Filtration

Petroleum, Filtration, Refinery Filtration, abbreviated as FLTR, is the process of separating solids, liquids, or gases from a mixture using a medium, called a filter, that allows only certain particles to pass through while retaining the others. The filter medium can be made of various materials such as paper, cloth, sand, or activated carbon, depending on the type of mixture being separated and the desired outcome. Filtration is used in a wide range of applications, from everyday tasks such as water purification and air conditioning, to industrial processes such as oil refining and pharmaceutical production. The purpose of filtration is to remove impurities or unwanted particles from a mixture, or to separate two or more components of a mixture based on their physical or chemical properties.

Filtration, abbreviated as FLTR, is the process of separating solids, liquids, or gases from a mixture using a medium, called a filter, that allows only certain particles to pass through while retaining the others. The filter medium can be made of various materials such as paper, cloth, sand, or activated carbon, depending on the type of mixture being separated and the desired outcome. Filtration is used in a wide range of applications, from everyday tasks such as water purification and air conditioning, to industrial processes such as oil refining and pharmaceutical production. The purpose of filtration is to remove impurities or unwanted particles from a mixture, or to separate two or more components of a mixture based on their physical or chemical properties.

| Engineering |

| Mechanical Engineering |

There are several types of filtration techniques, including gravity filtration, vacuum filtration, pressure filtration, and centrifugal filtration, each with its own advantages and disadvantages. The choice of filtration technique depends on the specific requirements of the application and the properties of the mixture being filtered.

- See Articles - List of Tags / List of Categories / List of Articles / List of Glossaries / Nomenclature and Symbols / (See Filtration Glossary)

Filtration Types

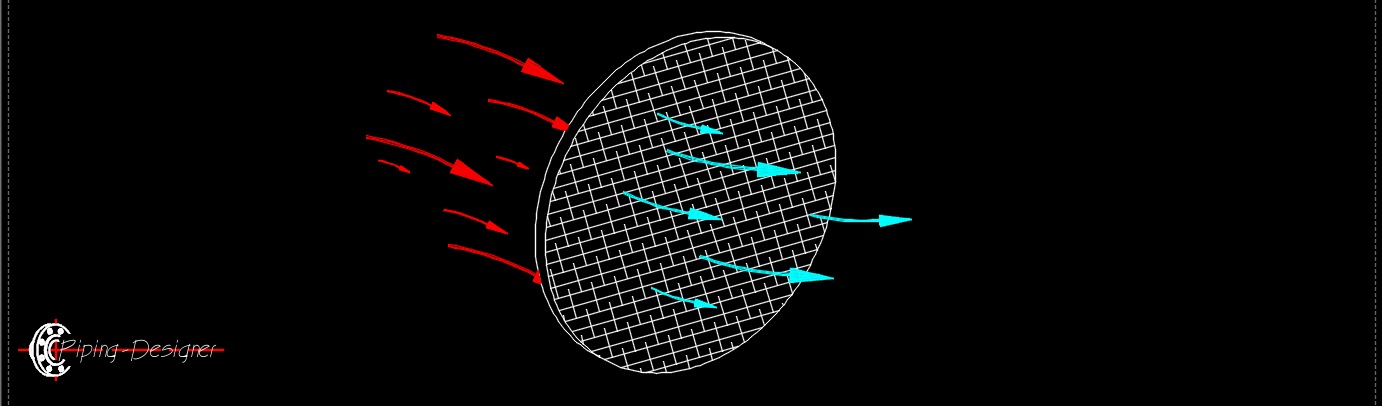

- Air Filtration - Air is forced through a mesh in which unwanted substances are removed by getting stuck to the filter and mesh.

- Bag Filtration - Settling of the particles in a bag while liquid is poured through the same bag is used for clarification of fluids. The bags come in a variance of sizes that depend on the matter to be filtered out.

- Cartridge Filtration - This eliminates harmful sediments through a cylindrical-shaped cartridge.

- Centrifugal Filtrarion - Takes place without any medium. A circled or rotational movement is made through the liquid or the semi-liquid that is to be filtered, and the velocity of the rotation separates the dense liquid from the productive liquid.

- Cold Filtration - Requires liquids to pass through a cold set of filters to remove suspended particles.

- Cyclone Filtration - A cyclone is created using an industrial fan to filter out the dust through an air stream. It is a low-cost form of filtration method and is used very often a variety of industries. Cyclone filters, also known as cyclone separators, are regularly employed as a pre-filter to remove large contaminants from the air before the stream moves to other filter types.

- HEPA Filtration - This filter is powerful enough to sift micro and nanoparticles such as chemical compounds, viruses, bacteria, and other particulates from the air that passes through it. A typical HEPA filter is made using tiny meshes of fibers in random alignment.

- Depth Filtration - Is a graded density process in which a medium itself collects different sizes of impurities to filter out the key element.

- Gravity Filtation - A process where there is no separate medium used but gravity itself. The flow of the liquid from top to bottom helps in removing solids because of the pressure in the atmosphere.

- Hot Filtration - When small sizes of crystal compounds need purification, the impurities in the element are melted out at high temperatures while the liquid is slowly cooled down to get back into its crystal form, separating the unwanted factors of the substance.

- Hydraulic Filtration - To filter out petroleum and other similar liquids, some industrial filters are used for purification using a hydraulic system to drain out oil impurities.

- Liquid Filtration - This filter is used to separate suspended solids from a fluid stream. A physical barrier, called the filter medium, is a prerequisite in the filtration process in which the liquid passes through and where the solids are retained. They are widely used in many solid-liquid mechanical separation processes.

- Mechanical Filtration - Uses the force of atmospheric pressure to carry out filtration.

- Multilayer Filtration - Frame filters with square filter elements arranged in vertical rows. They are equipped with a hydraulic lock for pressing the filter pack, a double-acting cylinder with automatic pressure control, a pneumatic drive and a control system.

- Panel Filtration - A panel-shaped filter is used very often in ventilation units, and comes in different types and sizes for wide applicability.

- Sand Filtration - A process in which the treatment of the water is realised by a porous nature of a sand layer which traps particles present in water.

- Strainer Filtration - Closed vessels that collect solid particles to be separated while passing a fluid through a removable screen.

- Temporary Strainer - A startup strainer, also called a witch’s hat or conical strainer, in installed in a system to remove unwanted debris from the process stream. It can be installed to protect a flow meter, pump, control or relief valves or other pieces of equipment during startup.

- Surface Filtration - Has a barrier to stop all unwanted particles from reaching the surface.

- UV Light Filtration - UV light filtration systems can render organisms unable to replicate and still leave the PH, taste, and color of the water untouched. UV treatment is necessary to remove various impurities such as ozone, bromine, chlorine, and chloramines, among many organic pollutants from water.

- Vacuum Filtration - Vacuum filters use the force of suction to create a static pressure in the vessel through which the dust (and any other unwanted) particles are separated from the usable material.