Working Pressure

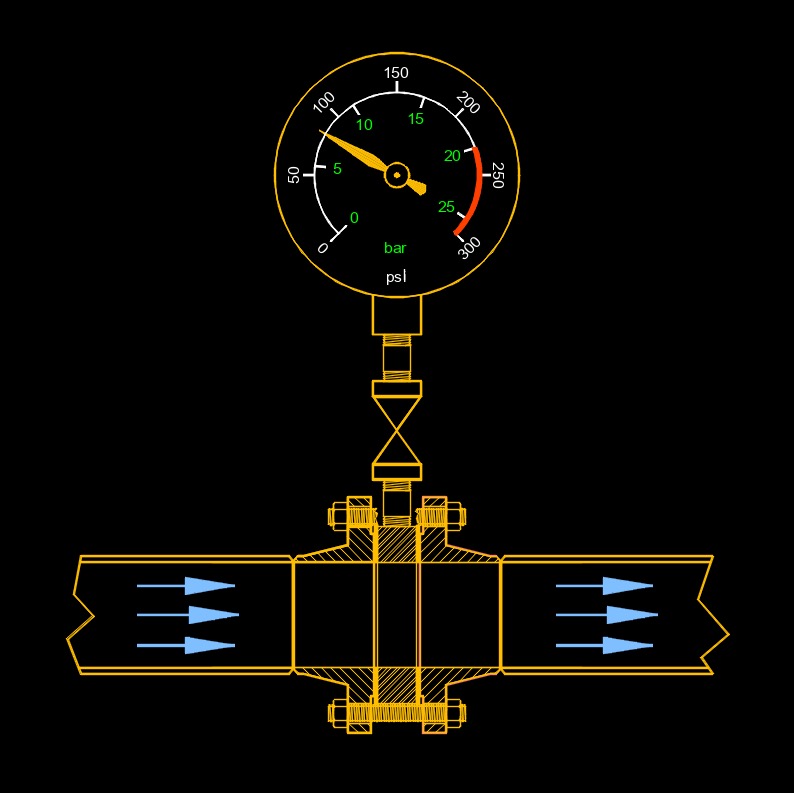

Working pressure, abbreviated as WPR, also called design pressure, is the normal pressure that a system operates at. It is the maximum allowable pressure at which a system, component, or equipment can operate safely and effectively under normal conditions. It is a critical parameter in various industries and applications to ensure the reliability, integrity, and safety of the equipment and processes involved. Working pressure takes into account factors such as the design, materials, construction, and intended use of the system or component. It's important to choose a working pressure that considers potential fluctuations in pressure, temperature variations, and other operational considerations.

Working pressure, abbreviated as WPR, also called design pressure, is the normal pressure that a system operates at. It is the maximum allowable pressure at which a system, component, or equipment can operate safely and effectively under normal conditions. It is a critical parameter in various industries and applications to ensure the reliability, integrity, and safety of the equipment and processes involved. Working pressure takes into account factors such as the design, materials, construction, and intended use of the system or component. It's important to choose a working pressure that considers potential fluctuations in pressure, temperature variations, and other operational considerations.

Key Points about Working Pressure

Safety - The working pressure is set below the pressure that could lead to structural failure, leakage, or other hazardous situations. It provides a safety margin to accommodate unexpected variations or transient conditions.

Equipment Rating - Many components, such as pipes, valves, and pressure vessels, are labeled with their working pressure rating, indicating the maximum pressure they can handle safely.

Design Standards - Industry standards and codes provide guidelines for determining working pressures based on various factors, including material properties, design factors, and operational conditions.

Pressure Relief - Working pressure should allow for proper pressure relief mechanisms, such as relief valves, to function effectively in case pressure exceeds safe levels.

Operating Conditions - Consideration should be given to the temperature, type of fluid being transported, and other factors that might affect the system's performance.

Pressure Testing - Equipment and systems are often pressure tested to ensure they can withstand the specified working pressure without failure.

It's important to note that working pressure is distinct from maximum allowable pressure (MAP) or maximum operating pressure (MOP). MAP refers to the absolute maximum pressure a system or component can handle before catastrophic failure, while MOP might be a pressure at which the equipment is intended to operate regularly. Working pressure is a critical specification that ensures the safe and reliable operation of various systems and components. Selecting the appropriate working pressure involves considering factors such as design, materials, industry standards, and operational conditions.