Bolt Tightening Procedure

Tags: Pipe Flange Valve Gasket Fastener

Tags: Pipe Flange Valve Gasket Fastener

Bolt tightening Procedure Index

- General Guidelines that can be Followed

- 4 and 8 Bolt Flanges Tightening Procedure

- 12 Bolt Flanges and More Tightening Procedure

- Bolt Standards

- ANSI Class Torque Factor

- Four Bolt Tightening Sequence

- Eight Bolt Tightening Sequence

- Twelve Bolt Tightening Sequence

- Sixteen Bolt Tightening Sequence

- Twenty Bolt Tightening Sequence

- Twenty Four Bolt Tightening Sequence

- Bolt Tightening Datasheets

general guidelines that can be followed

Bolt tightening procedures are typically specific to the application and the type of bolt being used.

- Use the correct torque specifications provided by the manufacturer for the particular bolt and application.

- Lubricate the threads and the contact surface of the bolt and nut with an appropriate lubricant.

- Tighten the bolts in a star pattern, tightening each bolt a little at a time to ensure that the load is evenly distributed.

- Use a calibrated torque wrench or tensioning device to achieve the correct level of bolt tension.

- Verify the torque or tension after a specified time has elapsed or after a specified number of cycles.

It is important to note that these general guidelines may not be sufficient for all applications, and that specific bolt tightening procedures should be followed for each application. Additionally, it is important to consider the environment and any safety factors that may be relevant to the application.

Start the tightening procedure by lubricating the nuts and bolts. Then hand tighten till they are snug against the flanges. If an air wrench is used make sure the pressure is set to the minimum. When tightening, always use the correct sequential bolt order for the flange.

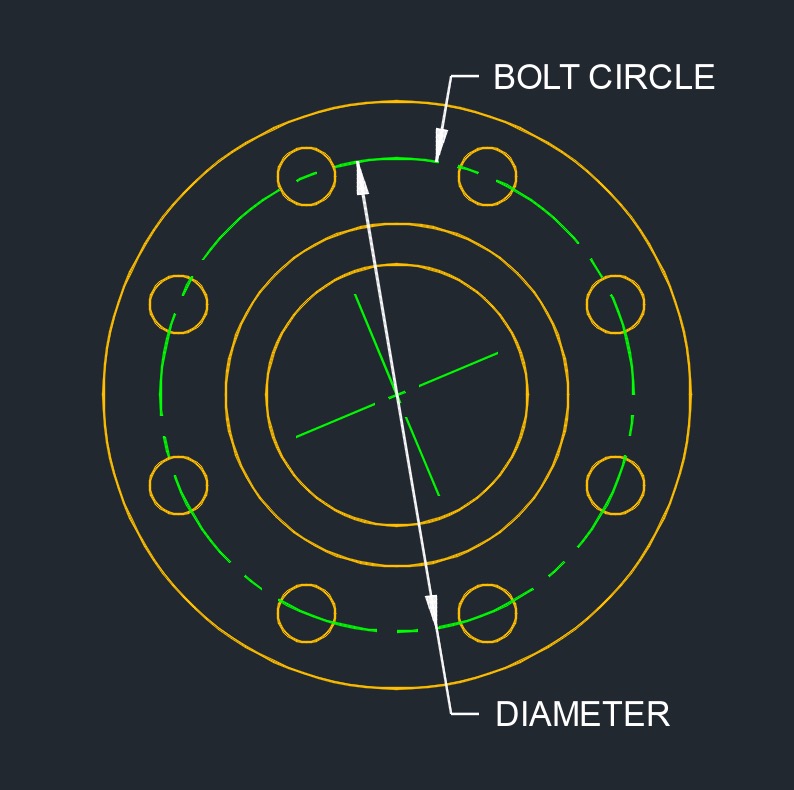

- See Article Links - Bolt Circle, Bolt Torque

4 and 8 Bolt Flanges

- First round - 30% of final torque (flange sequential order)

- Second round- 60% of final torque (flange sequential order)

- Third round - 100% of final torque (flange sequential order)

- One final time - clockwise or counter clockwise sequentially around the flange.

12 Bolt Flanges and More

- First round - 20% of final torque (flange sequential order)

- Second round - 40% of final torque (flange sequential order)

- Third round - 80% of final torque (flange sequential order)

- Fourth round - 100% of final torque (sequential order)

- One final time - clockwise or counter clockwise sequentially around the flange.

Bolt Standards

- ASME Standards

- ASME PCC-1 - Guidelines for Pressure Boundary Bolted Flange Joint Assembly

- ISO Standards

- ISO 4162 - Hexagon bolts with flange - Small series - Product grade A with driving feature of product grade B

- ISO 15071 - Hexagon bolts with flange - Small series - Product grade A

- ISO 15072 - Hexagon bolts with flange with metric fine pitch thread - Small series - Product grade A

- ISO 21670 - Fasteners - Hexagon weld nuts with flange

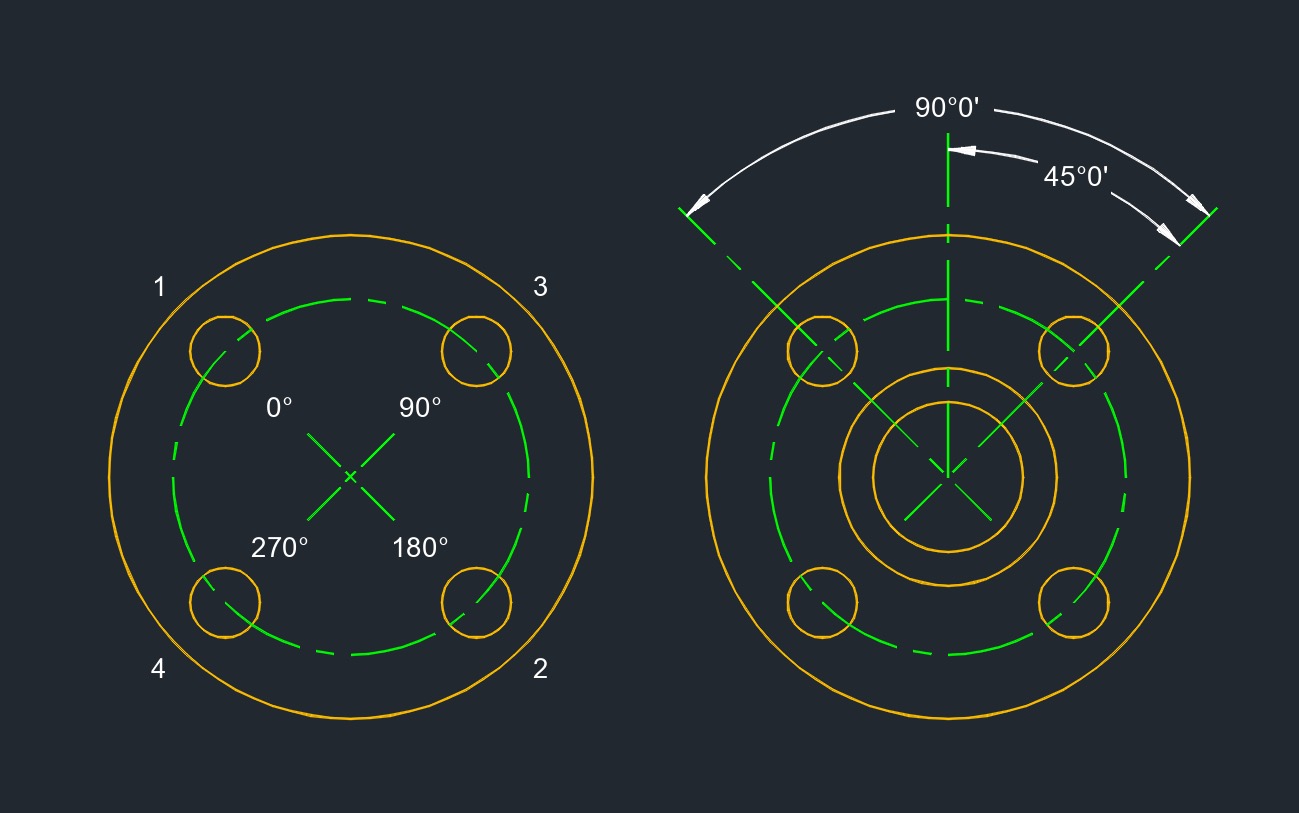

Four Bolt Tightening Sequence

- Sequential Order: 1-2, 3-4

- Rotation Order: 1, 3, 2, 4

Eight Bolt Tightening Sequence

- Sequential Order: 1-2, 3-4, 5-6, 7-8

- Rotation Order: 1, 5, 3, 7, 2, 6, 4, 8

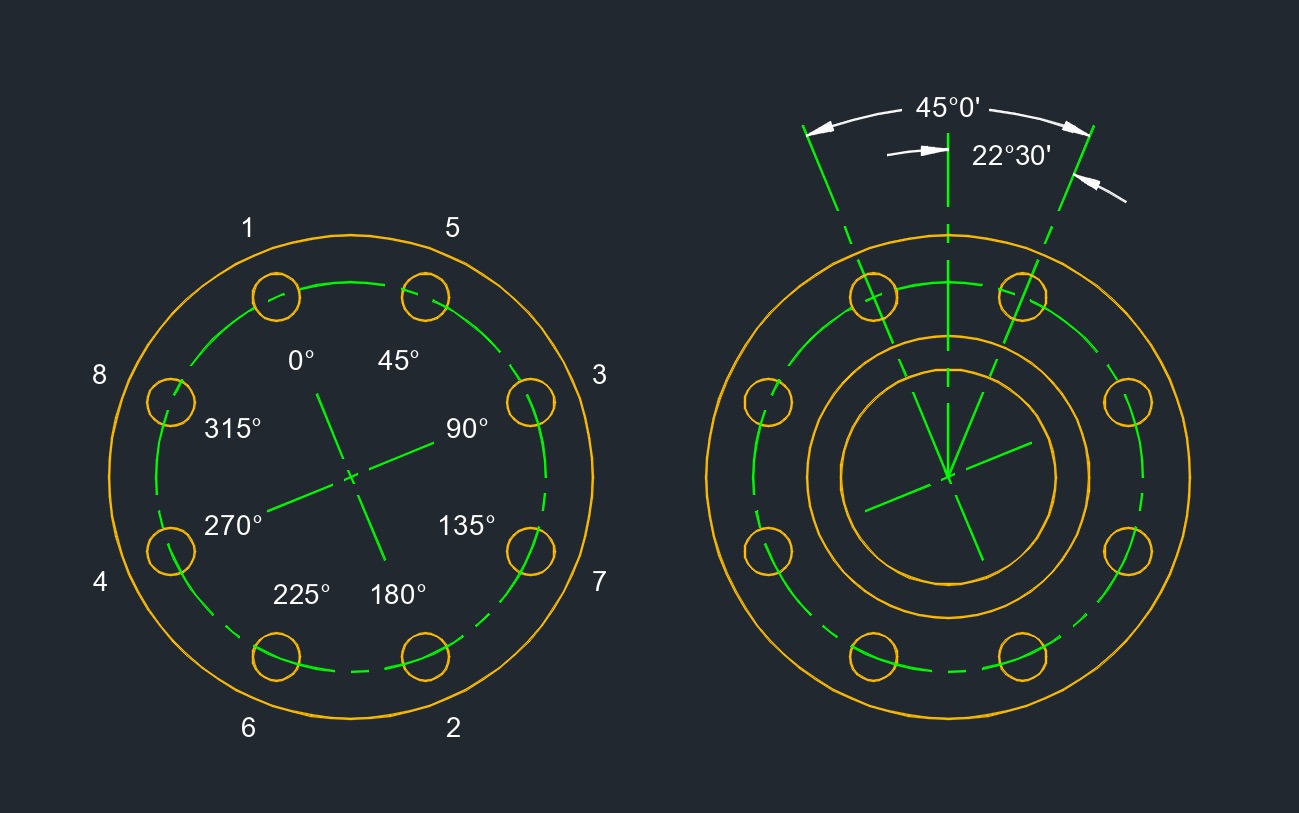

Twelve Bolt Tightening Sequence

- Sequential Order: 1-2, 3-4, 5-6, 7-8, 9-10, 11-12

- Rotation Order: 1, 5, 9, 3, 7, 11, 2, 6, 10, 4, 8, 12

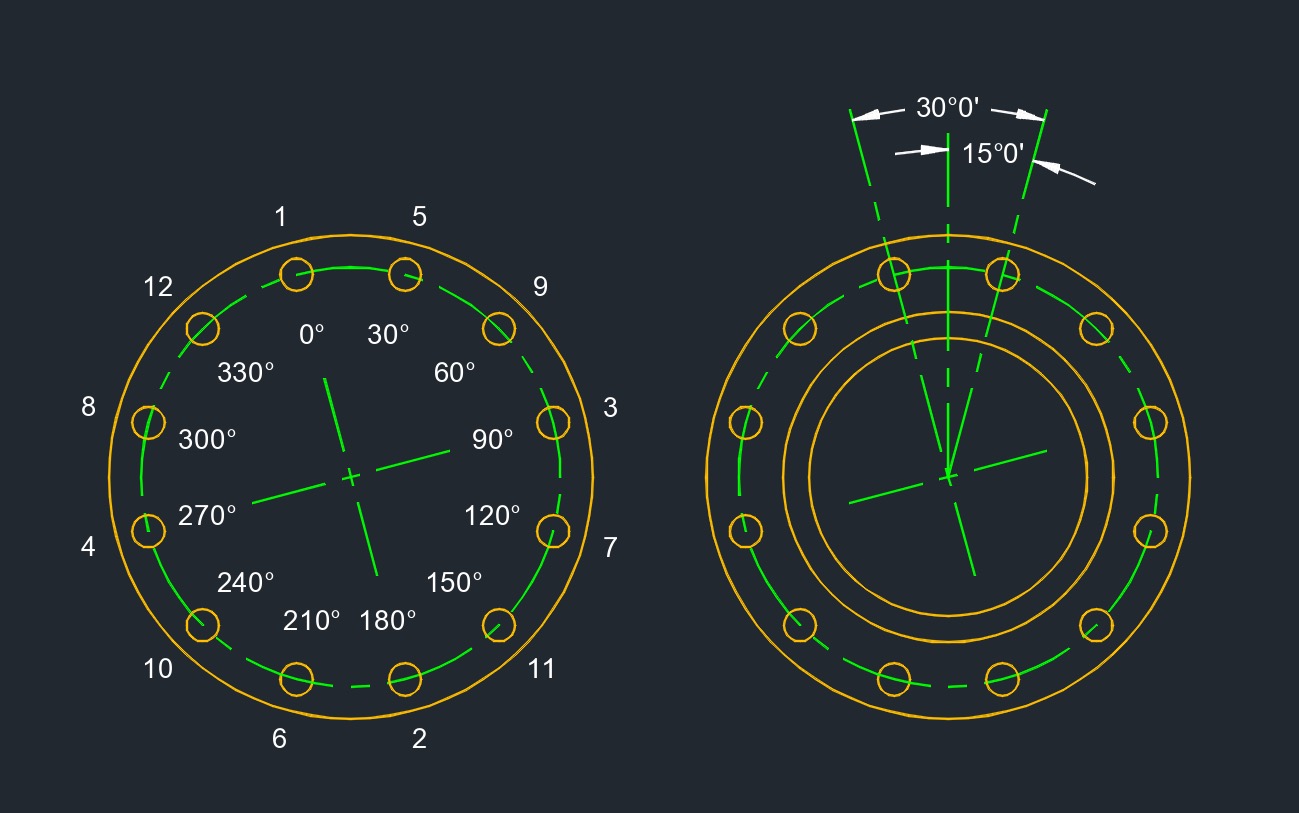

sixteen Bolt Tightening Sequence

- Sequential Order: 1-2, 3-4, 5-6, 7-8, 9-10, 11-12, 13-14, 15-16

- Rotation Order: 1, 9, 5, 13, 3, 11, 7, 15, 2, 10, 6, 14, 4, 12, 8, 16

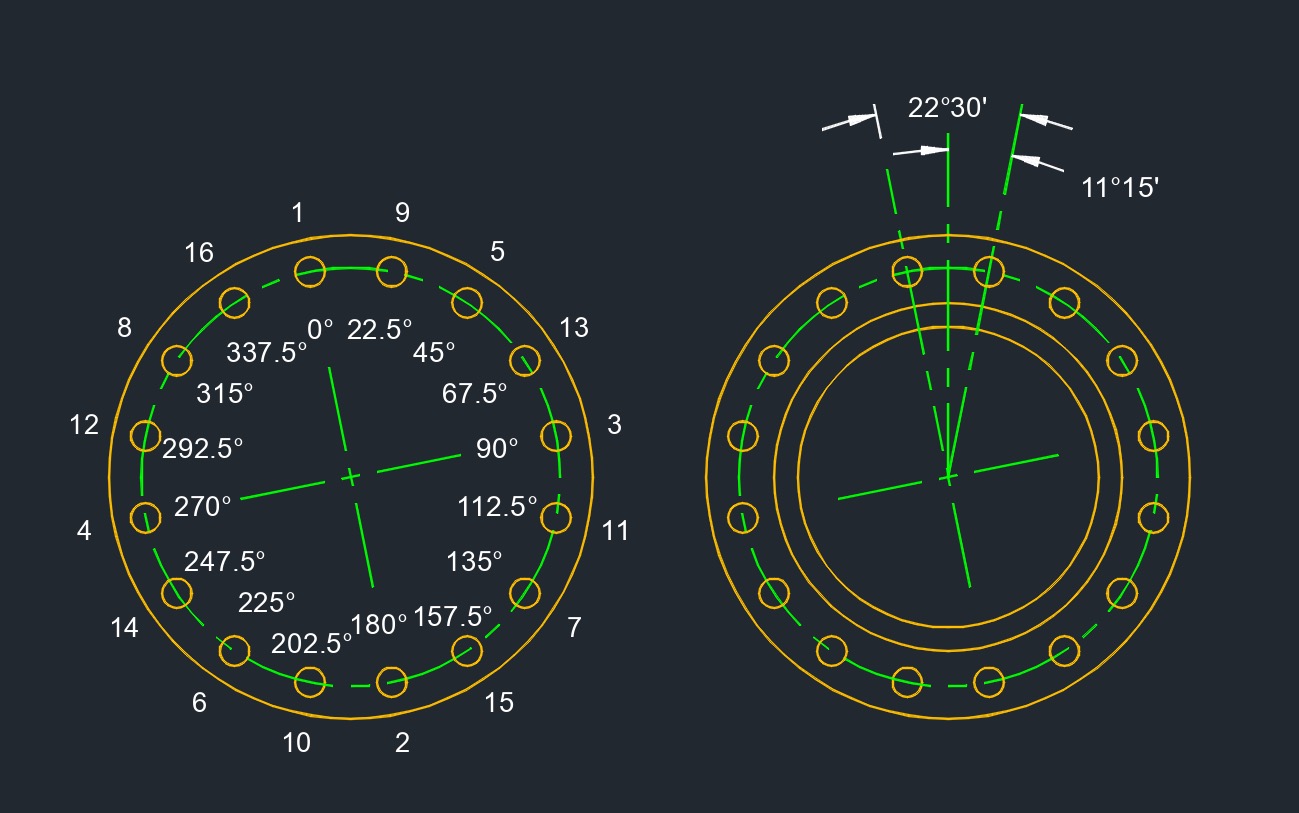

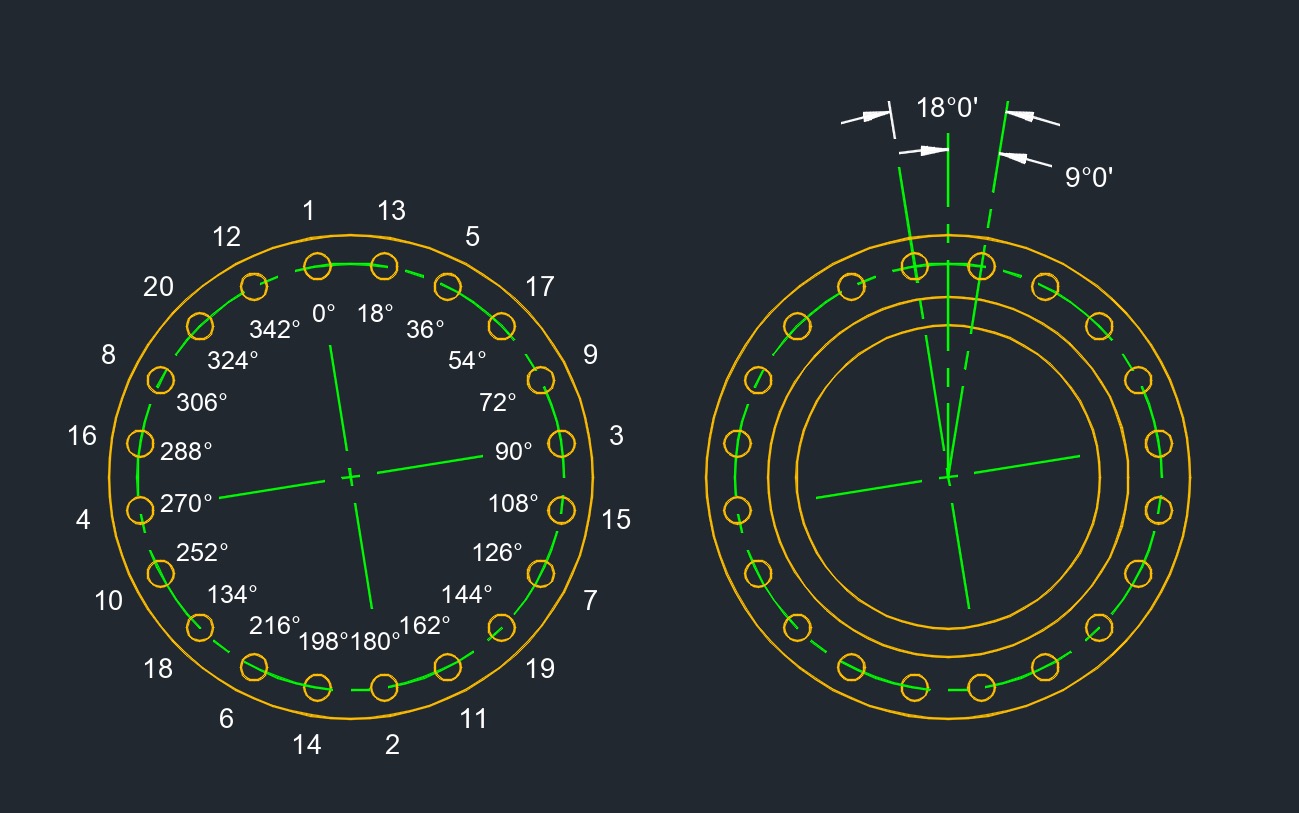

Twenty Bolt Tightening Sequence

- Sequential Order: 1-2, 3-4, 5-6, 7-8, 9-10, 11-12, 13-14, 15-16, 17-18, 19-20

- Rotation Order: 1, 9, 5, 13, 3, 11, 7, 15, 2, 10, 6, 14, 4, 12, 8, 16

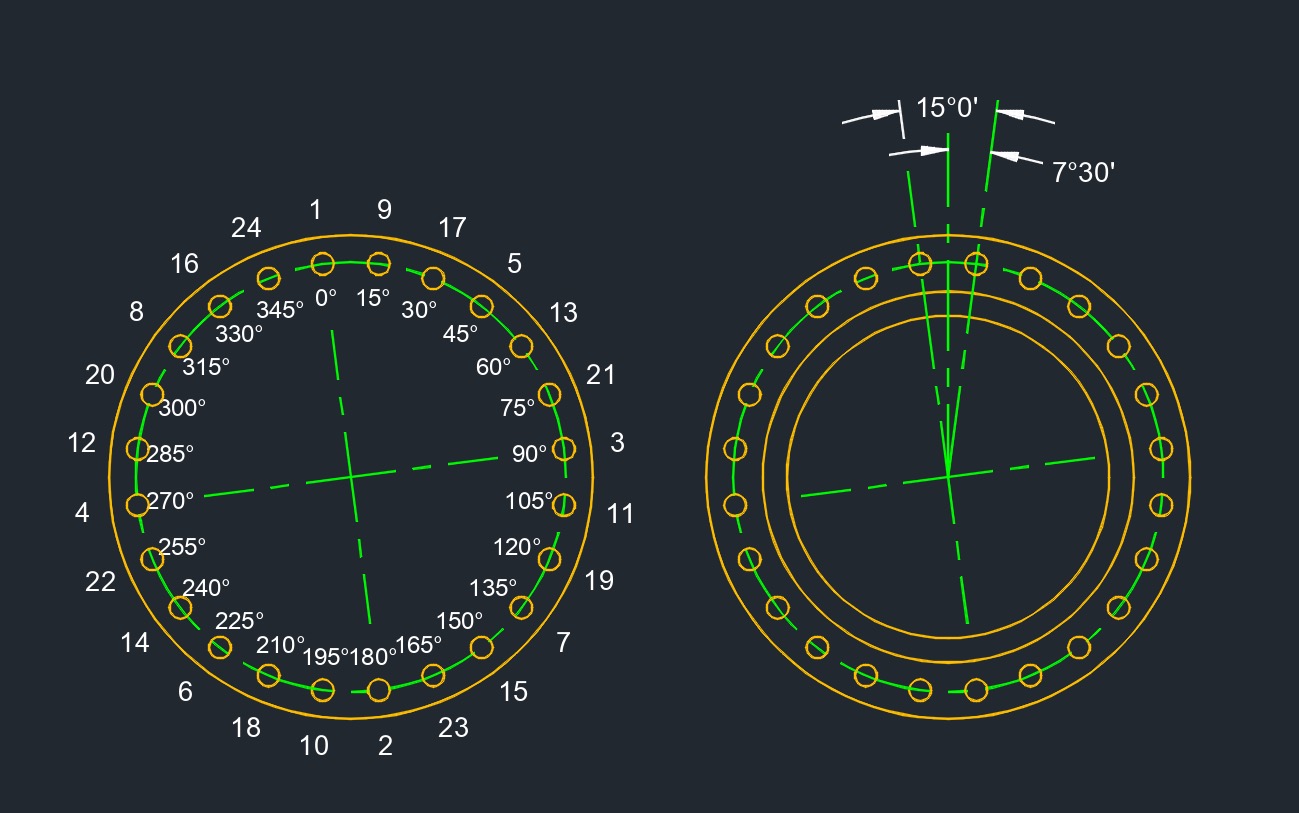

Twenty Four Bolt Tightening Sequence

- Sequential Order: 1-2, 3-4, 5-6, 7-8, 9-10, 11-12, 13-14, 15-16, 17-18, 19-20, 21-22, 23-24

- Rotation Order: 1, 9, 17, 5, 13, 21, 3, 11, 19, 7, 15, 23, 2, 10, 18, 6, 14, 22, 20, 8, 16, 24

Bolt Tightening Datasheets |

|

|

|

|

Tags: Pipe Flange Valve Gasket Fastener