Pipeline Pigging

Pipeline Pigging, Pipe, Corrosion, Pipeline Pipeline pigging is a method of cleaning, inspecting, and maintaining pipelines used for transporting liquids or gases, such as oil, gas, or water. A pipeline pig is a cylindrical device that is inserted into the pipeline and propelled through the pipeline by the flow of the product being transported. A Pipeline Inspection Gauge, abbreviated as PIG, can be made from a variety of materials, including foam, rubber, or metal, and can be configured in different ways depending on the specific application.

Pipeline pigging is a method of cleaning, inspecting, and maintaining pipelines used for transporting liquids or gases, such as oil, gas, or water. A pipeline pig is a cylindrical device that is inserted into the pipeline and propelled through the pipeline by the flow of the product being transported. A Pipeline Inspection Gauge, abbreviated as PIG, can be made from a variety of materials, including foam, rubber, or metal, and can be configured in different ways depending on the specific application.

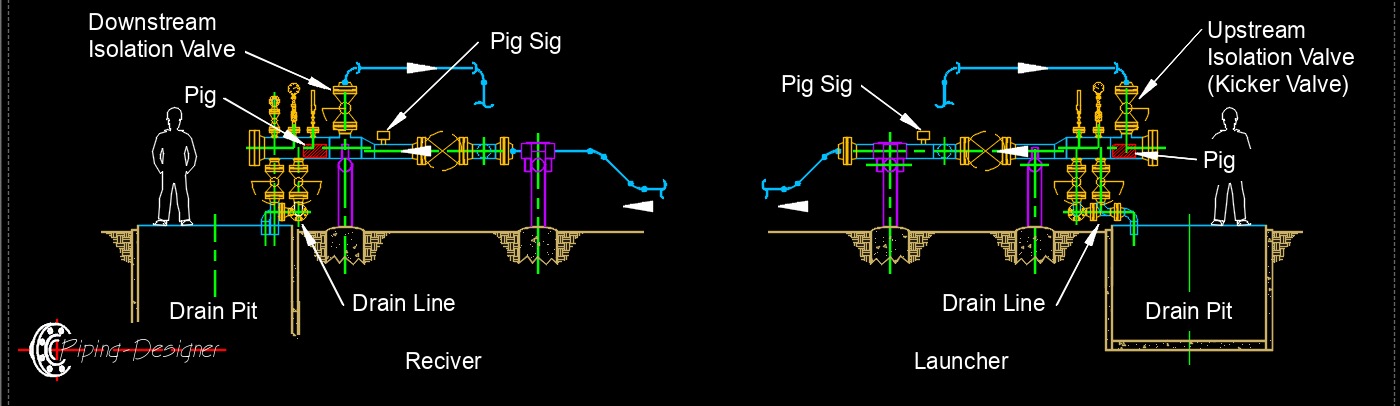

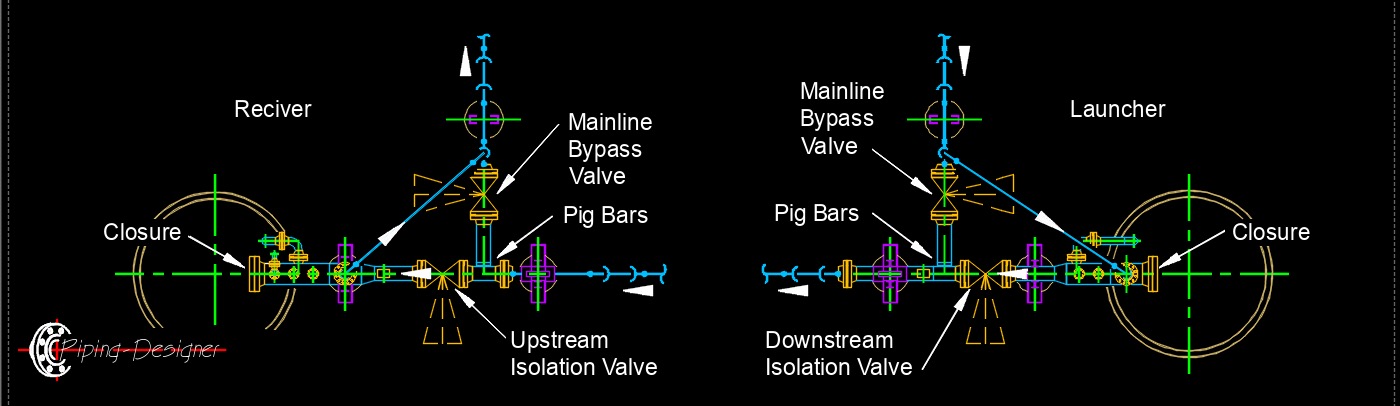

PIG's scrape the inside of the pipeline and perform various maintenance jobs like cleaning, clearing, maintenance, inspection, dimensioning, process and pipeline testing operations on new and existing pipelines. Smart PIG's inspect the integrity of the line for any potential problems. Pipelines need to be cleaned regulary to prevent debris or buildup from occuring that may slow down the movement of the fluid inside. The process of pigging is normally performed without stopping the flow of the product in the pipeline. The diameter and lengths of the pipelines determine the pig size and tend to be much larger than in liquid processing and manufacture. PIG launchers and receivers need to be installed at the approperate locations.

PIG's scrape the inside of the pipeline and perform various maintenance jobs like cleaning, clearing, maintenance, inspection, dimensioning, process and pipeline testing operations on new and existing pipelines. Smart PIG's inspect the integrity of the line for any potential problems. Pipelines need to be cleaned regulary to prevent debris or buildup from occuring that may slow down the movement of the fluid inside. The process of pigging is normally performed without stopping the flow of the product in the pipeline. The diameter and lengths of the pipelines determine the pig size and tend to be much larger than in liquid processing and manufacture. PIG launchers and receivers need to be installed at the approperate locations.

| Engineering |

| Chemical Engineering |

Pigging is an important part of maintaining the integrity and safety of pipelines, as it helps to prevent blockages, corrosion, and other issues that can cause leaks or failures. It is widely used in the oil and gas industry, as well as in other industries that rely on pipelines for transportation of liquids or gases.

- See Article - Pipeline Pigging Glossary

Pipeline Pig Types

- Utility (General Purpose) Pig - A general-purpose device used in pipelines for routine maintenance and operational tasks.

- Foam Pig - A versatile device used in pipelines for cleaning, batching, and drying. It's made from an open-cell polyurethane foam, which gives it a spongy, compressible nature.

- Solid Cast Pig - A robust and durable pipeline pig designed for heavy-duty cleaning, batching, and product removal applications.

- Spherical (Ball) Pig - A type of pipeline pig that is, as its name suggests, spherical in shape. Made from a durable, solid polyurethane elastomer, these pigs are highly flexible and conform to the internal shape of the pipeline.

- Cleaning Pig - A specialized device engineered to remove debris, deposits, and foreign materials from the interior walls of a pipeline.

- Brush Pig - A cleaning device used to perform various maintenance tasks. Essentially a cylindrical device with brushes, scrapers, or other tools attached to its exterior, it's inserted into a pipeline and then propelled through it by the flow of the product (oil, gas, water, etc.) or by a pressurized fluid.

- Scraper (Line Scraper) Pig - A specialized device used to clean the internal walls and remove various accumulated deposits. It's typically a cylindrical tool with an exterior equipped with blades, brushes, or other scraping element.

- Mandrel (Steel-bodied) Pig - A type of cleaning or utility pig, distinguished by its solid steel body or "mandrel." This internal structure allows for the attachment of various external components, such as replaceable cups, discs, and brushes, which can be configured to suit specific pipeline maintenance needs.

- Inspection (Smart/Intelligent) Pig - A sophisticated device equipped with advanced sensors and designed to gather detailed data about the internal condition of a pipeline.

- Magnetic Flux Leakage (MFL) Pig - A smart pig used for inspecting pipelines to detect and characterize flaws, primarily metal loss due to corrosion, pitting, or cracks.

- Ultrasonic Testing (UT) Pig - Used to measure the wall thickness and detect internal and external defects such as corrosion, cracks, laminations, and gouges.

- Caliper (Geometry/Deformation) Pig - A pig specifically designed to measure the internal diameter and detect deformations within a pipeline.

- Internal Measurement Unit (IMU) Pig - A pig to precisely map the three-dimensional (3D) trajectory and geometry of a pipeline. It's crucial for understanding pipeline movement, bending strain, and accurate location mapping, especially in environments where GPS signals are unavailable, such as underwater or buried pipelines.

- Special Purpose Pig - A pipeline pig designed for a specific, often unique, task beyond the general functions of cleaning, utility, or routine inspection.

- Gauge (Proving) Pig - A pig designed to verify the minimum internal diameter of a pipeline and detect any obstructions or deformations that could impede the passage of other, more sophisticated pigs (like smart pigs for inspection) or hinder product flow.

- Batching Pig - A pig primarily used to separate different products within a multi-product pipeline, or to separate product from a fluid used for maintenance activities like hydrostatic testing or dewatering.

- Dewatering Pig - A specialized type of pig primarily used to remove water or other liquids from a pipeline, typically after hydrostatic testing, cleaning, or a repair. The goal is to dry the pipeline interior to prevent corrosion, prepare it for gas service, or introduce a different product.

- Gel Pig - This is a unique type of cleaning or treatment pig consists of a highly viscous, often thixotropic (shear-thinning) liquid or semi-solid gel.

- Bi-directional (bi-di) Pig - A type of pig specifically designed to be symmetrical, allowing it to be propelled and effectively perform its function when pressure is applied from either direction within a pipeline.