Pipe Flange

Pipe, Pipe Fitting, Pipe Flange, Valve, Gasket, ASME Standards, Pipeline Flange, abbreviated as FLG, is a bolted connection where two pieces of pipe, equipment, fittings or valves are connected together to form a piping system. Flanges provide access for when equipment (or piping) needs to be cleaned, inspected or reconfigured. A flange pair is made up of two flanges and a gasket with bolts and nuts. Pipe flanges come in different styles, pressure ratings, materials and sizes to meet the design requirements. In the oil field, the two most commonly used flange standards are ANSI/ASME B16.5 and BS 1560. API Spec 6A is for flanges used on wellhead and christmas tree equipment.

Flange, abbreviated as FLG, is a bolted connection where two pieces of pipe, equipment, fittings or valves are connected together to form a piping system. Flanges provide access for when equipment (or piping) needs to be cleaned, inspected or reconfigured. A flange pair is made up of two flanges and a gasket with bolts and nuts. Pipe flanges come in different styles, pressure ratings, materials and sizes to meet the design requirements. In the oil field, the two most commonly used flange standards are ANSI/ASME B16.5 and BS 1560. API Spec 6A is for flanges used on wellhead and christmas tree equipment.

| Engineering |

| Mechanical Engineering |

Flanges of different standards or materials are not normally joined together. There are instances where the design may require dissimilar metals or different classifications are required to be bolted together. When this happens, be sure to seek engineering advise to ensure that the design is still within compliance with the applicable standards and specifications.

- See Articles - List of Tags / List of Categories / List of Articles / List of Glossaries / Nomenclature and Symbols / (See Pipe Flange Glossary)

Pipe Flange Datasheets | |

|---|---|

| Pipe Flange Type | Datasheets |

| Flange | All Flanges, ANSI (in) |

| Blind | Blind Flange, ANSI (in) |

| Ductile Iron | Ductile Iron Flange, ANSI (in) |

| Expander | Expander Flange, ANSI (in) |

| Flange Bolt | Flange Bolt, ANSI (in) |

| Lap Joint | Lap Joint Flange, ANSI (in) |

| Orifice | Orifice Flange, ANSI (in) |

| Slip-on | Slip-on Flange, ANSI (in) |

| Socket | Socket Flange, ANSI (in) |

| Standard Connection | Standard Connection Flange, ANSI (in) |

| Studded Outlet | Studded Outlet Flange, ANSI (in) |

| Threaded | Threaded Flange, ANSI (in) |

| Weld Neck | Weld Neck Flange, ANSI (in) |

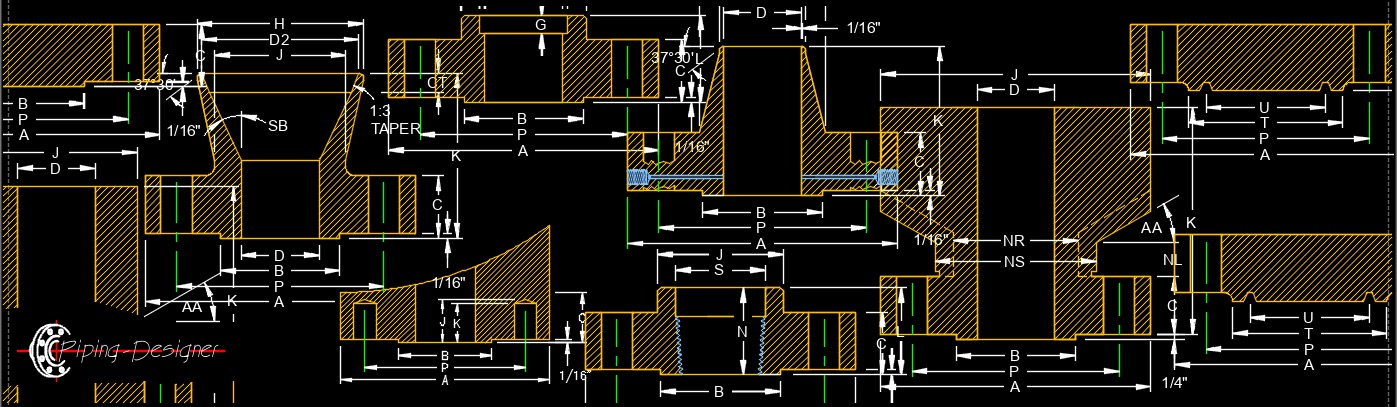

Pipe Flange Types

There are six basic types of flanges and are described by the way the connect to the piping system. Click on the links below to be taken to a page detailing the different types of flanges.

- Blind Flange - These flanges do not have a bore. It is used to blind off a flange or even a valve. When used at the end of a pipe or fitting, it provides an easy to open access for further extension of the pipe. The blind flange and its bolts are stressed more than any other flange.

- Lap Joint Flange - This flange is used with a lap joint stub end fitting. It is similar to a slip-on flange, but with two differences. The radius and the flat face, both allow the flange to secure against the stub end fitting. This is useful where alignment of bolt holes is difficult, such as with spools to be attached to flanged nozzles of vessels. A lap joint is used in low pressure applications and not suitable where high external of heavy loads are present.

- Slip-on Flange - Slip-on flanges are designed to slip over the outside of pipe, long-tangent elbows, reducers, and swages. The flange has poor resistance to shock and vibration. It is easier to align than a weld neck flange. This flange is ideal for low pressure applications since the strength when under internal pressure is about one third that of a weld neck flange.

- Socket Weld Flange - This is similar to a slip-on flange, except they have a bored and counter bore. The counter bore allows the pipe to fit into the socket/counter bore. The bore of the flange is the same diameter as the inside of the pipe. These flanges were first designed for small diameter, high pressure pipe.

- Threaded Flange - It is similar to a slip-on Flange, but has internal threads. It is normally used for low pressure and not used where temperature or stress is very high.

- Weld Neck Flange - This flange comes in two types, regular and long. The hub of the weld neck is designed to reduce the stress at the base of the flange. Regular weld neck flanges are used with buttweld fittings and long weld neck flanges are usually used with equipment and vessel nozzles. A long weld neck flange is rarely used with pipe. Both types of flanges are bored to match the inside diameter of the pipe or fitting to which it will be welded to. They are suitable where high pressure, extreme temperatures, shear impact and vibratory stresses apply.

Specialty Pipe Flange Types

- Orifice Flange - Orifice flanges are for metering the volumetric flow rate of liquids and gasses through a pipe. This flange is normally available in weld neck, slip-on, and threaded flanges.

- Standard Connection Flange - This flange is normally used for nozzles on pressure vessels and rarely used with pipe.

- Expander Flange - An expander flange is similar to a weld neck flange but with the hub expanding to a larger size (one or two sizes).

- Reducing Flange - Reducing flanges are designed for when there is a change in the pipe size.

- Studding Outlet Flange: Flat Bottom Mount - Shell/Head Mount - Tangential Mount - These flanges have shaped welded ends to match a tank or vessel.

- Weldoflange / Nipoflange - A weldoflange is an olet connection, it is simular to a nipoflange, both are used for a branch connection on a pipe.

Pipe Flange Classes

Only the most used flange classes are listed on this page. For more information on flanges and their respective standards, please follow the link below.

Pipe Flange Pressure Classes

Flanges are normally manufactured in seven basic ratings: 150 Lb, 300 Lb, 400 Lb, 600 Lb, 900 Lb, 1500 Lb and 2500 Lb. The ratings can be expressed in different ways but mean the same thing - 150 Lb, 150 Lbs, 150# or Class 150.

Each class of flange can handle more pressure than the previous class because of its construction. The higher the class is, the thicker the metal is. Thus a higher pressure can be handled. There a numerous factors that can affect the pressure capability of a flange, such as the type of metal that is used.

Pipe Flange Facing

There are three primary types of flange facings. Not all facings are available with each end connection. This is based on the design of the flange and design of the piping system. The typical flange facings are:

Raised Face Flange (RF)

Flat Face Flange (FF)

Ring Type Joint Flange (RTJ)