Flat Faced Flange

Flat faced flange, abbreviated as FF, is a flange that is machined flat and does not have a ridge like a raised face or ring type joint flange. The flat surface allows for the gasket to have full contact with the entire mating surface. The purpose of the flat face is to eliminate the bending moment put on the flange when the bolts are torqued. When using cast iron or fiberglass flanges, this bending moment can easily break the flange.

It is possible but uncommon for flat face flange gaskets to be metallic gaskets. Usually gaskets are made from non-metallic materials such as EPDM or Viton. It should go without saying that only flat face gaskets should be used on flat face flanges.

In general, flat faced flanges are used in low pressure and temperature environments such as water treatment or pump suction flanges. Flat face flanges are usually common when the piping or piping components are brittle such as plastic, fiberglass or cast iron. However, it should be noted that these flanges come in all different types of materials, including steel.

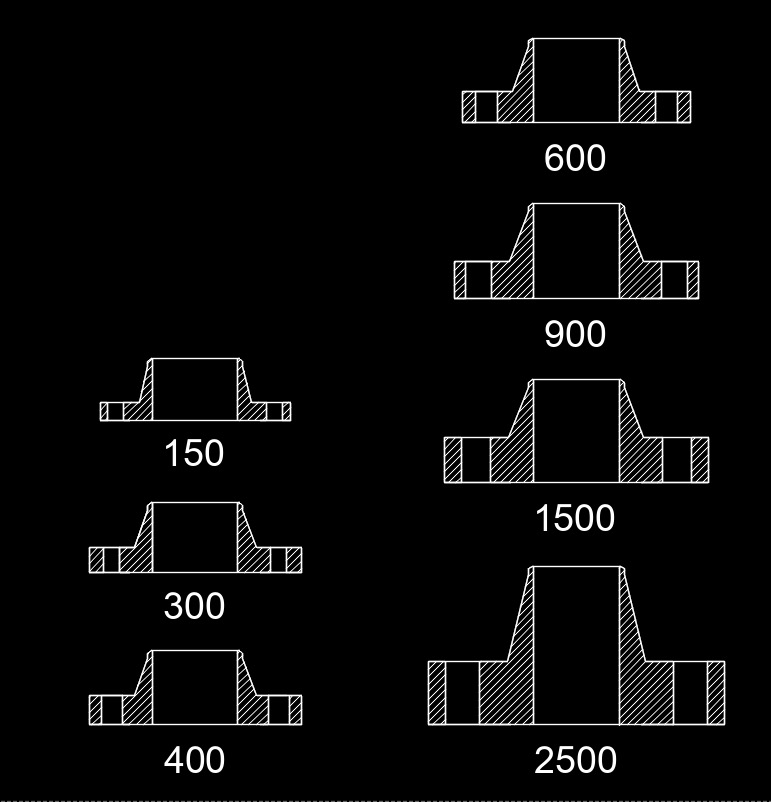

These flanges typically are available in weld neck, slip-on, socket weld, or threaded. Typically, flat face flanges are found in ANSI 150 & 300 ratings.

Flat Faced Flange Design Considerations

Flat faced flanges should not be installed to flanges that are not flat faced. While some codes specify that mating surfaces should both be flat (ASME B31.1), it is good design practice to not mix flange facings whenever possible. The reasoning for this is that the flat faced flange may not be designed to withstand the forces put on the outer most edge when the bolts and nuts are tightened.

The dimensions for a flat faced flange are the same as the dimenisions for a raised face flange but without the raised face.