A blind flange, abbreviated as BF, is a piping component for covering or closing the end of a pipe, valve, vessel or tank. When used at the end of a pipe, vessel or tank, it provides an easy open access for further extension of the pipe. Because the blind flange’s sole purpose is to contain the pressure of the pipe, it (and its bolts) are stressed more than any other flange.

A blind flange, abbreviated as BF, is a piping component for covering or closing the end of a pipe, valve, vessel or tank. When used at the end of a pipe, vessel or tank, it provides an easy open access for further extension of the pipe. Because the blind flange’s sole purpose is to contain the pressure of the pipe, it (and its bolts) are stressed more than any other flange.

Blind flanges are commonly used in any industries that utilize piping. They are available in all face types (RTJ, Raised and Flat Face) at all pressure ratings. A blind can be inserted between two flanges to block flow but this isn’t good practice in most piping. When trying to block flow temporarily in a pipe, the designer should use a spectacle blind instead.

A blind flange would be used at the end of a valve to ensure the accidental opening of a valve will not cause an escape of the process fluid.

When designing a piping system for expansion, a blind flange can be used to allow for bolting on piping when the expansion is completed. This design allows for expansion or continuation of the pipeline by simply adding onto the final flange. If used on a manifold in dirty service a blind flange can be used by the operations and maintenance staff to clean out or inspect the piping during a shutdown.

When placing a blind flange on a vessel manway, consider how it will be removed. It may require the addition of a lifting eye for a crane or a specially designed davit to hold the flange in place after the bolts are removed. Care should be taken in that the davit must be designed to be able to hold the entire weight of the flange.

Blind Flange Advantages and Disadvantages

|

|---|

| Advantages | Disadvantages |

|---|

- A blind flange is to close the end of a pipe, providing a sealed and closed system. This is useful during maintenance, testing, or when a pipe or vessel is not in use.

- Blind flanges are often used during pressure testing of a pipeline. They can be installed temporarily to block the flow, allowing pressure tests to be conducted on the system.

- When a pipeline or vessel needs to be kept free from contaminants or foreign material, a blind flange can be used to seal off the end and prevent unwanted substances from entering.

- Blind flanges are relatively simple to install and remove, making them convenient for temporary closures or when frequent access is required.

- Blind flanges come in various materials, sizes, and pressure ratings, making them suitable for a wide range of applications across different industries.

|

- While blind flanges provide a sealed closure, they also hinder access to the interior of the pipe or vessel. Complete removal of the blind flange is necessary to access the system, which can be time consuming.

- Improper installation or damaged gaskets can lead to leakage in the sealed system. Regular inspection and maintenance are essential to prevent potential issues.

- Blind flanges, especially in larger sizes or high pressure applications, can be more expensive than some alternative closure methods. The cost of materials and installation should be considered in the overall project budget.

- In large diameter pipes or high pressure systems, blind flanges can be heavy and bulky. Handling and installing them may require additional equipment and manpower.

- If blind flanges are used in systems that require frequent access, the need to install and remove them regularly can pose challenges in terms of maintenance and operational downtime.

|

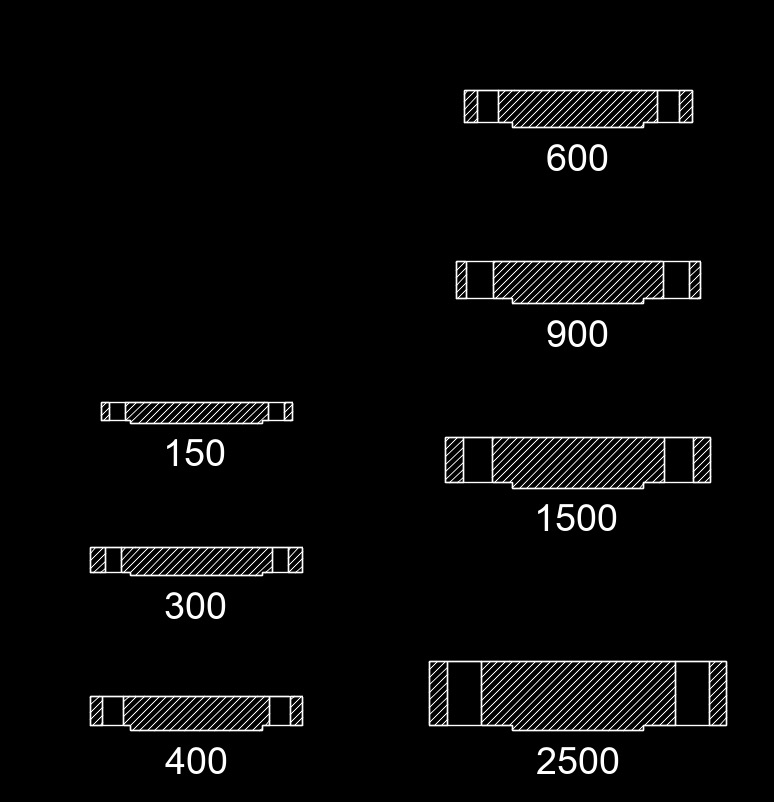

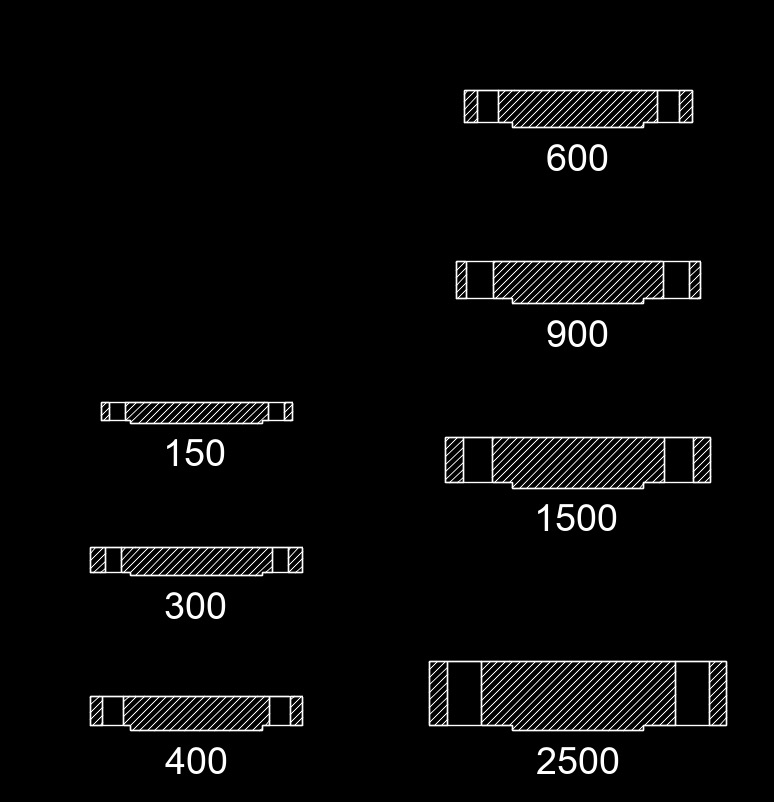

Blind Flange Datasheets

The datasheets we have on this site are shown below. For simplicity sake, only datasheets that adhere to B16.5 are shown. ASME B16.5 covers flange dimensions from ½” to 24”. For sizes larger than this (ASME B16.47 Series A & B), please visit our flange datasheets page.

|

|---|

| Class | Flat Faced | Raised Face | Ring Type Joint |

|---|

| ANSI 150 |

Blind Flange, ANSI 150 FF (in) |

Blind Flange, ANSI 150 RF (in) |

Blind Flange, ANSI 150 RTJ (in) |

|---|

| ANSI 300 |

Blind Flange, ANSI 300 FF (in) |

Blind Flange, ANSI 300 RF (in) |

Blind Flange, ANSI 300 RTJ (in) |

|---|

| ANSI 400 |

Blind Flange, ANSI 400 FF (in) |

Blind Flange, ANSI 400 RF (in) |

Blind Flange, ANSI 400 RTJ (in) |

|---|

| ANSI 600 |

Blind Flange, ANSI 600 FF (in) |

Blind Flange, ANSI 600 RF (in) |

Blind Flange, ANSI 600 RTJ (in) |

|---|

| ANSI 900 |

Blind Flange, ANSI 900 FF (in) |

Blind Flange, ANSI 900 RF (in) |

Blind Flange, ANSI 900 RTJ (in) |

|---|

| ANSI 1500 |

Blind Flange, ANSI 1500 FF (in) |

Blind Flange, ANSI 1500 RF (in) |

Blind Flange, ANSI 1500 RTJ (in) |

|---|

| ANSI 2500 |

Blind Flange, ANSI 2500 FF (in) |

Blind Flange, ANSI 2500 RF (in) |

Blind Flange, ANSI 2500 RTJ (in) |

|---|

A blind flange, abbreviated as BF, is a piping component for covering or closing the end of a pipe, valve, vessel or tank. When used at the end of a pipe, vessel or tank, it provides an easy open access for further extension of the pipe. Because the blind flange’s sole purpose is to contain the pressure of the pipe, it (and its bolts) are stressed more than any other flange.

A blind flange, abbreviated as BF, is a piping component for covering or closing the end of a pipe, valve, vessel or tank. When used at the end of a pipe, vessel or tank, it provides an easy open access for further extension of the pipe. Because the blind flange’s sole purpose is to contain the pressure of the pipe, it (and its bolts) are stressed more than any other flange.