Welding Engineering

Mechanical, Welding, Engineering Welding is the fabrication process that fuses like materials togeather by heating them to a suitable temperatures, this can be acomplished by brazing, soldering or welding. The filler metal has a melting point approximately the same or below that of the metals being joined togeather. Welding is done by melting like metals then add a filler material to the joint, once cooled forming a sturdy joint. Brazing and soldering is the melting of a filler material that is pulled into the gap between materials joining them togeather. The brazing filler has a melting point below the materials being joind togeather.

Welding is the fabrication process that fuses like materials togeather by heating them to a suitable temperatures, this can be acomplished by brazing, soldering or welding. The filler metal has a melting point approximately the same or below that of the metals being joined togeather. Welding is done by melting like metals then add a filler material to the joint, once cooled forming a sturdy joint. Brazing and soldering is the melting of a filler material that is pulled into the gap between materials joining them togeather. The brazing filler has a melting point below the materials being joind togeather.

| Engineering |

| Mechanical Engineering |

- See Articles - Beam Design Formulas / Frame Design Formulas / Plate Design Formulas / Geometric Properties of Structural Shapes / Welding Stress and Strain Connections / Welding Symbols / Welding Glossary

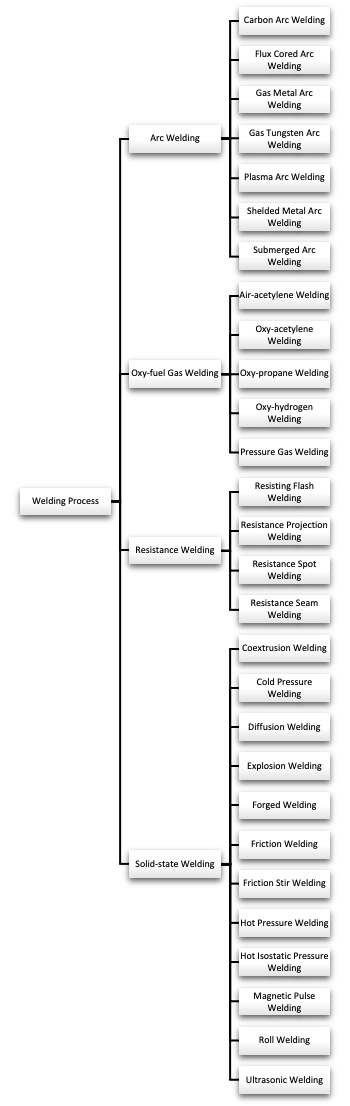

Welding Process

Arc Welding

A group of welding processes used to weld metal using heat of an electric arc, with or without filler material.

- Carbon Arc Welding - A process with an electric arc is struck between a carbon electrode and the work piece.

- Flux Cored Arc Welding - This process has a constantly fed electrode that becomes part of the weld. The flux cored electrode is a composit tubular filler metal surounded with a core of mineral compounds and powdered metals.

- Gas Metal Arc Welding - Also called MIG (metal inert gas) welding. This process has a constantly fed electrode that becomes part of the weld. Also a seperate tank adds inert gas to the arc in order to ensure that oxidation does not occur during the menting process.

- Gas Tungsten Arc Welding - Also called TIG welding and heliarc welding. The arc is created between a non-consumable tungsten electrode and the workpiece.

- Plasma Arc Welding - The arc is created between a non-consumable tungsten electrode and the workpiece. Plasma gas, usually argon, is added between the electrode and the nozzle.

- Shielded Metal Arc Welding - Also called stick welding. Is one of the older arc welding method by heating with an arc between a flux covered electrode (filler material) that melts to form a weld pool, which cools and joins the two to metals.

- Submerged Arc Welding - This type of weld is usually used on thick steel with longer welds. It is created by submerging the electric arc beneath a layer of powdered flux.

Oxy-fuel Gas Welding

Oxy-fuel Gas Welding

A group of welding processes used to weld metal using heat from a combination of oxygen and a fuel gas.

- Air-acetylene Welding - Uses air-aceetylene flame without the application of pressure. Not used very often.

- Oxy-acetylene Welding - Uses acetylene as a fuel gas.

- Oxy-propane Welding - Uses propane as a fuel gas.

- Oxy-hydrogen Welding - Uses hydrogen as a fuel gas.

- Pressure Gas Welding - Makes a weld simultaneously over the entire surface. This is done with pressure and without filler material.

Resistance Welding

A group of welding processes used to weld metal using electric current to force join by pressure of the metals. The current passed through and heats the metals until they begin to melt at the spot where they are in contact.

- Resistance Flash Welding - Also called butt welding. The work pieces act as an electrode and the entire cross-section gap is welded. Two secured work pieces are placed close togeather and a current is applied. The current creates an arc between the two work pieces, melting both togeather.

- Resistance Projection Welding - The curent is focused from electrode to electrode through the tip of the projection. This concentrates on specific raised sections or projections of a work piece. The weld current and force can be forcused into a small area of the projection to produce heat at a specific spot. During the process the projection collapses making it impossible for further welding since the large surface of the electrode diffuses under current density.

- Resistance Spot Welding - The curent is focused from electrode to electrode and disperced between the two. Two operlapping work pieces are placed togeather creating a surface between the two. An electrode is placed on each side of the work piece across from each other. An electric charge between the two electrodes melts the two pieces togeather from the center out.

- Resistance Seam Welding - The electroces are two copper wheels constantly applying force to the work piece, each rooling on opposite sides of the materials. The electric charge can be applied in spurts or at a constant feed.

Solid-state Welding

A group of welding processes used to weld metal by requiring a temperatures below the melting point of the base metal being joined, without the addition of brazing filter metal.

- Coextrusion Welding - Dissimilar metals are extruded through the same die.

- Cold Pressure Welding - A pressure is applied at room temperature to cause compress and bond the materials togeather. This process has no heat or flux and one of the materials must be highly ductile.

- Diffusion Welding - Uses heat and pressure in a controlled atmosphere, with enough time for diffusion and coalescence to happen.

- Explosion Welding - Also called explosive cladding. Combines two metals togeather with an explosive force causing enough energy to form a metallic bond.

- Forge Welding - The workpieces are heated to the welding temperature and hamered togeather to make the weld.

- Friction Welding - The compressive force contact of workpieces rotating or moving relative to one another to produce heat from the faying surfaces.

- Friction Stir Welding - A rapidly rotating tool traversing a joint between two metals creating friction heating and plastic material displacement welding the seam togeather.

- Hot Pressure Welding - Metals are pressed togeather at elevated temperatures below the melting point in a vacuum or an inert gas atmosphere.

- Hot Isostatic Pressure Welding - A hot inert gas applies pressure inside a pressure vessel.

- Magnetic Pulse Welding - Short electromagnetic pulses produce a high-density magnetic field in the workpiece. This causes plastic deformation along the workpiece and the two pieces to share electrons at the atomic level.

- Roll Welding - Also called roll bonding is a cold welding process. Two or more metals are fed through a cold rolling mill under enough pressure to compress and bond the materials togeather.

- Ultrasonic Welding - Two workpieces are held togeather, the oscillatory shear stresses of ultrasonic frequency causes coalescence or welding.