Flex Connector Datasheets

|

| Class |

Flex Connector |

| Flex Connector |

|

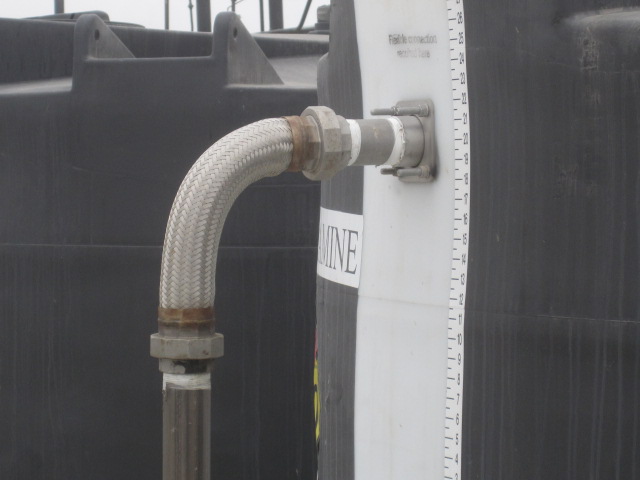

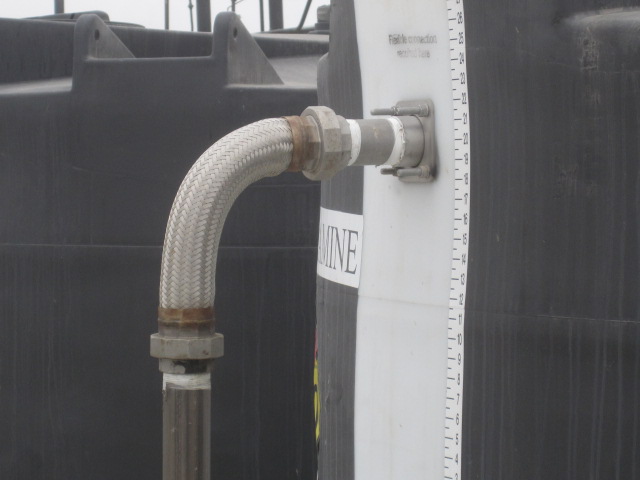

Flex connector, also called flexible pipe connector or expansion joint, is a mechanical device used in piping systems to absorb and compensate for movements, vibrations, thermal expansion, and contraction. These movements can occur due to changes in temperature, pressure, or mechanical forces, and they can stress or damage the piping system if not properly managed.

A flex connector is used primarily to take the stress off pumps and motors when noise absorption, vibration, or thermal growth may happen. Also if you did not engineer or install the equipment properly it can allow minor alignment to happen. Which is not the idea. The coupling is a stainless steel corrugated hose with stainless steel braid and comes in all sizes and lengths. Both ends do not have to be the same.

Piping Flex Connectors Serve Several Important Purposes

Absorb Thermal Expansion and Contraction - Piping systems can experience temperature variations, causing

pipes to expand and contract. Flex connectors provide flexibility, preventing excessive stress on the system and maintaining the integrity of the pipes.

Dampen Vibration and Shock - In systems where there is vibration or pulsation, such as in industrial processes or HVAC (heating, ventilation, and air conditioning) systems, flex connectors absorb and dampen these vibrations, reducing the risk of damage to the pipes and connected equipment.

Isolate Noise - Flex connectors can also help in reducing noise transmission within a piping system, which is especially important in applications where noise control is a consideration.

Compensate for Misalignment - Flex connectors can compensate for slight misalignments or offsets in the piping system, ensuring a proper fit and preventing leaks or damage that might occur if pipes were rigidly connected.

Maintain System Integrity - By accommodating movements and stress, flex connectors help extend the life of the piping system and prevent leaks or catastrophic failures.

Piping flex connectors come in various designs, including bellows style, braided, or other flexible configurations. The choice of flex connector type depends on the specific requirements of the piping system, such as the type of fluid being transported, temperature ranges, pressure levels, and the nature of movements or vibrations that need to be accommodated.

These connectors are essential components in various industries, including chemical processing, petrochemical, power generation,

HVAC, and more, where maintaining the integrity and safety of piping systems is critical. Proper selection and installation of flex connectors are crucial to ensuring the efficient and reliable operation of piping systems while minimizing maintenance and repair costs.