Dummy Support

It's important to note that the design and implementation of dummy pipe supports depend on factors such as the type of piping system, the materials used, the operating conditions, and the specific requirements of the project. Proper engineering and design considerations are essential to ensure the safety and functionality of the entire piping system.

- See Article - Pipe Support Dont's

Key Points about Dummy Pipe Supports

Thermal Expansion - Piping systems are subject to temperature changes, and when pipes heat up, they can expand. This expansion can put stress on the piping and its components. Dummy pipe supports are strategically placed to accommodate thermal expansion without causing excessive stress or deformation.

Preventing Sagging - In some situations, long sections of piping might sag due to their own weight or thermal expansion. To prevent this sagging from causing issues with proper flow or structural integrity, dummy pipe supports are used to hold up the pipe at specific intervals.

Equipment Movement - In industrial environments, there might be instances where equipment needs to be temporarily moved or replaced. Dummy pipe supports can be used to hold the pipes in place while the equipment is being worked on, preventing disruption to the entire piping system.

Construction and Maintenance - During the construction phase of a piping system or when maintenance work is being performed, dummy pipe supports can be used to temporarily hold pipes in place until the permanent supports are installed or the maintenance is complete.

Horizontal Support

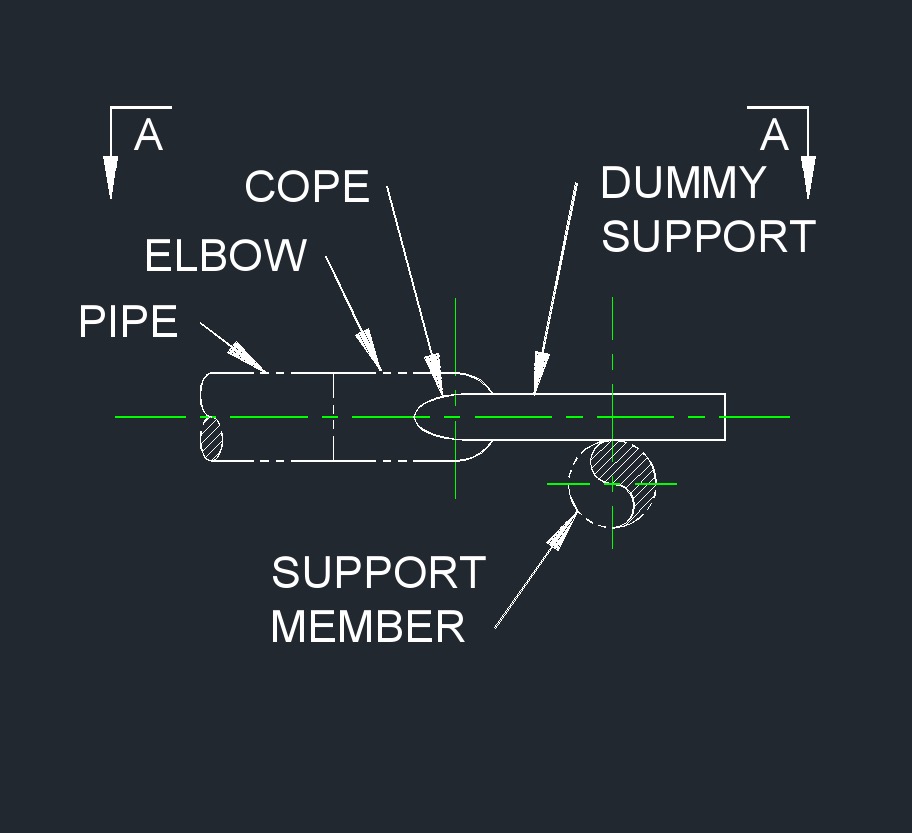

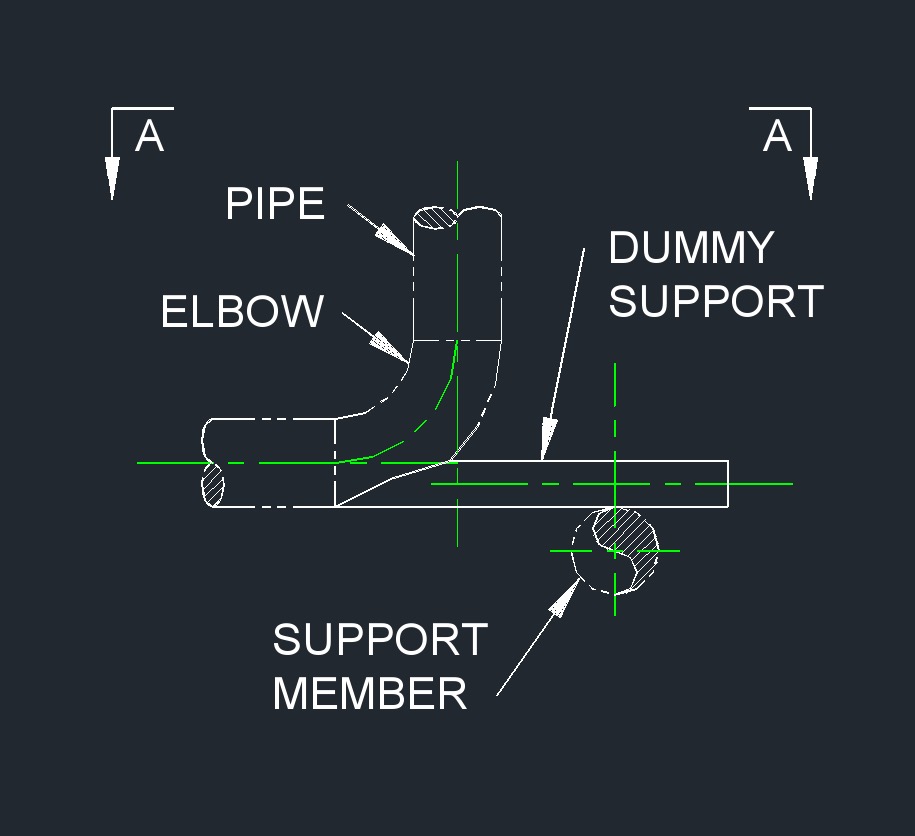

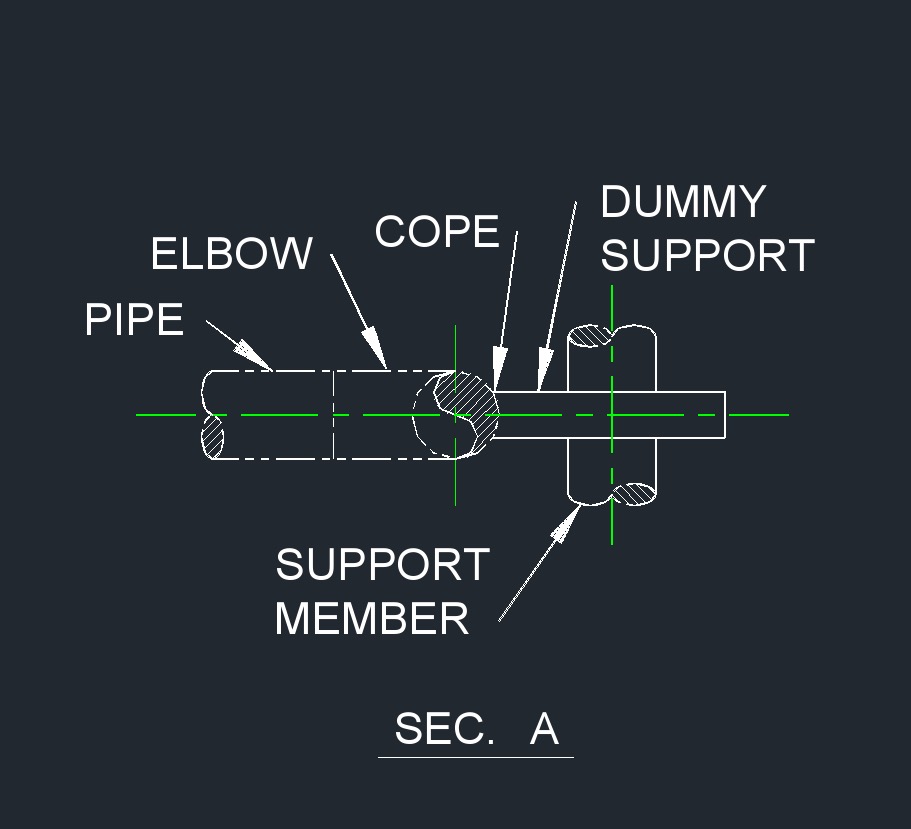

Horizontal 90 on Pipe

Horizontal 90 on Pipe

Horizontal 90 on Pipe

Horizontal 90 on Pipe

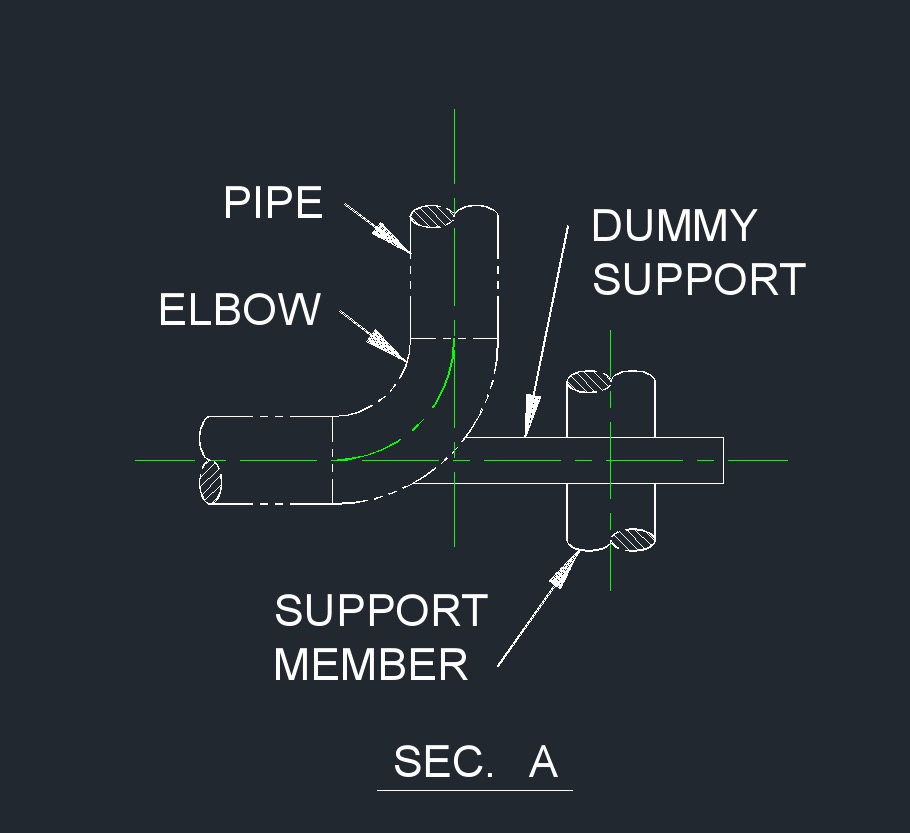

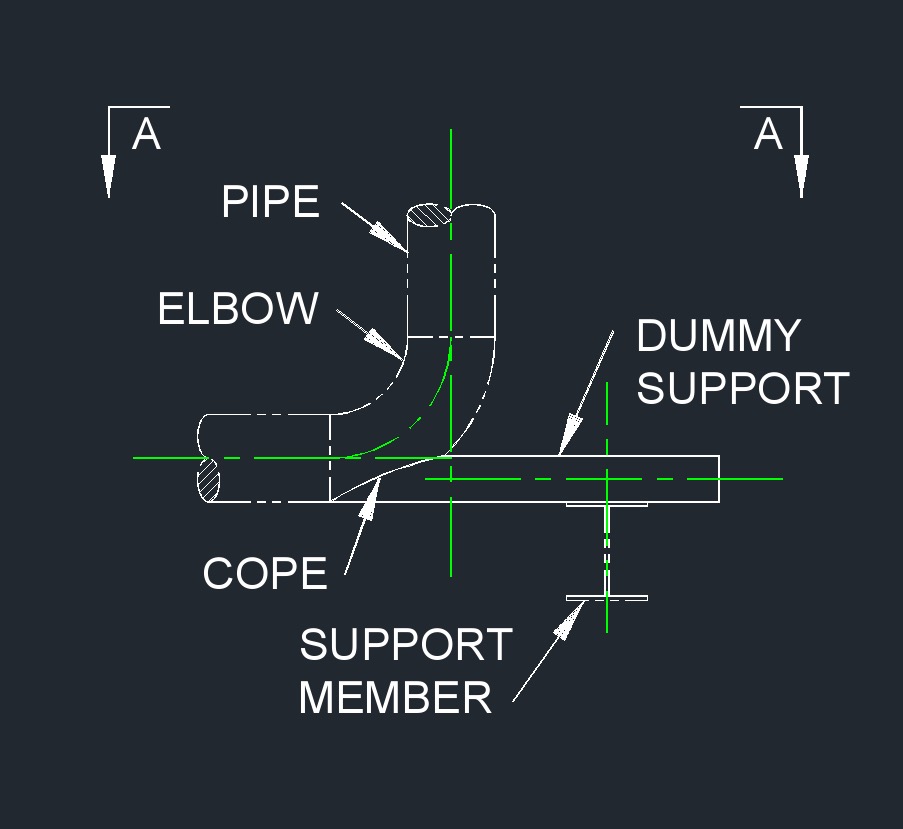

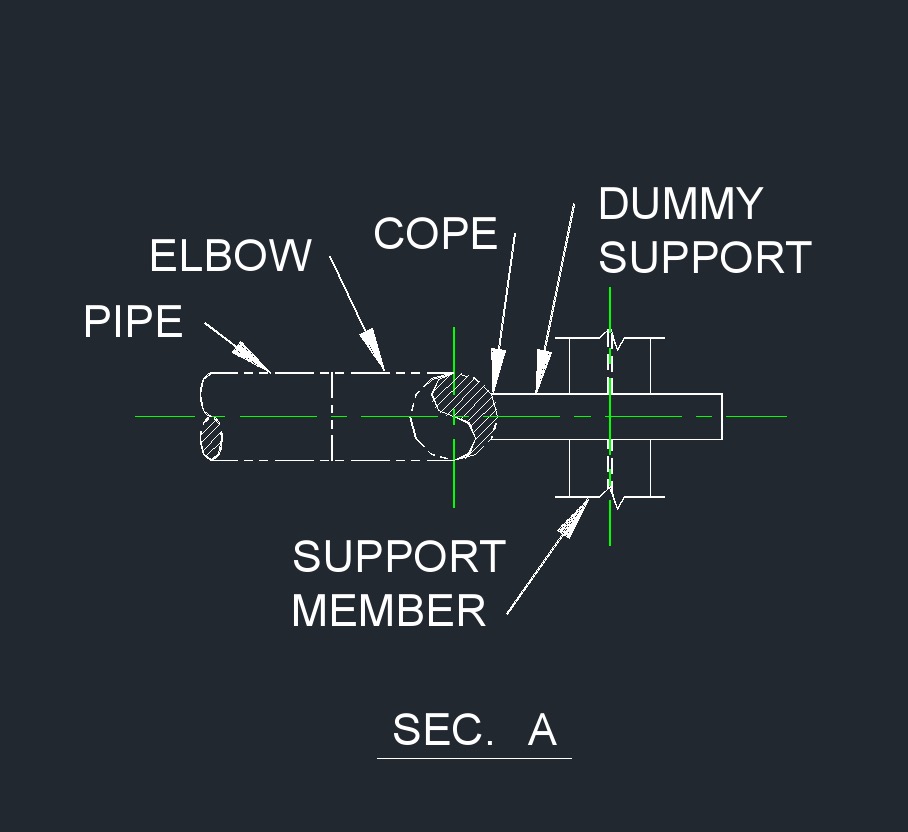

Horizontal 90 on Beam

Horizontal 90 on Beam

Horizontal 90 on Beam

Horizontal 90 on Beam

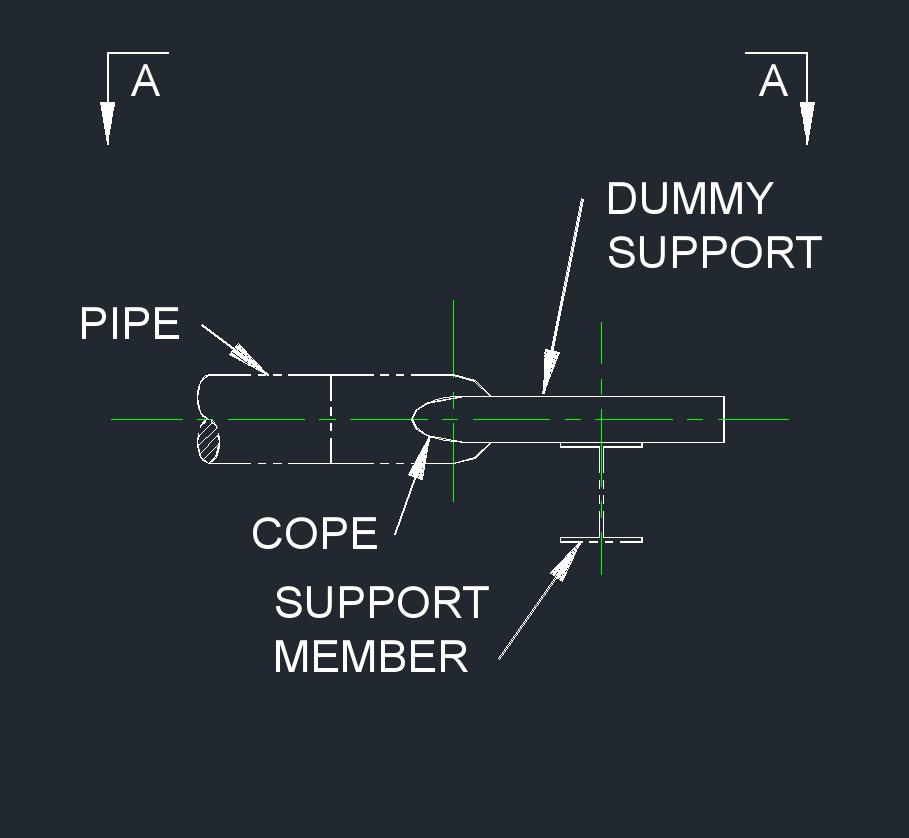

Horizontal 90 on Pipe

Horizontal 90 on Pipe

Horizontal 90 on Pipe

Horizontal 90 on Pipe

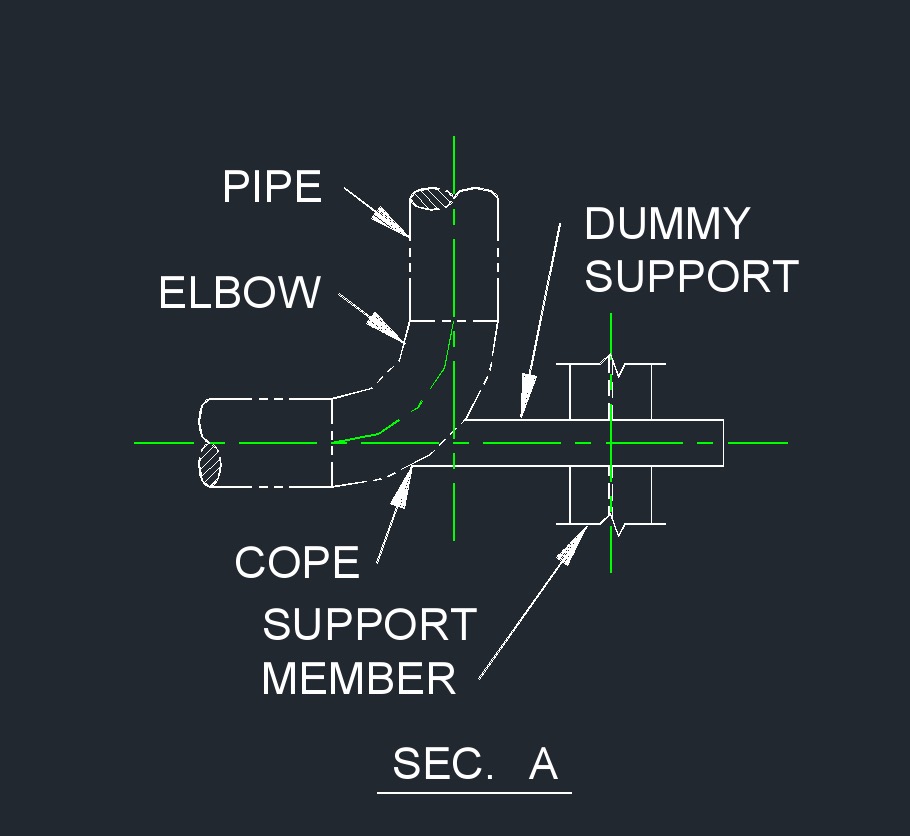

Horizontal 90 on Beam

Horizontal 90 on Beam

Horizontal 90 on Beam

Horizontal 90 on Beam

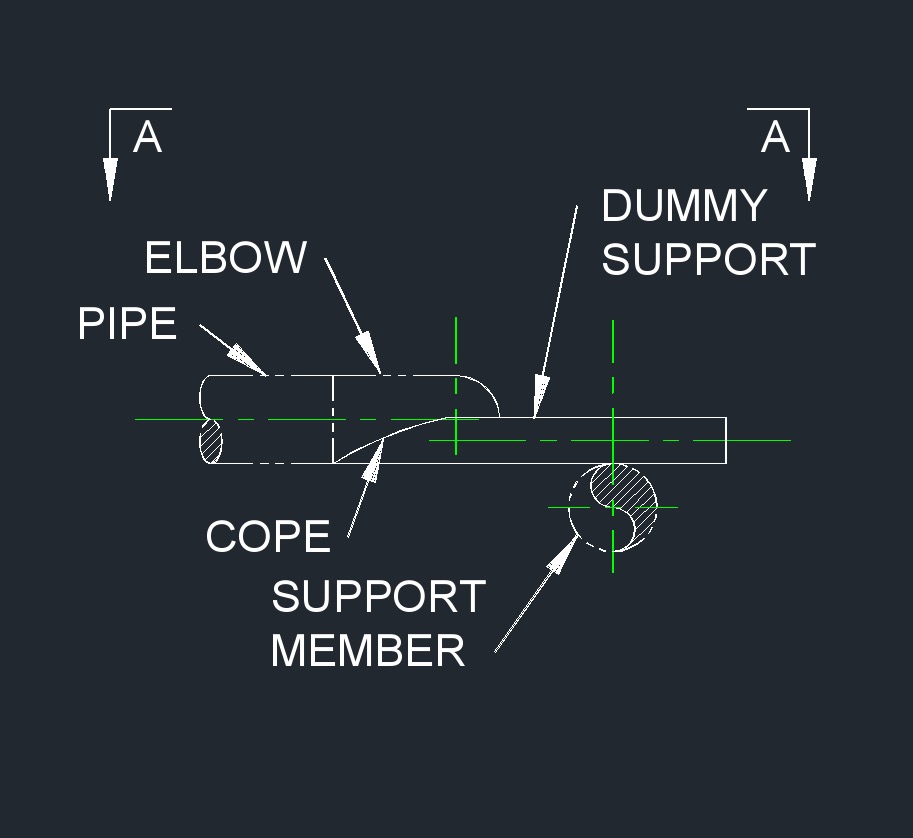

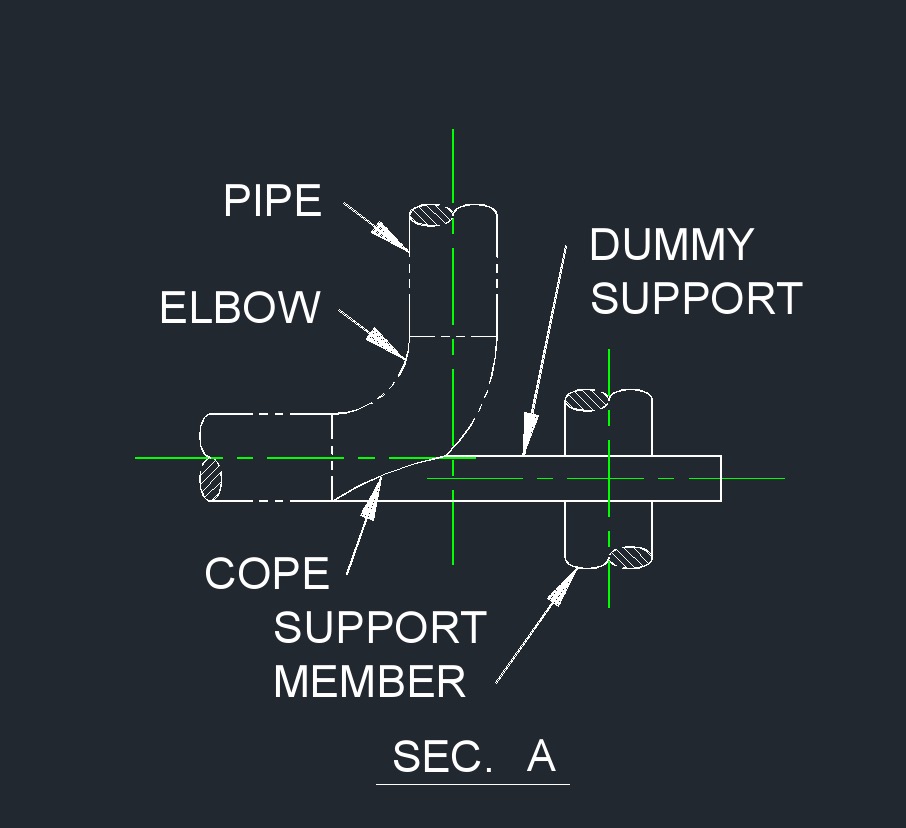

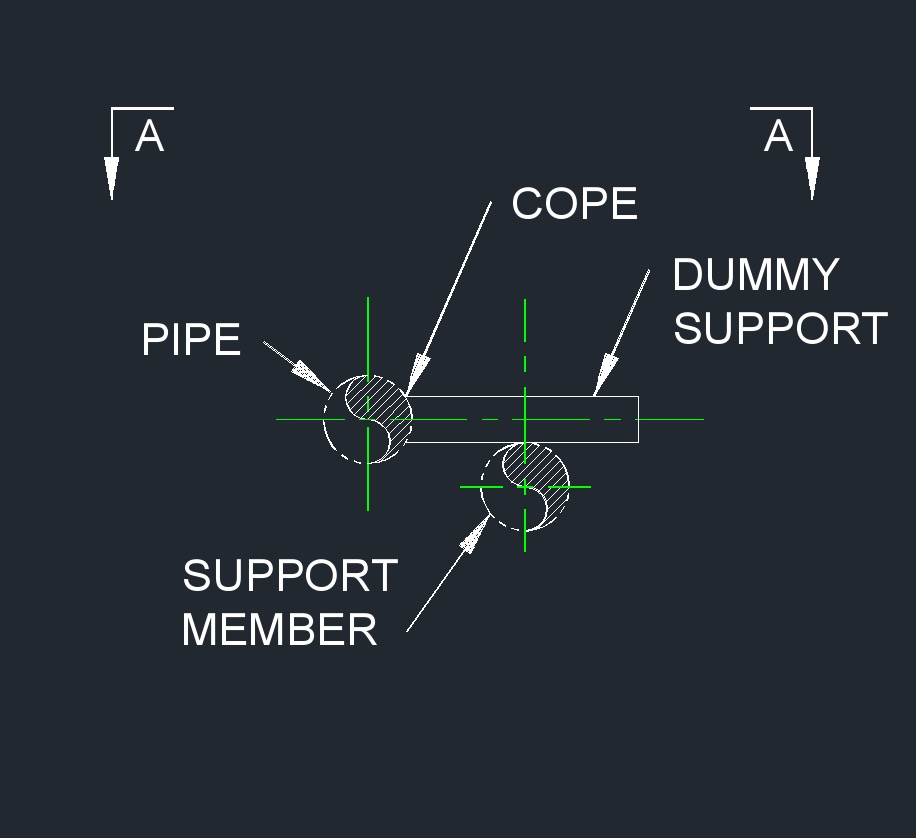

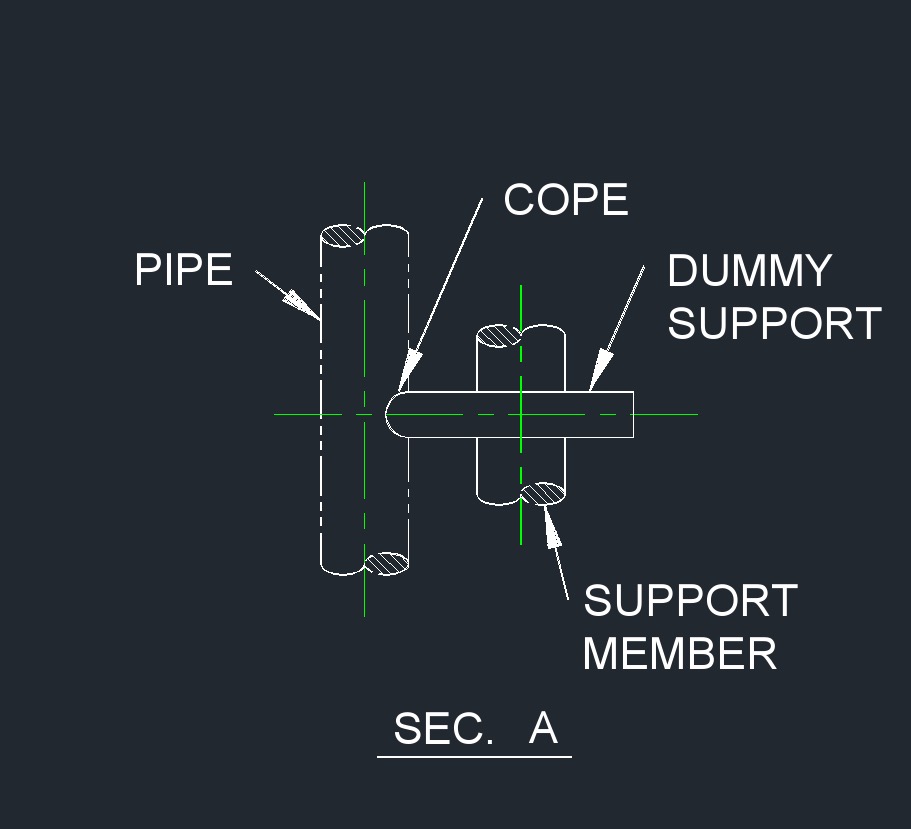

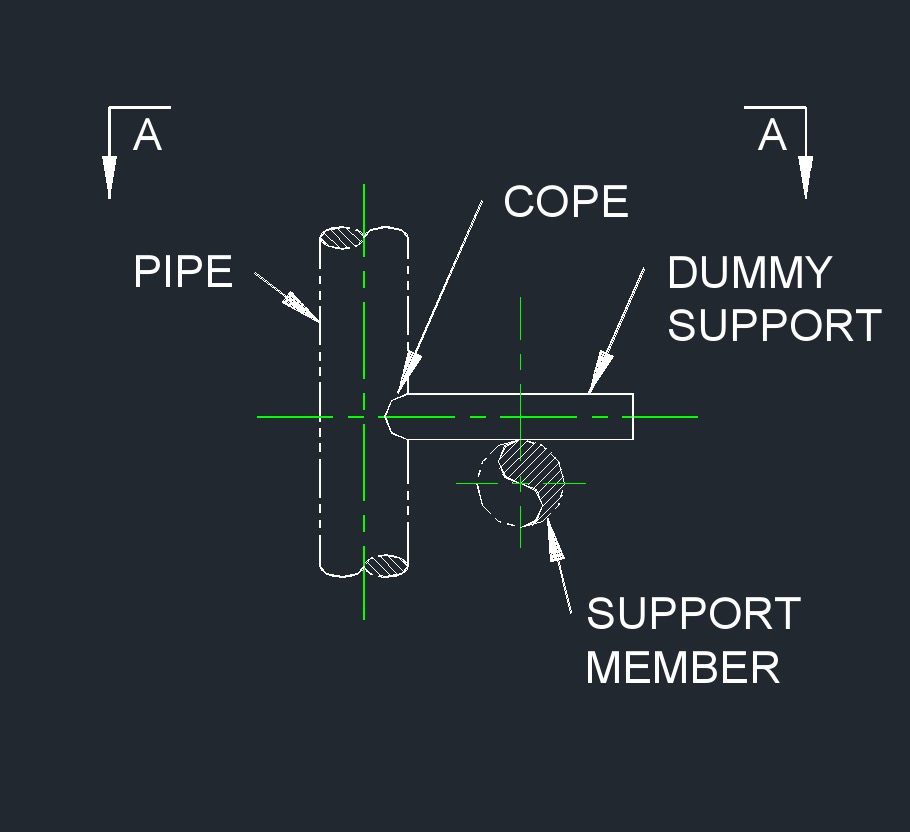

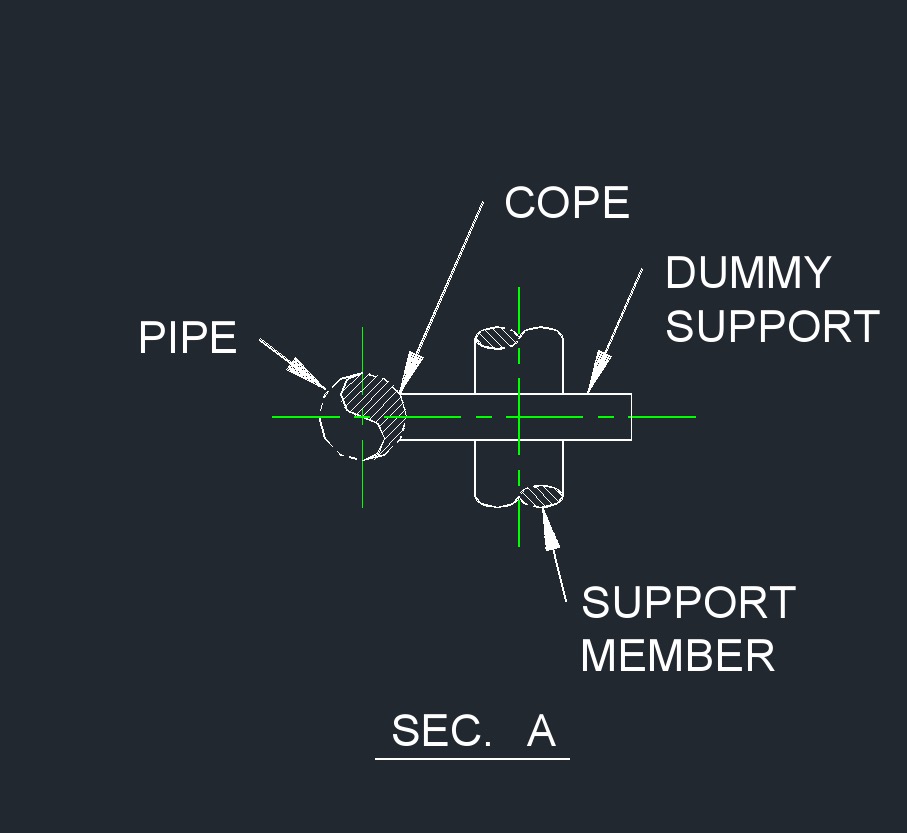

Horizontal Pipoe on Pipe

Horizontal Pipoe on Pipe

Horizontal Pipe on Pipe

Horizontal Pipe on Pipe

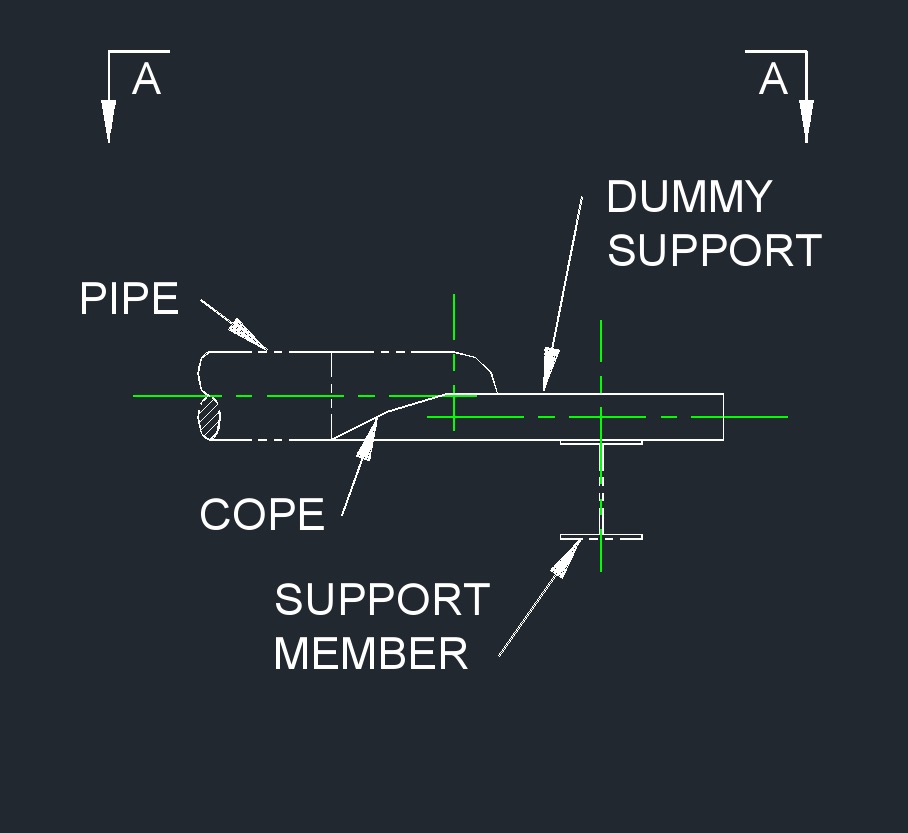

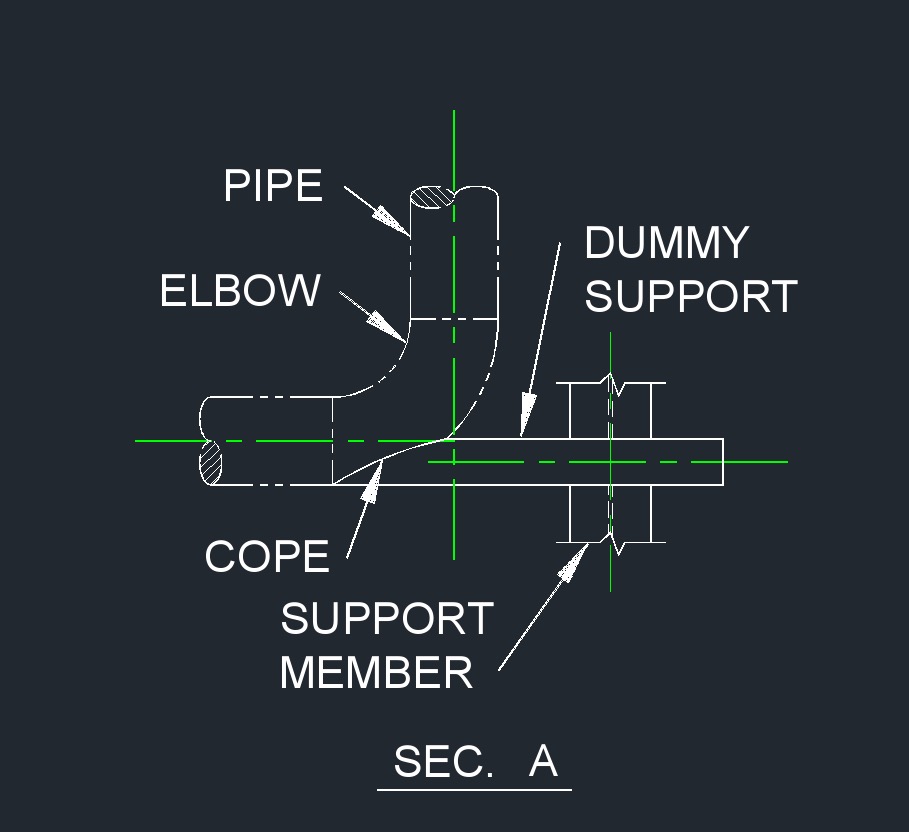

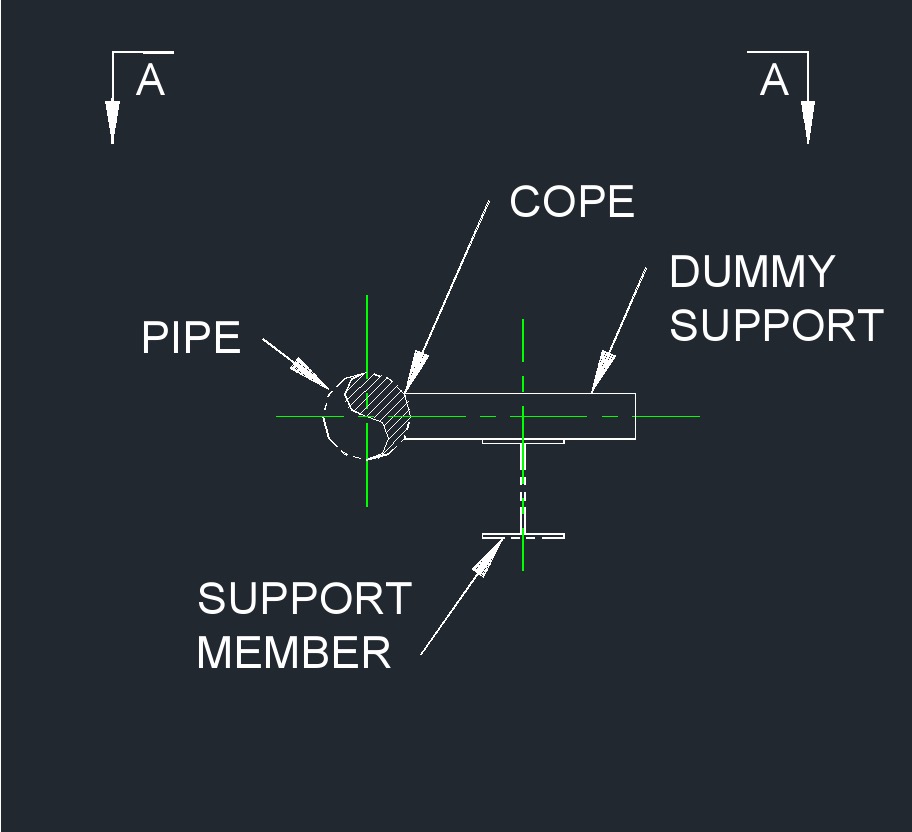

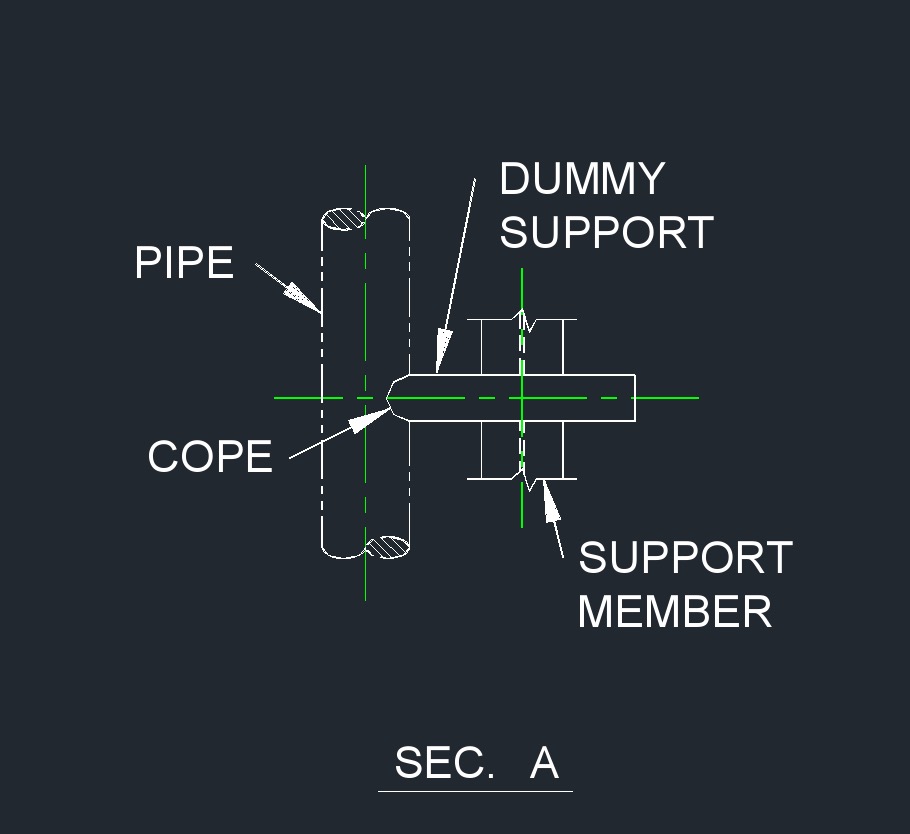

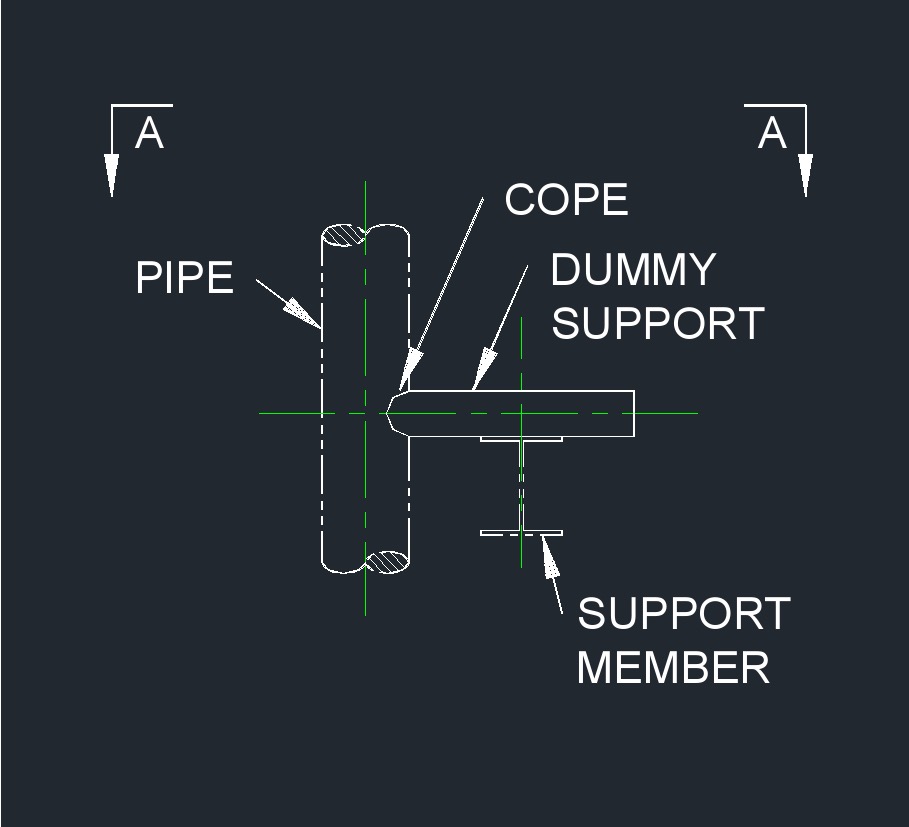

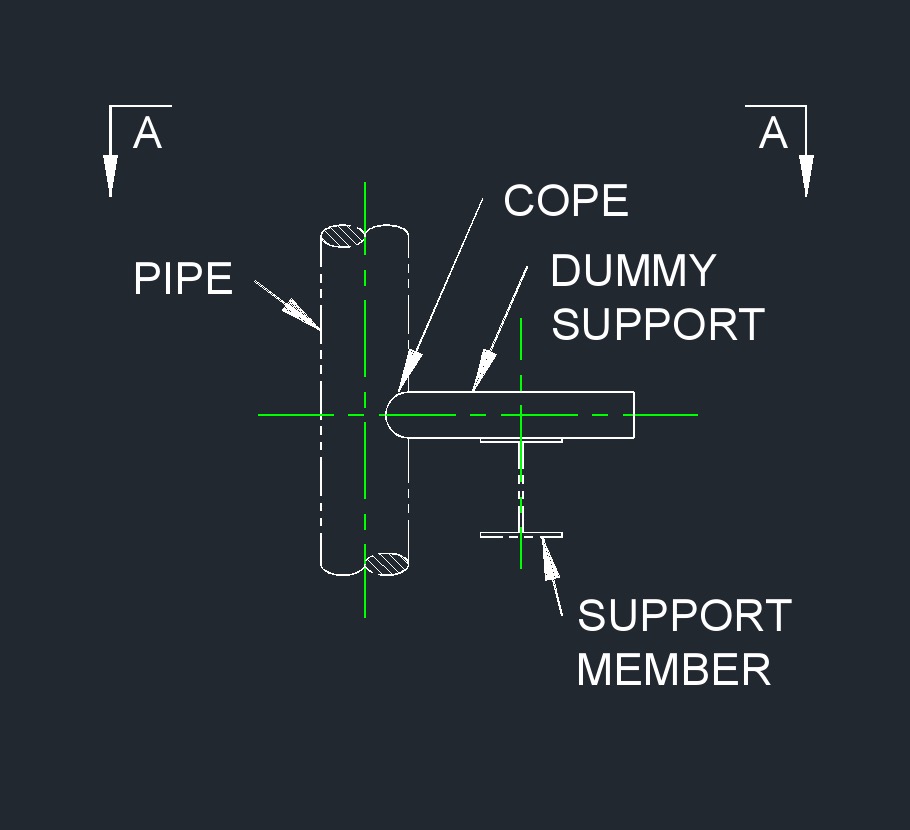

Horizontal 90 on Beam

Horizontal 90 on Beam

Horizontal 90 on Beam

Horizontal 90 on Beam

Vertical Support

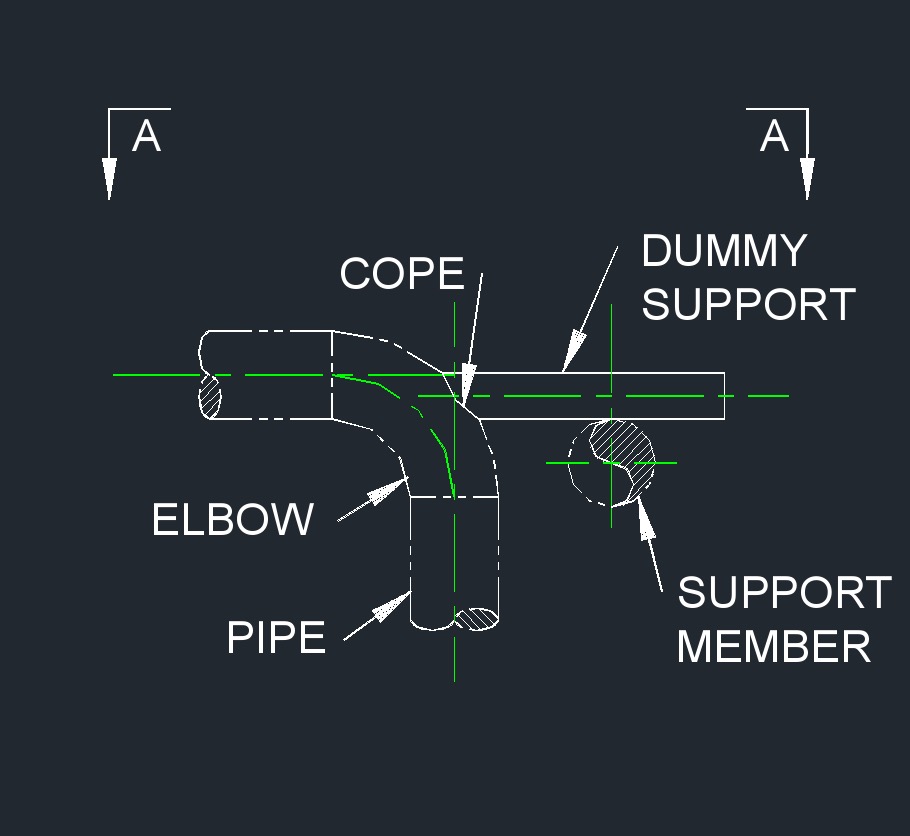

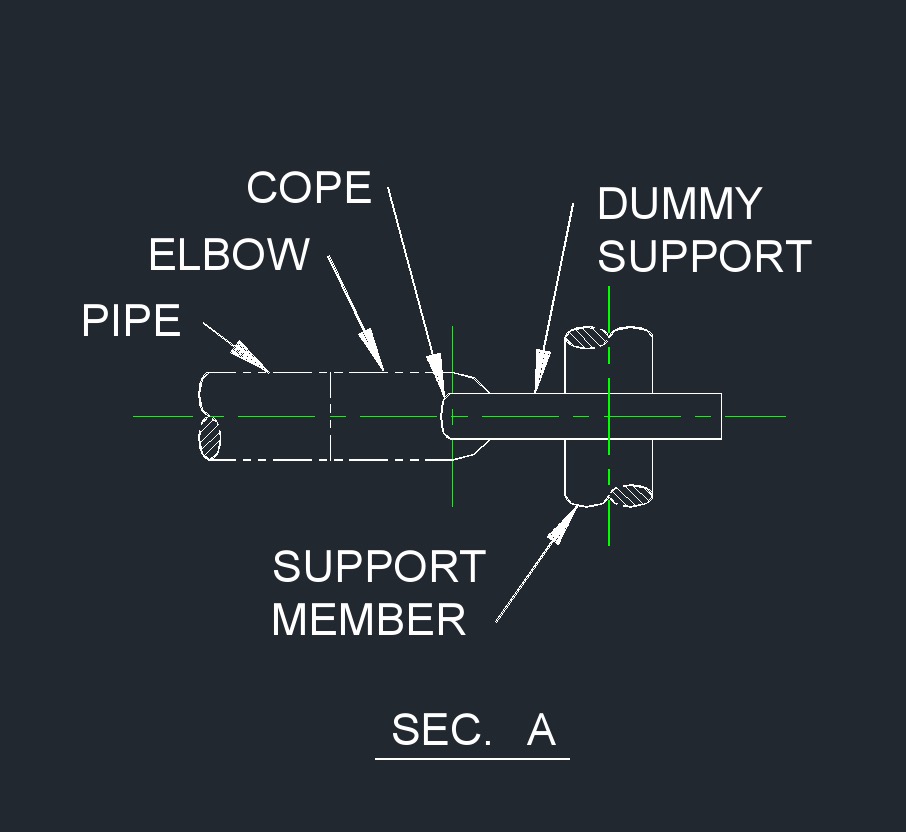

Vertical Up 90 on Pipe

Vertical Up 90 on Pipe

Vertical Up 90 on Pipe

Vertical Up 90 on Pipe

Vertical 90 on Beam

Vertical 90 on Beam

Vertical 90 on Beam

Vertical 90 on Beam

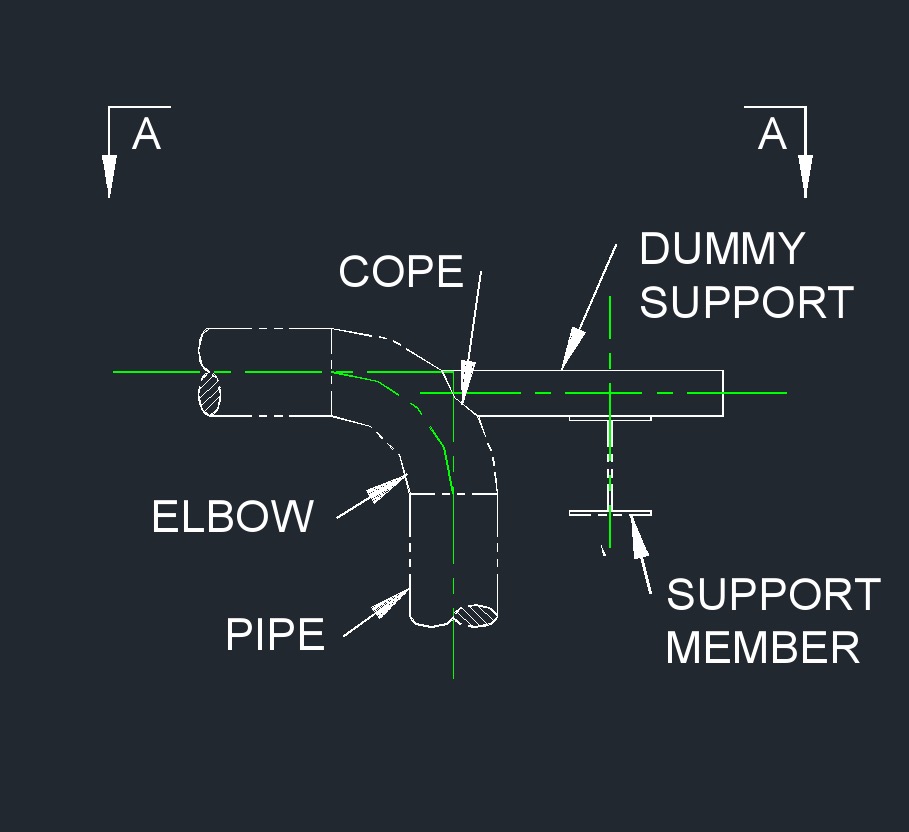

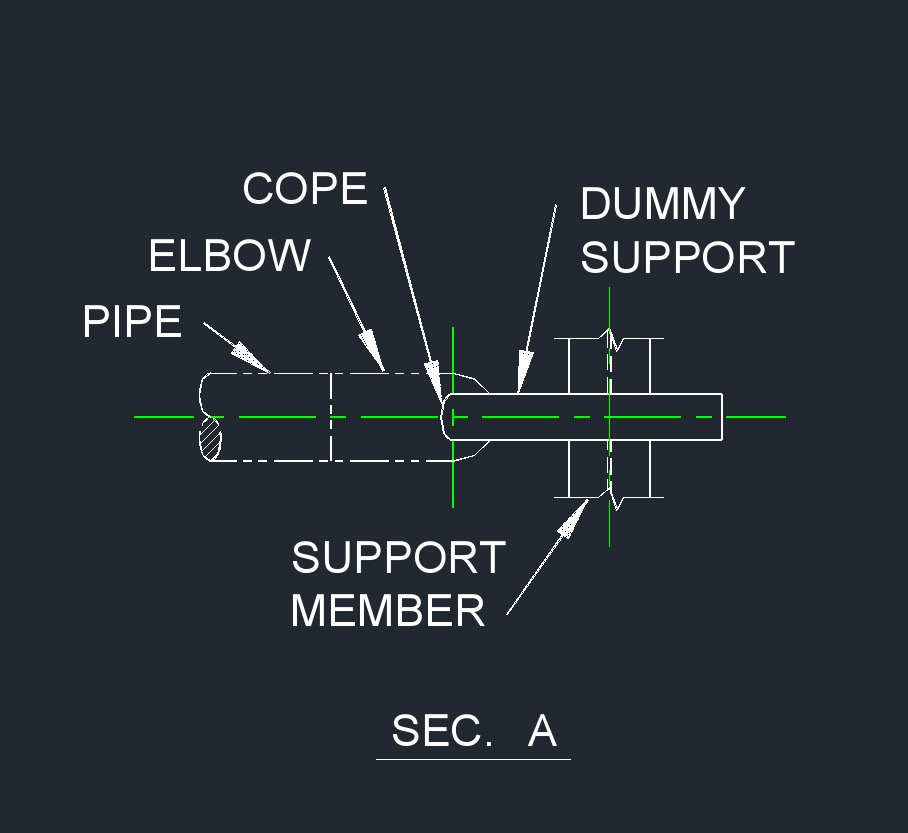

Vertical Down 90 on Pipe

Vertical Down 90 on Pipe

Vertical Down 90 on Pipe

Vertical Down 90 on Pipe

Vertical 90 on Beam

Vertical 90 on Beam

Vertical 90 on Beam

Vertical 90 on Beam

Vertical Pipe on Pipe

Vertical Pipe on Pipe

Vertical Pipe on Pipe

Vertical Pipe on Pipe

Vertical 90 on Beam

Vertical 90 on Beam

Vertical 90 on Beam

Vertical 90 on Beam