Cantilever Pipe Support

Cantilever pipe support is used to hold and secure pipes that are extended horizontally from a wall or structure, without the need for additional support beneath the pipe. The term "cantilever" refers to a structural element that is anchored on one end and protrudes horizontally, without any additional support on the free end. In the context of pipe supports, a cantilever pipe support is designed to provide horizontal support to pipes that might be located in situations where it's not feasible or practical to install vertical supports beneath them. This could be due to space limitations, structural considerations, or other factors.

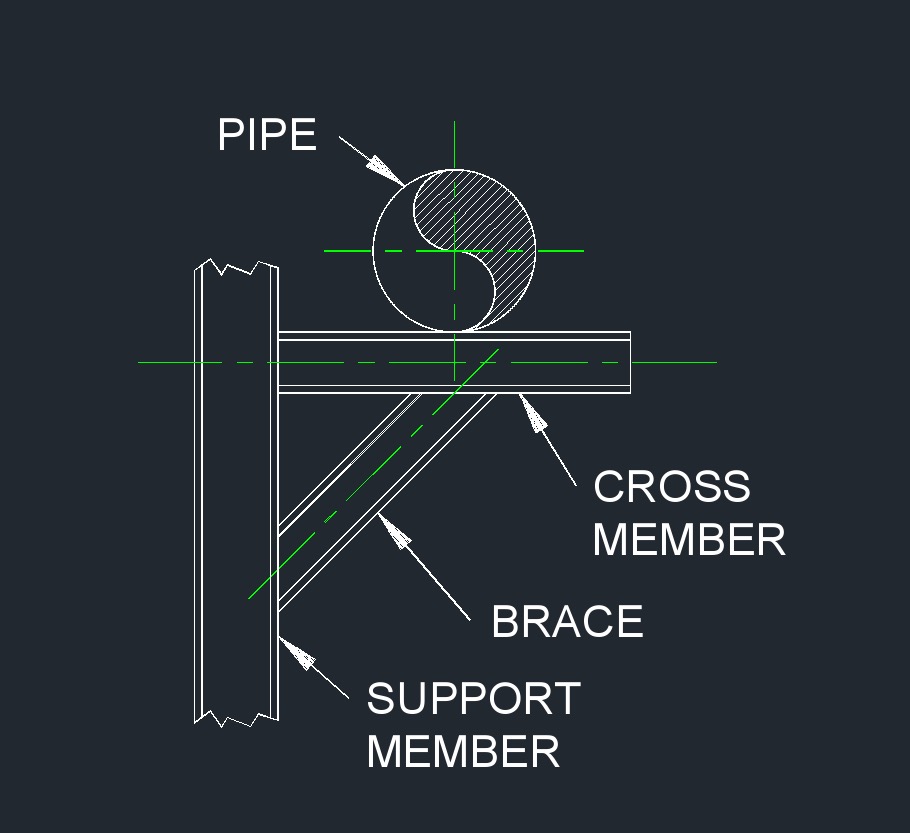

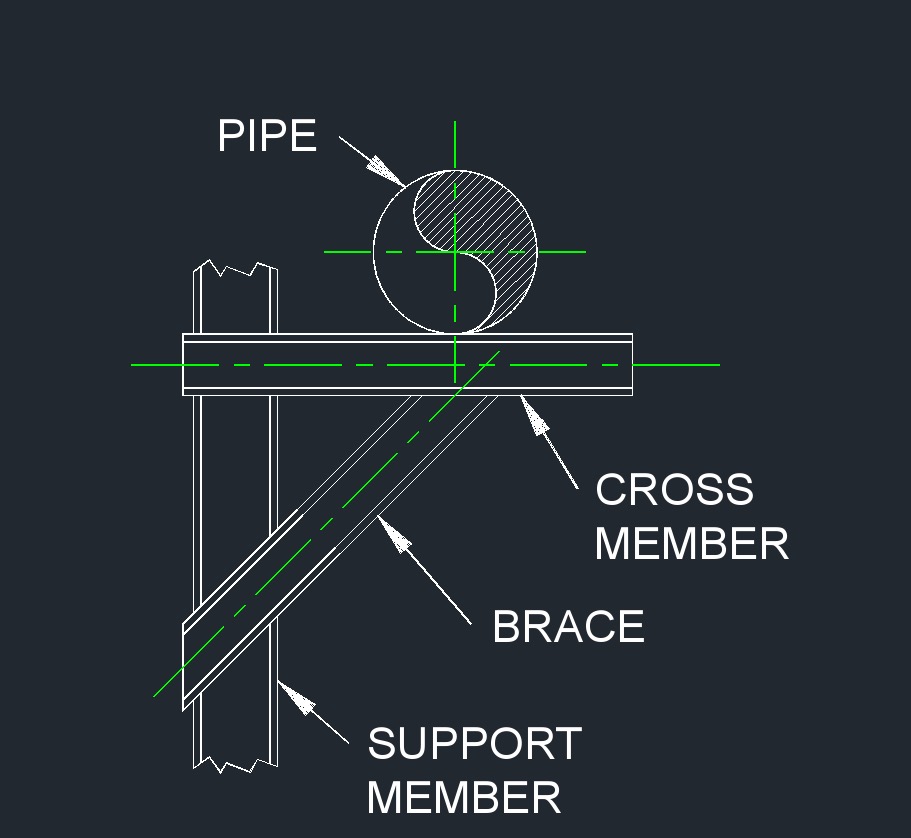

It's important to note that while cantilever supports provide horizontal support, they do not provide vertical support or resistance against vertical loads. Therefore, their use should be carefully considered based on the specific requirements of the application and the structural integrity of the installation. Designing and implementing cantilever pipe supports requires careful engineering to ensure that the selected support system can handle the weight and stress of the pipes, the materials being transported, and any potential dynamic forces such as vibrations or thermal expansion.

- See Article - Pipe Support Dont's

Key Points about Cantilever Pipe Support

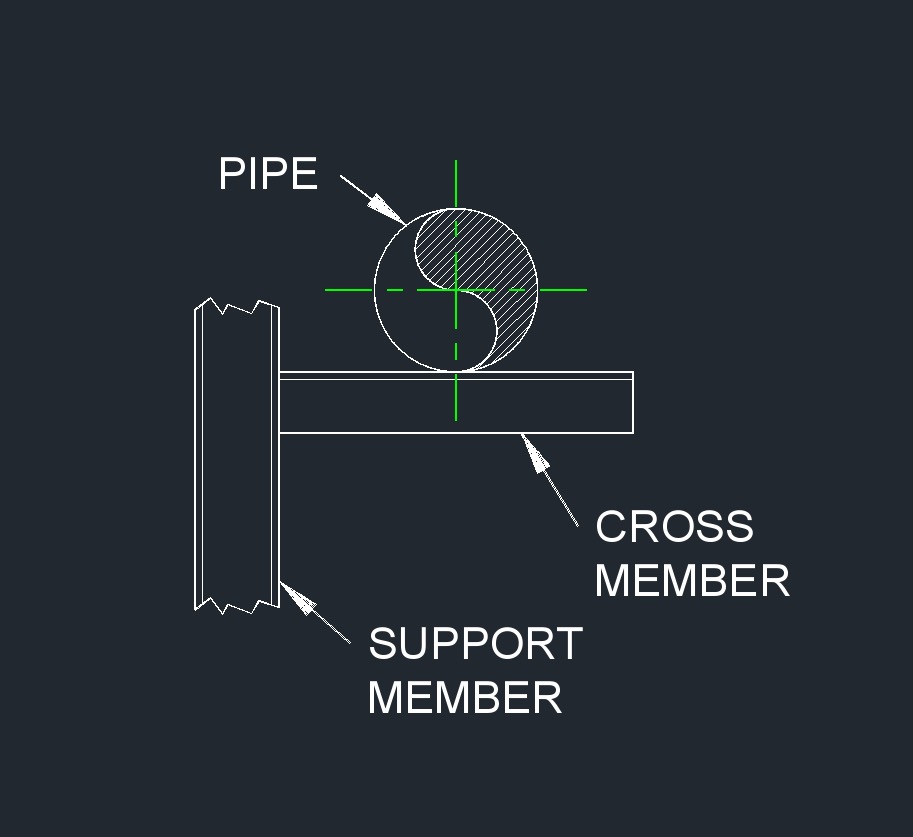

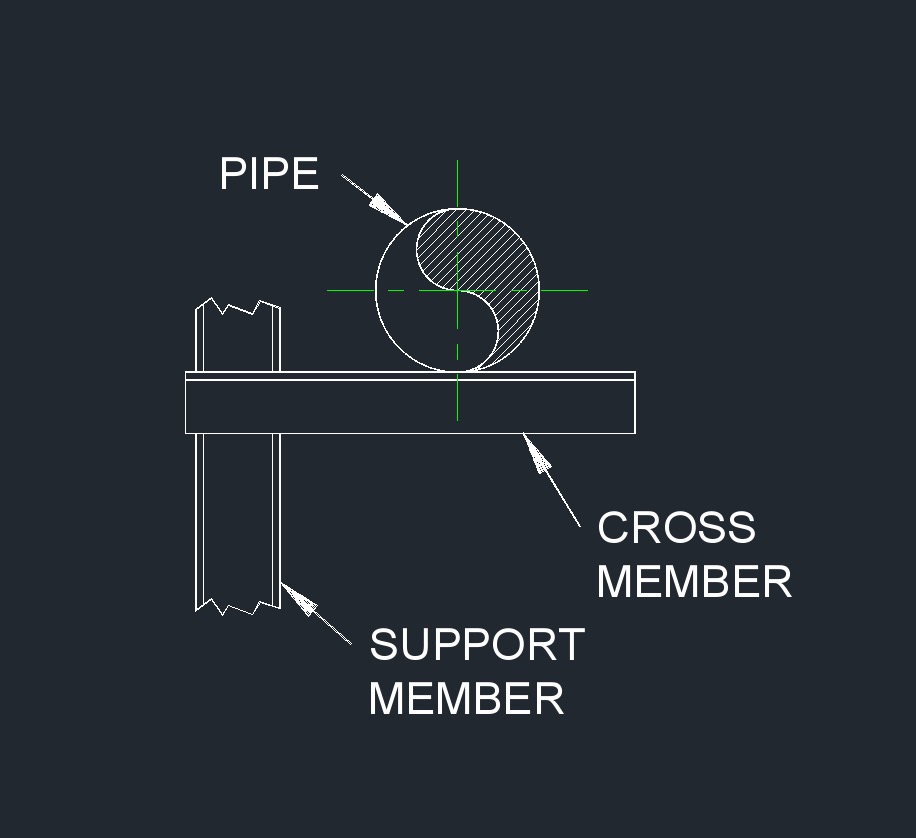

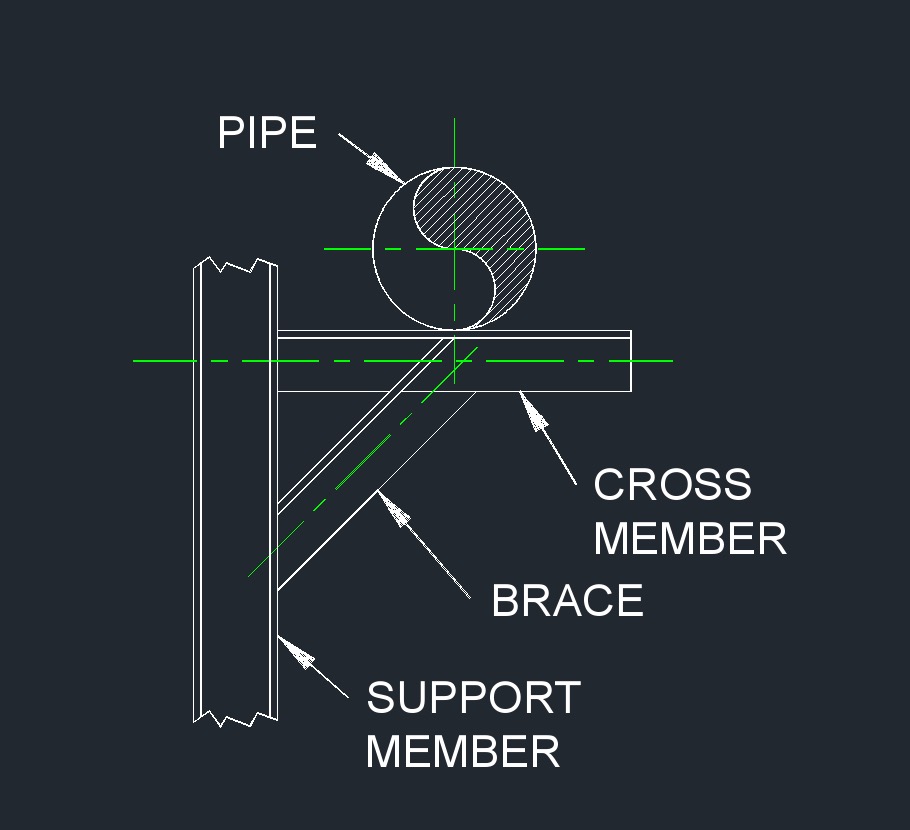

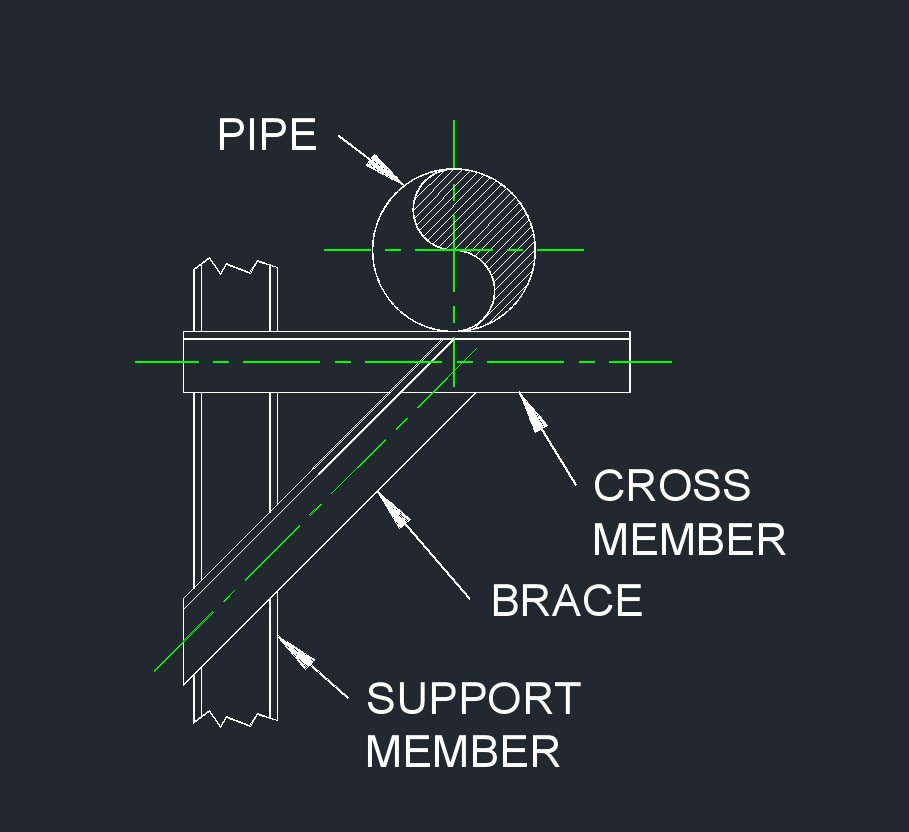

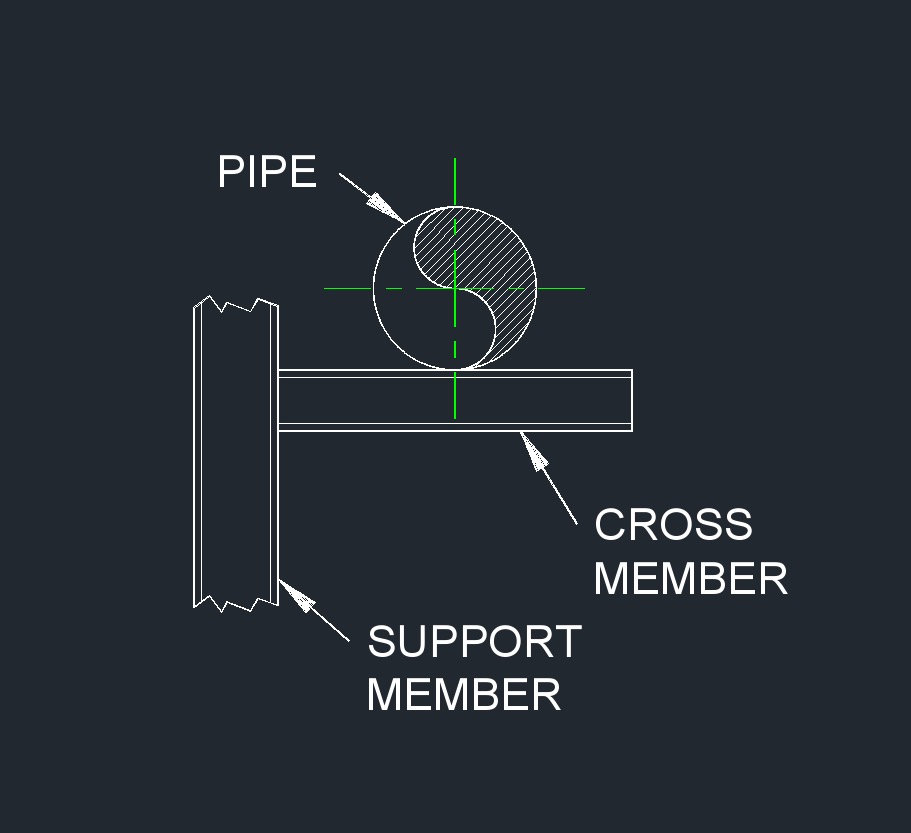

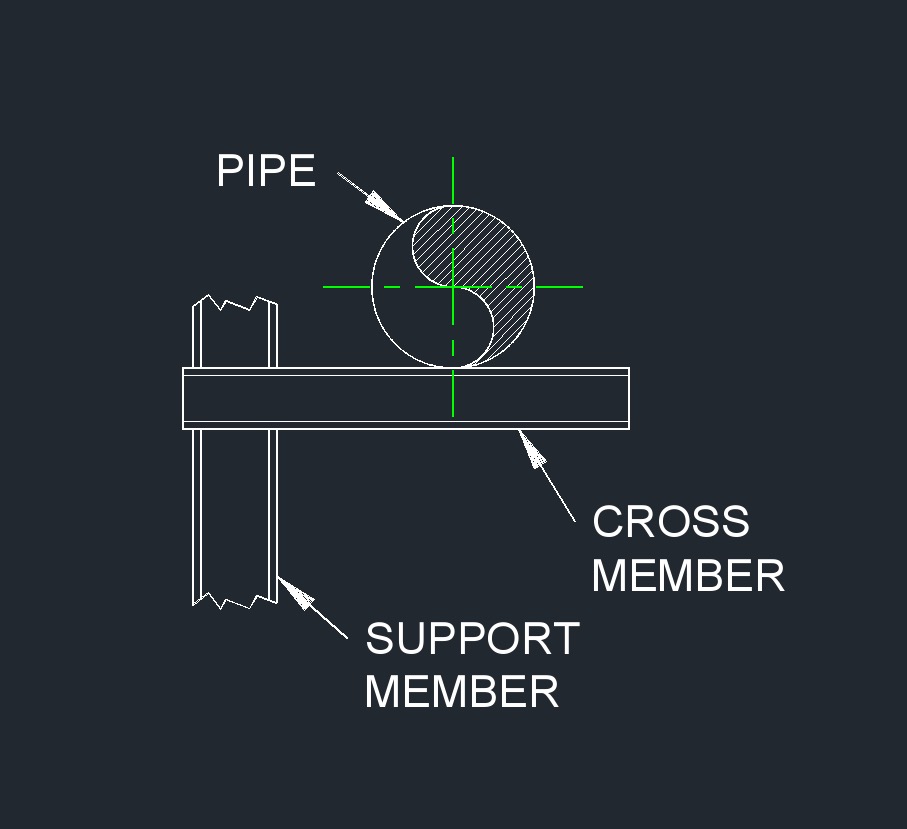

Bracket or Arm - The cantilever support typically consists of a bracket or arm that is securely anchored to a wall, column, or other structural element. This bracket extends outward horizontally.

Pipe Rest - The outer end of the bracket has a mechanism to hold and secure the pipe. This could be a saddle shaped cradle or other configurations that prevent the pipe from sliding off.

Common uses of Cantilever Pipe Supports

Pipelines on Walls - When pipes need to run along walls without touching the ground or other structures, cantilever supports can be used to hold the pipes in place.

Pipes Above Equipment - In industrial settings, where pipes might need to pass over equipment or machinery, cantilever supports can help suspend the pipes without interfering with the equipment.

Building Facades - In some architectural designs, pipes might need to be placed along the exterior of a building's façade. Cantilever supports can help achieve this while maintaining a clean appearance.

Aesthetic Considerations - In certain scenarios, installing vertical supports might be undesirable due to aesthetic reasons. Cantilever supports can offer a solution by allowing pipes to extend horizontally.

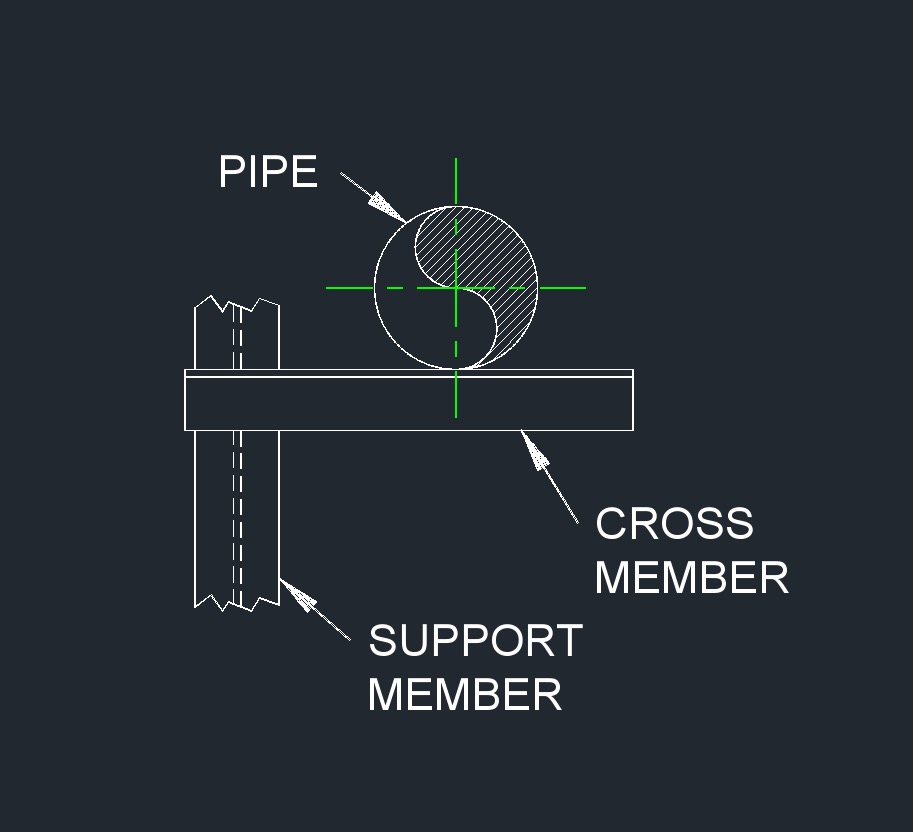

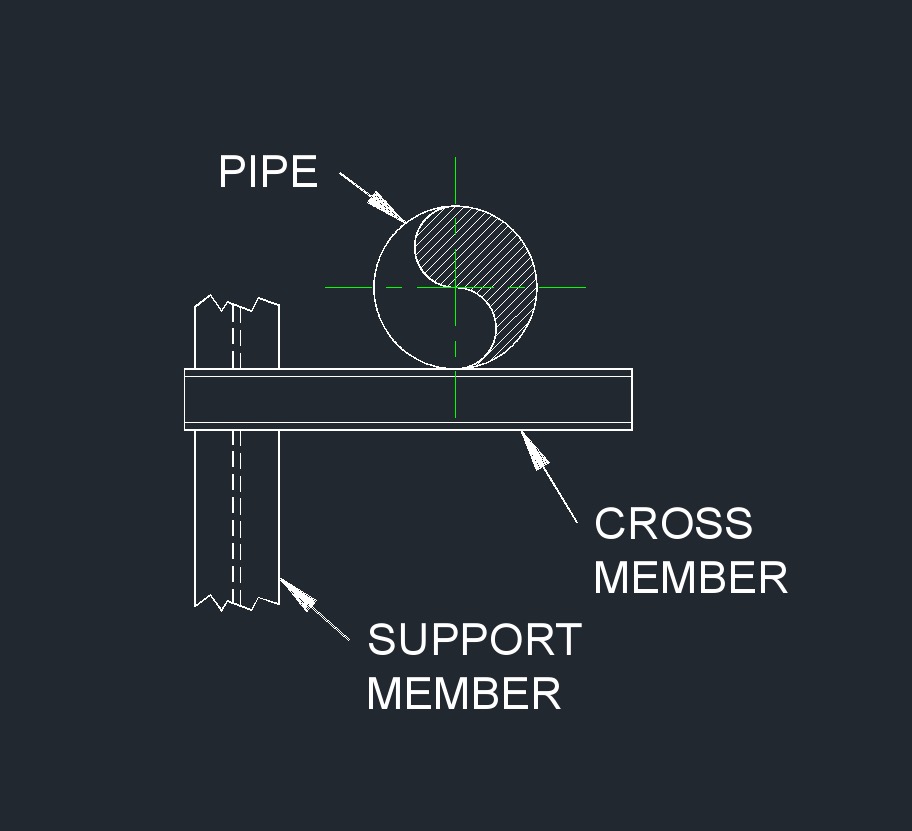

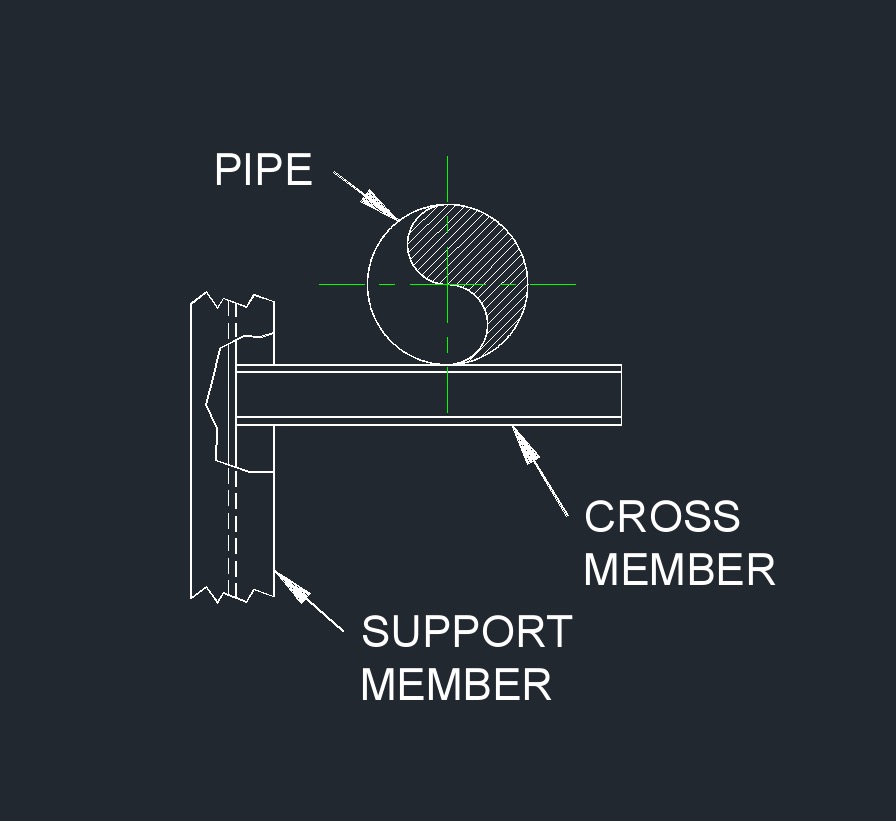

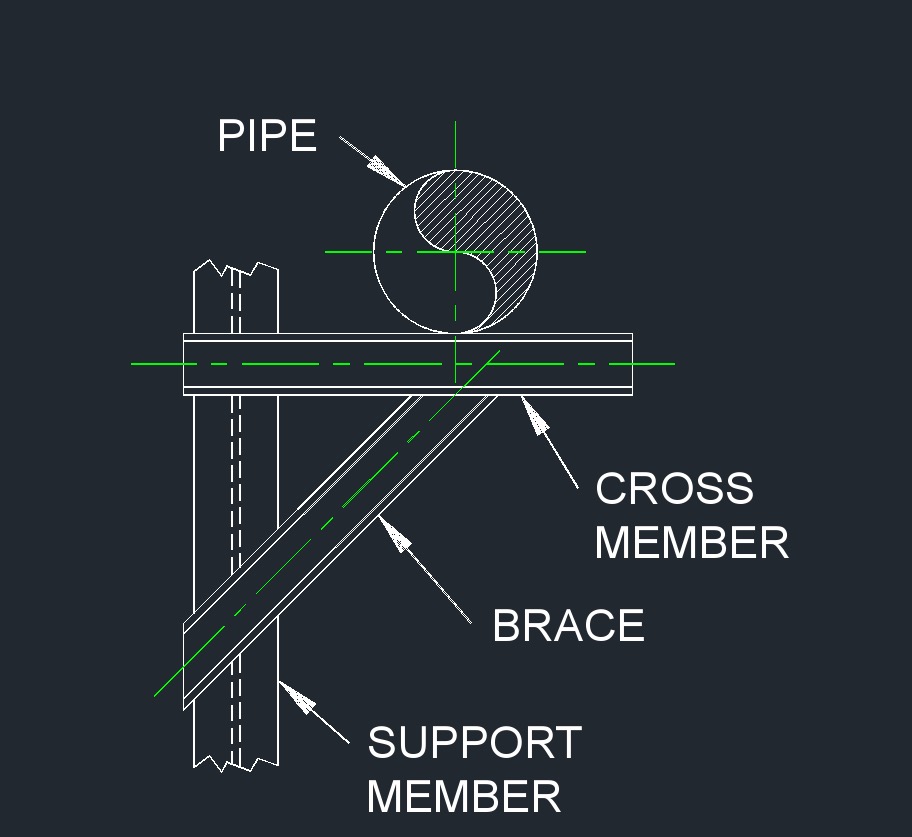

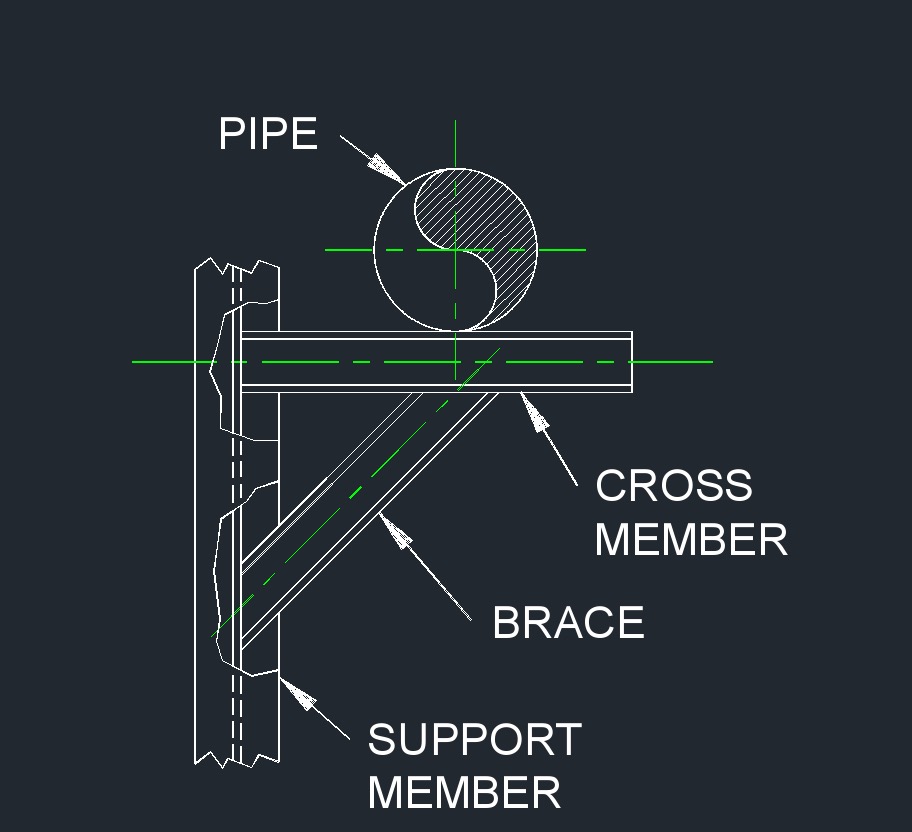

Angle Iron Support

Beam Side Weld

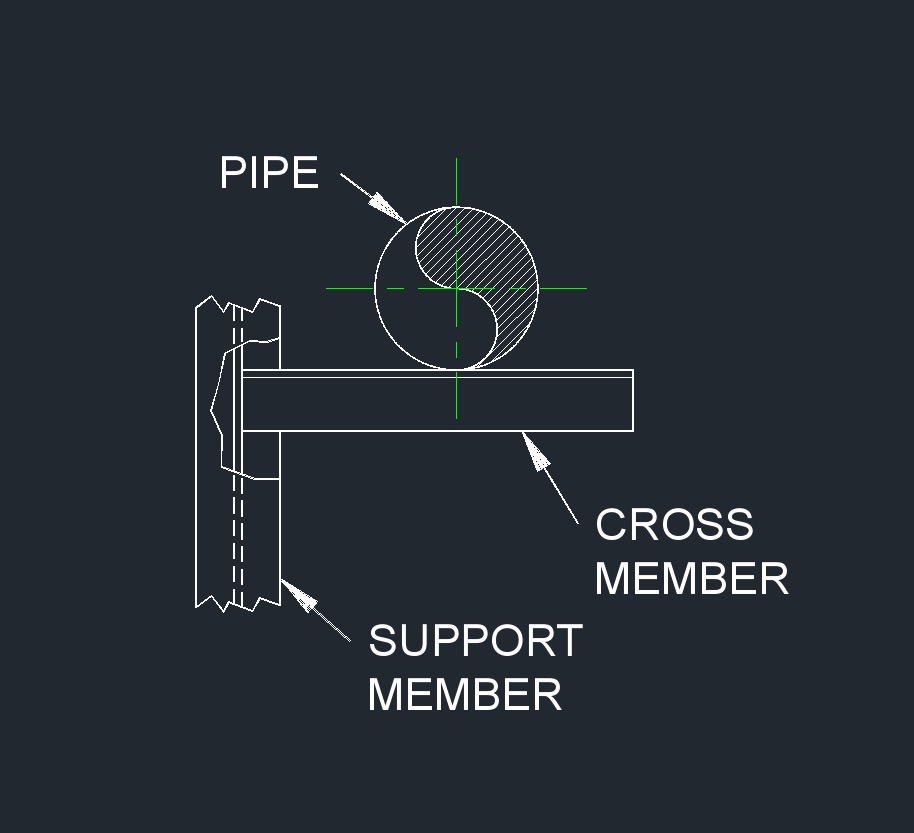

Beam Side Weld

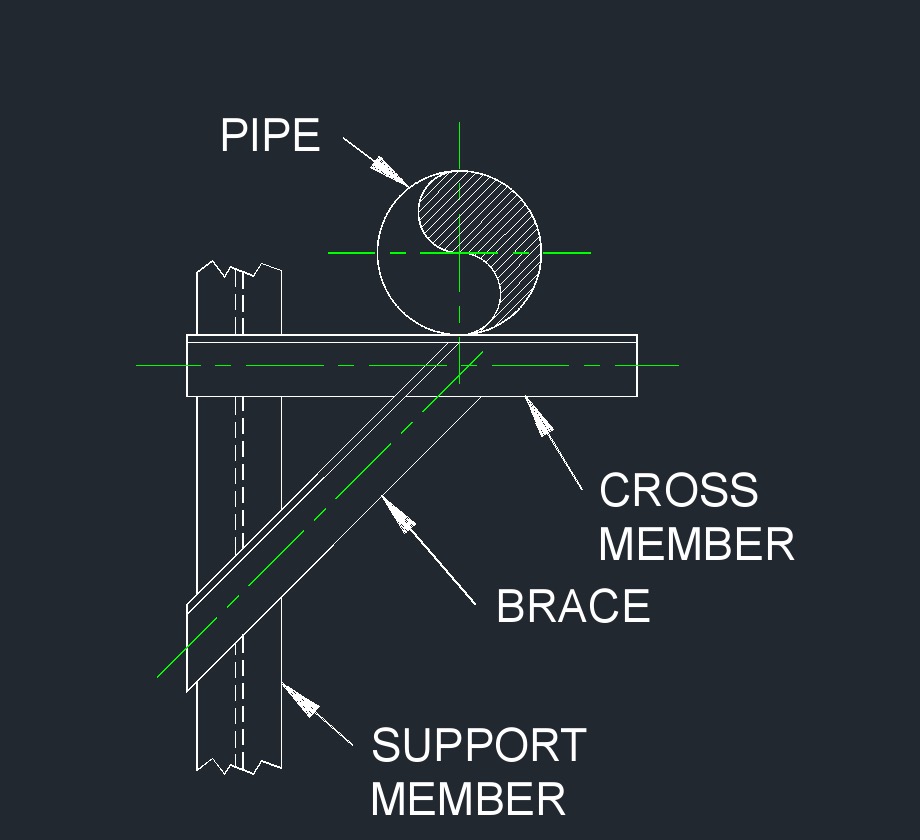

Beam Web Weld

Beam Web Weld

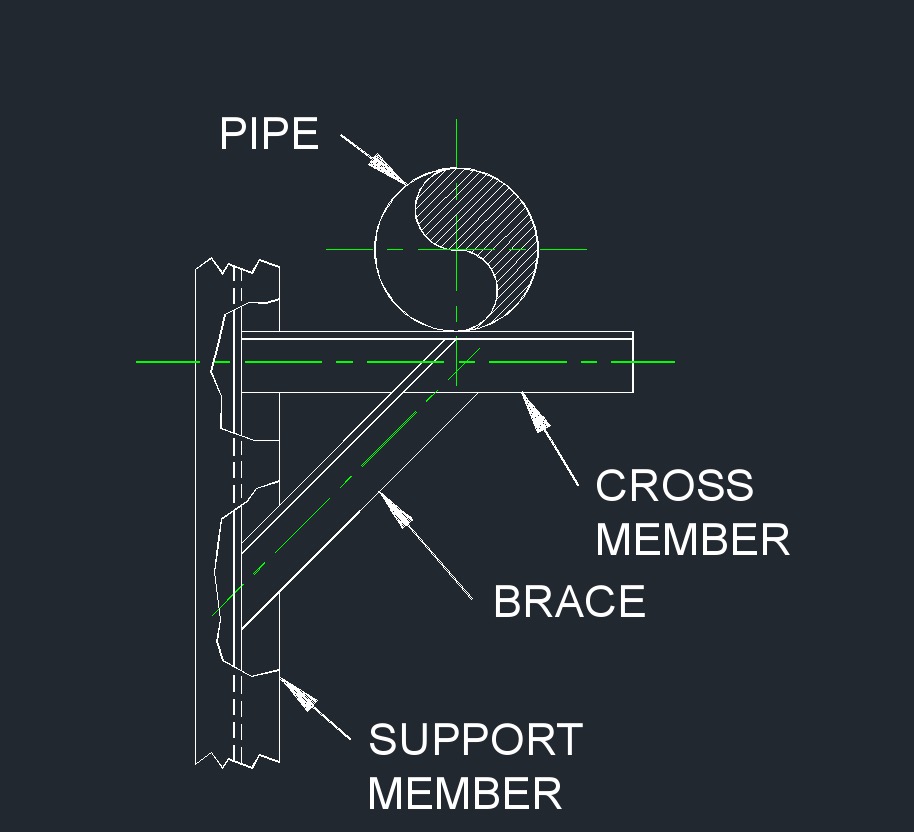

Beam Side Weld

Beam Side Weld

Beam Web Weld

Beam Web Weld

Beam End Weld

Beam End Weld

Beam Flange Weld

Beam Flange Weld

Beam End Weld

Beam End Weld

Beam Flange Weld

Beam Flange Weld

Beam Support

Beam Side Weld

Beam Side Weld

Beam Web Weld

Beam Web Weld

Beam Side Weld

Beam Side Weld

Beam Web Weld

Beam Web Weld

Beam End Weld

Beam End Weld

Beam Flange Weld

Beam Flange Weld

Beam End Weld

Beam End Weld

Beam Flange Weld

Beam Flange Weld