Barred Tee

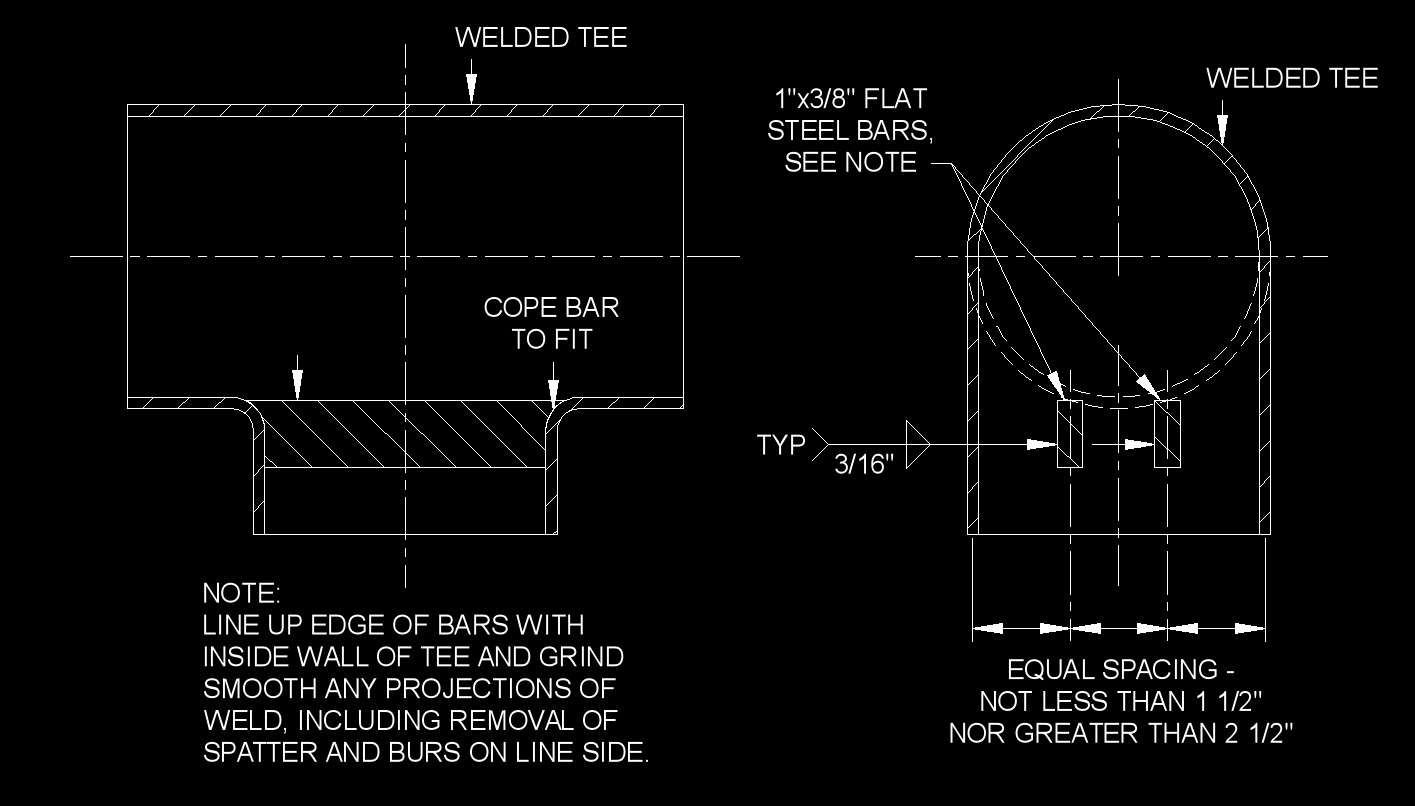

A barred tee is a tee or any fitting with a branch used in pipelines that is pigged and has a restriction bar welded internally preventing the pig from traveling down a branch connection. The bars are installed so they are flush with the inside diameter of the pipeline to keep the pig from hanging up when it passes through. The bars should be of a similar or identical material as the parent material.

A barred tee is a tee or any fitting with a branch used in pipelines that is pigged and has a restriction bar welded internally preventing the pig from traveling down a branch connection. The bars are installed so they are flush with the inside diameter of the pipeline to keep the pig from hanging up when it passes through. The bars should be of a similar or identical material as the parent material.

Bars are placed on the internal side of a tee or really any branch connection big enough to sidetrack a pig while traveling down a pipeline. The size of the bars on the tee should be small enough so that they do not restrict the flow from the branch connection. However, they should be large enough to prevent breakage based on the flow rate through the branch connection of the tee.

Barred Tee Advantages and Disadvantages | |

|---|---|

| Advantages | Disadvantages |

|

|

Tee vs Barred Tee

A tee and a barred tee are both types of pipe fittings used in plumbing and piping systems, but they serve different purposes.

- Tee - A tee is a T-shaped pipe fitting with three openings. It allows the flow of fluid to be combined or divided into two directions. Tees are commonly used in pipelines to create branch connections, allowing for the distribution of fluid to multiple locations. They come in various configurations, such as straight tee (where all three openings are of the same size) and reducing tee (where one or more openings are of a different size than the others).

- Barred Tee - A barred tee is a type of tee fitting with a "bar" across the branch opening. This solid barrier helps to deflect the flow of fluid in one direction while allowing flow to continue in the other direction. Barred tees are typically used in pipelines where pigging operations are necessary. Pigging involves using devices called pigs to clean, inspect, or maintain pipelines. The solid bar in a barred tee helps guide the pig through the pipeline without it entering the branch line.

In summary, the main difference between a tee and a barred tee lies in their design and intended use. Tees are used to create branch connections in piping systems, while barred tees are specifically designed to facilitate pigging operations in pipelines by providing a solid barrier to guide pigs.

Barred Tee Design Requirements

- The applications of these tees can be in used above ground or subsea pipelines.

- The bar plates prevent the pig from changing direction or becoming jammed at the branch outlet.

- The bar plates must be of good quantity, thickness, and spacing for the pig to maintain a smooth flow through the pipe with no interference from the branch.

- A rule of thumb is that the opening in the branch pipeline after guided bars does not exceed 40% of the main pipeline area.

- The branch connection bars size must be small enough not to limit flow while being large enough not to restrict the flow pressure.

- The bar plates must be machined to match the branch curve and sharp edges, spatters must be eliminated.

- The smoothness of the pigging procedure is critical for protecting the pig’s sensor from harm.

- The bar plates should be evenly spaced.

- A bridge plate should be installed in the middle of larger tee, sizes 14 inches and higher, to support the bar stiffness when hit by the pig.

- The material of the bar plates is generally the same as the material of the tee.

Barred Tee Buying

- Whearher the tee is welded or seamless

- Standards needed to follow

- Size and dimensions

- Wall thickness

- Material used to construct

- High pressure and temperature resistance

- Corrosion resistance

Barred Tee Standards

- ASME Standards

- ASME B16.9 - Factory-Made Wrought Buttwelding Fittings

- MSS Standards

- MSS SP-75 - High Test Wrought Butt Welding Fittings