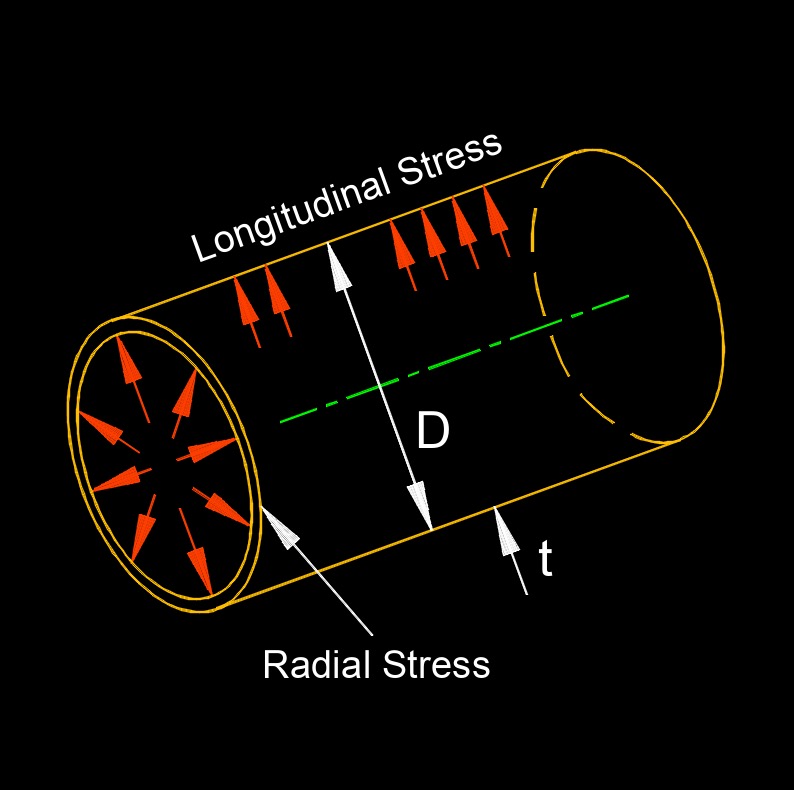

Barlow's formula, abbreviated as \(Ba\), Barlow's equation, relates to burst pressure, the point just before or at when a pipe or tubing fails under pressure. This formula is used to calculate the maximum allowable pressure (or stress) in a thin walled cylindrical pressure vessel, such as a pipe or tube. It is commonly employed in engineering and industry to determine the safe operating limits of pressure vessels. Barlow's formula assumes that the vessel is subjected to internal pressure only and neglects other factors such as external forces, temperature effects, and geometric imperfections. It is applicable for relatively thin walled vessels, where the ratio of the wall thickness to the outside diameter is small.

Barlow's formula, abbreviated as \(Ba\), Barlow's equation, relates to burst pressure, the point just before or at when a pipe or tubing fails under pressure. This formula is used to calculate the maximum allowable pressure (or stress) in a thin walled cylindrical pressure vessel, such as a pipe or tube. It is commonly employed in engineering and industry to determine the safe operating limits of pressure vessels. Barlow's formula assumes that the vessel is subjected to internal pressure only and neglects other factors such as external forces, temperature effects, and geometric imperfections. It is applicable for relatively thin walled vessels, where the ratio of the wall thickness to the outside diameter is small.

It's important to note that Barlow's formula is derived based on certain assumptions and limitations. It assumes linear elastic behavior of the material, neglects the effect of axial or hoop stress, and does not account for factors like corrosion, fatigue, or weld efficiency. Therefore, it should be used with caution, and engineering standards and codes specific to pressure vessels should be consulted for accurate and reliable design calculations.