Orifice Plate

Orifice Flange and Plate Datasheets | |||

|---|---|---|---|

| Class | Orifice Flange Raised Face | Class | Orifice Plate Raised or Flat Face |

| ANSI 300 | Orifice WNF, ANSI Class 300 (in) | ANSI 125 - 2500 | Orifice Plate - ANSI Class 125-2500 (in) |

| ANSI 400 | Orifice WNF, ANSI Class 400 (in) | ||

| ANSI 600 | Orifice WNF, ANSI Class 600 (in) | ||

| ANSI 900 | Orifice WNF, ANSI Class 900 (in) | ||

| ANSI 1500 | Orifice WNF, ANSI Class 1500 (in) | ||

| ANSI 2500 | Orifice WNF, ANSI Class 250o (in) | ||

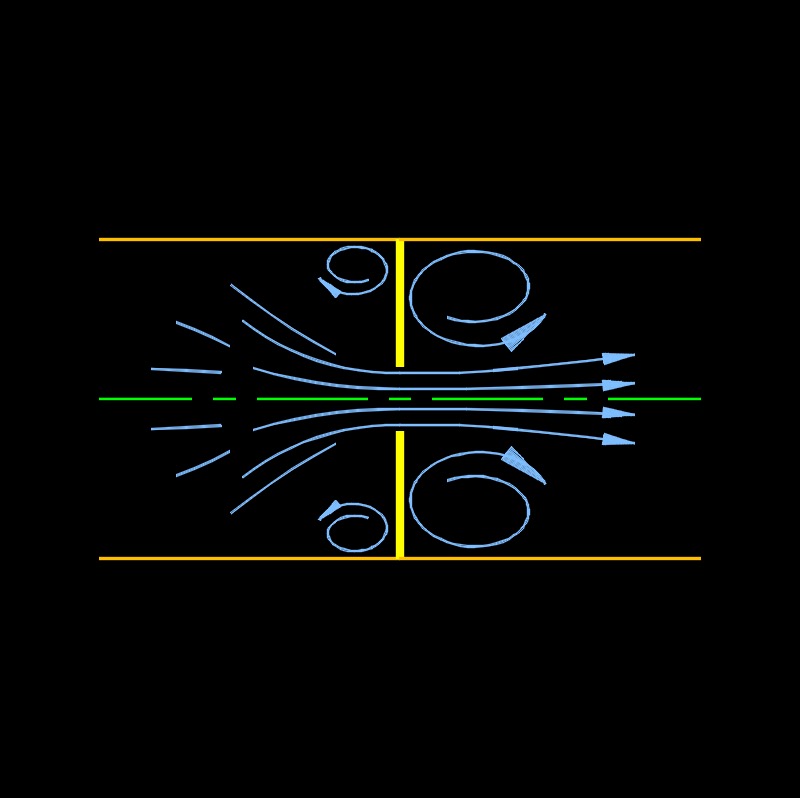

An orifice plate measures the flow of a liquid or gas by the difference in pressure from the upstream to the downstream. This plate creates a restriction in a pipe that causes a difference in pressure between the two sides. A meter then measures the difference in pressure across the orifice plate. The plates should be installed in a straight run of pipe in order to avoid turbulance at the plate. The upstream side is longer than the downstream in order to straighten the flow before the plate. It is calculated at so many diameters of pipe, 10D, 12D, ect. for the length. Orifice plates are used between orifice flanges and are part of an orifice meters.

An orifice plate measures the flow of a liquid or gas by the difference in pressure from the upstream to the downstream. This plate creates a restriction in a pipe that causes a difference in pressure between the two sides. A meter then measures the difference in pressure across the orifice plate. The plates should be installed in a straight run of pipe in order to avoid turbulance at the plate. The upstream side is longer than the downstream in order to straighten the flow before the plate. It is calculated at so many diameters of pipe, 10D, 12D, ect. for the length. Orifice plates are used between orifice flanges and are part of an orifice meters.

The orifice plate is described as a thin plate and with sharp edge, because the thickness of the plate material is small compared with the internal diameter of the measuring aperture (bore) and because the upstream edge of the measuring aperture is sharp and square. Plates should not be bent or have any nicks in the internal bore, this will create an error in the data.

Information about the plate should be stamped where it can be easily identified after installation. Orifice plates have data stamped on upstream face. Following installation, care should be taken to ensure the gasket does not protrude into the flow area. Pressure taps should be on the top or side of a pipe to prevent sediment/partials from settling in them.

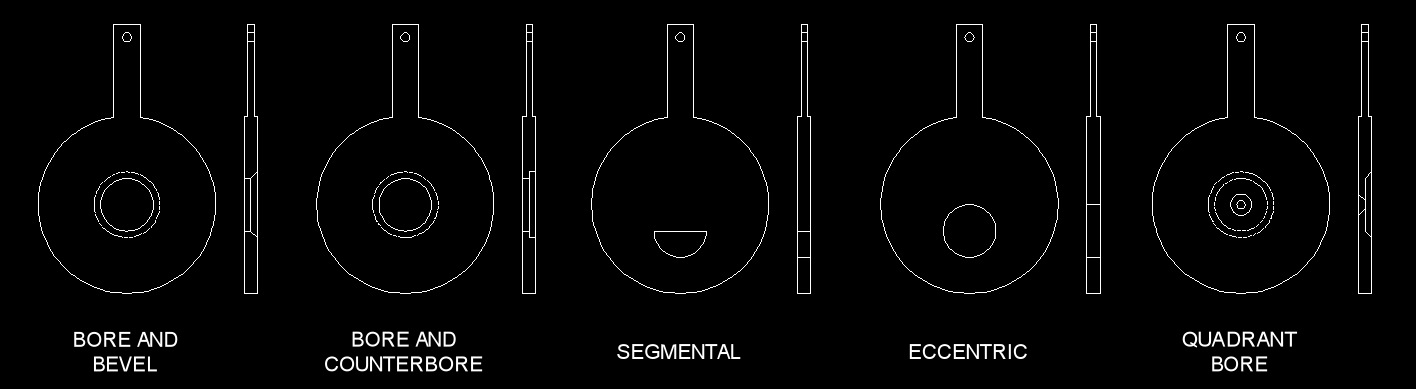

Orifice Plate Design Classification

Bore and Bevel - This is the most common plate method used. The bevel is at a 45° angle and can be machined to a specified plate thickness. The bore and bevel is the standard method of limiting the plate edge thickness. Unless otherwise specified, plates will be bevelled to 1/50 of the line I.D. or 1/8 of the orifice bore, minimum governing.

Bore and Counterbore - This plate can be counter bored to make the desired plate thickness. This bore is a special method in limiting the plate edge thickness. Instead of beveling at the normal 45°, the plate is counter bored to the desired edge thickness.

Conditioning - A conditioning orifice plate has four holes and requires no more than two diameters of straight pipe upstream and downstream. A conventional orifice plate has a single hole. Another advantage is the ability to place one of the holes at the bottom of the pipe to minimize the risk of liquid restriction. Conditioning plates are specially designed with additional flow conditioning elements, such as flow straighteners or multi-hole configurations. These elements help to improve the flow profile and reduce turbulence effects, leading to more accurate measurements. Conditioning orifice plates are used in applications where flow disturbances or non-ideal flow profiles need to be mitigated.

Eccentric - This plate is for measuring solids or slurries. This is used in steel, water treatment, sewer treatment, oil, and paper. In an eccentric orifice plate, the orifice opening is offset from the center of the plate. This design helps to reduce the potential for blockage or clogging, making it suitable for fluids with suspended solids or debris. Eccentric orifice plates are often used in applications where avoiding the buildup of debris or sediments is crucial.

Quadrant Bore - This plate has an orifice with the inlet edge rounded. The thickness of the throat is equal to the radius. This design is for fluids of high velocity, such as heavy crudes, slurries and syrups. This design helps to minimize the impact of turbulence and reduce the sensitivity to flow disturbances. Quadrant edge orifice plates are often used in applications where a smooth and stable flow profile is desired.

Segmental - This plate is for measurements where solids are mixed in a gas or liquid flow stream. You can place the opening either at the top or bottom of the pipe. This is used in steel, water treatment, sewer treatment, oil, and paper. The segmental orifice plate has a segment shaped orifice opening instead of a circular one. This design is particularly useful for measuring viscous fluids, as it reduces the pressure drop across the plate and minimizes the potential for flow disturbances. These are commonly used in applications where accurate measurements of high viscosity fluids are required.

What is an Orifice

An orifice is a small opening or hole through which fluid or gas can flow. It is typically a narrow passage that controls the rate of flow or pressure of the fluid or gas. Orifices can be found in various systems and devices, such as pipes, nozzles, valves, and meters.

In fluid dynamics, an orifice is often used to measure or control the flow rate of a fluid. By placing an orifice plate or a similar device with a precisely sized hole in a pipe, the flow of the fluid can be restricted, and the pressure difference across the orifice can be measured to determine the flow rate. This principle is utilized in applications like flow meters and flow control valves.

Orifices can also be used to create pressure differentials or generate specific fluid behaviors. For instance, in some fluid systems, orifices are employed to increase the velocity of a fluid by reducing the area cross-section, which can be useful in applications such as atomization or creating a jet of fluid.

The term "orifice" is often associated with fluid dynamics and engineering but can be used more broadly to refer to any small opening or hole through which things can pass.

Geometric Orifice Area (GOA) - The orifice opening

Effective Orifice Area (EOA) - The minimal cross-section area of the downstream jet.

Contraction Coefficient (\(C_c\)) - The ratio of the area measured at the vena contracta (EOA), to the area of the orifice (GOA) or \(C_c = \frac{EOA}{GOA}\)

Discharge Coefficient (\(C_d\)) - The ratio of actual flow to ideal flow or \(C_d = \frac{Q_a}{Q_i}\)

Orifice Plate Standards

- ISO 5167-1 - Measurement of fluid flow by means of pressure differential devices inserted in circular cross-section conduits running full -- Part 1: General principles and requirements

- ISO 5167-2 - Measurement of fluid flow by means of pressure differential devices inserted in circular cross-section conduits running full -- Part 2: Orifice plates