Thrust Block

Step 1 - Resultant thrust FormulasResultant thrust is the overall thrust force acting on a pipeline at a change in direction or slope. It is the combined effect of the horizontal and vertical components of the thrust force. When a pipeline changes direction or slope, there is a tendency for the pipe to exert a force on the surrounding soil. The resultant thrust (R) is the vector sum of these horizontal and vertical components and is calculated using the Pythagorean theorem. |

||

|

\( R \;=\; \sqrt{ T_h^2 + T_v^2 } \) (Resultant Thrust) \( T_a \;=\; p \; A_c \) (Axial Thrust) \( T_h \;=\; T_a \; tan \left(\theta\right) \) (Horizontal Thrust) \( T_v \;=\; T_a \; tan \left(m\right) \) (Vertical Thrust) |

||

| Symbol | English | Metric |

| \( R \) = Resultant Thrust | \( lbf \) | \( N \) |

| \( T_h \) = Horizontal Thrust (Axial Thrust Caused by Changes in Slope) | \( lbf \) | \( N \) |

| \( T_v \) = Vertical Thrust (Axial Thrust Caused by Changes in Slope) | \( lbf \) | \( N \) |

| \( T_a \) = Axial Thrust (Force Acting Along the Pipe due to Changes in Direction or Slope) | \( lbf \) | \( N \) |

| \( p \) = Pipeline Internal Pressure | \(lbf \;/\; in^2\) | \( Pa \) |

| \( A_c \) = Pipeline Area Cross-section | \( in^3 \) | \( mm^3 \) |

| \( \theta \) = Bend Angle | \( deg \) | \( rad \) |

| \( m \) = Pipeline Slope | \( ft \) | \( m \) |

Thrust block, abbreviated as TB, is a structural component used in plumbing and pipeline systems to resist the axial forces or thrust generated by the fluid pressure within the pipes. These forces can occur when the fluid inside the pipe changes direction, such as when there are bends, tees, or other fittings in the pipeline. Thrust blocks are commonly used in underground water and sewer systems, as well as in other fluid transport systems. The primary purpose of a thrust block is to prevent the pipes from moving or separating due to the internal pressure forces.

Step 2 - thrust block Volume FormulasThrust block volume is the amount of concrete or material needed to construct a thrust block, which is a stabilizing structure used in the design of pipelines at changes in direction or slope. The purpose of a thrust block is to resist the forces generated by changes in the direction or slope of a pipeline and prevent movement or displacement. It's important for the thrust block to extend below the frost line and provide sufficient resistance against the horizontal and vertical components of the thrust forces. |

||

|

\( V_{tb} \;=\; M_b \;FS \;/\; S \; h \; FS_s \) (Thrust Block Volume) \( M_a \;=\; D \;/\; 2 \) (Moment Arm) \( M_b \;=\; R \; M_a \) (Bending Moment) |

||

| Symbol | English | Metric |

| \( V_{tb} \) = Thrust Block Volume | \( in^3 \) | \( mm^3 \) |

| \( M_b \) = Bending Moment | \(lbf \;/\; sec\) | \(kg-m \;/\;s\) |

| \( FS \) = Factor of Safety | \(dimensionless\) | \(dimensionless\) |

| \( S \) = Concrete Allowable Stress | \(lbf \;/\; in^2\) | \(Pa\) |

| \( h \) = Depth of the Thrust Block (How Deep the Block Extends into the Ground) | \( ft \) | \( m \) |

| \( FS_s \) = Factor of Safety of Soil Bearing Capacity | \(dimensionless\) | \(dimensionless\) |

| \( M_a \) = Moment Arm | \(lbf \;/\; sec\) | \(kg-m \;/\; s\) |

| \( D \) = OD of Pipe | \( in \) | \( mm \) |

| \( R \) = Resultant Thrust (see step 1) | \( lbf \) | \( N \) |

Thrust Block Advantages and Disadvantages | |

|---|---|

| Advantages | Disadvantages |

|

|

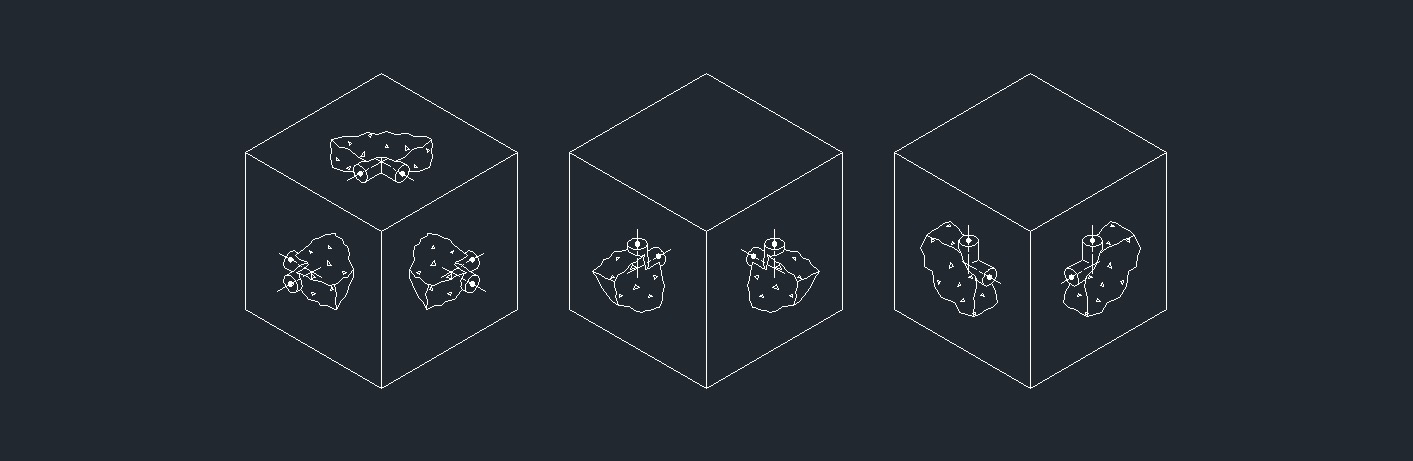

Thrust Block Drawings