Logistics & Transportation Engineering

Transportation, Engineering, Civil Logistics and Transportation are closely related concepts in supply chain management, but they refer to different aspects of the process of moving goods and materials. They are a collection of processes involved in the production, storage, inventory, delivery, and distribution of different commodities or specific goods. The primary goal of transport and logistics is to effectively track the shipment of supplies from point A to point B, and for customers to receive products on time, damage-free, and in accordance with expectations.

Logistics and Transportation are closely related concepts in supply chain management, but they refer to different aspects of the process of moving goods and materials. They are a collection of processes involved in the production, storage, inventory, delivery, and distribution of different commodities or specific goods. The primary goal of transport and logistics is to effectively track the shipment of supplies from point A to point B, and for customers to receive products on time, damage-free, and in accordance with expectations.

- See Article - Logistics and Transportation Glossary

| Engineering |

| Civil Engineering |

Logistics

Logistics is the overall management of how resources are acquired, stored, and transported to their final destination. It includes the planning, implementation, and control of efficient movement and storage of goods, services, and information within the supply chain. Logistics encompasses a wide range of activities including transportation, warehousing, inventory management, demand forecasting, order fulfillment, packaging, material handling, and supply chain management.

The goal of logistics is to manage the supply chain efficiently, ensuring that products are delivered to the right place, at the right time, in the right condition, and at the right cost. Logistics often involves strategic planning and management of the entire supply chain, including coordination with suppliers, manufacturers, and retailers.

Transportation

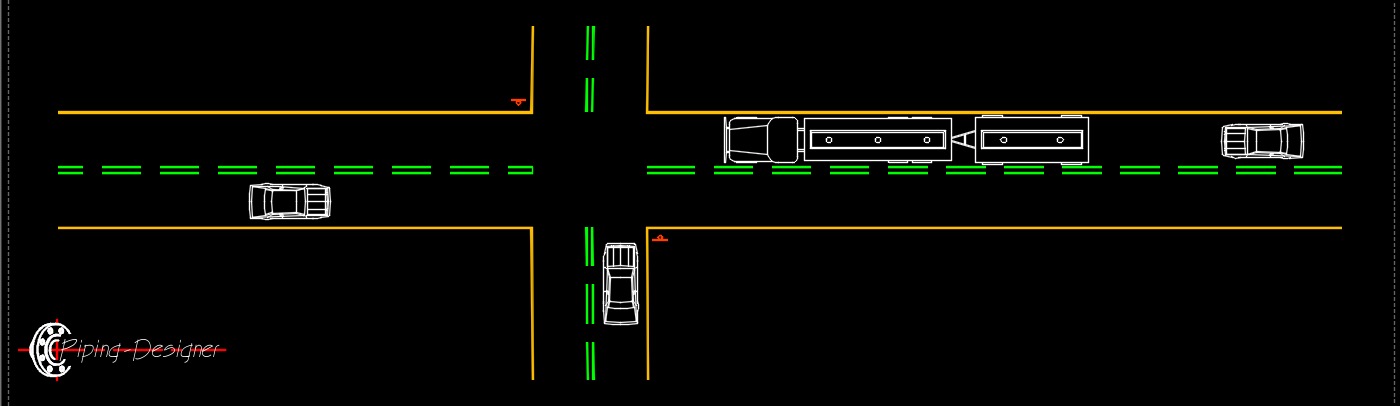

Transportation is a subset of logistics. It specifically refers to the movement of goods from one location to another using various modes such as trucks, trains, ships, or airplanes. Transportation focuses solely on the actual movement of goods between locations. It’s about choosing the right mode of transportation, managing routes, and ensuring timely delivery. It involves choosing carriers, managing vehicle fleets, route planning, freight management, and ensuring compliance with regulations related to the movement of goods.

The goal of transportation is to move products from point A to point B as efficiently and cost-effectively as possible.