Petroleum Engineering

Mechanical, Petroleum, Storage Tank and Pressure Vessel, Engineering, Drilling, Refinery, Annular, Drilling Mud, Drilling Cement, Drilling Pump, Drill Pipe Petroleum, also known as crude oil, is a naturally occurring fossil fuel that is found beneath the earth's surface. It is formed from the remains of dead plants and animals that have been buried and subjected to high pressure and temperature over millions of years. Petroleum is a complex mixture of hydrocarbons, which are molecules made up of hydrogen and carbon atoms. It is a valuable resource that is used to produce a wide range of products, including gasoline, diesel fuel, jet fuel, lubricants, plastics, and chemicals.

Petroleum, also known as crude oil, is a naturally occurring fossil fuel that is found beneath the earth's surface. It is formed from the remains of dead plants and animals that have been buried and subjected to high pressure and temperature over millions of years. Petroleum is a complex mixture of hydrocarbons, which are molecules made up of hydrogen and carbon atoms. It is a valuable resource that is used to produce a wide range of products, including gasoline, diesel fuel, jet fuel, lubricants, plastics, and chemicals.

| Engineering |

| Mechanical Engineering |

The extraction and processing of petroleum involve drilling wells into underground reservoirs and pumping the crude oil to the surface. The crude oil is then transported to refineries, where it is processed into various products using techniques such as distillation, cracking, and reforming. The refining process involves separating the different hydrocarbons in the crude oil and converting them into more useful products

- See Articles - Petroleum Glossary / Reservoir Glossary / Drilling Glossary / Refinery Glossary

EPA Crude Oil Types

- Class A: Light, Volatile Oils - These oils are highly fluid, often clear, spread rapidly on solid or water surfaces, have a strong odor, high evaporation rate, and is usually flammable. They penetrate porous surfaces such as dirt and sand, and may be persistent in such a matrix. They do not tend to adhere to surfaces. Flushing with water generally removes them. Class A oils may be highly toxic to humans, fish, and other organisms. Most refined products and many of the highest quality light crudes can be included in this class.

- Class B: Non-sticky Oils - These oils have a waxy or oily feel. Class B oils are less toxic and adhere more firmly to surfaces than Class A oils, although they can be removed from surfaces by vigorous flushing. As temperatures rise, their tendency to penetrate porous substrates increases and they can be persistent. Evaporation of volatiles may lead to a Class C or D residue. Medium to heavy paraffin-based oils fall into this class.

- Class C: Heavy, Sticky Oils - These oils are viscous, sticky or tarry, and brown or black. Flushing with water will not readily remove this material from surfaces, but the oil does not readily penetrate porous surfaces. The density of Class C oils may be near that of water and they often sink. Weathering or evaporation of volatiles may produce solid or tarry Class D oil. Toxicity is low, but wildlife can be smothered or drowned when contaminated. This class includes residual fuel oils and medium to heavy crudes.

- Class D: Nonfluid Oils - These oils are relatively non-toxic, do not penetrate porous substrates, and are usually black or dark brown in color. When heated, Class D oils may melt and coat surfaces making cleanup very difficult. Residual oils, heavy crude oils, some high paraffin oils, and some weathered oils fall into this class.

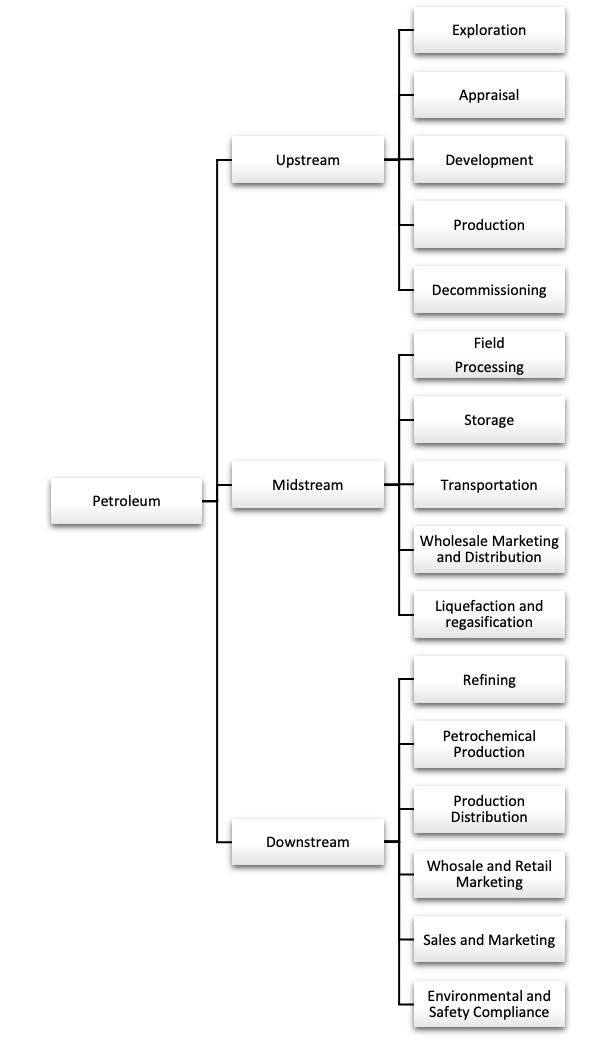

Oil & Gas Upstream, Midstream, and Downstream

Upstream

Upstream

Anything having to do with the exploration and production of oil and natural gas. Upstream activities are highly technical and capital-intensive, requiring significant investment in technology, equipment, and skilled labor. They also involve a high degree of risk due to the uncertainties associated with finding and developing hydrocarbon reserves.

- Exploration - Using various techniques like seismic surveys, geologists and geophysicists study subsurface structures to identify potential oil and gas reservoirs. Drilling exploratory wells to confirm the presence and extent of the hydrocarbon reserves.

- Appraisal - Additional wells are drilled to assess the size, quality, and production potential of the discovered reservoir. Analyzing the data from appraisal wells to estimate the quantity of recoverable oil and gas.

- Developement - Designing a comprehensive plan for extracting hydrocarbons, including the layout of production wells, infrastructure, and processing facilities. Drilling production wells based on the development plan to start the extraction process.

- Production - Bringing the oil and gas to the surface using various methods like natural flow, artificial lift, or enhanced recovery techniques. Initial treatment of the extracted hydrocarbons to separate oil, gas, water, and other impurities.

- Decommissioning - Properly sealing and closing wells that are no longer productive. Restoring the environment around the production site to its original state or as close as possible.

Midstream

Anything required to transport and store crude oil and natural gas before they are refined and processed into fuels and key elements. Midstream activities are crucial for ensuring a steady and reliable supply of oil and gas from production sites to end-users. This sector requires significant investment in infrastructure and technology to ensure safety, efficiency, and environmental compliance.

- Field Processing - Facilities that remove impurities and by-products from raw natural gas to produce pipeline-quality dry natural gas and other valuable components like natural gas liquids (NGLs). Facilities that maintain the pressure and flow of natural gas through pipelines. Facilities that separate mixed NGLs into individual products like ethane, propane, butanes, and pentanes.

- Storage - Large facilities where crude oil, natural gas, and refined products are stored in tanks before being transported to refineries or distribution centers. Natural gas is often stored in underground facilities, such as depleted reservoirs, aquifers, or salt caverns, to manage supply and demand fluctuations. Specially designed tanks for storing liquefied natural gas at very low temperatures.

- Transportation - The most common and efficient method for transporting large volumes of oil and gas over long distances. Pipelines can be for crude oil, natural gas, or refined products. Used for transporting oil, especially in areas where pipeline infrastructure is not available. Used for shorter distances or for locations not accessible by pipelines or rail. Tankers and barges are used for international and coastal transportation of oil and liquefied natural gas (LNG).

- Wholesale Marketing and Distribution - Points where oil and gas are transferred from one mode of transportation to another, such as from pipeline to truck or ship. Infrastructure for delivering natural gas to industrial, commercial, and residential customers.

- Liquefaction and Regasification - Facilities for liquefying natural gas for transport (liquefaction) and converting it back to gas form (regasification) at the destination.

Downstream

This includes everything involved in turning crude oil and natural gas into thousands of finished products. Downstream activities are essential for delivering the final products that fuel transportation, power industries, heat homes, and provide raw materials for countless goods. The sector is characterized by complex logistics, significant infrastructure investments, and a focus on efficiency and environmental responsibility.

- Refining - The process of converting crude oil into various petroleum products like gasoline, diesel, jet fuel, heating oil, lubricants, asphalt, and petrochemicals. Refineries use a combination of physical and chemical processes such as distillation, cracking, and reforming. Further processing of natural gas to separate and purify methane and other valuable components like ethane, propane, butane, and natural gas liquids (NGLs).

- Petrochemical Production - Production of fundamental chemicals such as ethylene, propylene, benzene, toluene, and xylene, which serve as building blocks for a wide range of products. Conversion of basic petrochemicals into intermediate products like plastics, synthetic rubber, solvents, and fibers.

- Product Distribution - Transportation of refined products through pipelines to distribution terminals. Movement of refined products to markets and consumers where pipelines are not available or feasible. Storage tanks and terminals where refined products are held before further distribution.

- Wholesale and Retail Marketing - Selling large quantities of refined products to bulk consumers, such as industrial clients, utility companies, and transportation fleets. Selling refined products to end consumers through gas stations, convenience stores, and direct sales channels. This includes the branding and operation of fuel retail outlets.

- Sales and Marketing - Marketing and sales of finished products like gasoline, diesel, kerosene, lubricants, and heating oil. Supply of products for industrial use, including feedstocks for manufacturing, agriculture, and energy production.

- Environmental and Safety Compliance - Ensuring that all activities meet environmental regulations and standards set by government bodies. Implementing procedures and practices to ensure the safety of workers and the public.