Socket Weld Fitting

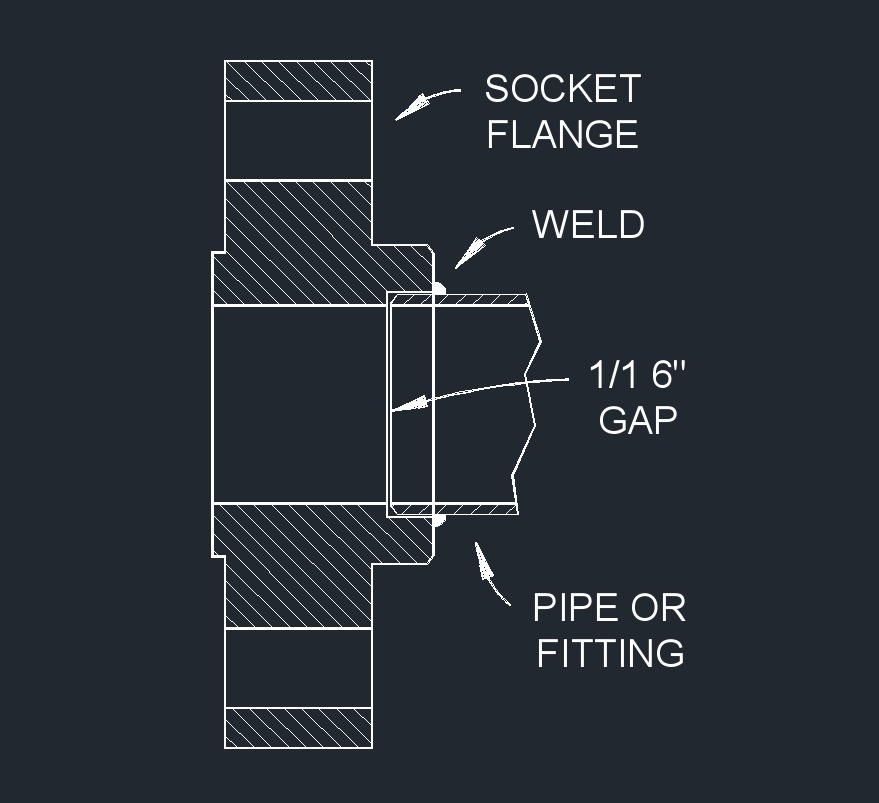

Socket weld flange with pipeSocket weld pipe fittings, abbreviated as SWF, are a type of pipe fitting used in various industries, including plumbing, oil and gas, petrochemical, and more. These fittings are designed for connecting pipes or tubes of the same nominal size, typically in small to medium sized pipelines. The pipe is inserted into a recessed area of the fitting before it is welded. In order to prevent damage to the pipe and fitting, the pipe is then backed out a minimum of 1/16” to allow for thermal expansion of the pipe during the welding procedure. If this clearance is not made, the weld can crack due to the pipe expanding against the fitting. Socket weld fittings are known for their strength, durability, and leak free connections.

Socket weld flange with pipeSocket weld pipe fittings, abbreviated as SWF, are a type of pipe fitting used in various industries, including plumbing, oil and gas, petrochemical, and more. These fittings are designed for connecting pipes or tubes of the same nominal size, typically in small to medium sized pipelines. The pipe is inserted into a recessed area of the fitting before it is welded. In order to prevent damage to the pipe and fitting, the pipe is then backed out a minimum of 1/16” to allow for thermal expansion of the pipe during the welding procedure. If this clearance is not made, the weld can crack due to the pipe expanding against the fitting. Socket weld fittings are known for their strength, durability, and leak free connections.

- See Articles - List of Tags, List of Categories, List of Articles, List of Glossaries, Nomenclature and Symbols

Here's a Brief Overview of Socket Weld Pipe Fittings

Socket Weld Design - Socket weld fittings have a socket (or female) end and a plain (or male) end. The socket end is designed to accept the pipe, while the plain end is inserted into the socket of another fitting or pipe. The connection is made by welding the pipe into the socket.

Connection Method - The connection is made by inserting the pipe into the socket and then applying heat to the joint. Once the material reaches the proper welding temperature, it is allowed to cool and solidify, creating a strong and permanent connection. Non metallic pipe almost exclusively uses sock weld fittings for their permanent connections. This is because the socket gives ample surface area for the glue to bond the two pieces together.

Size - SW fittings are used for piping that has a nominal pipe size (NPS) of 3 inches and below.

Welding - Because a fillet weld is used instead of a butt weld, there is no possibility for weld metal to enter the bore of the pipe. Because a fillet weld is used, it can only be inspected by using non radiographic methods, such as magnetic particle or liquid dye penetrant methods.

Types of Socket Weld Fittings - There are various types of socket weld pipe fittings available. There are three different pressure classes available for socket welded, 3000, 6000 and 9000. In general, Class 3000 is for use with Schedule 80 pipe, 6000 - Schedule 160 and 9000 – XXH. The pressure classes are based on the cold working pressure limits of 3000, 6000 and 9000 psi.

Materials - Socket weld fittings are available in various materials, including stainless steel, carbon steel, alloy steel, brass, and more. The choice of material depends on the application's requirements, such as the fluid being transported and the operating conditions.

Socket weld pipe fittings are commonly used in applications where a secure and leak free connection is essential, such as in industrial processes and systems handling high pressure fluids. Proper welding and installation are crucial to ensure the integrity and performance of the system.

Socket Weld Fitting Datasheets

- See Article - Socket Fitting Datasheets

Forged Fittings Socket Class TypesClass designations correspond to the maximum cold working pressure of fittings in pounds force per square inch. | ||||

|---|---|---|---|---|

| Pressure Class | 2000 | 3000 | 6000 | 9000 |

| Socket Fitting | - | 80/XH | 160 | XXH |

| Threaded Fitting | 80/XH | 160 | XXH | - |

The following links are for datasheets for the socket fitting range sizes covered by ASME B16.11. If you would like to browse the datasheets for pipe fittings, please visit our Fittings Datasheets page.

Forged Fittings Socket SIZES

| |||

|---|---|---|---|

|

Fitting |

3000 |

6000 |

9000 |

| 45 Elbow | 1/8 - 4 | 1/8 - 2 | 1/2 - 2 |

| 90 Elbow | 1/8 - 4 | 1/8 - 2 | 1/2 - 2 |

| Cap, Round | 1/8 - 4 | 1/8 - 2 | 1/2 - 2 |

| Coupling, Full | 1/8 - 4 | 1/8 - 2 | 1/2 - 2 |

| Coupling, Half | 1/8 - 4 | 1/8 - 2 | 1/2 - 2 |

| Cross | 1/8 - 4 | 1/8 - 2 | 1/2 - 2 |

| Lateral | 3/8 - 2 | 3/8 - 1 1/2 | 1/2 - 1 1/2 |

| Reducer | 1/8 - 4 | 1/2 - 4 | 1/2 - 2 |

| Tee | 1/8 - 4 | 1/2 - 4 | 1/2 - 2 |

| Union | 1/8 - 3 | 1/8 - 2 | - |

Socket Fitting Advantages and Disadvantages | |

|---|---|

| Advantages | Disadvantages |

|

|

Tags: Pipe Fitting