Welding Symbols

Welding symbols are graphical representations used in engineering and construction to convey information about the welding process and requirements for joining metal components. These symbols are standardized and follow guidelines established by organizations like the American Welding Society (AWS) and the International Organization for Standardization (ISO).

Welding symbols are typically included in engineering drawings and blueprints to provide welders, inspectors, and other stakeholders with clear and concise information about the type of weld, its dimensions, location, and other essential details. These symbols help ensure consistency and accuracy in the welding process.

|

See Articles

|

See Articles

|

Welding symbols play a crucial role in ensuring that welding processes are accurately understood and executed according to design specifications. They facilitate effective communication between design engineers, welders, and quality control personnel, ultimately leading to properly welded joints that meet the required standards for strength, integrity, and appearance.

Weld Symbols

Fillet

Fillet  Square Groove

Square Groove  Plug or Slot

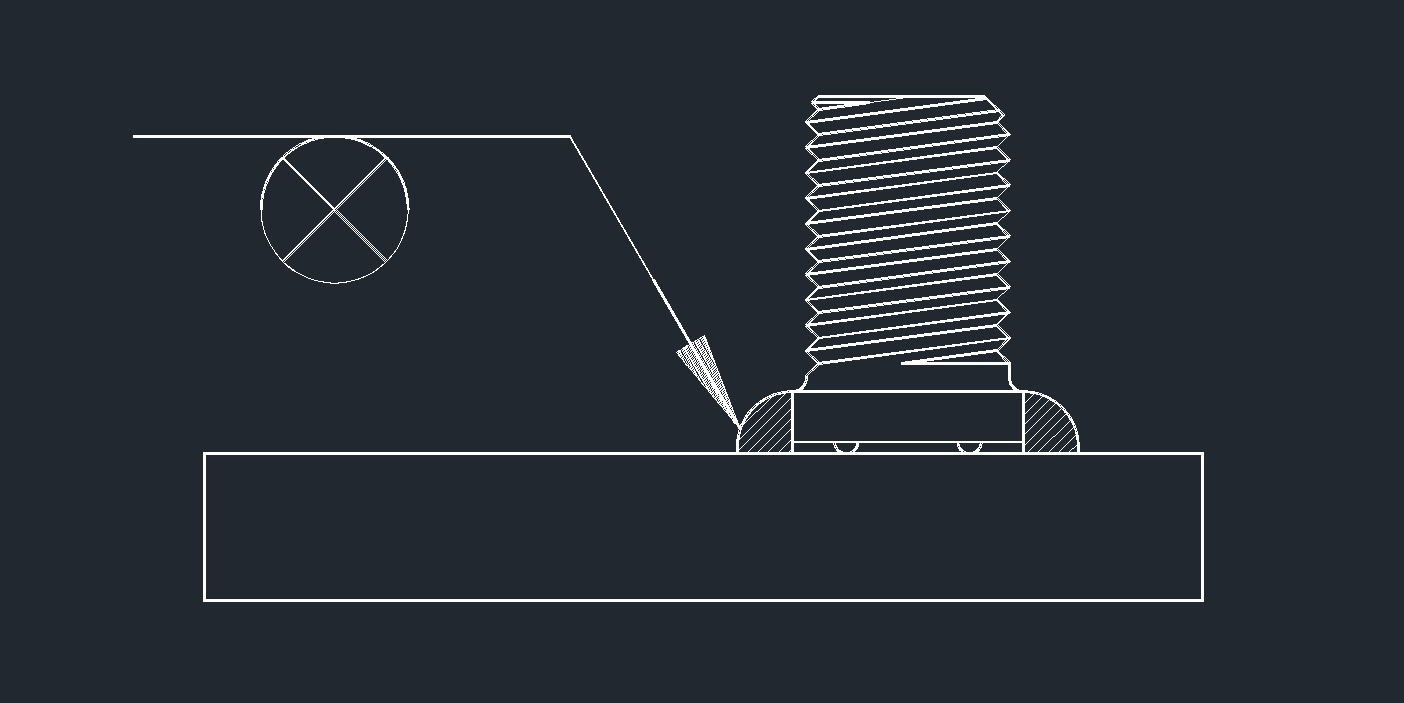

Plug or Slot  Stud

Stud

Flare Bevel

Flare Bevel  Flare Groove

Flare Groove  Bevel Groove

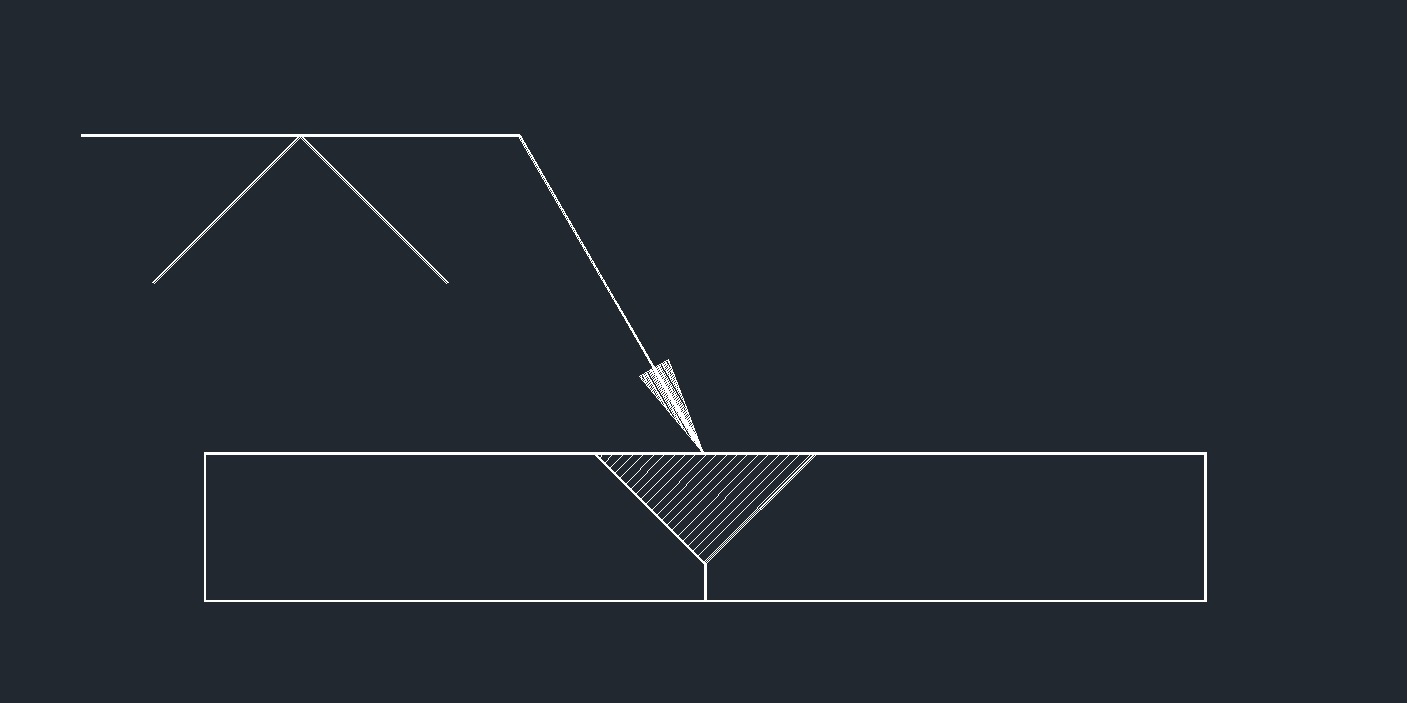

Bevel Groove  V Groove

V Groove

J Groove

J Groove  U Groove

U Groove  Flange Corner

Flange Corner  Flange Edge

Flange Edge

Back of Backing

Back of Backing  Surfacing

Surfacing  Spot or Projection

Spot or Projection  Seam

Seam

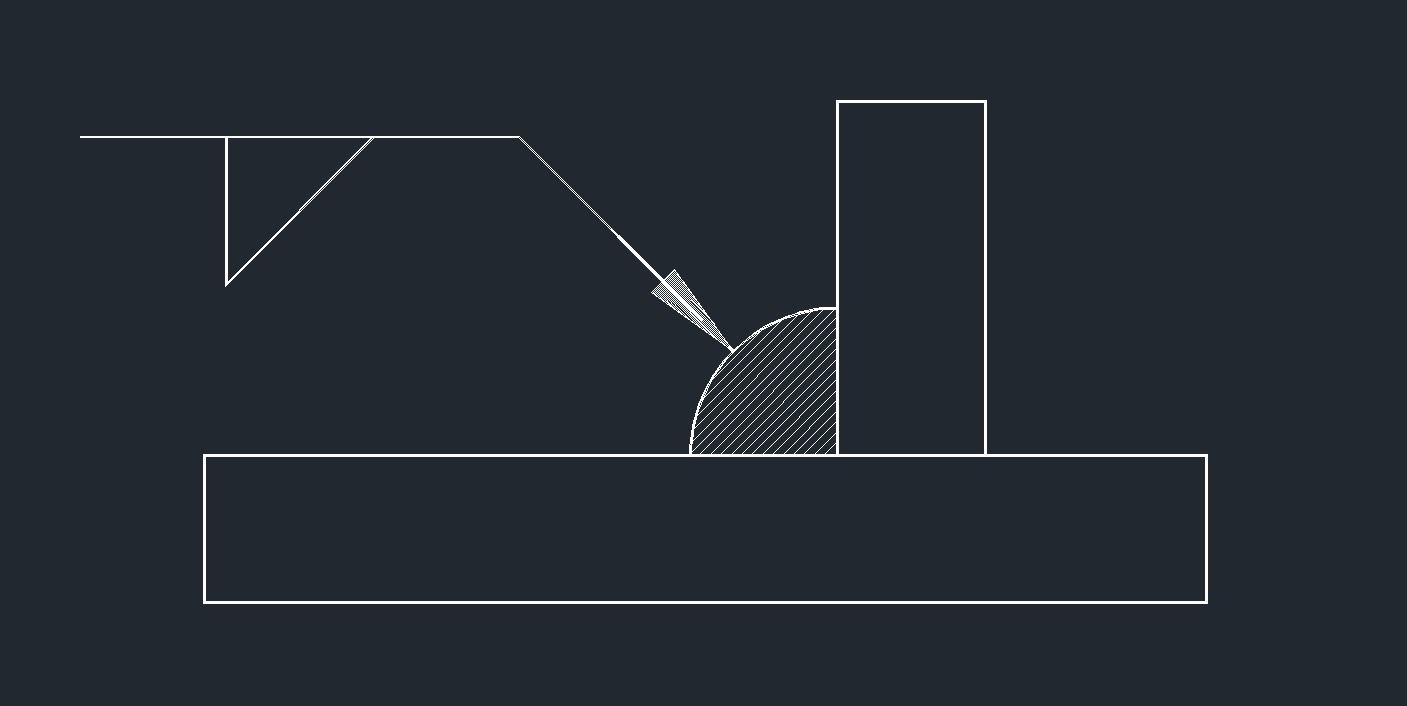

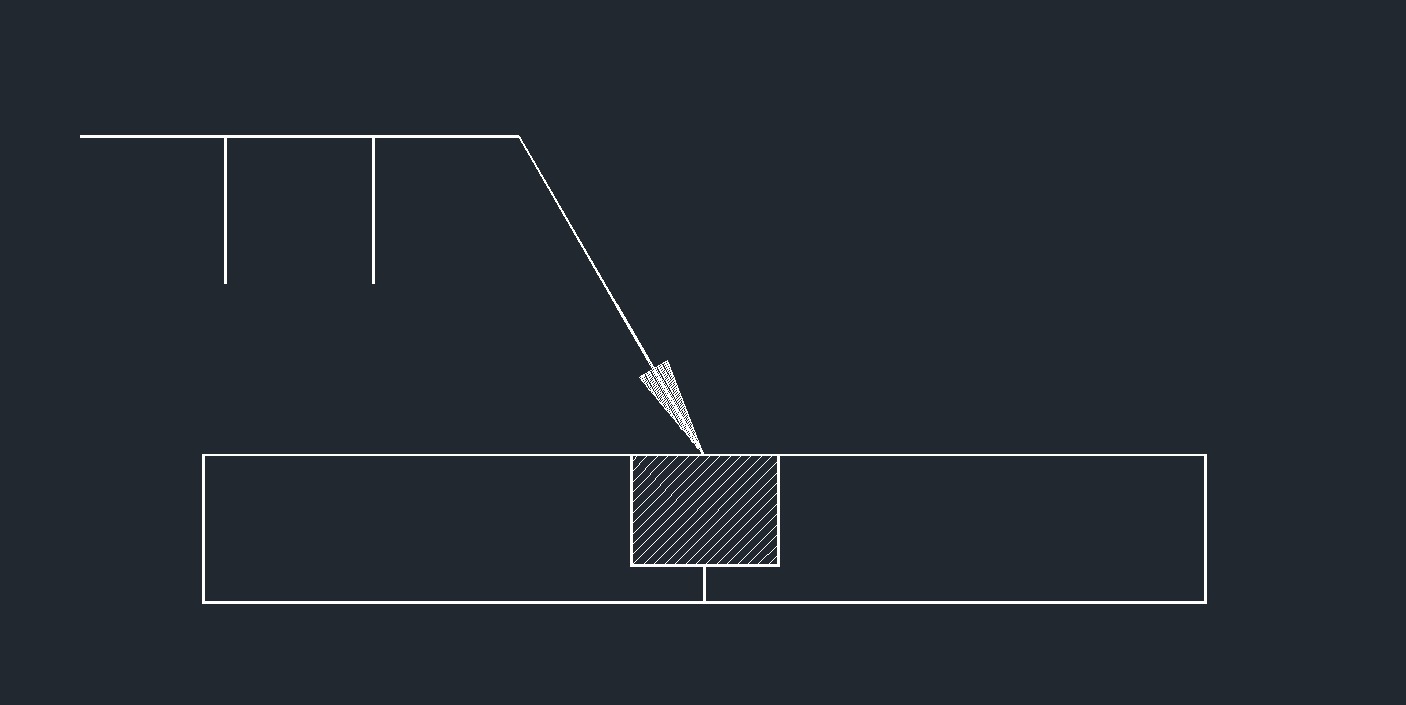

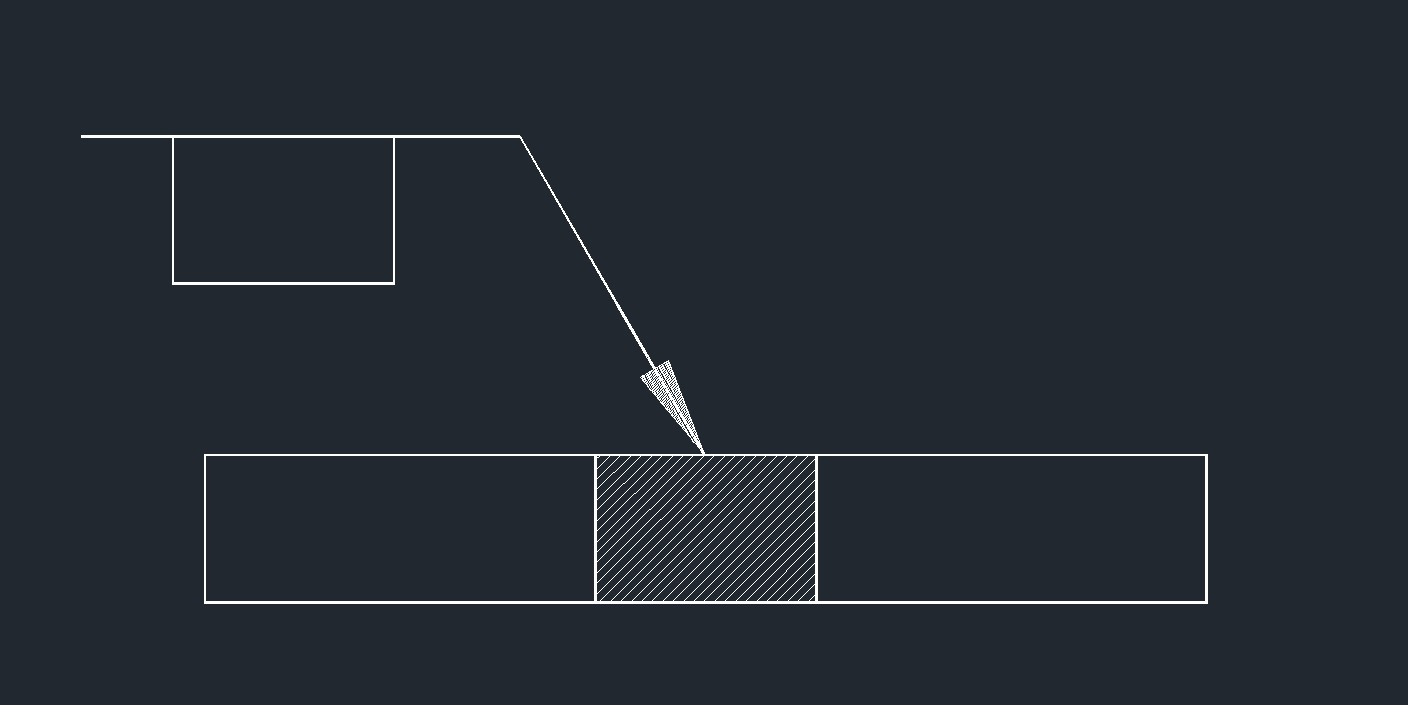

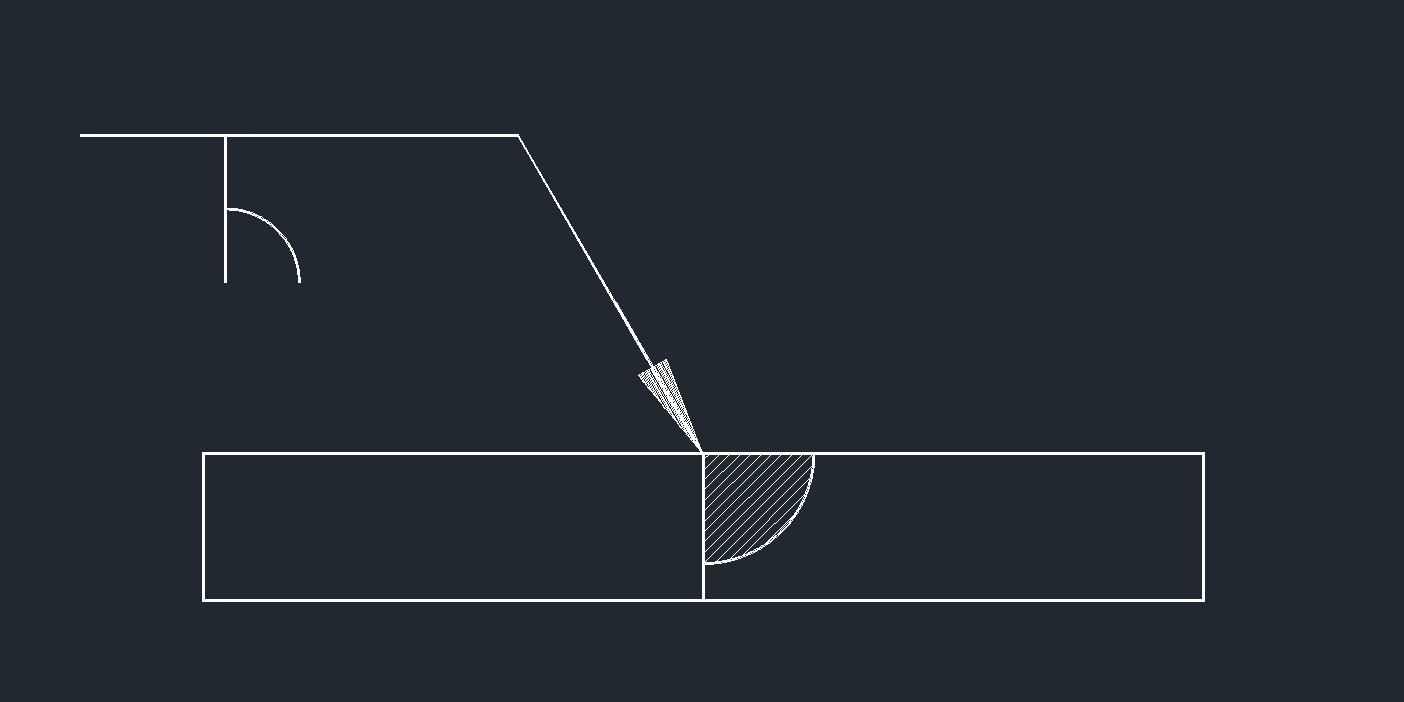

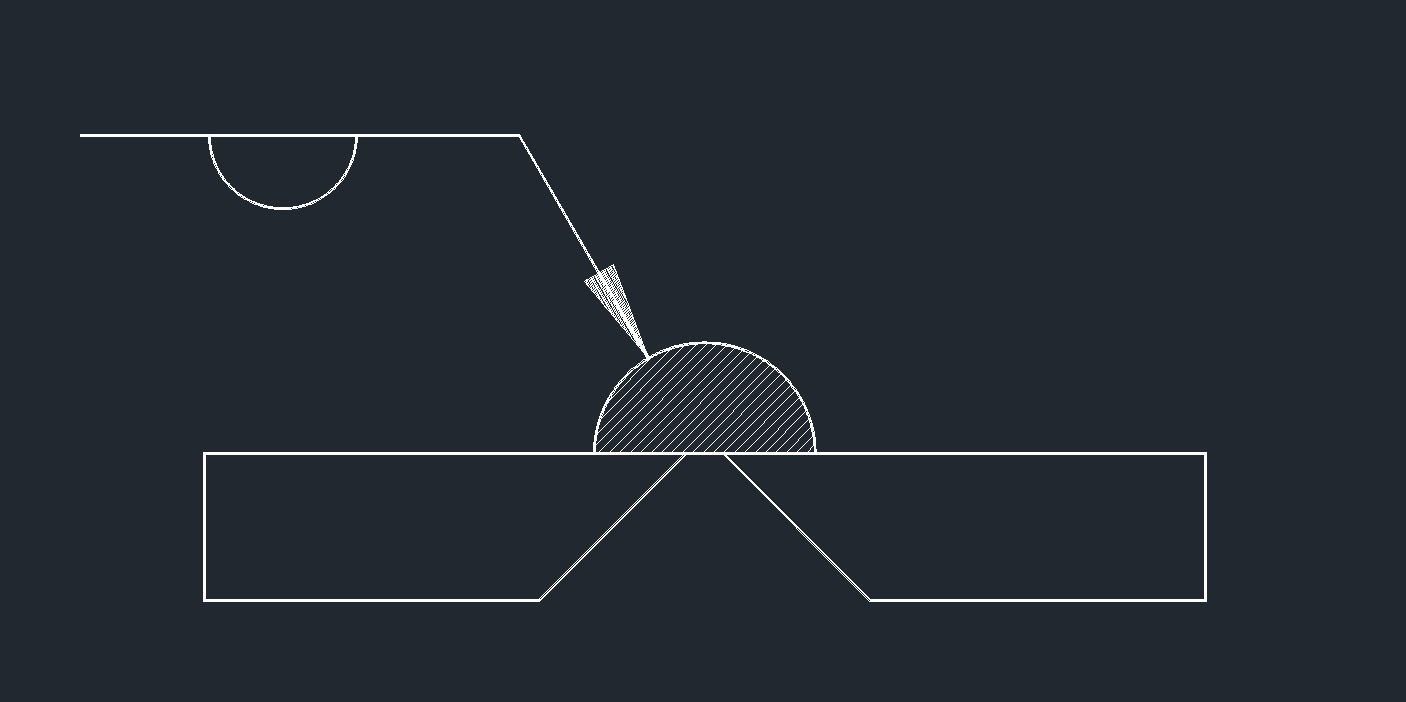

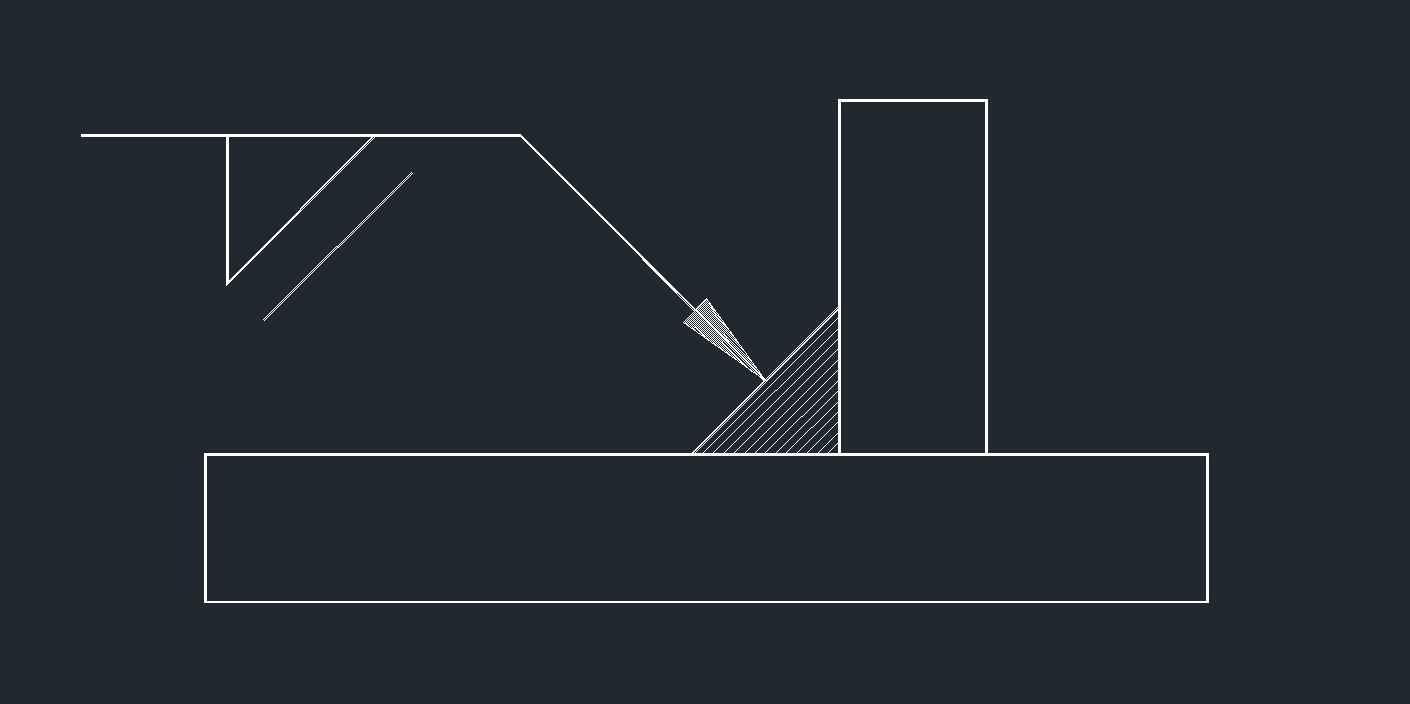

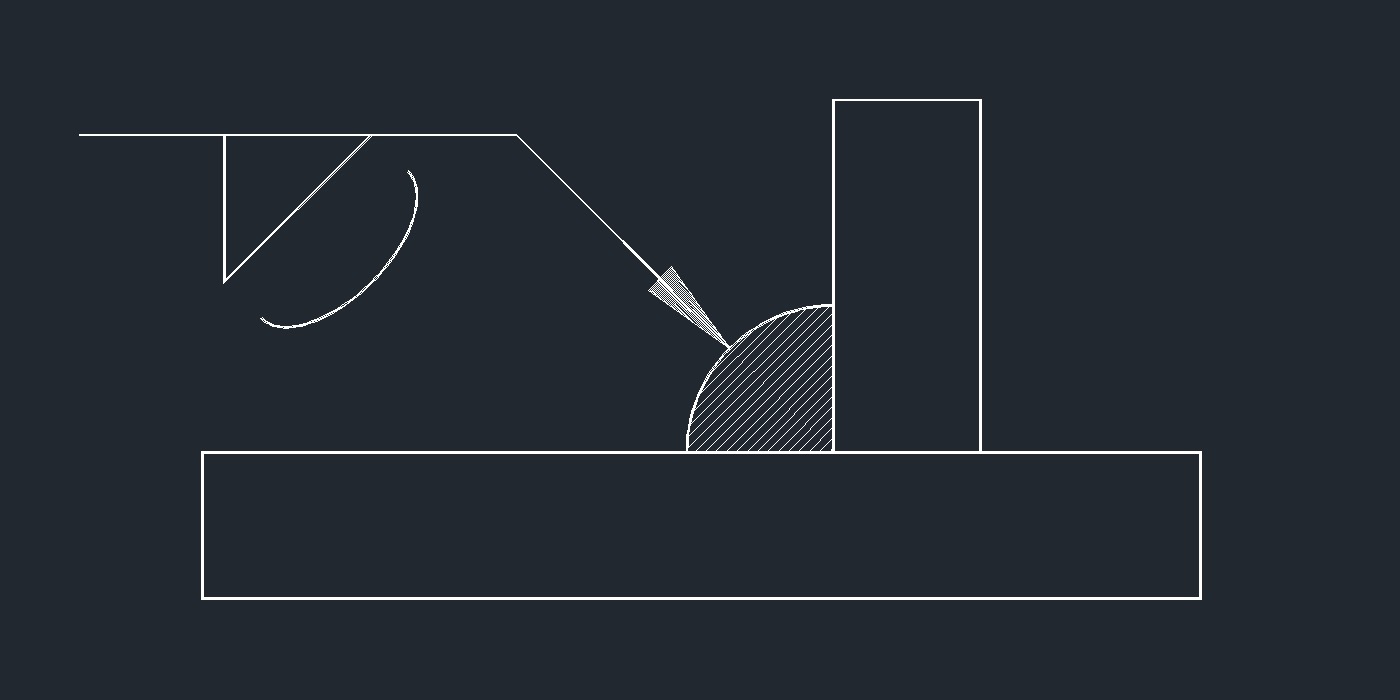

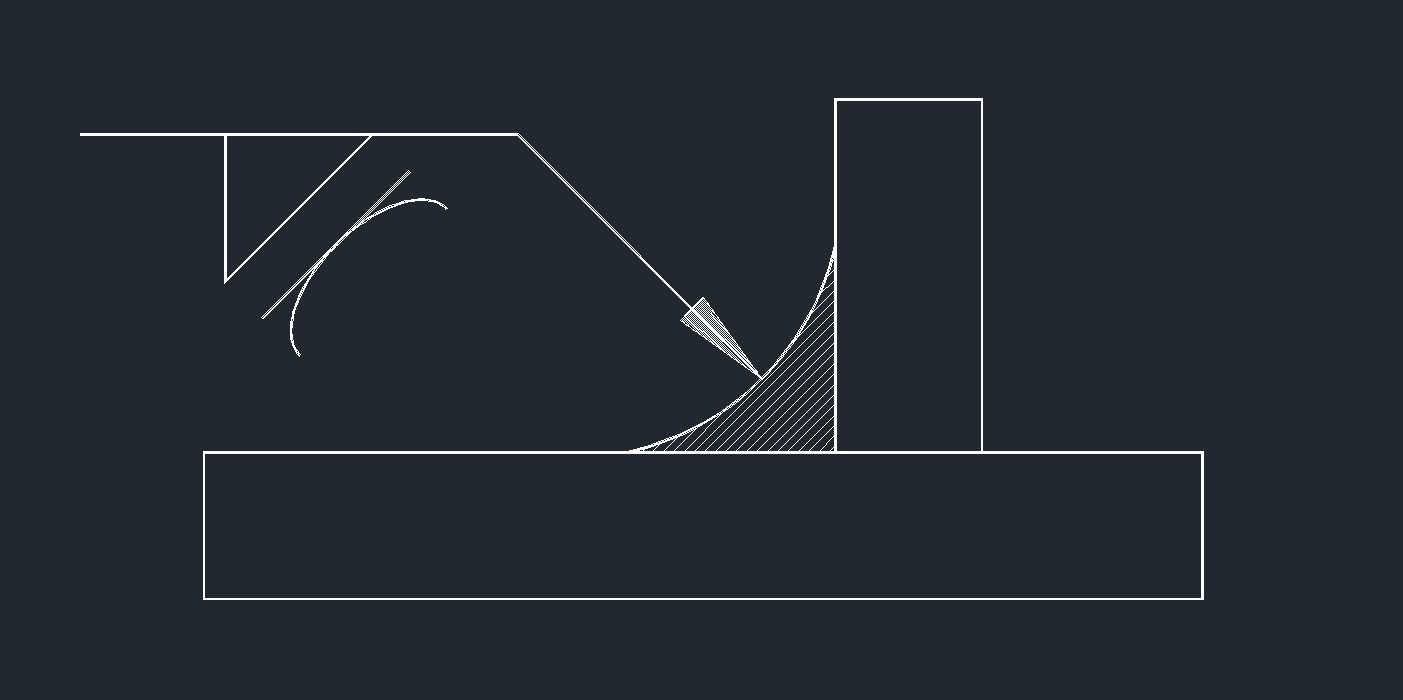

Fillet Weld Symbols

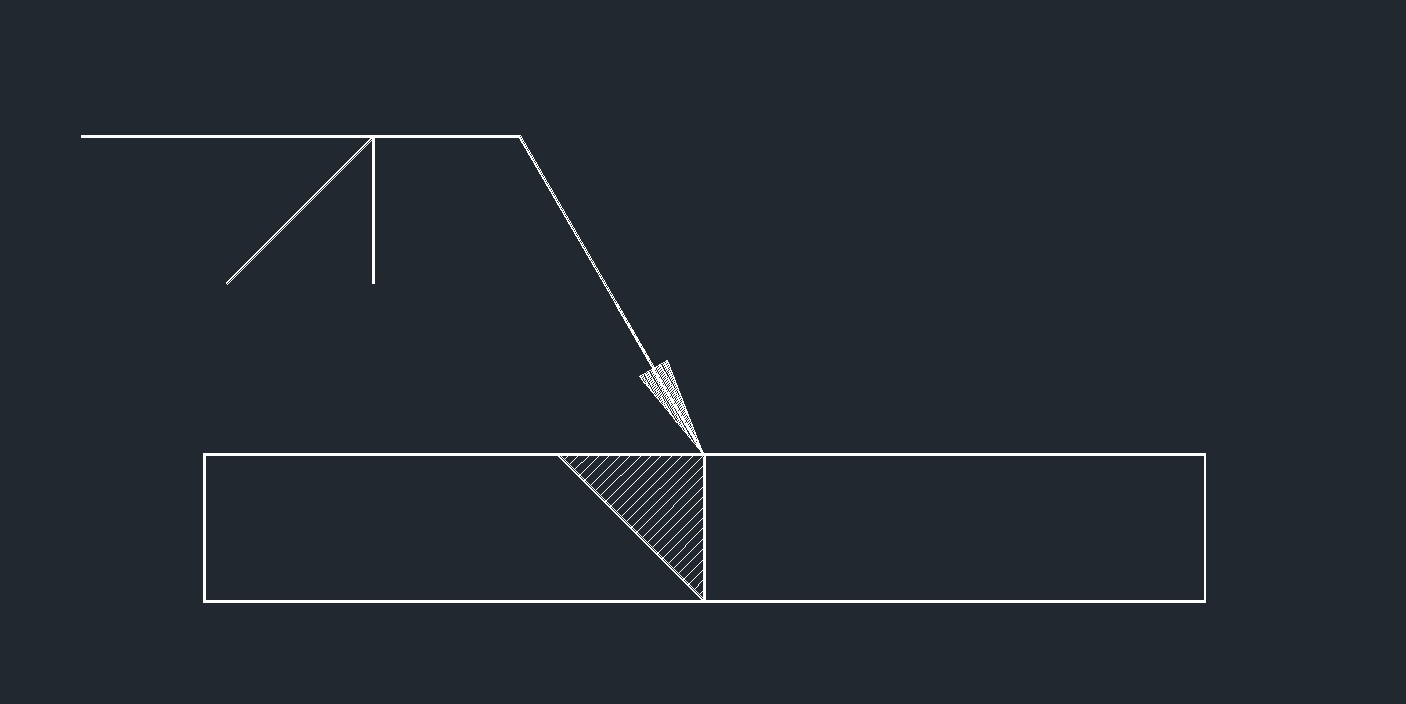

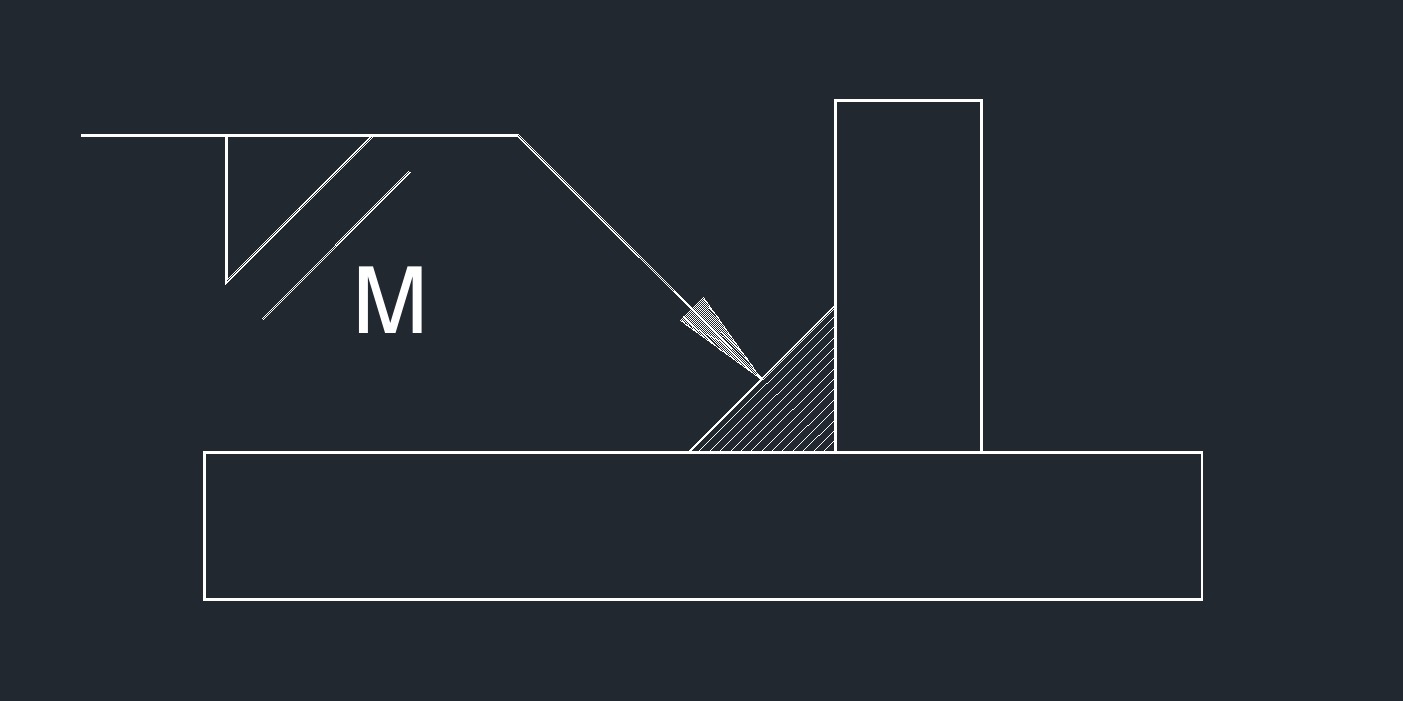

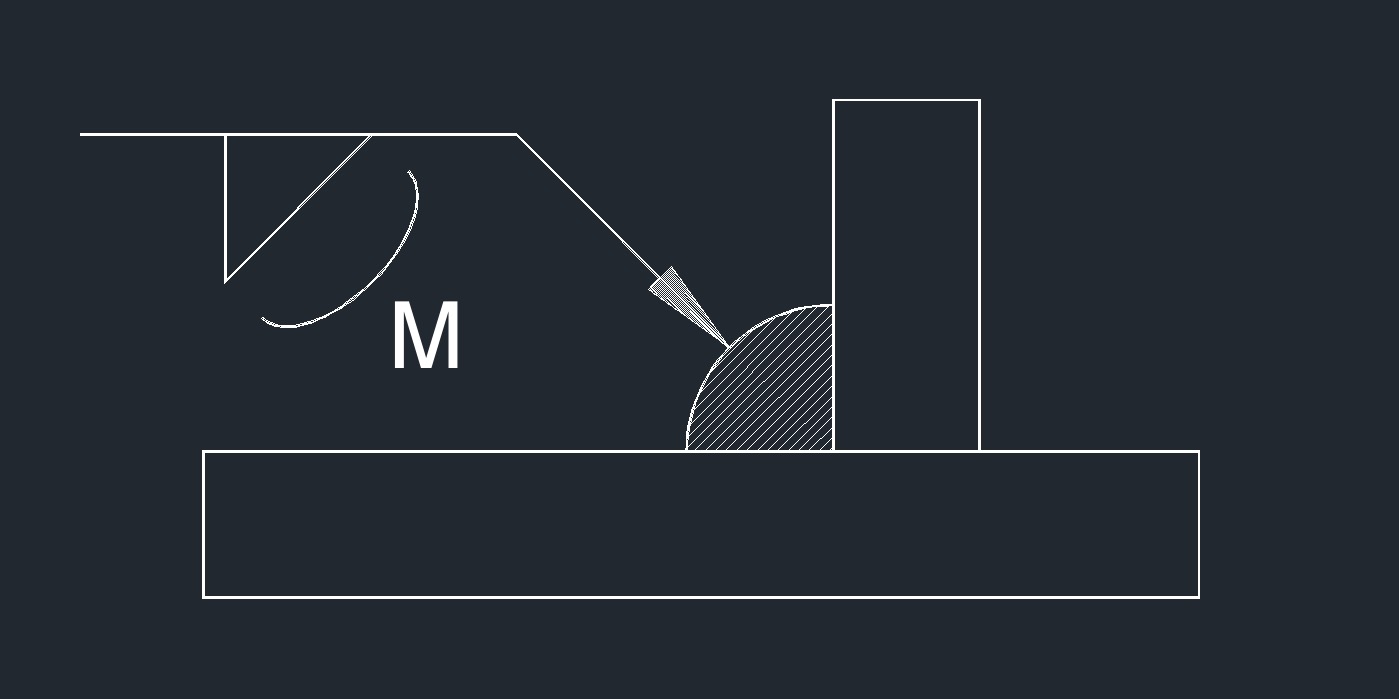

Miter Contour Fillet

Miter Contour Fillet Miter Machining Fillet

Miter Machining Fillet  Miter Grinding Fillet

Miter Grinding Fillet  Miter Chipping Fillet

Miter Chipping Fillet

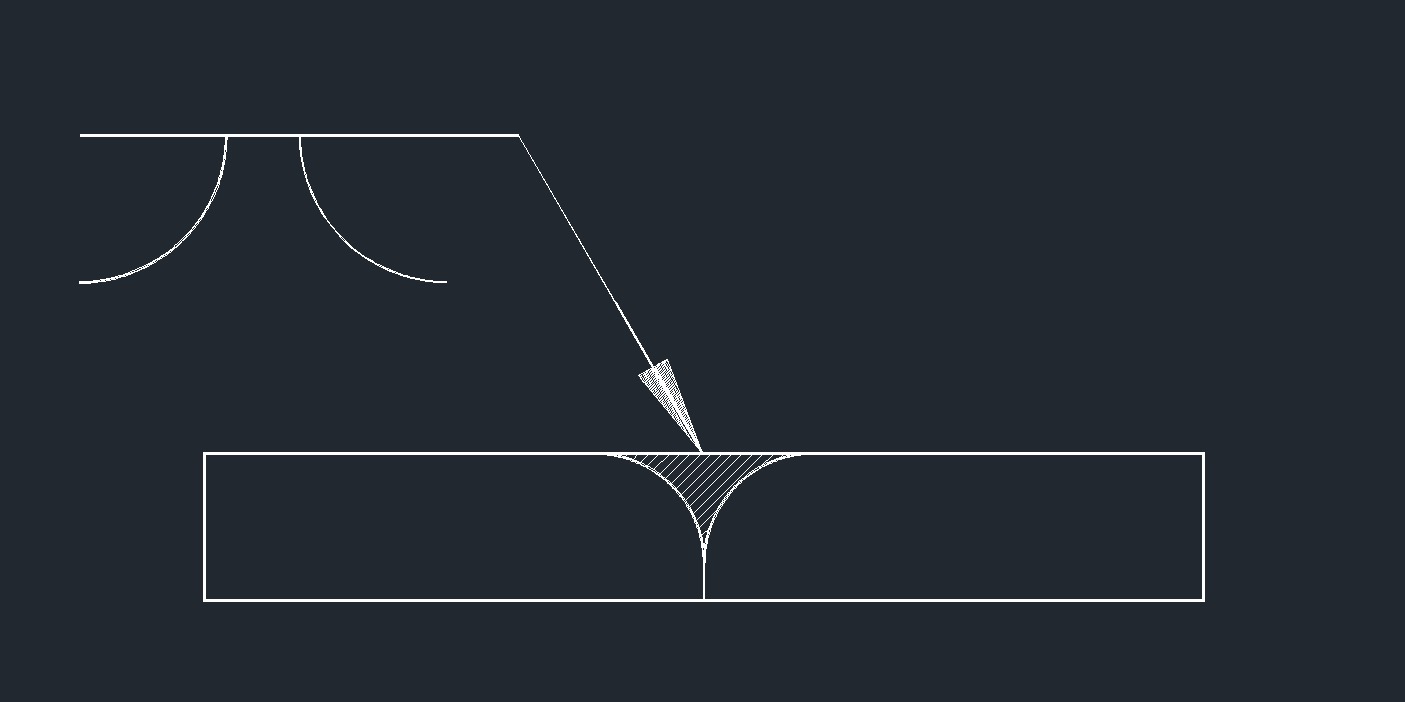

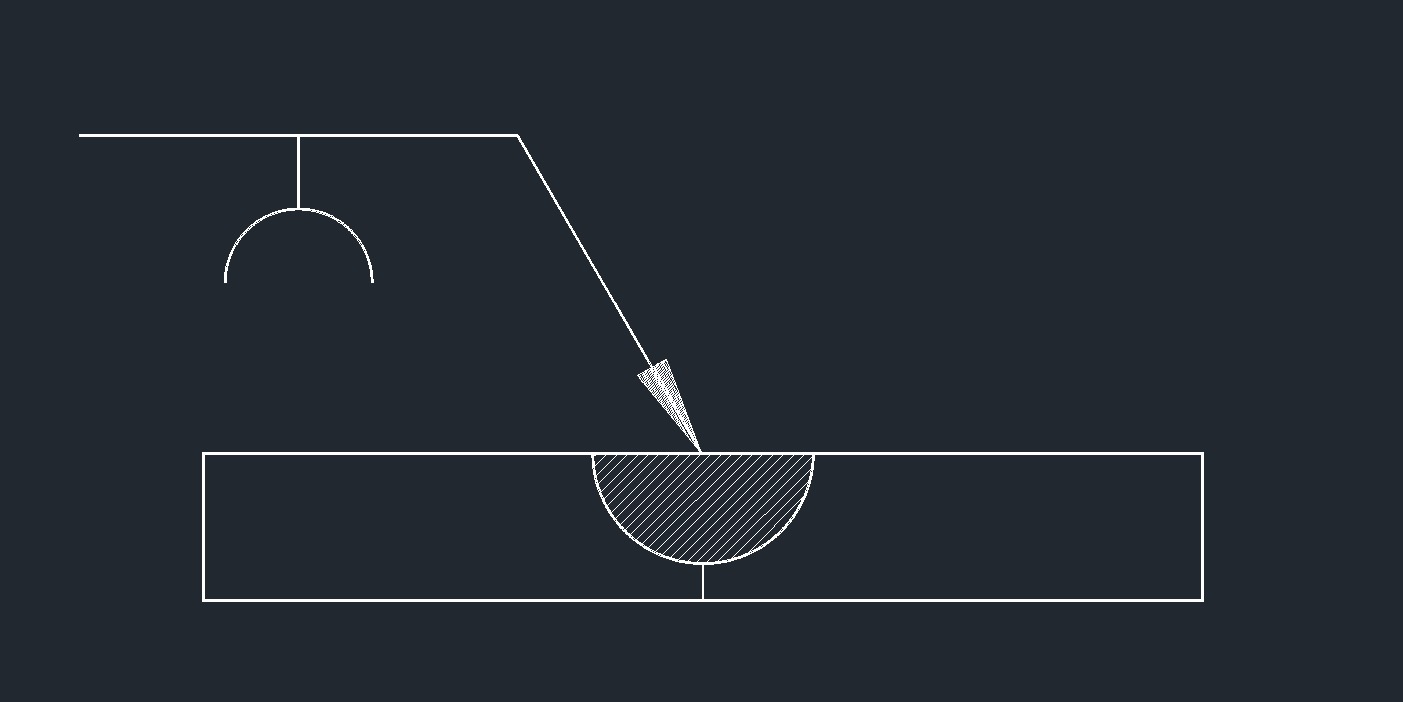

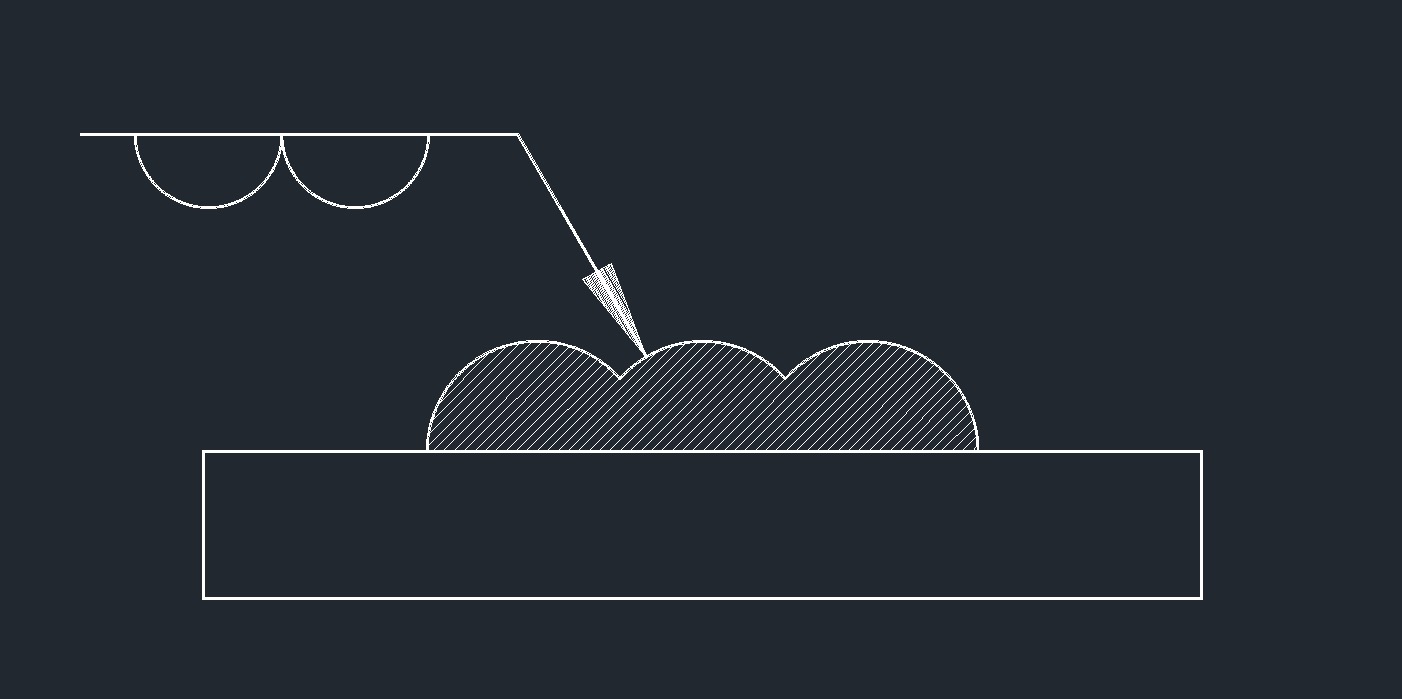

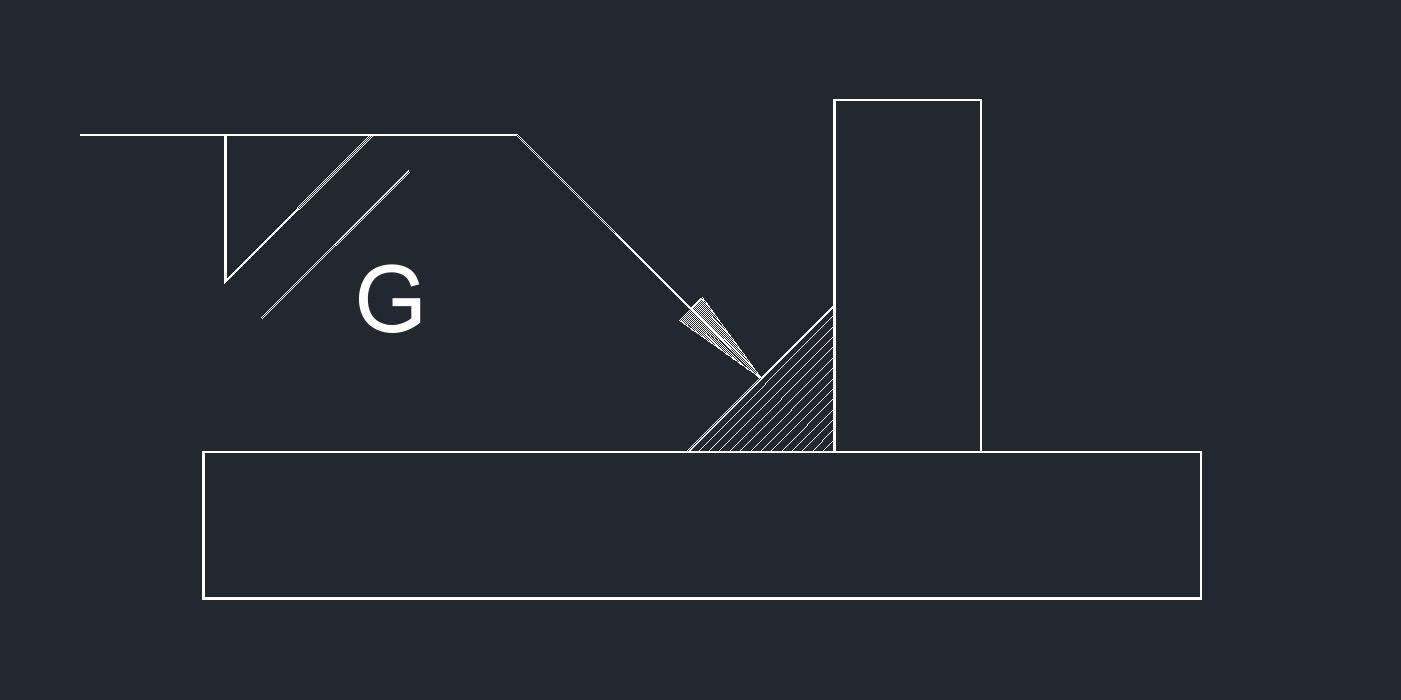

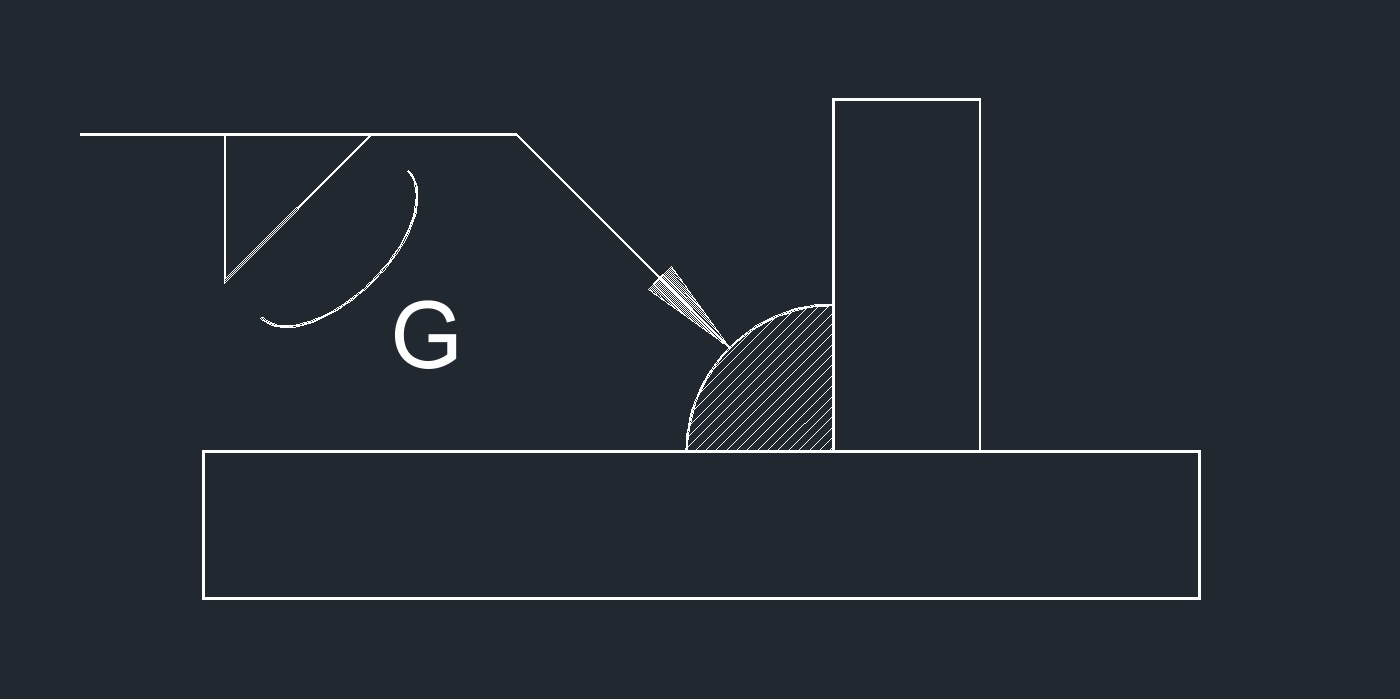

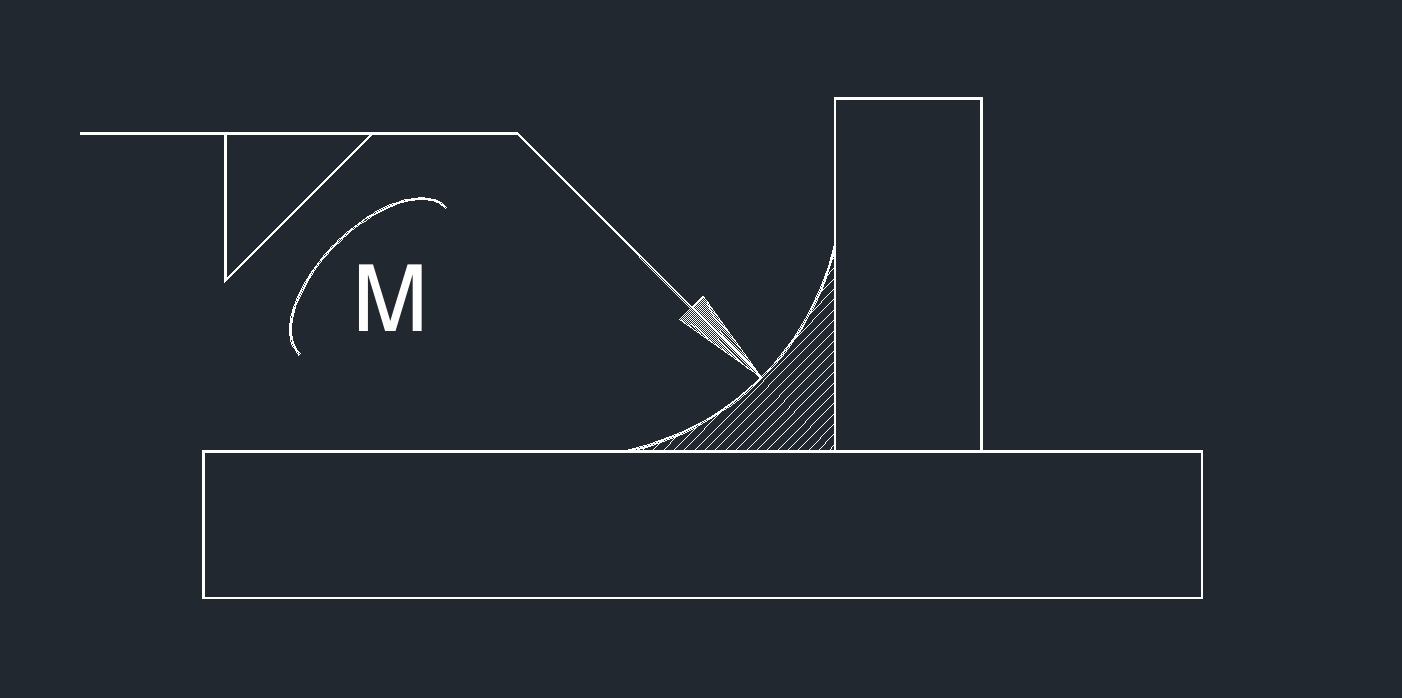

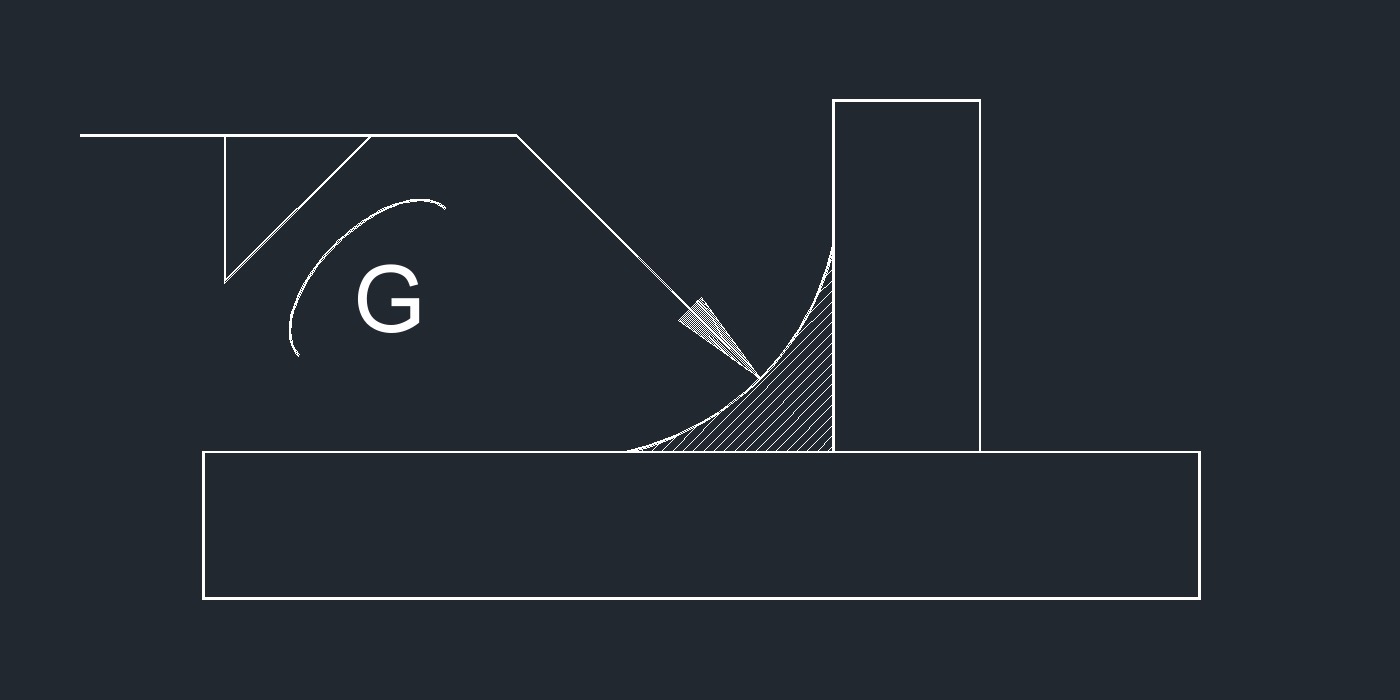

Convex Contour Fillet

Convex Contour Fillet  Convex Machining Fillet

Convex Machining Fillet  Convex Grinding Fillet

Convex Grinding Fillet  Convex Chipping Fillet

Convex Chipping Fillet

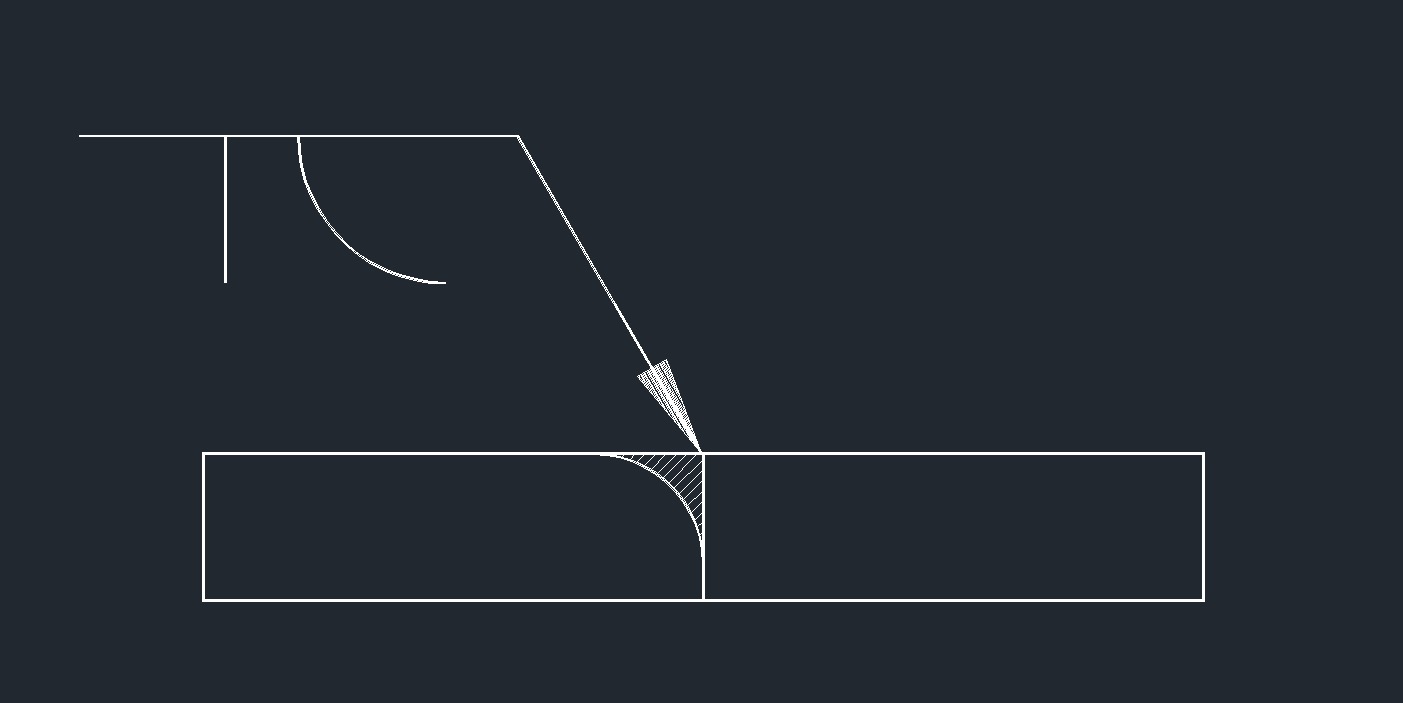

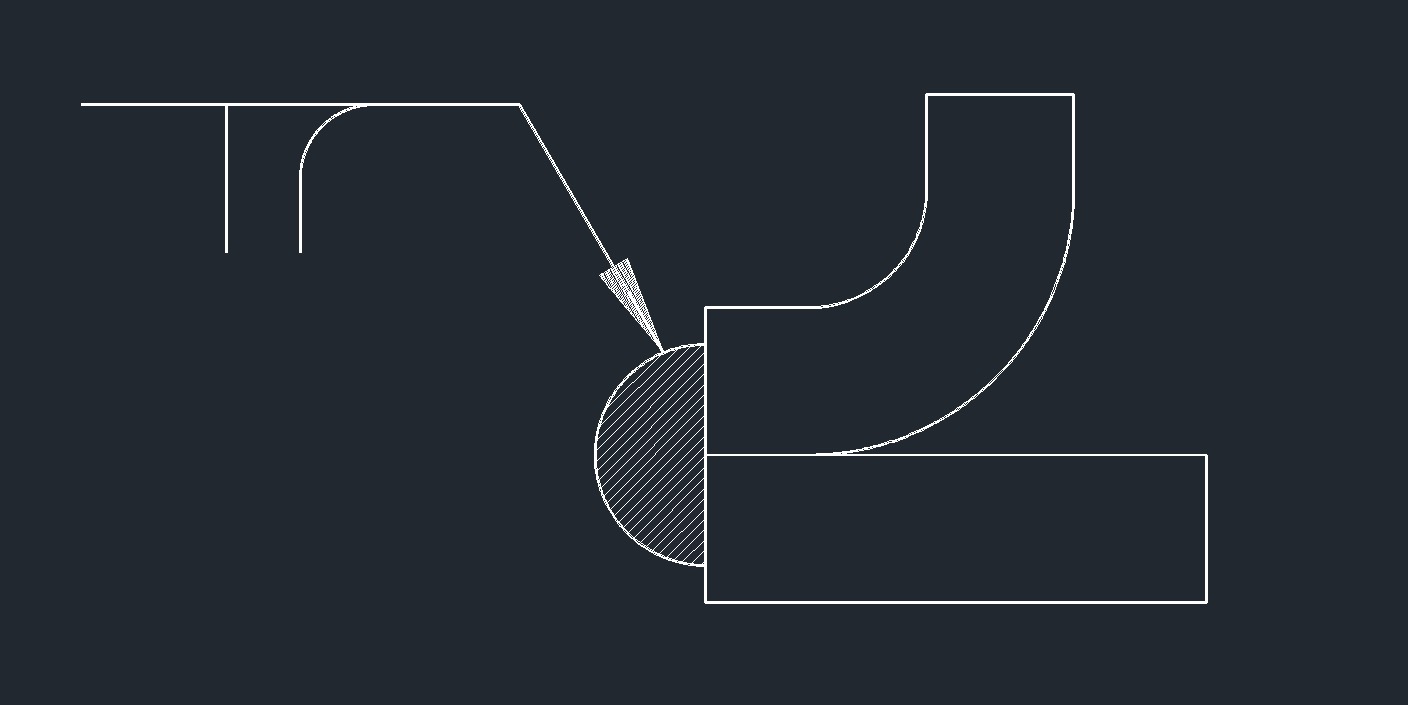

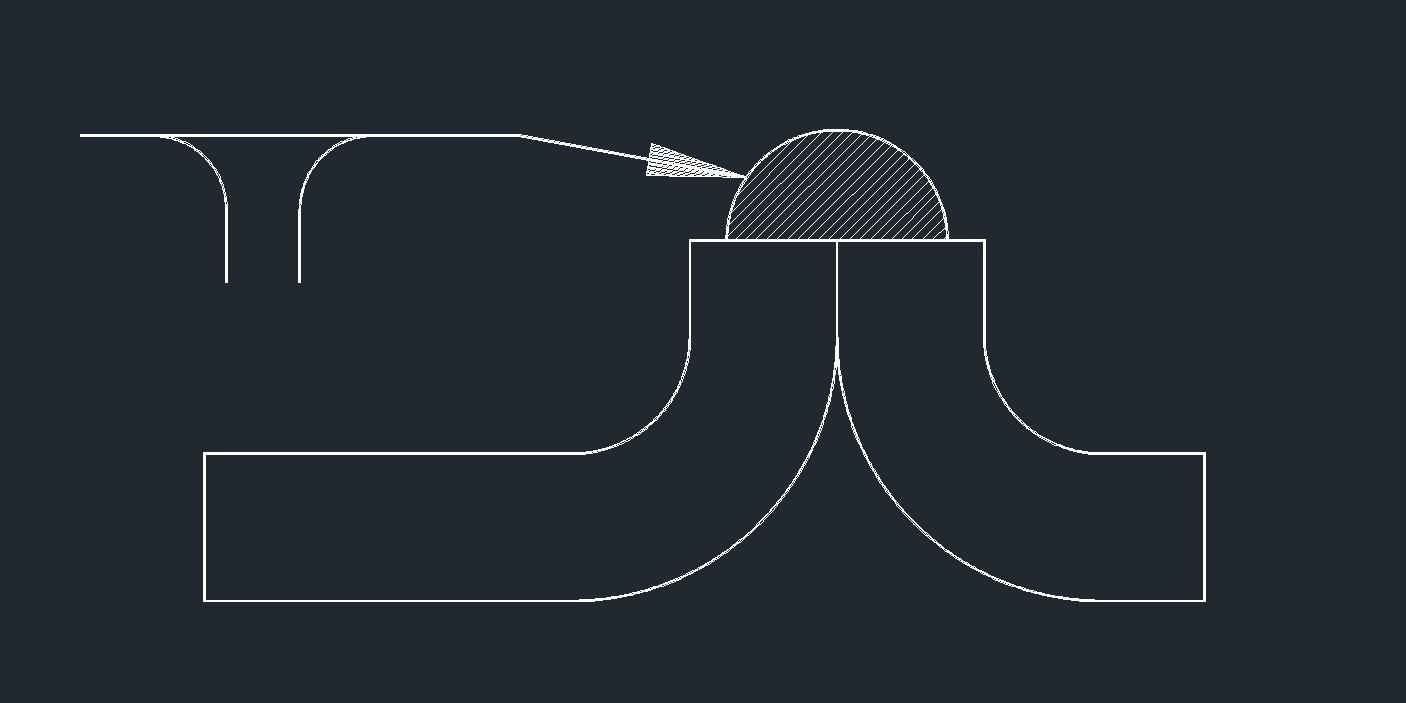

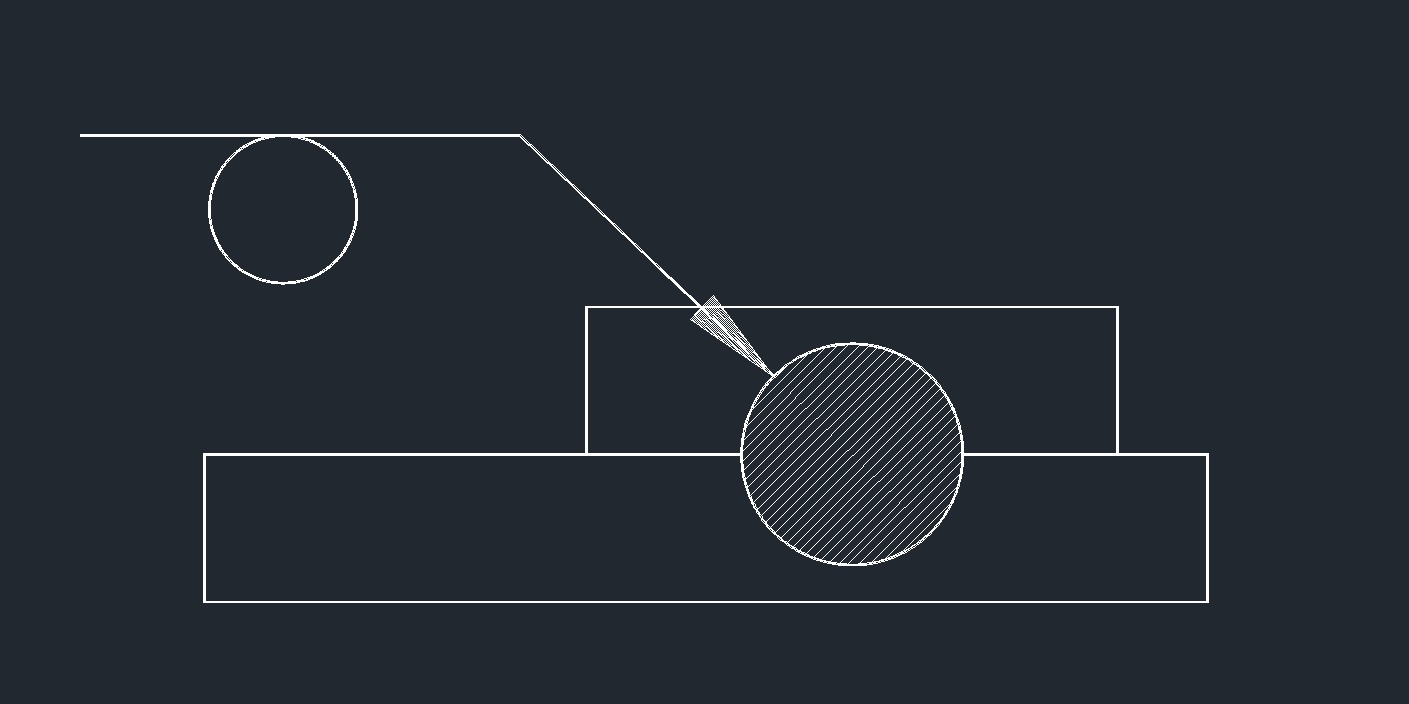

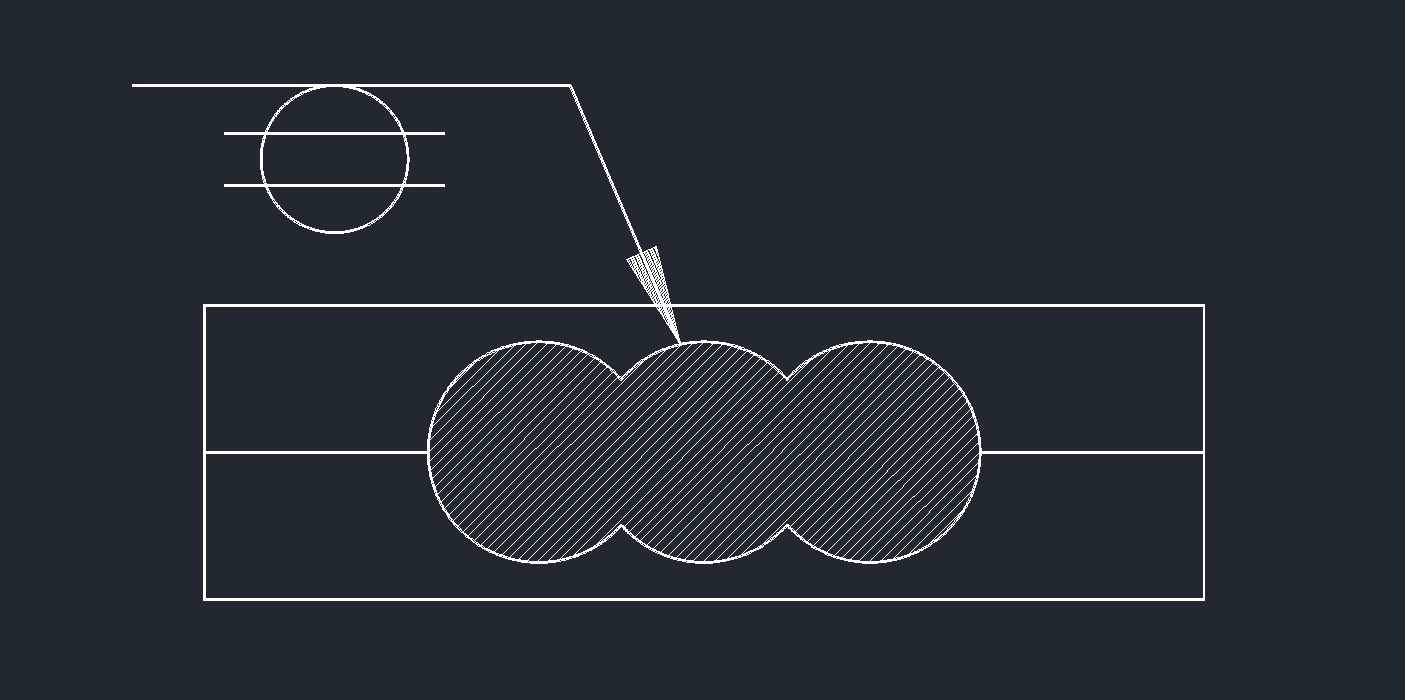

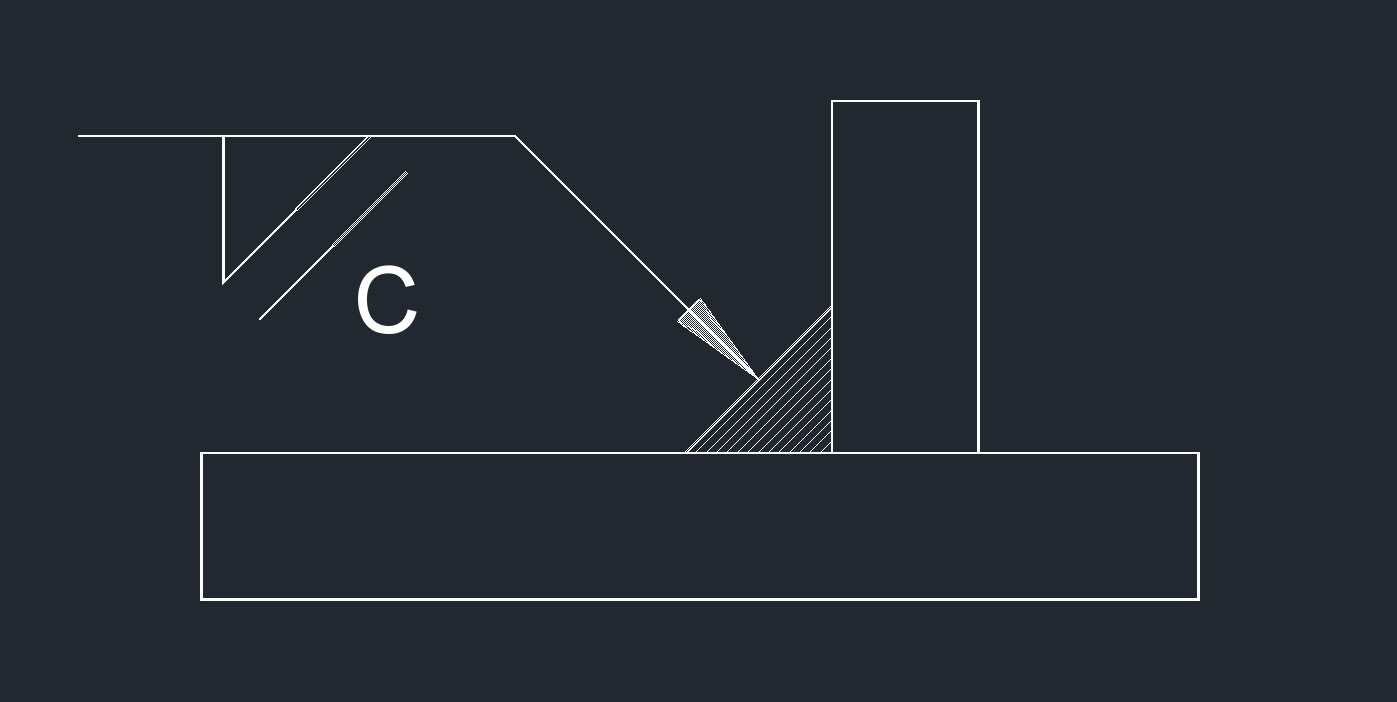

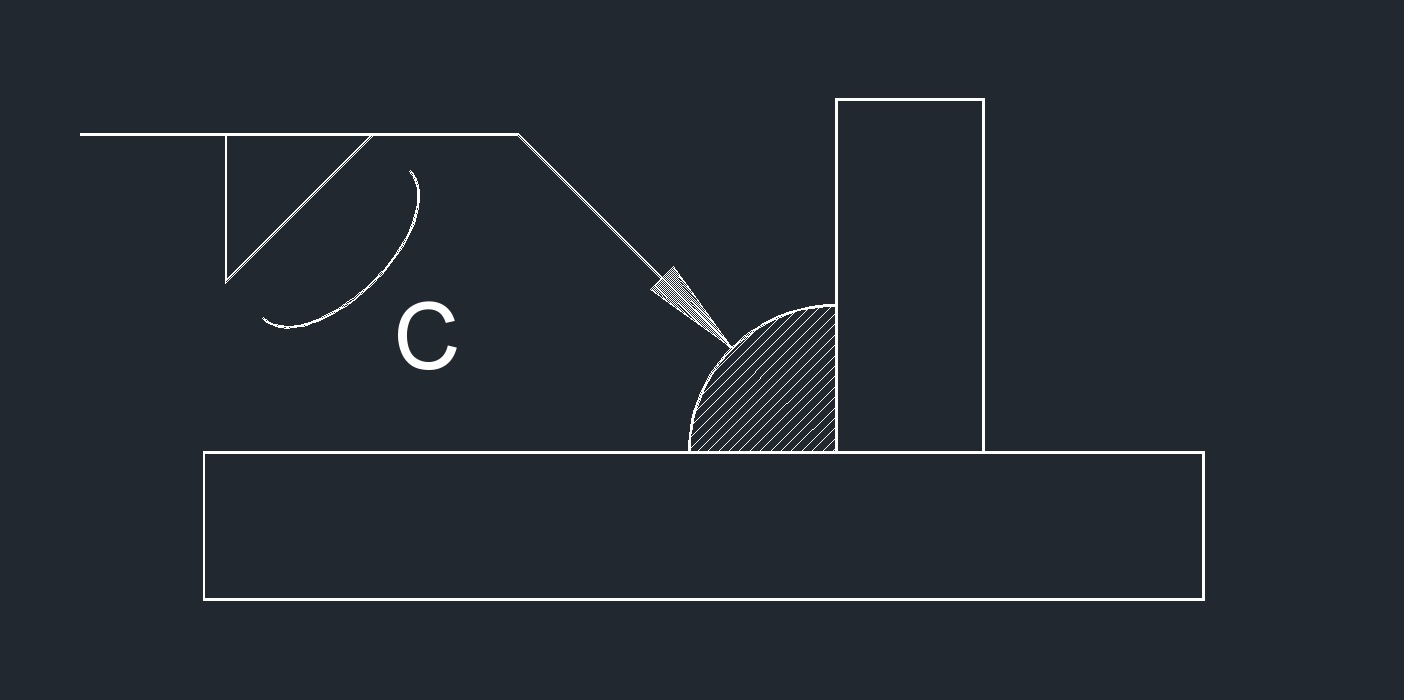

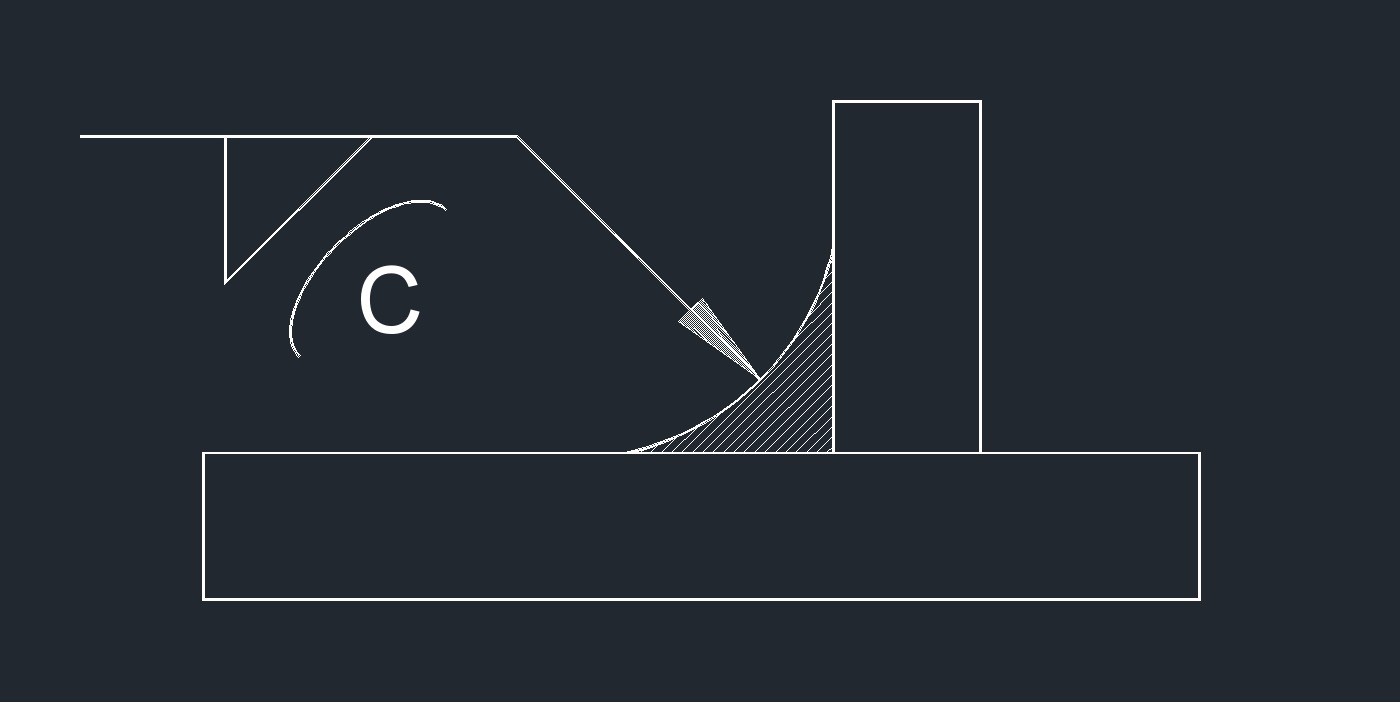

Concave Contour Fillet

Concave Contour Fillet  Concave Machining Fillet

Concave Machining Fillet  Concave Grinding Fillet

Concave Grinding Fillet  Concave Chipping Fillet

Concave Chipping Fillet