Cantilever Pipe Support Vessel

Cantilever pipe support for a vessel refers to a type of pipe support mechanism designed specifically for pipes that are connected to or associated with pressure vessels, storage tanks, or similar containers. These supports are used to hold and secure pipes that are connected to the vessel without the need for additional vertical support beneath the pipes. Pressure vessels are containers designed to hold gases or liquids at high pressures, and they are commonly used in various industrial processes, including chemical manufacturing, oil refining, and power generation. These vessels often have pipes or piping systems connected to them to facilitate the movement of fluids in and out of the vessel. Cantilever pipe supports for vessels play a crucial role in maintaining the integrity and safety of these piping systems.

Cantilever pipe supports for vessels might vary in design based on factors such as the size of the vessel, the type of fluids being transported, the operating conditions, and the structural characteristics of the installation site. These supports are critical for ensuring the proper functioning of pressure vessel systems and preventing potential leaks, failures, and safety hazards. Designing and implementing cantilever pipe supports for vessels requires engineering expertise to ensure that the supports are adequately designed to withstand the unique challenges posed by pressure vessels and their associated piping systems.

- See Article - Pipe Support Dont's

Key Points about Cantilever Pipe Supports for Vessels

Structural Integrity - The supports must be designed to handle the weight of the pipes, their contents, and any potential pressure fluctuations within the vessel. They should be structurally sound to prevent stress, deformation, or failure.

Thermal Expansion - Just like other types of cantilever pipe supports, those designed for vessels need to account for the thermal expansion and contraction of pipes due to temperature changes. Adequate flexibility should be provided to accommodate these movements without causing damage to the vessel or the pipes.

Vibration and Movement - Vibration and movement are potential challenges, especially in industrial environments. Cantilever supports should be designed to dampen vibrations and prevent unnecessary movement that could strain the vessel and the connected pipes.

Corrosion Resistance - Depending on the nature of the fluids being transported, vessels and pipes can be exposed to corrosive materials. The materials used in the construction of cantilever supports should be chosen to resist corrosion and ensure long term reliability.

Maintenance Access - Cantilever supports should be designed with consideration for maintenance and inspection access. Being able to easily inspect and maintain both the supports and the pipes they hold is important for safety and operational efficiency.

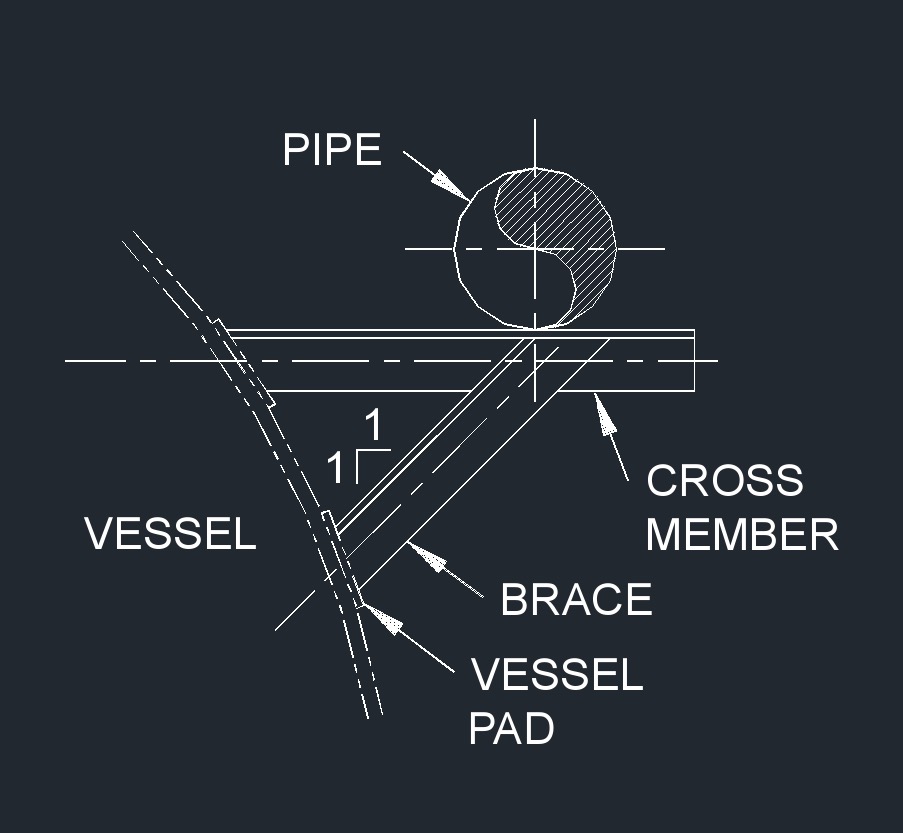

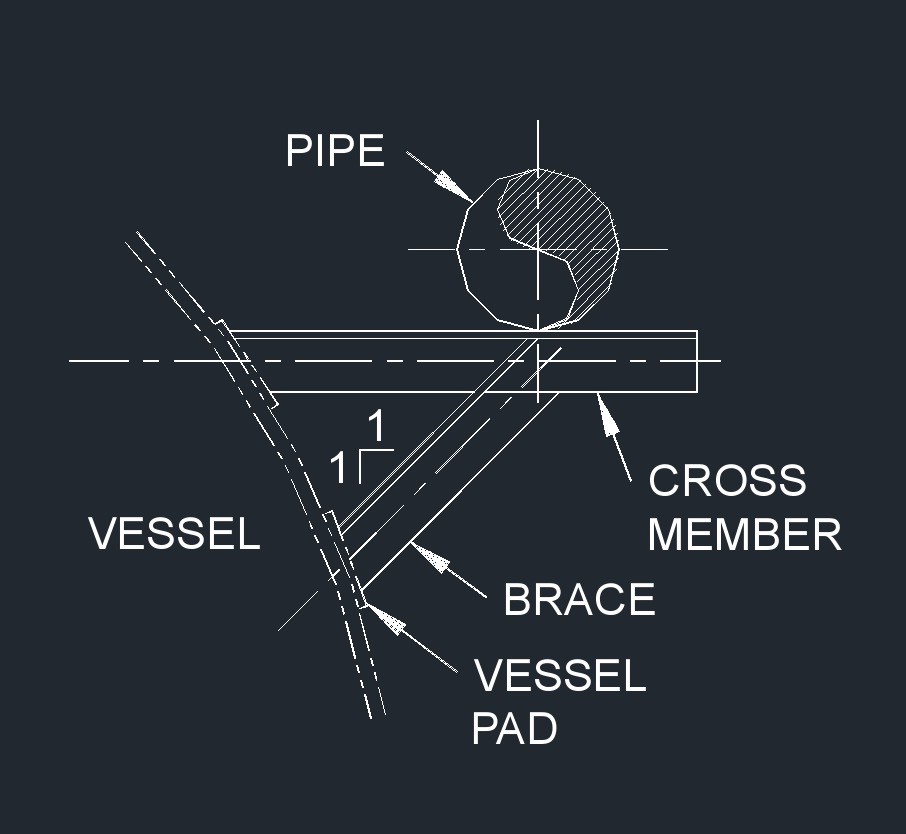

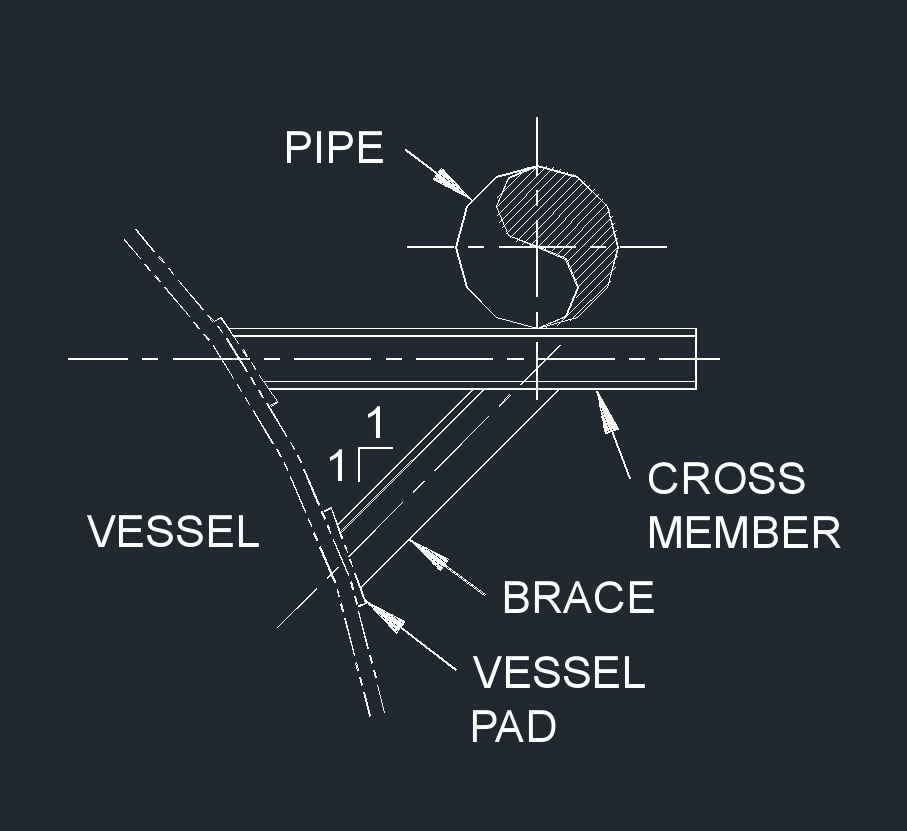

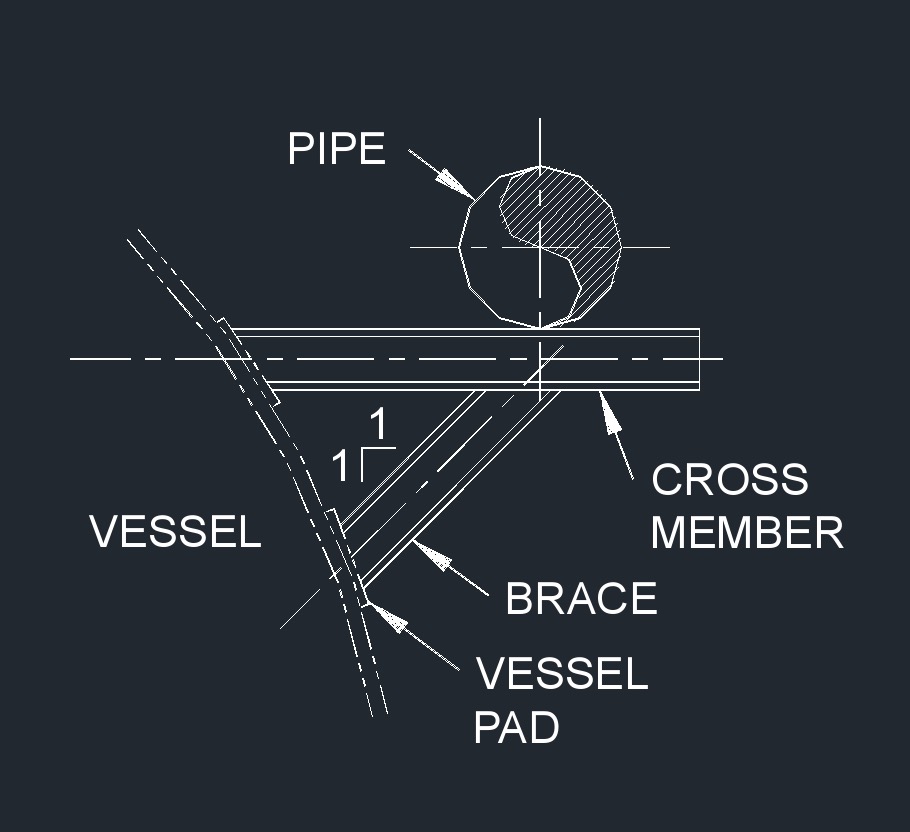

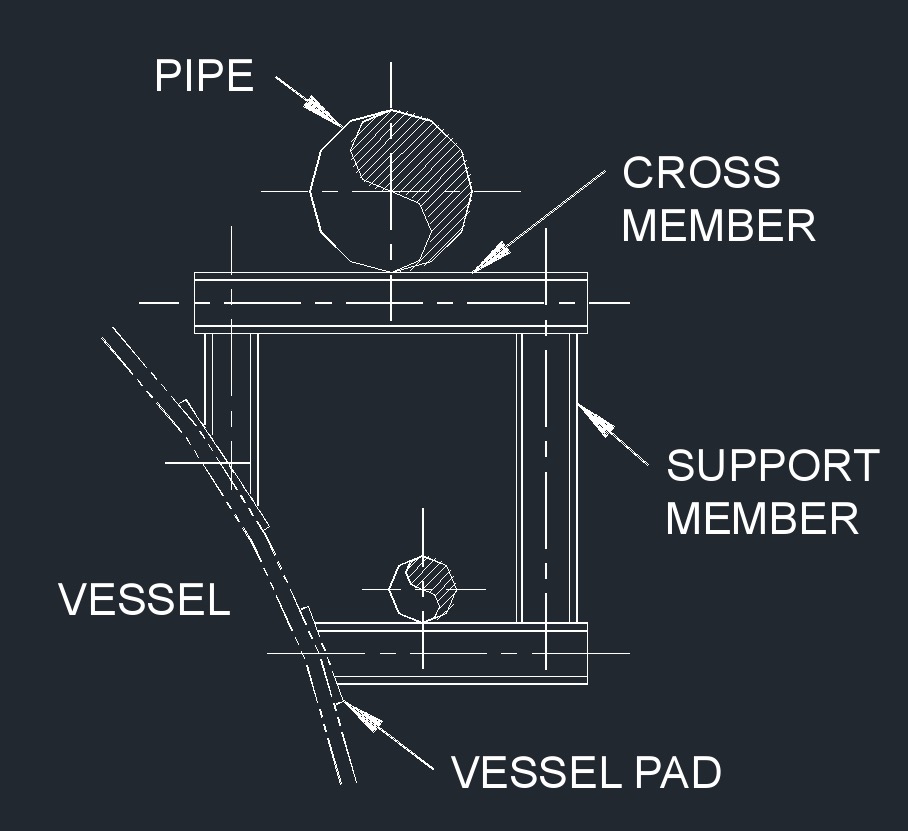

Attaching to a Horizontal Vessel

Angle Iron

Angle Iron

Angle Iron

Angle Iron

Angle Iron

Angle Iron

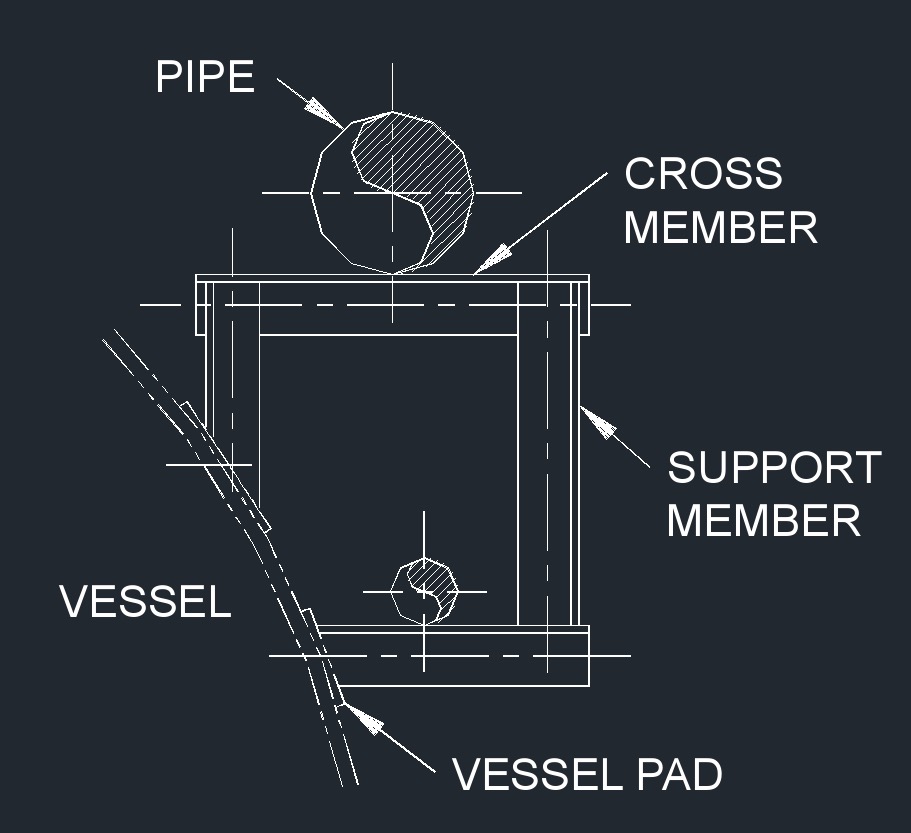

Angle Iron and Channel Beam

Angle Iron and Channel Beam

Channel Beam

Channel Beam

Channel Beam

Channel Beam

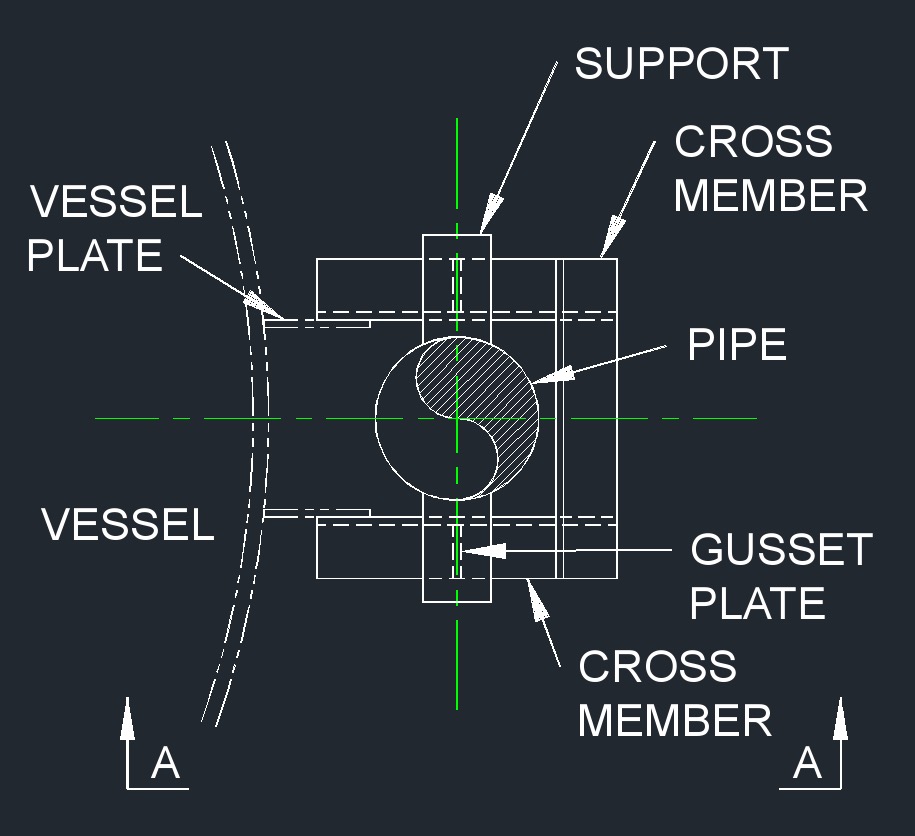

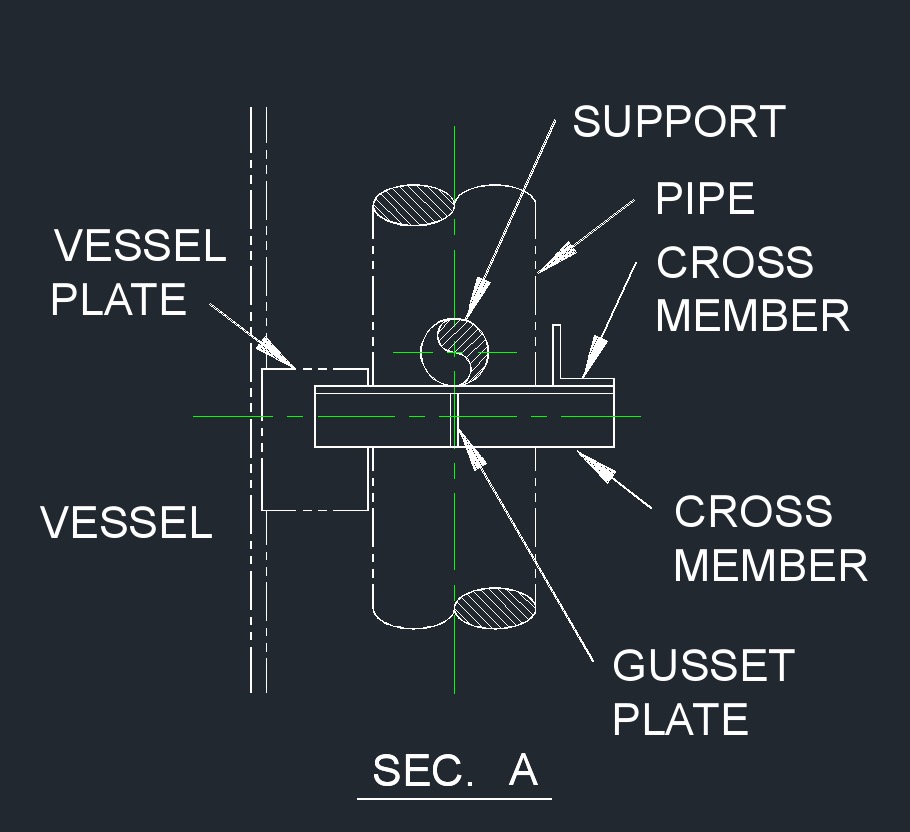

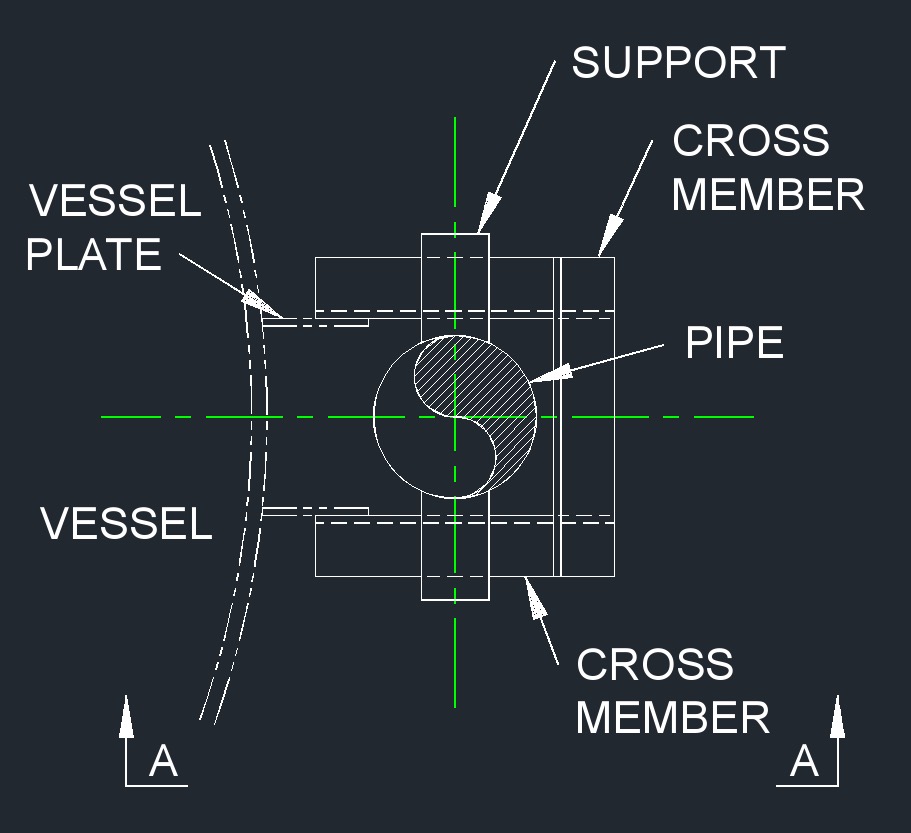

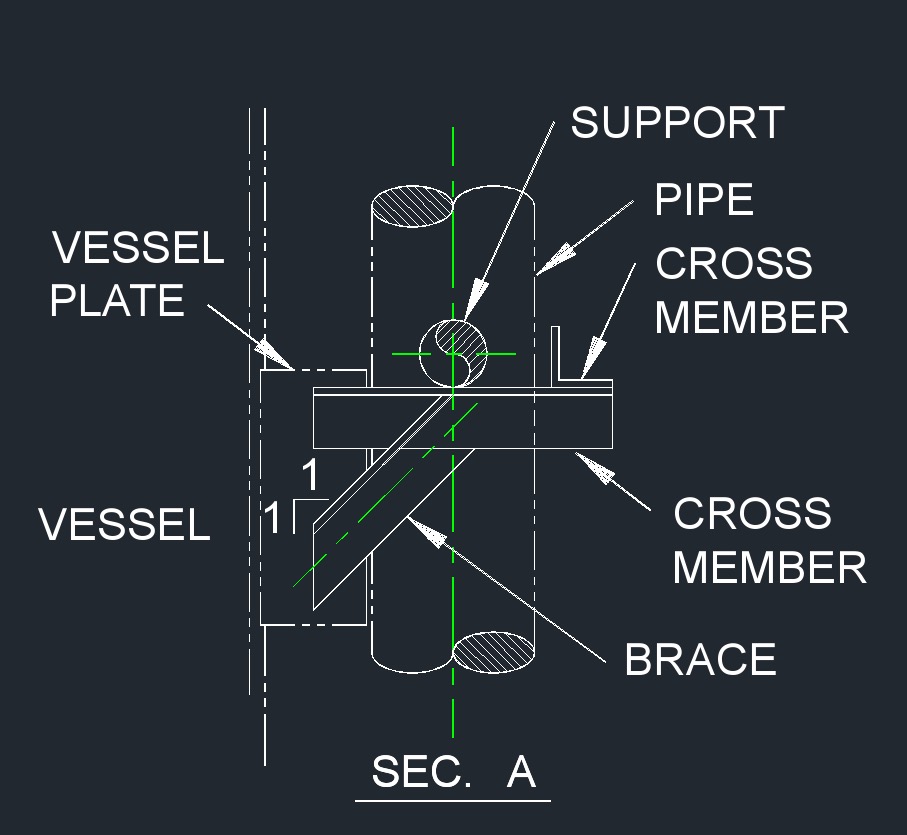

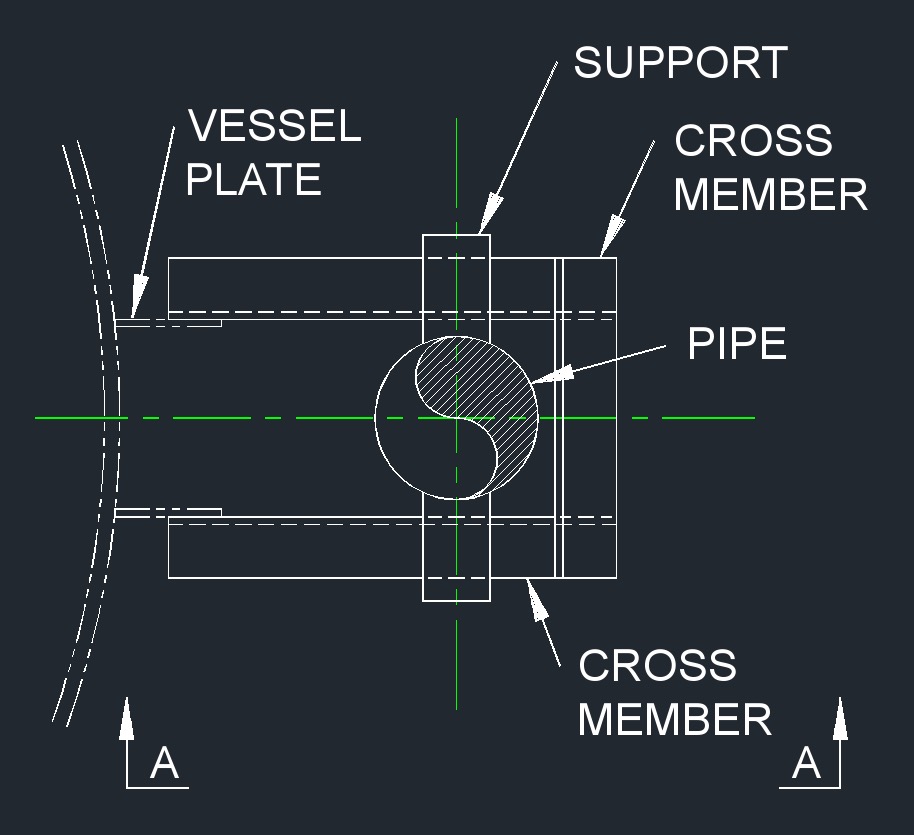

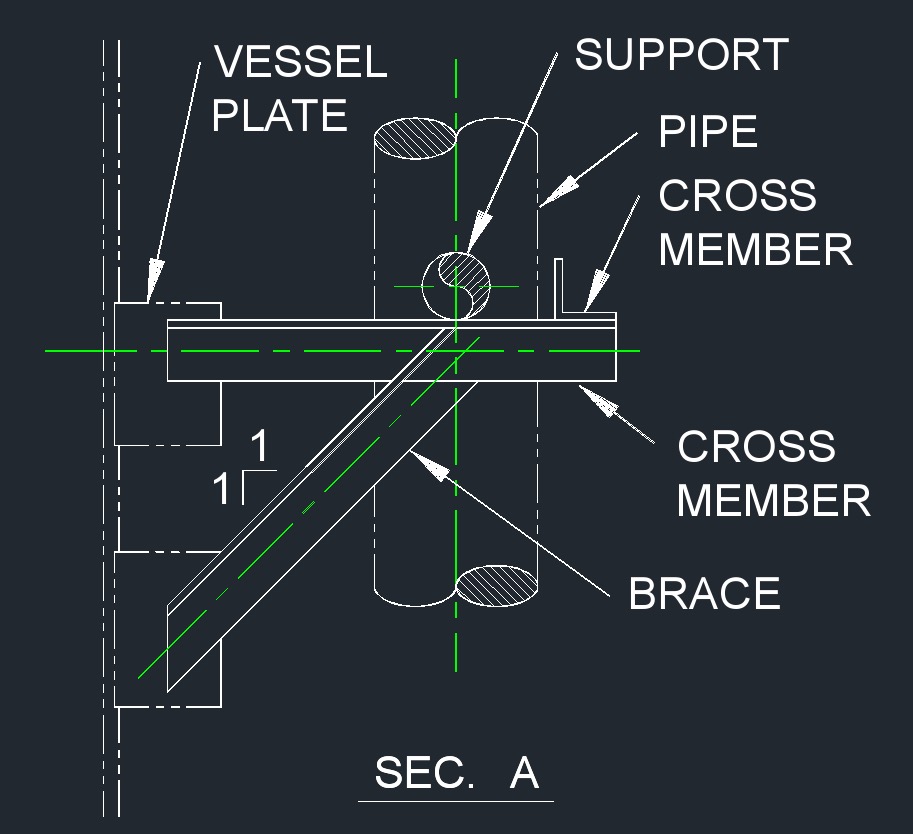

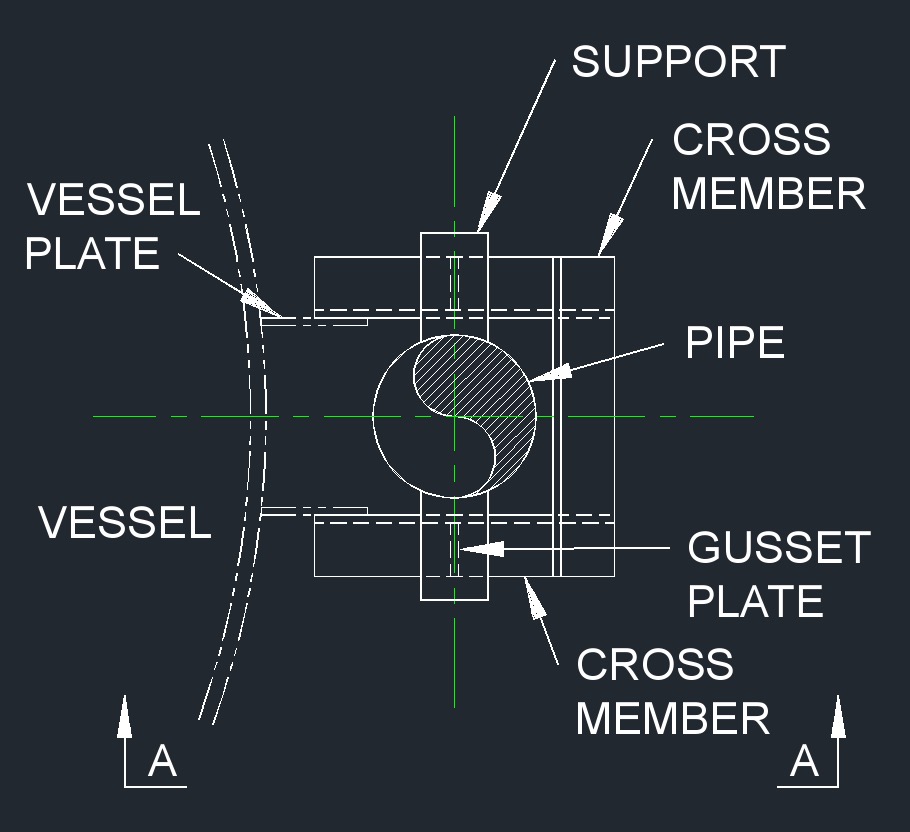

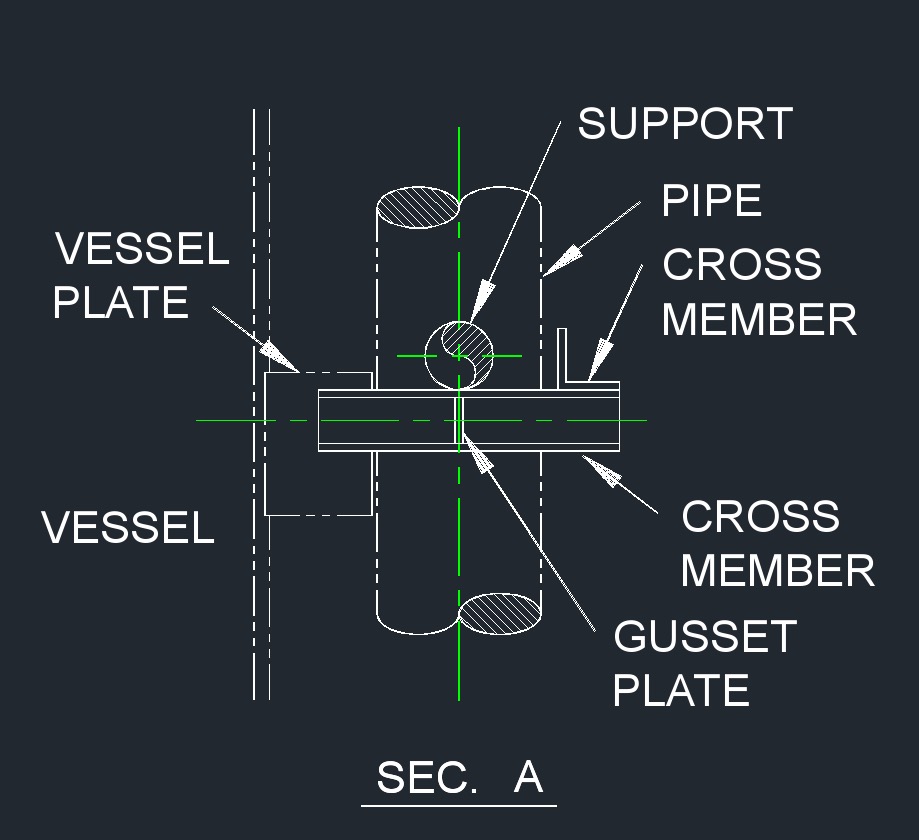

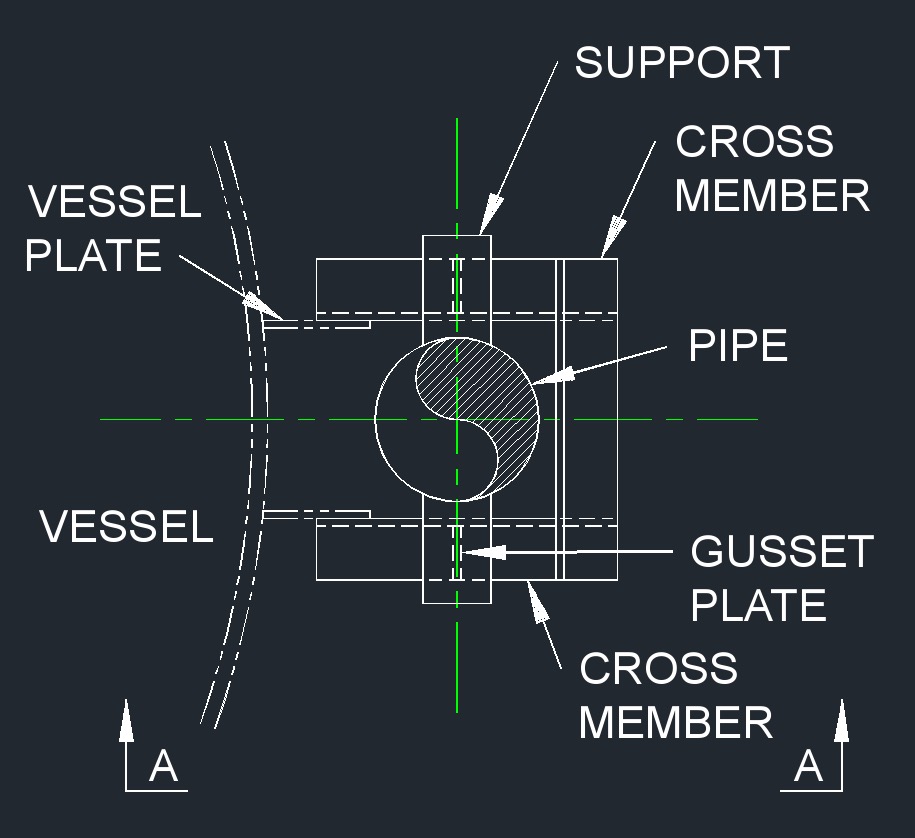

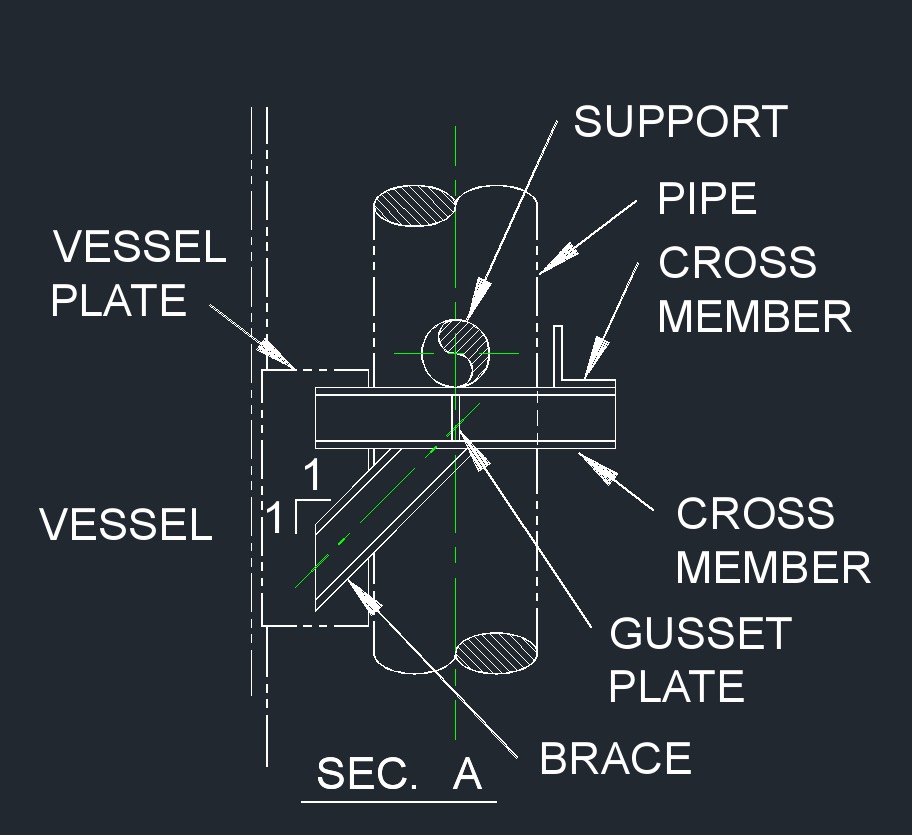

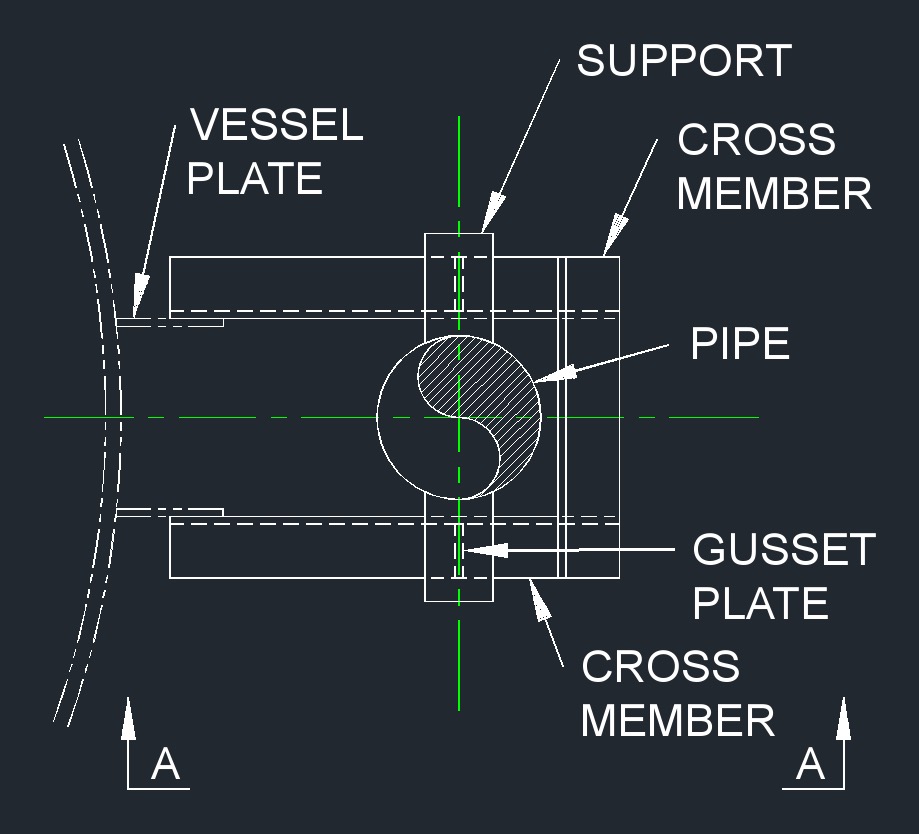

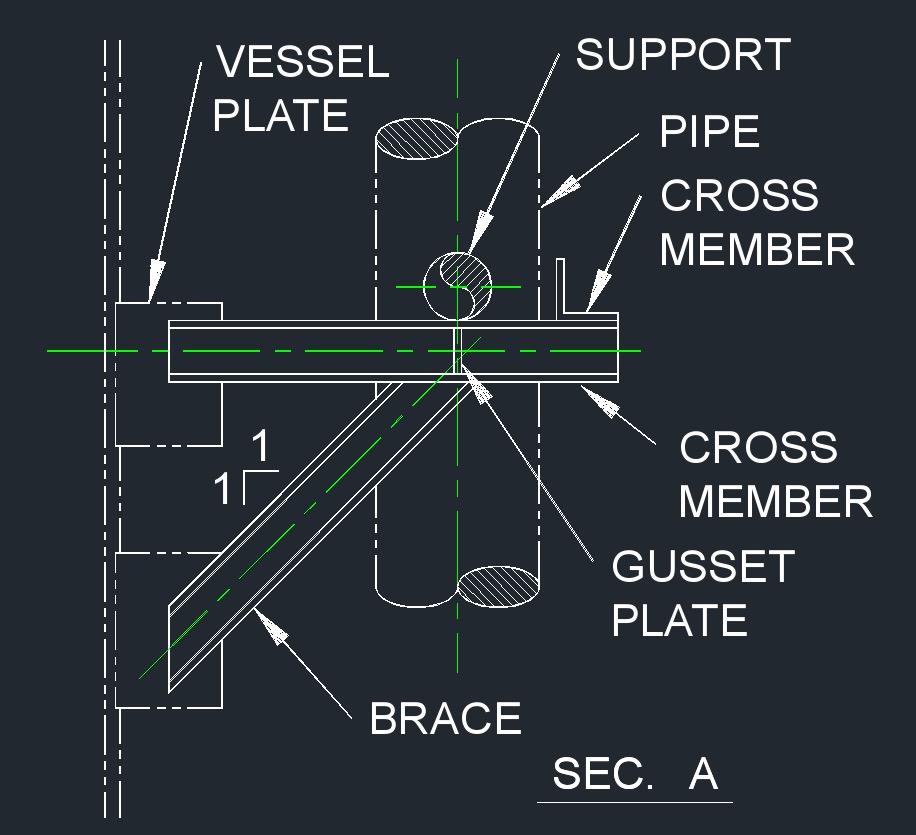

Attaching to a Vertical Vessel

Angle Iron

Angle Iron

Angle Iron

Angle Iron

Angle Iron

Angle Iron

Angle Iron

Angle Iron

Angle Iron

Angle Iron

Angle Iron

Angle Iron

I Beam

I Beam

I Beam

I Beam

I Beam

I Beam

I Beam

I Beam

I Beam

I Beam

I Beam

I Beam