Welding to a Flange

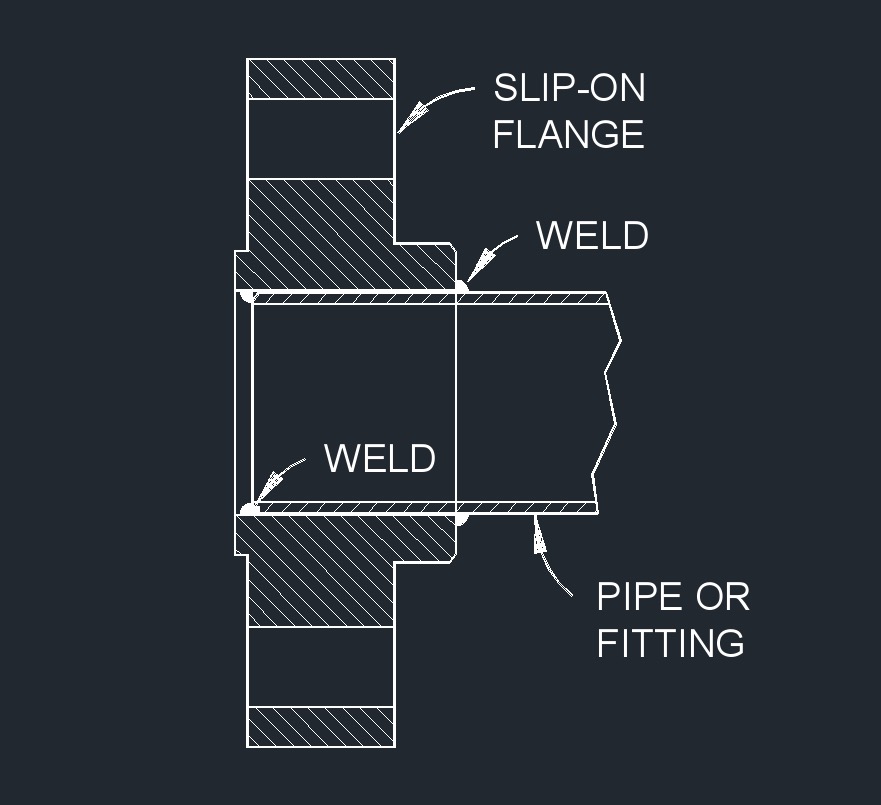

When welding a flange, fitting or a piece of pipe together the gap spacing for welding them is established by the Welding Qualification. API Std 1104 (Standard for Welding of Pipelines and Related Facilities) calls for a 1/16" space. On a socket weld, its 1/16" and can be established with a special spring. The offset between welds cannot be greater than 1/8". When welding a slip-on flange, the pipe or fitting is set back from the face of the flange a distance equal to the wall thickness -0" +1/16".

Welding to a flange typically refers to the process of joining a component, such as a pipe, fitting, or another flange, to the flanged end of another component. Flanges are flat, typically circular, or square plates with holes used to connect and seal pipes, valves, and equipment in various industries. Welding to a flange can be done using different welding techniques based on the specific requirements of the application.

Welding to a Flange general Overview Process

Preparation - Ensure that the flange and the component to be welded are clean and free from contaminants, oil, and debris. Verify the dimensions and alignment to ensure a proper fit between the flange and the component.

Welding Technique - The choice of welding technique depends on the type of flange, material being welded, and the application. Common methods include:

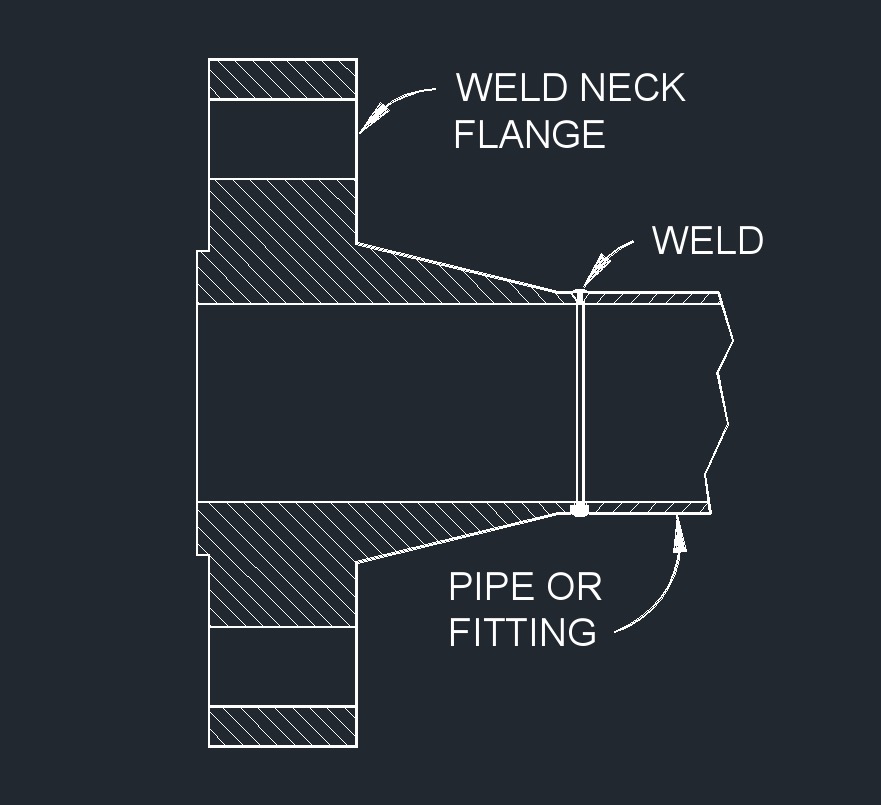

- Welding Neck Flange - This type of flange has a neck that extends from the flange body. It's typically welded to the pipe using a full penetration weld.

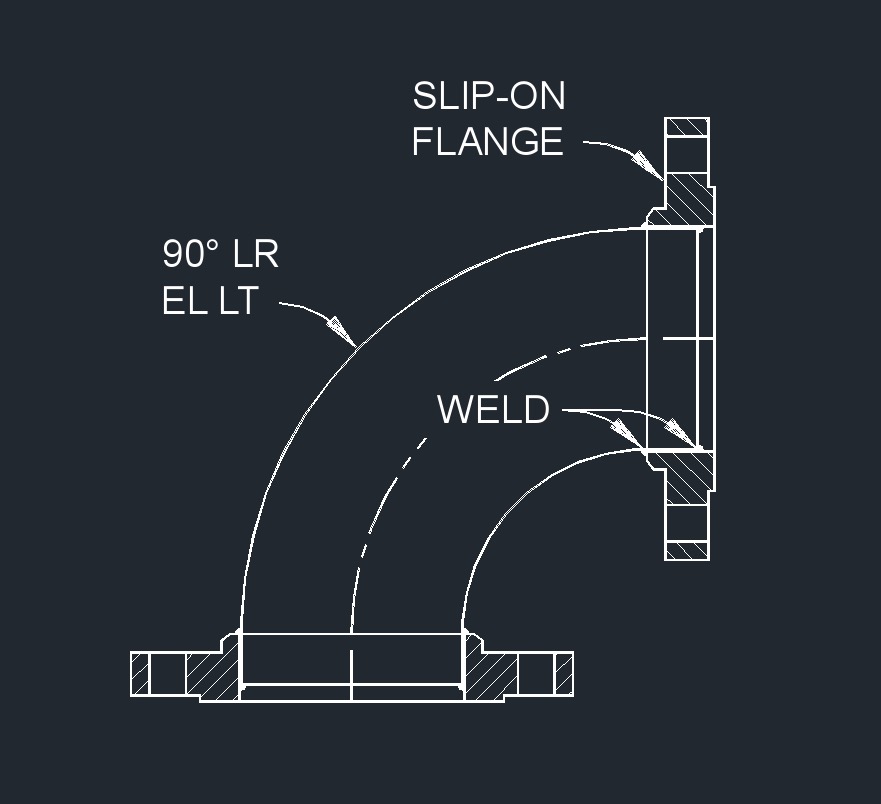

- Slip-On Flange - The pipe or component slips over the flange, and welding is done around the inner and outer diameters.

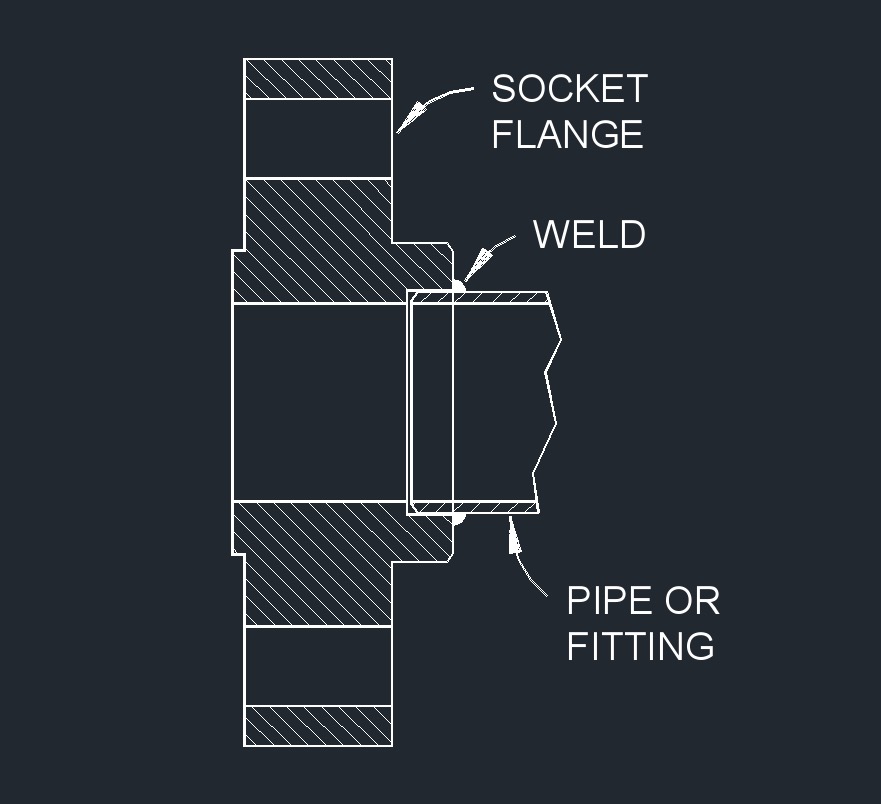

- Socket Weld Flange - The pipe is inserted into the socket of the flange, and a fillet weld is made at the base of the socket.

- Threaded Flange - Instead of welding, this flange is connected by screwing the pipe into the threaded bore of the flange.

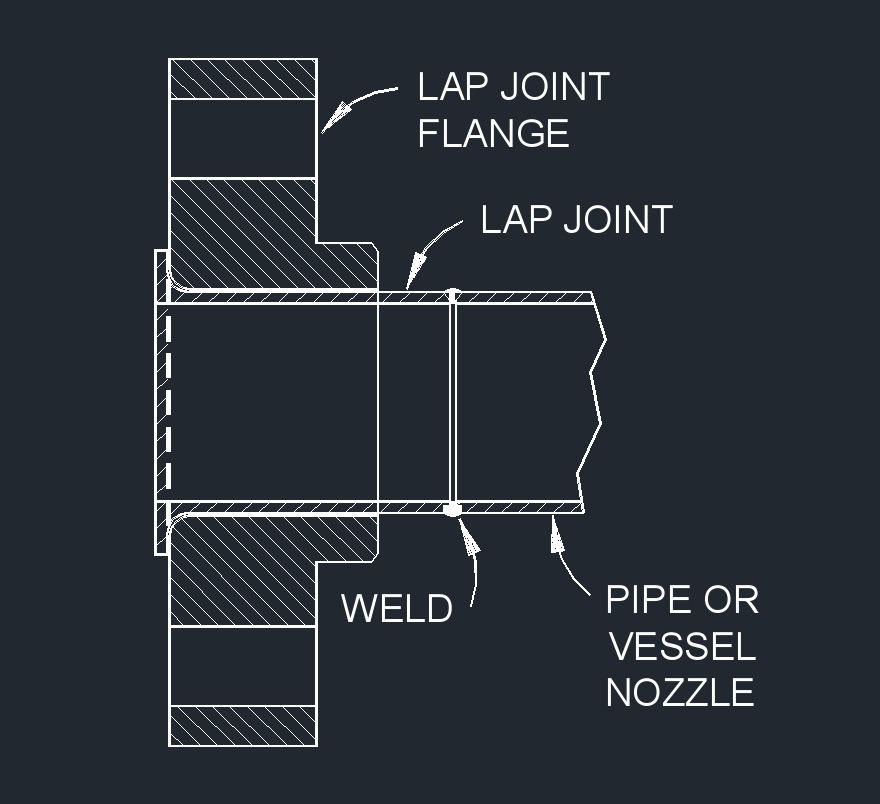

- Lap Joint Flange - This type of flange is used in conjunction with a stub end fitting. The stub end is welded to the pipe, and the lap joint flange is slipped over the stub end and welded to it.

Welding Procedure - The welding process used could be TIG (Gas Tungsten Arc Welding), MIG (Gas Metal Arc Welding), or other methods. Depending on the type of flange and component, welding parameters such as current, voltage, travel speed, and filler material are adjusted for proper fusion and penetration.

Quality Control - Inspect the weld joint visually to ensure complete fusion, penetration, and absence of defects such as cracks or voids. Non-destructive testing (NDT) methods like X-rays, ultrasonic testing, or dye penetrant testing might be used for critical applications to verify the integrity of the weld.

Post-weld Treatment - Depending on the application and material, post-weld treatments like stress relieving or heat treatment might be necessary to ensure the stability and strength of the welded joint.

Welding to a flange requires careful consideration of factors like the type of flange, the material being welded, the welding method, and the intended use of the assembly. Proper welding practices and quality control measures are crucial to achieve a strong, reliable, and leak-free joint.

Weld Neck Flange

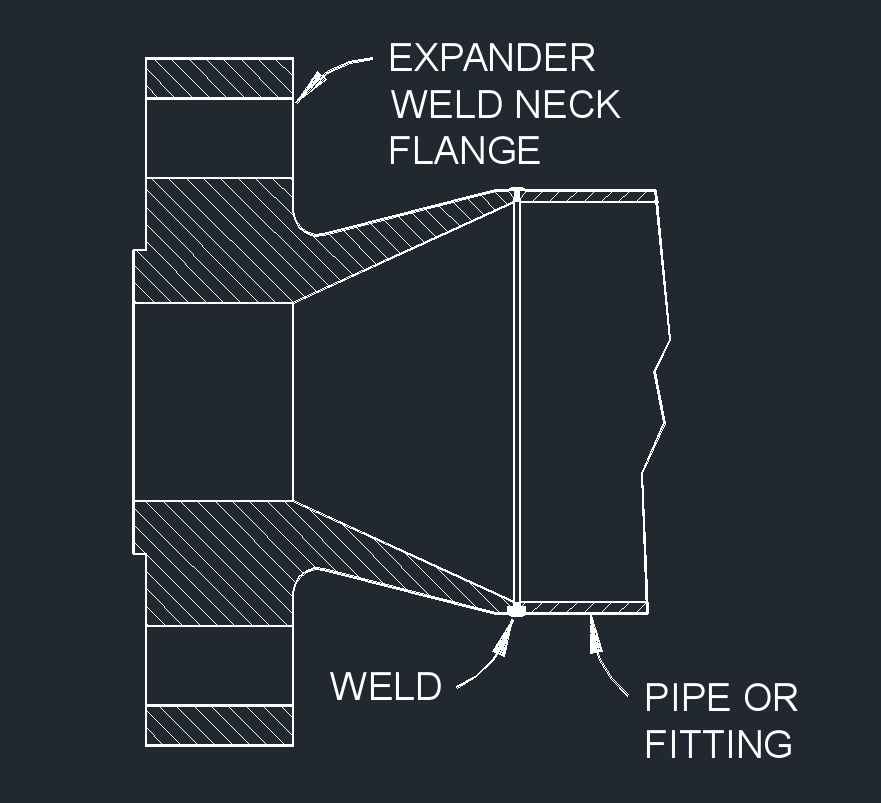

Weld Neck Flange Expander Flange

Expander Flange Lap Joint Flange

Lap Joint Flange

Slip-on Flange

Slip-on Flange Socket Weld Flange

Socket Weld Flange Slip-on Flange w/90 Elbow Long Tangent

Slip-on Flange w/90 Elbow Long Tangent

Tags: Pipe Fitting Pipe Flange Welding