Refinery Engineering

Oil refining is the industrial process of converting crude oil into useful petroleum products such as gasoline, diesel, jet fuel, heating oil, lubricants, asphalt, and petrochemicals. This process involves several complex physical and chemical processes designed to separate, convert, and purify the components of crude oil. Oil refining is a highly technical and capital-intensive process that requires sophisticated equipment and technologies to ensure efficiency, safety, and environmental compliance. Refineries are designed to maximize the yield of high-value products while minimizing waste and emissions.

Oil refining is the industrial process of converting crude oil into useful petroleum products such as gasoline, diesel, jet fuel, heating oil, lubricants, asphalt, and petrochemicals. This process involves several complex physical and chemical processes designed to separate, convert, and purify the components of crude oil. Oil refining is a highly technical and capital-intensive process that requires sophisticated equipment and technologies to ensure efficiency, safety, and environmental compliance. Refineries are designed to maximize the yield of high-value products while minimizing waste and emissions.

Hydrocarbons do not come from the oil refinery process. They are the primary components of crude oil and natural gas. The oil refinery process involves separating and refining these hydrocarbons into useful products such as gasoline, diesel, jet fuel, and petrochemicals. During refining, the crude oil is subjected to various processes like distillation, cracking, and reforming to break down and rearrange the hydrocarbons into different forms suited for specific uses.

Petrochemicals are chemical products derived from petroleum (crude oil) or natural gas. They are a crucial part of the chemical industry and serve as the building blocks for a wide range of products that are used in everyday life. Petrochemicals are typically produced in large quantities through processes such as cracking, distillation, and reforming in refineries or chemical plants. These petrochemicals are then used to create a wide variety of products, including plastics, detergents, fertilizers, pharmaceuticals, and more. Petrochemical products are essential in various industries, including automotive, construction, agriculture, and healthcare.

- See Articles - List of Tags, List of Categories, List of Articles, List of Glossaries, Nomenclature and Symbols, (See Refinery Glossary)

Science Branches |

| Science |

| Applied Science |

| Engineering |

| Mechanical Engineering |

Oil Refinery Processes (Downstream)

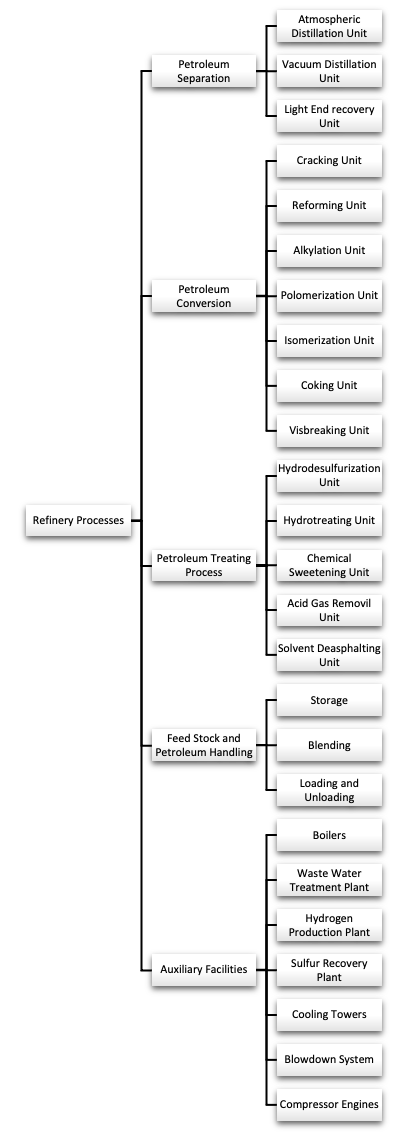

These are the general refinery processes:

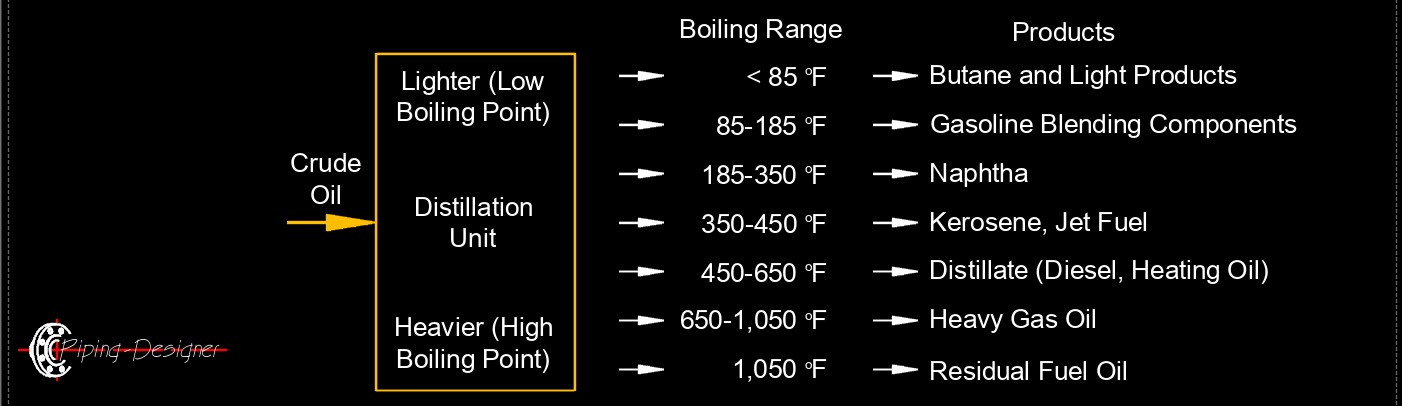

Petroleum Separation - The first phase in petroleum refining operations is the separation of crude oil into its major constituents using 3 petroleum separation processes listed below. Crude oil consists of a mixture of hydrocarbon compounds including paraffinic, naphthenic, and aromatic hydrocarbons with small amounts of impurities including sulfur, nitrogen, oxygen, and metals. Refinery separation processes separate these crude oil constituents into common boiling-point fractions.

- Atmospheric Distillation Unit - This distillation unit begins with desalting of the crude and then continues through significant heat exchange train and fired heater prior to entering the main atmospheric column. The main column itself is designed with several sections with side product draws to produce the various product streams such as light ends, naphtha, kerosene, diesel, gas oil, and the bottoms reduced crude stream.

- Vacuum Distillation Unit - Topped crude withdrawn from the bottom of the atmospheric distillation column is composed of high boiling-point hydrocarbons. When distilled at atmospheric pressures, the crude oil decomposes and polymerizes and will foul equipment. To separate topped crude into components, it must be distilled in a vacuum column at a very low pressure and in a steam atmosphere.

- Light End Recovery (Gas Processing) Unit - The light ends recovery unit uses absorption and distillation steps to remove propane and heavier components from refinery gas streams prior to their use as fuel gas. The recovered components are then separated and used in various product streams.

Petroleum Conversion (Cracking) - To meet the demands for high-octane gasoline, jet fuel, and diesel fuel, components such as residual oils, fuel oils, and light ends are converted to gasolines and other light fractions. Cracking, coking, and visbreaking processes are used to break large petroleum molecules into smaller ones. Polymerization and alkylation processes are used to combine small petroleum molecules into larger ones. Isomerization and reforming processes are applied to rearrange the structure of petroleum molecules to produce higher-value molecules of a similar molecular size.

- Cracking Unit - Catalytic cracking, using heat, pressure, and catalysts, converts heavy oils into lighter products with product distributions favoring the more valuable gasoline and distillate blending components. Feedstocks are usually gas oils from atmospheric distillation, vacuum distillation, coking, and deasphalting processes

- Reforming Unit - Catalytic reforming is a process to reform hydrotreated naphtha feed into high octane gasoline to meet today’s requirement for high efficiency, high compression engines. Reforming is the result of several simultaneous reactions. The most important products are aromatics which can be used as high-octane blending components or petrochemicals.

Alkylation Unit - This is a secondary refinery unit operation that because it adds high octane hydrocarbons to motor and aviation gasoline. High octane hydrocarbons are needed to help prevent autoignition of gasoline (knocking) in an engine and to meet recommended engine octane ratings. The process combines an unsaturated light hydrocarbon with isobutane to produce alkylate. Either sulfuric or hydrofluoric acid is used as the catalyst for the alkylation reaction. Alkylate is high in octane but has low volatility and can be added to motor gasoline and aviation gasoline to increase octane while meeting stringent volatility specifications.

Alkylation Unit - This is a secondary refinery unit operation that because it adds high octane hydrocarbons to motor and aviation gasoline. High octane hydrocarbons are needed to help prevent autoignition of gasoline (knocking) in an engine and to meet recommended engine octane ratings. The process combines an unsaturated light hydrocarbon with isobutane to produce alkylate. Either sulfuric or hydrofluoric acid is used as the catalyst for the alkylation reaction. Alkylate is high in octane but has low volatility and can be added to motor gasoline and aviation gasoline to increase octane while meeting stringent volatility specifications.- Polomerization Unit - The process of converting light olefin gases including ethylene, propylene, and butylene into hydrocarbons of higher molecular weight and higher octane number that can be used as gasoline blending stocks. Polymerization combines two or more identical olefin molecules to form a single molecule with the same elements in the same proportions as the original molecules. Polymerization may be accomplished thermally or in the presence of a catalyst at lower temperatures.

- Isomerization Unit - Converts linear molecules such as normal pentane into higher-octane branched molecules for blending into the end-product gasoline. Also used to convert linear normal butane into isobutane for use in the alkylation unit.

- Coking Unit - Coking is a thermal cracking process used to convert low value residual fuel oil to highervalue gas oil and petroleum coke. Vacuum residuals and thermal tars are cracked in the coking process at high temperature and low pressure. Products are petroleum coke, gas oils, and lighter petroleum stocks. Delayed coking is the most widely used process today, but fluid coking is expected to become an important process in the future.

- Visbreaking Unit - Topped crude or vacuum residuals are heated and thermally cracked in the visbreaker furnace to reduce the viscosity, or pour point, of the charge. The cracked products are quenched with gas oil and flashed into a fractionator. The vapor overhead from the fractionator is separated into light distillate products. A heavy distillate recovered from the fractionator liquid can be used as either a fuel oil blending component or catalytic cracking feed.

Petroleum Treatment Process - Petroleum treating processes stabilize and upgrade petroleum products by separating them from less desirable products and by removing objectionable elements. Undesirable elements such as sulfur, nitrogen, and oxygen are removed by hydrodesulfurization, hydrotreating, chemical sweetening, and acid gas removal. Treating processes, employed primarily for the separation of petroleum products, include such processes as deasphalting. Desalting is used to remove salt, minerals, grit, and water from crude oil feedstocks before refining. Asphalt blowing is used for polymerizing and stabilizing asphalt to improve its weathering characteristics.

- Hydrodesulfurization Unit (HDS) - A catalytic process to remove sulfur from natural gas and refined products, including gasoline, jet fuel, diesel fuel, fuel oil, and naphtha. Sulfur removal is critical in order to reduce the sulfur dioxide emissions from the combustion of those fuels in automobiles, aircraft, locomotives, ships, power plants, residential or industrial furnaces, etc. Sulphur removal from naphtha is also important in a refinery as it can poison, or render ineffective, the noble metal catalysts, such as platinum and rhenium, used in the catalytic reforming units necessary to upgrade the naphtha octane ratings, even in very minute concentrations.

- Hydrotreating Unit (HDT) - A process performed to produce high-quality fuels and feedstocks. It involves reducing sulfur or nitrogen content, saturating olefins for stability improvement, or reducing aromatic content. During hydrotreating, refineries use filters to filter the hydrotreater feed to prevent plugging and fouling of the catalyst fixed bed. These filters are also vital for filtering hydrotreater product to capture catalyst fines that may escape from the fixed bed. This filter processes hydrotreater product, recycles any catalyst that escapes from the ebullated bed, and ensures the integrity and efficiency of the hydrotreating process.

- Chemical Sweetening Unit - This is the process for removal of mainly acid gases (H2S and CO2) and, in addition, the simultaneous removal of sulphur organic species (RSH, COS, CS2) from process gas. It is an essential step of sour gas processing for natural gas treatment, NGL recovery, LNGs, refineries and petrochemicals in order to meet transport and market specifications, to comply with environmental regulations for emissions and to control corrosion.

- Acid Gas Removal Unit (AGR) (Amine Gas Treating) - Involve removal of inert gasses such as carbon dioxide, hydrogen sulfide, and nitrogen from unprocessed natural gas. These must be removed prior to use or sale of the natural gas to meet standards of less than 4% inert gases. Acid gases such as carbon dioxide (CO2) and hydrogen sulfide (H2S) are corrosive when water molecules are present and represent the major source of maintenance problems in pipelines. Acid gas removal plants are essential to natural gas processing and transportation and are one of the major parts of natural gas processing equipment manufactured.

- Solvent Deasphalting Unit (SDA) - A separation process in which residues are selectively separated by molecular type by mixing with paraffinic solvents and precipitating out of solution asphaltenes and other residue heavy components. SDA produces a low-contaminant, relatively high hydrogen deasphalted (DOA) oil product and a pitch product that contains the majority of the residue’s contaminants (CCR) (metals, asphaltenes).

Feed Stock and Production Handling - The refinery feedstock and product handling operations are listed below.

- Storage - An oil terminal, also called tank farm, oil installation or oil depot, is an industrial facility for the storage of oil, petroleum and petrochemical products, and from which these products are transported to end users or other storage facilities. An oil terminal typically has a variety of above or below ground tankage and pipeline connections.

- Blending - The major refinery products produced by the product blending process are gasoline, jet fuels, heating oils, and diesel fuels.

The objective of product blending is to allocate the available blending components in such a way as to ensure all product

demands and specifications are met at the least cost and to produce products which maximize overall profit. - Loading and Unloading - Pipeline infrastructure includes numerous miles of small diameter pipeline gathering systems that move crude oil and natural gas from the wellhead to storage, processing facilities and connections to larger pipeline systems. It also includes pipelines that transport and distribute consumer-grade natural gas to refineries, petrochemical plants and power generation facilities that support refinery and petrochemical manufacturing operations.

Auxiliary Facilities - A wide assortment of processes and equipment not directly involved in the refining of crude oil is used in functions vital to the operation of the refinery. Examples are listed below. Products from auxiliary facilities (clean water, steam, and process heat) are required by most process units throughout the refinery.

- Boilers - Boilers are used in many different processes in the oil and gas industry, including drilling and refining. Boilers are used to generate hot water and steam for drilling operations, such as to power the drilling rig, heat the drilling mud, and melt the drilling bit. Boilers are also used in the refining process to heat the crude oil and separate it into its various components. Boilers can also be used to power pumps, compressors, and other machinery used in the refining process.

- Waste Water Treatment Plant - Typical refinery wastewater treatment includes primary treatment such as oil/water separation, and a clarifier to remove solids and secondary treatment to remove organics, metals, and other contaminants; and tertiary treatment for polishing before discharge into the environment.

- Hydrogen Production Plant - To produce hydrogen, it must be separated from the other elements in the molecules where it occurs. Hydrogen can be produced from many different sources in different ways to use as a fuel. The two most common methods for producing hydrogen are steam-methane reforming and electrolysis (splitting water with electricity).

- Sulfur Recovery Plant - Sulfur recovery plants are used in petroleum refineries to convert the hydrogen sulfide (H2S) separated from refinery gas streams into the more disposable byproduct, elemental sulfur. Emissions from sulfur recovery plants and their control are discussed in Section 8.13, "Sulfur Recovery".

- Cooling Towers - Cooling towers are used extensively in refinery cooling water systems to transfer waste heat from the cooling water to the atmosphere. The only refineries not employing cooling towers are those with once-through cooling. The increasing scarcity of a large water supply required for once-through cooling is contributing to the disappearance of that form of refinery cooling. In the cooling tower, warm cooling water returning from refinery processes is contacted with air by cascading through packing.

- Blowdown System - The blowdown system provides for the safe disposal of hydrocarbons (vapor and liquid) discharged from pressure relief devices.

- Compressor Engines - For various processes, refineries use a compressor type unique to the functions and needs of the oil and gas industry, the gas compressor. Whereas an air compressor pressurizes air by reducing its volume, gas compressors do the same with gases. Inside a gas compressor, incoming gas supplies get pressurized in a compression chamber and released for various uses. Gas compressors are common for hydrocracking, hydrotreating, diesel and gas desulfurization, catalytic reforming and other processes.

Tags: Mechanical Petroleum Storage Tank and Pressure Vessel Engineering Drilling Refinery