Valve Installation Guide

The valve should be inspected to make sure the opening is free from dirt and foreign matter. The flange faces need to be free of dirt, grease, or any surface defects that may cause leakage. Also, the connecting pipeline should be free of any foreign materials, such as rust or welding slag that could damage the seat and disc sealing surface.

Actuators should be mounted on the valve prior to installation so the propper alignment can be made. Make sure the valve, flanges, and pipe are all compatible with the correct pressure class and materials specified before installation. Check the flange bolts or studs for the correct size and length. The connecting equipment and lines should have the proper alignment prior to valve installation. When installing the valve and gaskets, the pipe should be spread apart just enough to allow the valve and gaskets without actually coming in contact with the flanges. Care should be taken to not damage the surfaces of the flanges or valve. At this point the bolt tightaning procedure should be followed.

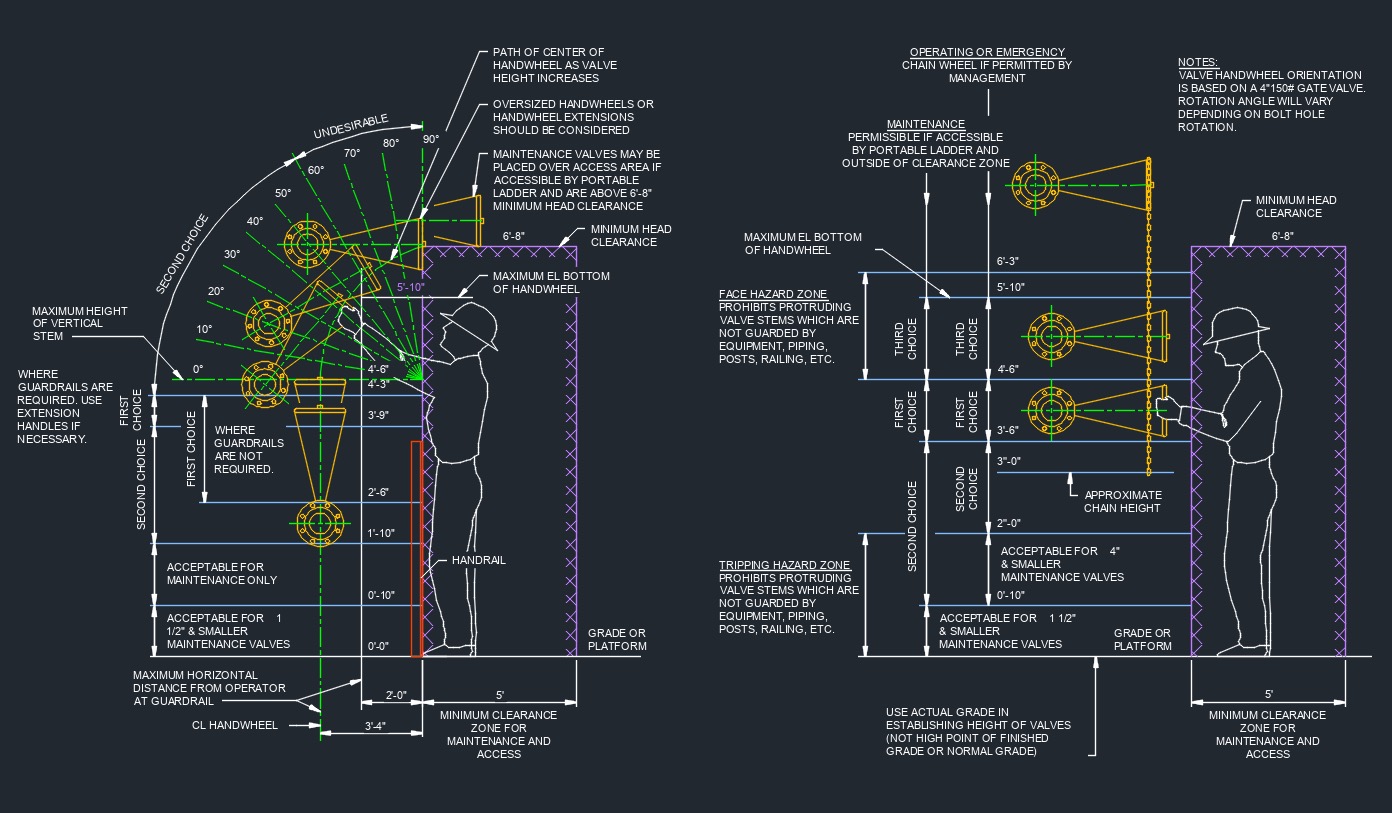

Valve Orientation

When ever possible, valves should be installed with the stem pointed straight up, since this position makes it much easier for maintenance. Valves can be rotated in the horizontal position with no real maintenance problems. But they should not be installed with the stem rotated downward unless needed for the design location. With the stem rotated down, the bonnet acts as a trap for abrasive material sediment and water.

Valves should be placed in the boundries of platforms within easy reach for operation and maintenance access.

Valve handles and levers should have a minimum 3" clearance.

Chain wheel operators can be used in hard-to-reach and inaccessible places to operate valves with the purpose to protect the employees and equipment. The valve stem needs to be horizontal to use a chain operator. Chains should never hang lower than the minimum required height so they do not become an obstacle or tripping hazard. The chains should always be smooth and free of burs or sharp edges.