Heater Treater

A heater treater is a pressure vessel that uses heat and residence time to separate clean, dry oil from incoming fluids. It usually is located immediately downstream of the Free Water Knockout during the oil dehydration process. The heat allows for easier separation of the oil and water and also allows solid particles such as sand and corrosive products to settle out. The quality of the effluent oil is measured with a bulk sediment and water (BS&W) probe.

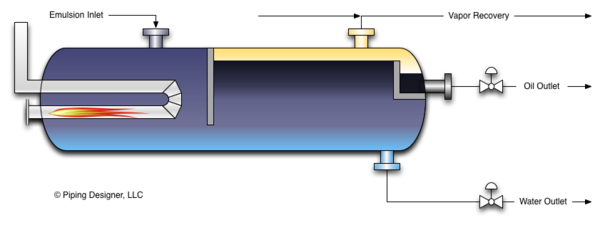

There are two separate sections in a heater treater, the heating section and the treating section. The heating section is where fluid is received and heat is applied. Heat can be applied with a burner or steam coils. The heat causes the viscosity of the oil to drop and flow through the water phase easier. At the boundary of the heating section, there is an internal weir which directs flow to the treating section. In the treating section, a lowered oil viscosity and residence time cause the oil to separate from the water.

Gas from the process stream collects in the top portion of the vessel and exits the vessel through a nozzle designed to hold back pressure on the vessel. Water from the stream exits through the bottom of the vessel. The water is then sent to further processing to remove any additional bulk sediment or trace oil particles. Following this, the water may be filtered and softened for use in steam generation or water injection.

Oil is collected from a weir box near the top of the vessel. Oil discharge may be flow controlled by a control valve or might dump with assistance of an on/ off control valve. At this point, the oil should of sufficient quality for sale and it either transferred directly to a LACT Unit or a holding tank.

Schematic View of a Heater Treater

Schematic View of a Heater Treater

Heater Treater Advantages and Disadvantages | |

|---|---|

| Advantages | Disadvantages |

|

|

Heater Treater Styles

Heater treaters can be either direct fired or indirect fired. The orientation of the pressure vessel can be horizontal or vertical. The main difference between a horizontal and vertical orientation is residence time. A horizontal heater treater has longer residence time than a vertical one.

- Direct Heater - A direct fired heater treater is designed such that the transfer of heat is accomplished by direct contact of the fluid with the firebox/ fire-tube. Direct fired heater treaters are more efficient than indirect fired heater treaters. With a direct fired heater treater, care must be taken to ensure that the fluid level never drops below any portion of the fire tube. If the level drops below the top of the firebox/ fire-tube the heat generated by the burner cannot be dissipated as quickly by the fluids and could cause self-ignition of the gas blanked. For this reason, the heated section of a heater treater is usually fluid packed.

- Indirect Heater - An indirect fired heater treater is one where the heating element heats the water or another heating medium and the heating medium is then used to transfer heat to the process stream. An indirect fired heater treater might be used if the production stream is sandy. Sand falling out of the emulsion can collect on the fire-tube and cause overheating (hot spots) of the tube. In general, an indirect fired heater is less efficient than a direct fired heater because heat from the burner needs to be transferred to the heating medium which is then transferred to the process stream.

Heater Treater Design Considerations

- Sand & Sediment - Solid particles such as sand and sediment will separate from the emulsion and will collect at the bottom of the heater treater. Over time, solids accumulation will cause the capacity of the treater to become diminished. Just as importantly, if particulate collects on the fire tubes, it will create hotspots and cause failure of the fire tube. Vessel design is very important to mitigate issues caused by sand. Water jets can be used in conjunction with sand drains to remove accumulated sand. Other design features can help keep clean the heater treater by using currents caused by the heating process.

- Sizing - A heater treater should be designed for a certain amount of residence time. This would be dictated by the API gravity, inlet temperature, flow rate, emulsion tightness and specifications required of the outlet stream. For example, sale quality oil (3% BS&W) will need to spend more time in the heater treater than oil that is not sale quality.

- Pressure Relief - All pressure vessels should have some pressure relief device to guarantee that the internal pressure does not exceed design requirements. Ensure that the pressure relief valve does not get plugged up with sand or sediment. To mitigate against this, locate the relief device near the top of the vessel.