Pipe Fitting

Pipe, Pipe Fitting, Pipe Flange, Valve, Pipeline Pipe fittings are components used to connect and join sections of pipe or tubing together. They are used to change the direction of flow, control the flow rate, or to provide a connection between different types of pipes or tubing. Pipe fittings come in many different types, materials, and sizes, depending on the specific application and requirements. They can be made of materials such as metal, plastic, or rubber, and can be designed to handle different levels of pressure, temperature, and corrosiveness. Pipe fittings are essential components of many industrial and commercial applications, such as in the oil and gas industry, water treatment plants, and HVAC systems. They play a critical role in ensuring the safe and efficient flow of fluids and gases, and are often subject to strict regulations and standards to ensure their performance and durability.

Pipe fittings are components used to connect and join sections of pipe or tubing together. They are used to change the direction of flow, control the flow rate, or to provide a connection between different types of pipes or tubing. Pipe fittings come in many different types, materials, and sizes, depending on the specific application and requirements. They can be made of materials such as metal, plastic, or rubber, and can be designed to handle different levels of pressure, temperature, and corrosiveness. Pipe fittings are essential components of many industrial and commercial applications, such as in the oil and gas industry, water treatment plants, and HVAC systems. They play a critical role in ensuring the safe and efficient flow of fluids and gases, and are often subject to strict regulations and standards to ensure their performance and durability.

| Engineering |

| Mechanical Engineering |

- See Articles - List of Tags / List of Categories / List of Articles / List of Glossaries / Nomenclature and Symbols / (See Pipe Fitting Glossary)

Pipe Fitting Datasheets | |

|---|---|

| Pipe Fitting Type | Datasheets |

| Fittings | All Fittings, ANSI (in) |

| Buttweld | Buttweld Fitting, ANSI (in) |

| Ductile Iron Flange | Ductile Iron Flange Fitting, ANSI (in) |

| Flex Connector | Flex Connector Fitting, ANSI (in) |

| O'let | O'let Fitting, ANSI (in) |

| PVC | PVC Fitting, ANSI (in) |

| Socket | Socket Fitting, ANSI (in) |

| Threaded | Threaded Fitting, A |

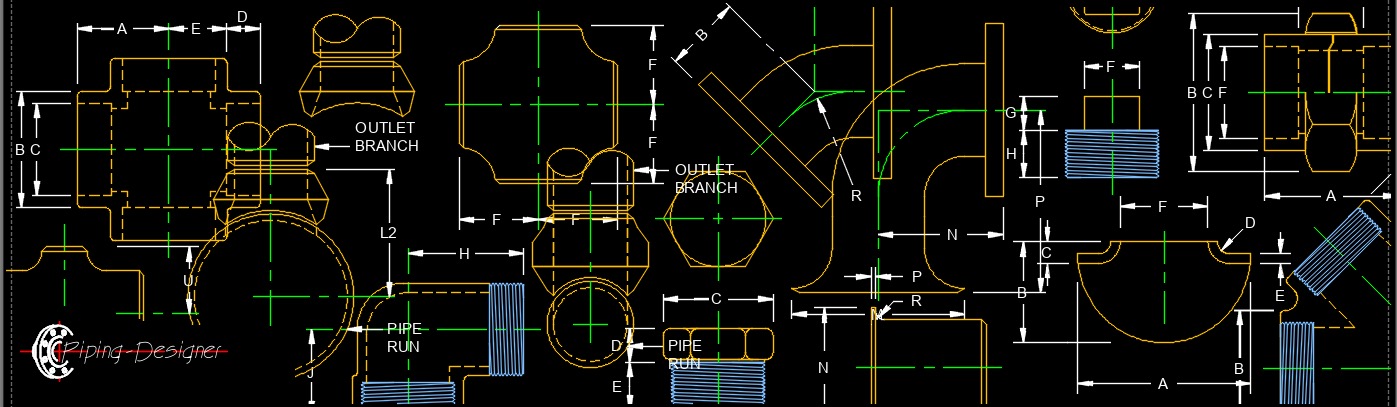

Pipe Fitting Types

Pipe fittings can be broken down into several categories:

- Branch Connection - Branch connections are used when two or more pipes come together. These can be in the form of a complete fitting, such as a tee or cross. They can also be in the form of an O’let which is a branch connection that is designed to attach directly to the pipe. Branch connections are available in buttweld, socket weld, threaded and flanged.

- Cap - Weld caps are used to seal the end of the piping. It might be used when old pipe is being abandoned or with a tee to form a hydraulic elbow. Caps are available in buttweld only.

- Coupling - Couplings are used to join two different threaded pieces of pipe. When a coupling is used, it is important not to over torque the piping, otherwise damage to the coupling or union can occur. Couplings are available for threaded pipe only.

- Elbow - These are useful when needing to change direction of flow. Typical elbow directions are 45, 90 and 180 degrees. Elbows are available in buttweld, socket weld, threaded and flanged.

- Reducer - Reducers are used when the pipe needs to change diameter. Reducers are available in buttweld, socket weld, threaded and flanged.

Pipe Fitting End Connection Types

There are four different type of connections that are used for fittings:

- Buttweld Fitting - Probably the most common type of fitting. They are easily manufactured and are easily installed. Butt weld fittings can be connected directly to each other. This is called fitting make up.

- Flanged Fitting - Flanged fittings are piping components where the flange is an integral component of the fitting. These are most often used in water treatment applications or lined piping where welding would be destructive to the liner.

- Socket Weld Fitting - These fittings have a socket weld connection on each end. They might be used for smaller diameter piping. These fittings utilize a single fillet weld to join the piping with the fitting.

- Threaded Fitting - Threaded fittings are generally four inches and smaller. The reason for this size constraint is the pipe end needs to be threaded with a male type connection and die sizes are unobtainable in the larger diameters.