Safety Engineering

Safety engineering, abbreviated as SAF, also known as safety management or safety science, is a discipline that focuses on ensuring the safety of people, equipment, processes, and environments. It involves the application of scientific and engineering principles to identify, assess, and control potential hazards and risks in various settings. The primary goal of safety engineering is to prevent accidents, injuries, and adverse events by designing and implementing effective safety measures and controls. It encompasses a wide range of industries and sectors, including manufacturing, construction, transportation, healthcare, energy, and more.

Science Branches |

| Science |

| Applied Science |

| Engineering |

| Management and Systems Engineering |

|

Overall, safety engineering is a multidisciplinary field that combines engineering, science, psychology, and management principles to create safe and secure environments for individuals and society as a whole.

- See Articles - List of Tags, List of Categories, List of Articles, List of Glossaries, Nomenclature and Symbols, (See Safety Glossary)

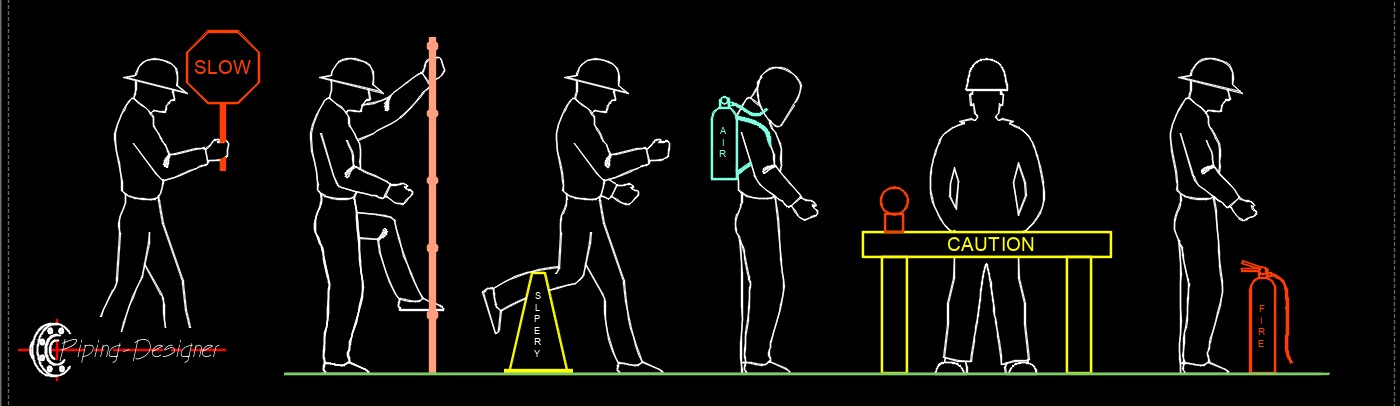

Work Place Hazards

Biological

- Animal and bird droppings

- Bacteria and viruses

- Blood and other body fluids

- Fungi/mold

- Insect bites

- Plants

Chemicals

- Carcinogens

- Corrosives

- Gasses

- Flammable materials

- Irritants

- Liquids

- Mutagens

- Pesticides

- Sensitizers

- Teratogens

- Vapors

Ergonomic

- Frequent lifting

- Poor posture

- Vibration

Physical

- Awkward movements

- Burns

- Constant loud noise

- Crush injuries

- Falls

- Having to use too much force

- High exposure to sunlight/ultraviolet light

- Improperlt adjusted workstation and chair

- Radiation

- Temperature extremes

Psychosocial

- Harassment

Safety hazard

- Confined spaces

- Electrical

- Fire

- Forklifts

- Lockout/tagout

- Machinery

- Lack of PPE

- Lack of training

- Poor housekeeping

- Spills

- Tools

- Working at height