Spring Pitch

Spring Pitch formula |

||

| \( p \;=\; \left( \dfrac{ L - h }{ n_a } \right) + d \) | ||

| Symbol | English | Metric |

| \( p \) = pitch | \( deg \) | \( rad \) |

| \( L \) = free length | \( in \) | \( mm \) |

| \( h \) = solid coil height | \(in \) | \(\ mm \) |

| \( n_s \) = spring rate | \(lbf\;/\;in\) | \(kg\;/\;mm\) |

| \( d \) = wire diameter | \( in \) | \( mm \) |

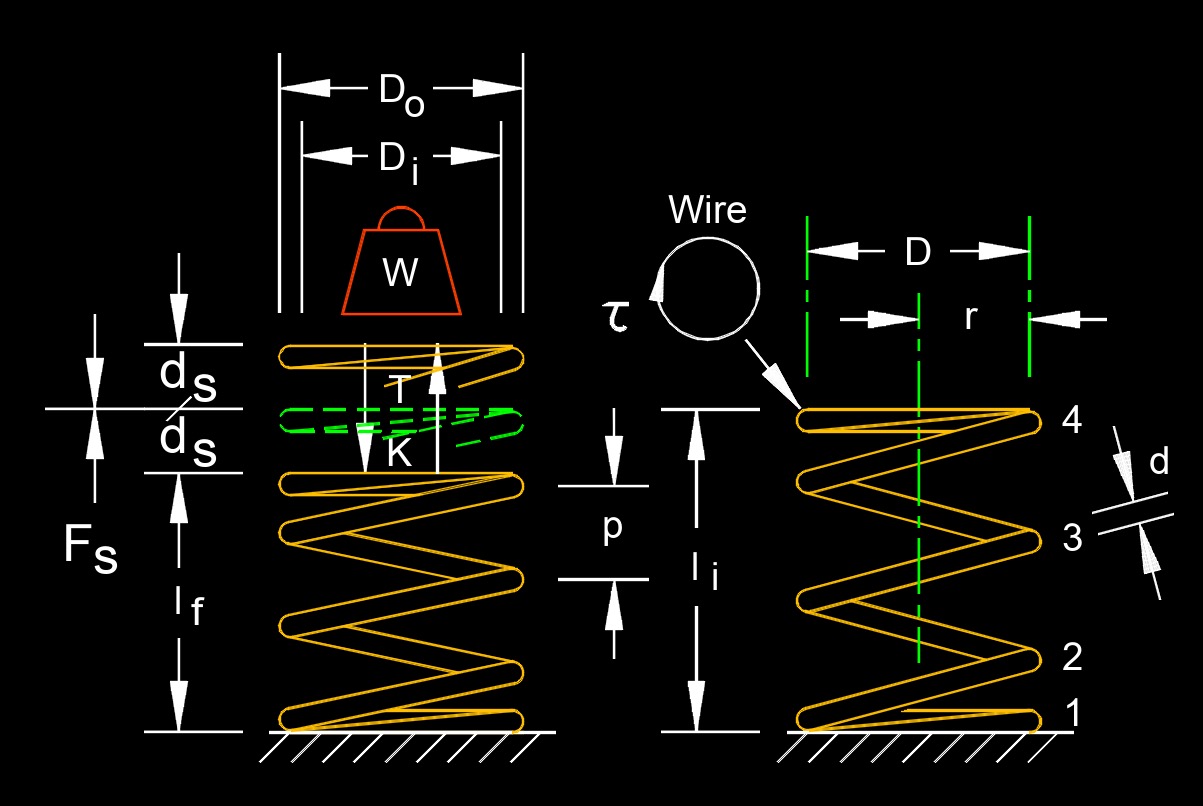

Spring pitch, abbreviated as p, is to the distance between successive coils or turns in a helical spring. It is an important parameter that defines the spring's geometry and can affect its performance characteristics, such as stiffness and load carrying capacity. The spring pitch is measured along the axis of the spring and is the axial distance between two adjacent points on the wire that forms the coil. In other words, it is the distance from one point on a coil to the corresponding point on the next coil, measured parallel to the axis of the spring.

Spring pitch, abbreviated as p, is to the distance between successive coils or turns in a helical spring. It is an important parameter that defines the spring's geometry and can affect its performance characteristics, such as stiffness and load carrying capacity. The spring pitch is measured along the axis of the spring and is the axial distance between two adjacent points on the wire that forms the coil. In other words, it is the distance from one point on a coil to the corresponding point on the next coil, measured parallel to the axis of the spring.

The spring pitch is an essential factor in designing springs for specific applications. It is related to the spring's wire diameter, the number of coils, and the spring's overall length. By altering the pitch, you can change the spring's characteristics, such as its stiffness and the amount of force it can exert when compressed or extended.

Spring Pitch Considerations

- Spring Function -

- Compression Springs (K) - For compression springs, the pitch affects the load bearing characteristics and the spring's ability to compress. A larger pitch means the coils are more spaced out, allowing for more compression before the coils touch each other.

- Tension Springs (T) - In tension springs, the coils are usually closely wound with no initial pitch. However, a small pitch can be present to ensure that the coils do not touch each other when the spring is in a relaxed state.

- Stress Distribution - The pitch affects the distribution of stress within the spring. Uneven pitch can lead to non-uniform stress distribution, potentially causing premature failure or unwanted deformation.

- Spring Rate (Stiffness) - The pitch, in conjunction with the wire diameter and coil diameter, influences the spring rate (stiffness) of the spring. A larger pitch generally decreases the spring rate, making the spring less stiff, whereas a smaller pitch increases the spring rate, making the spring stiffer.

- Solid Height - The solid height of a spring is the height of the spring when all coils are compressed together. The pitch plays a role in determining the maximum compression distance before the spring becomes solid (all coils touching).

- Manufacturing Constraints - When designing a spring, it's important to consider the manufacturing process. A very small or very large pitch can be challenging to produce accurately and consistently.

- Buckling - For long, slender compression springs, a larger pitch can increase the risk of buckling under load. The spring may bend or buckle instead of compressing uniformly.

- End Coil Configuration - The pitch at the ends of the spring might be different from the pitch of the active coils to create closed and ground ends, which provide a flat surface for the spring to sit on and ensure even load distribution.