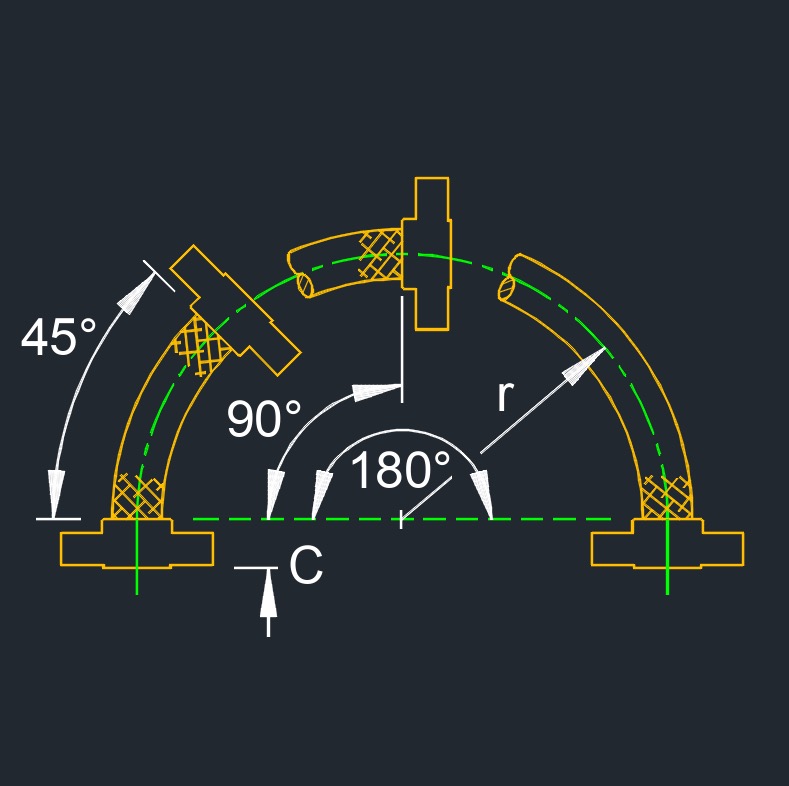

Flex Connector - Hose Length for Degree of Bend

Flex Connector - Hose Length for Degree of Bend | |||

|---|---|---|---|

| Centerline Bend Radius "r" (in) | Minimum Live Length | ||

| 45° | 90° | 180° | |

| 1 | 1 | 2 | 4 |

| 2 | 2 | 3 1/2 | 7 |

| 3 | 2 1/2 | 5 | 10 |

| 4 | 3 1/2 | 6 1/2 | 13 |

| 5 | 4 | 8 | 16 |

| 6 | 5 | 10 | 20 |

| 7 | 5 1/2 | 11 | 22 |

| 8 | 6 1/2 | 13 | 26 |

| 9 | 7 1/2 | 14 1/2 | 29 |

| 10 | 8 | 16 | 32 |

| 11 | 9 | 18 | 36 |

| 12 | 10 | 19 1/2 | 39 |

| 13 | 10 1/2 | 21 | 42 |

| 14 | 11 1/2 | 22 1/2 | 45 |

| 15 | 12 | 24 | 48 |

| 16 | 13 | 26 | 52 |

| 17 | 13 1/2 | 27 | 54 |

| 18 | 14 1/2 | 29 | 58 |

| 19 | 15 1/2 | 30 1/2 | 61 |

| 20 | 16 | 32 | 64 |

| 21 | 17 | 33 1/2 | 67 |

| 22 | 17 1/2 | 35 | 70 |

| 23 | 18 1/2 | 36 1/2 | 73 |

| 24 | 19 | 38 | 76 |

| 25 | 20 | 40 | 80 |

Flex Connector - Hose Length for Degree of Bend | |||

|---|---|---|---|

| Centerline Bend Radius "r" (in) | Minimum Live Length | ||

| 45° | 90° | 180° | |

| 26 | 21 | 42 | 83 |

| 27 | 21 1/2 | 43 | 86 |

| 28 | 22 1/2 | 44 1/2 | 89 |

| 29 | 23 | 46 | 92 |

| 30 | 24 | 48 | 95 |

| 31 | 24 1/2 | 49 | 98 |

| 32 | 25 1/2 | 51 | 101 |

| 34 | 27 | 54 | 108 |

| 36 | 28 1/2 | 57 | 114 |

| 38 | 30 | 60 | 120 |

| 40 | 32 | 83 | 126 |

| 45 | 36 | 72 | 144 |

| 50 | 40 | 80 | 160 |

| 55 | 45 | 90 | 180 |

| 60 | 49 | 97 | 194 |

| 65 | 53 | 105 | 210 |

| 70 | 56 | 112 | 224 |

| 80 | 65 | 130 | 260 |

| 90 | 73 | 145 | 290 |

| 100 | 80 | 160 | 320 |

| 120 | 95 | 190 | 380 |

| 140 | 112 | 225 | 450 |

| 160 | 128 | 255 | 510 |

| 180 | 143 | 285 | 570 |

| 200 | 160 | 320 | 640 |

- To determine the centerline bend radius required. Under the column headed "Centerline Bend Radius (in)", find the radius and read horizontally to be desired degree of bend (45°, 90°, 180°). The number in the column will be the minimum live hose length required to make the degree of bend along the centerline radius.

- Add fitting dimension "C" (end connection) to each end of hose for overall length.

- For calculating length of hose see angular deflection.