Choke Valve

Choke Valves are valves used in severe service valves designed for oil and gas applications. They are used for controlling the flow rates or pressure on production, steam or water injection. Choke Valves are subjected extreme conditions which can cause erosion, corrosion and other damage. When used on controlling production flowback, solids that are found in the well bore may come up with the production fluids. Additionally, entrained gas may flash across the choke causing cavitation of the valve. For high differential pressure (DP) applications, the velocity through the valve may be very high causing erosion of the internal components.

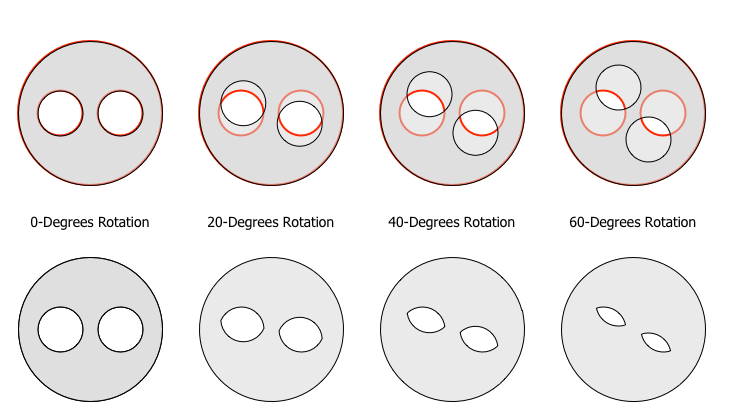

Chokes can be adjustable or non-adjustable based on the valve design. Adjustable chokes can have a very high turndown to cover a very wide range of flow rates or pressure differentials. An example of an adjustable choke profile is below. There are two disks that sit on top of each other. When the valve is completely open, holes in the disk are perfectly aligned, letting the fluid pass through relatively unobstructed. As the valve is turned, the upper disk is rotated causing the flow path to get smaller. As the holes get smaller, the velocity through the disks increases. Downstream of these disks will subject to extreme conditions of high velocity flow rates and cavitation in the valve.

Equipment Multi Orifice Choke Profile - Click to Enlarge

Equipment Multi Orifice Choke Profile - Click to Enlarge

Non-adjustable chokes typically have a piece of metal inthe choke, called a 'bean' which is designed to a specific flow rate and DP. A bean is a rod with a set diameter that decreases the flow area through the valve which affects the pressure drop. Like any non-adjustable control valve, using a bean choke is best served in applications that have very little fluctuation in upstream flow and pressure.