Butterfly Valve Datasheets

Face to face dimensions for full and standard port valves is the same. All ball valves 2" and below are both standard and full port valves. |

|---|

| Butterfly Type | Datasheets | Butterfly Type | Datasheets |

|---|

|

- Butterfly Valves, Wafer, Lug, Flange

|

|

- Butterfly Valves, Triple-offset

|

A butterfly valve, abbreviated as BTFLV, is a quarter turn valve (90° or less) with a circular disk as its closing element. The standard design has the valve stem running through the disk, giving a symmetrical appearance. Other designs offset the stem. Advantages include less wear and tear on the disk and seats, and tighter shut-off capabilities. When space is limited, sometimes larger valves may use a hand wheel with a gear arrangement. Butterfly valves are rather easy to maintain. These valves are used for gases, liquids, slurries, powders, and vacuum.

There are Two Butterfly Valve Categories

Category A - Manufacturer's rated cold working pressure (CWP) butterfly valves, usually with a concentric disc and seat configuration. Sizes covered are NPS 2 to NPS 48 for valves having ASME Class 125 or Class 150 flange bolting patterns.

Category B - Pressure-temperature rated butterfly valves that have an offset seat and either an eccentric or a concentric disc configuration. These valves may have a seat rating less than the body rating. Sizes covered are NPS 3 to NPS 24 for Classes 150, 300, and 600.

Butterfly Valve Design Classification

Double Offset Butterfly Valve - This valve features the stem center deviated from the center of the disc and valve. With this structure, the valve disc can leave the valve seat quickly, greatly reducing unnecessary over compression and scraping between them. This structure also helps decrease the wearing process and prolongs the operational life of the valve.

Fire Tight Valve - When using valves in a service that may provide fuel to a fire, it is important to ensure that they are fire tight. Typically the seat in a soft seated fire tight valve contains a metal strip that will provide additional sealing should the seat be burnt or melted away. Fire tight valves can be found on fuel gas applications, VRU systems and in other flammable systems.

Flange Style Butterfly Valve - A butterfly valve with a flange on each end. These have a larger face to face dimension than the wafer and lug style butterfly valves and should not be used when there is limited space. These valves connect directly to the flanges by means of machine bolt to each side of the valve. If the valve torque is high or valve operations become too frequen, a manual flanged butterfly valves can be automated if need be.

High Performance Butterfly Valve - A valve in which the stem is not collinear to the disc centerline but rather offset from the center. The use of offset design helps to enhance uniform tight shut-off against the valve seat and also reduce wear due to friction. This valve can be used for shut-off and throttling fluid flow applications. This valve is made to handle different fluids from general fluid flow applications to viscous and corrosive fluids. The corrosive fluids can be gases or steam. High-performance butterfly valves are mostly of large sizes like 60 inch diameter.

Lug Style Butterfly Valve - Lug butterfly valves connect directly to the flanges by means of a lug or machine bolt. Since these are attached directly to the flanges, each length of pipe on either side of hte valve can be removed and replaced independant of the other. Unlike a wafer type butterfly valve, a lug style valve can serve as an end of the line valve. Lug style butterfly valves have the same face to face dimensions as a wafer style butterfly valve. The valves can be used for end of line service but a blind flange is always recommended. The valves are manufactured to be compatible with either pneumatic or electric actuation.

Triple Offset Butterfly Valve - The design eliminates the rubbing between the seat and seal ring through the flow path, reducing seat and seal wear and extending cycle life. They are used in applications similar to gate valves, where a metal seat is required, and tight shutoff and/or quarter-turn actuation is desired. Triple offset butterfly valves can open and close more quickly and can be frequently operated, even if there is an emergency shutoff. This valve has low torque and is recommended for both high and low temperature applications.

Wafer Style Butterfly Valve - Most wafer style butterfly valves are engineered with four holes that align with the connected pipeline. The valve is sandwiched between two flanges. The rubber valve seat creates a strong seal between the valve and flange connection. Unlike lug style butterfly valves, wafer style butterfly valves cannot be used as pipe ends or end of line service. The entire line must be shut down if either side of the valve requires maintenance. Wafer style butterfly valves are manufactured to be compatible with either pneumatic or electric actuation. Disc and seat material should be determined based on application and flow media.

Zero Offset Butterfly Valve - Concentric or rubber seated are other names for the zero-offset design. Zero offset means there is no offset by the stem of the valve. The valve seals via interference along the disc edge at the stem between the disc and the rubber seat.

-

Modulus

Modulus is a measuring quantity or parameter that expresses the magnitude or strength of a property rather than a direction. In science and engineering, it is used to indicate how strongly something responds to an influence, such as how resistant a material is to deformation or how large a mathematical quantity is in absolute terms. Depending on the context, modulus can refer to the stiffness of a material (as in elastic modulus), the absolute value of a number (as in mathematical modulus), or a constant that scales a physical response, but in all cases it conveys the idea of a standardized measure of intensity or magnitude.

Read more

-

Resultant

Resultant is a single vector that represents the combined effect of two or more individual vectors acting on a body or at a point. It shows the overall magnitude and direction of all the forces, velocities, or other vector quantities applied. In other words, the resultant is the vector sum of all the component vectors and can replace them without changing the physical effect on the system. For example, if several forces act on an object, the resultant force determines the object’s motion according to Newton’s laws. The process of finding the resultant involves combining the vectors using graphical or mathematical methods such as the parallelogram law, triangle law, or vector addition formulas.

Read more

-

Physics Glossary

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Angular Acceleration - Of an object is the rate at which the angle velocity changes with respect to time.

- Alternating Current - An electric current that reverses its direction over and over.

- Aerodynamics - How forces act on the way objects move through air.

- Acoustics - Studies the interactions of acustic waves with gas, liquid, and solid medias on a macro and micro level.

- Acceleration - The rate of change of velocity.

- Absolute Zero - The temperature at which all motion within molecules completely stops. Below absolute zero temperature does not exist. At this temperature nothing is in motion.

- Angular Displacement - The angle through which a body moves in a circular path.

- Angular Momentum - How much an object is rotating around a fixed point. The angular momentun of a body is equal to the mass of the body multiplied by the cross product of the position vector of the particle with its vertical velocity.

- Astrobiology - The search for life outside earth.

- Astrogeology - The geology of planets and their moons, astroids, comets, and meteorites.

- Astrometry - The percise measurement of where stars and other celestial bodies are positioned and move in space.

- Astronomy - Anything in the universe beyond earth.

- Astrophysics - The way our solar system and earth formed and the functions of planets and other celestrial bodies.

- Atmospheric Physics - The study of physics to the atmosphere; aerosols, clouds, and gasses, basically airborne particles, that surround the planetary bodies of the solar system.

- Atomic - The study of atoms as an isolated system of electrons and an atomic nucleus.

- Atomic Mass Unit - The unit of mass used to measure atoms and molecules.

- Atomic Number - Is equal to the number of protons in an atom's nucleus. The atomic number determines which element an atom is.

- Avogadro's Gas Law - When temperature and pressure are held constant, the volume of a gas is proportional to the number of moles of gas present.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Binding Energy - The energy required to break a nucleus into its constituent protons and neutrons or the energy equivalent released when a nucleus is formed.

- Biology (Biological) - The study of living organisms such as animals and plants.

- Biophysics - Studies the laws and principles in physics that describes patterns seen in biological systems.

- Black Hole - A point or extreme mass in spacetime with a radius, or event horizon, inside of which all electromagnetic radiation is trapped by gravety.

- Boyles Law - States that the volume occupied by a given mass of gas varies inversely with the absolute pressure if the temperature remains constant.

- Butterfly Effect - A name given to the extreme sensitivity of chaotic systems, in which small changes or disturbance lead to drastically different outcomes.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Chaos Theory - Deals with complex systems whose behavior is highly sensitive to slight change in conditions.

- Centrifugal Force - When a force pushes away from the center of a circle, but this does not really exist. When an object travels in a circle, the object always wants to go straight, but the centripetal force keeps the object traveling along an axis of rotation.

- Centripetal Force - The force that makes an object follow a curved path. Is a force generated when an object keeps traveling along a axis of rotation.

- Chemical Physics - The study of physics theories before modern physics.

- Chemistry (Chemical) - Uses techniques from atoms, molecular physics, and matter physics to study chemical processes from the point of view of physics.

- Classical - A division of physics that encompasses Classical Mechanics, Electromagnetism, Newton's Laws of Motion, and Thermodynamics.

- Classical Mechanics - The study of bodies in motion, including bodies that remain at rest.

- Climatology - Climate and how it changes over time.

- Condensation - A physical change of a substance from a gas phase to a liquid phase. Certain natural events cause condensation of water vapor in the atmosphere such as clouds, fog, and mist.

- Convection - Convection is the energy transfer of heat by air, water, or any other fluid to and object. It includes energy transferred by random molecular motion as well as energy transferred by the bulk motion of the fluid.

- Cosmology - The origin and eventual fate of the universe.

- Coulomb's Law - The magnitude of the electrostatic force between two electric charges.

- Current - The rate of flow of electricity in a circuit, measured in amperes.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Density - The ratio of the amount of matter in an object compared to its volume.

- Direct Current - An electric current that flows in only one direction.

- Displacement - The change in position.

- Dynamics - The relationships between different motions of objects and what affects them like force, mass, momentum and energy.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Econophysics - The economic system which are not subsets of energy and matter.

- Elasticity - Measures the stiffness of an elastic material. Elasticity can deform bodies and return to its original shape when the forces exerted are removed.

- Electric Field - An invisible space around a charged particle where an electric force is exerted on other charged particles, in tha same way as a magnetic field is the field of force that surrounds a magnet.

- Electrical Resistance - The property of opposing or reducing electric current.

- Electromagnetic Radiation - A wave that travels through space at the speed of light, consisting of an electrical field that periodically grows and dies, alternating with a magnetic field that periodically grows and dies.

- Electromagnetism - The basic forces of nature that determine the effect between energy and matter.

- Empirical - Refers to an approach or formula based on observation, experimentation, or real world data rather than deriving it from theoretical principles or first principles. Empirical models are developed by collecting and analyzing data to establish relationships between variables and make predictions or estimates.

- Energy - Never created or destroyed First Law of Thermodynamics, but it can be transferred from one object to another.

- Entropy - Measures the unavailable energy in a heat system.

- Escape Velocity - The minimum velocity required to leave a planet or moon or the minimum velocity to overcome the pull of gravity.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Field Theory - A theory that describes physical reality, including spacetime continuum, by means of the influence of a field, such as gravity on objects.

- Flowing Time - A view of spacetime that supports the truly temporal character of time as a fourth dimension and thus insists that flowing time is integral to the structure of reality.

- Fluid Dynamics - The motion in fluids for both liquids and gases.

- Force - The push or pull of an object resulting in a change from rest or motion.

- Freezing Point - The temperature at which a phase change of liquid to solid takes place.

- Friction - The mechanical resistance to the relative movement of two surfaces. The frictional force on each body is in an opposite direcrion to the motion of the other body.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Galaxy - A large collection of stars, gasses, and dust that are part of the universe bound togeather by gravitational forces.

- Gamma Ray - A form of electromagnetic radiation produced by some kinds of radioactive decay.

- Gas - Able to be compressed to fit a confined space and expanded when released.

- General Relativity - Space-time tells matter how to move, matter tells space-time how to curve.

- Geomagnetism - The origin and nature of the earth's magnetic field.

- Geophysics - The physical properties and dynamics of the earth and planets.

- Gravity - A force pulling togeather all matter.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Heat - A form of energy that causes physical change in what is being heated. The lack of heat is cold. This physical change comes from total amount of internal energy (kinetic energy and potential energy) possessed by an object or substance.

- Hydrodynamics - The motion of fluids and the way different forces affect their movement.

- Hydrology - The study of water in the environment.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Ice point - A transitional phase of a substance from a liquid to a solid.

- Internal Energy - The total of all energies associated with the motion of the molecules in the system.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Kinematics - Studies the trajectory of particles or bodies and does not take into account the mass of each particle in the system. Can be considered a branch of mathmatics.

- Kepler's First Law - The orbit of every planet is an ellipse with the sun at one of the two foci.

- Kepler's Second Law - A line joining a planet and the Sun sweeps out equal areas during equal intervals of time.

- Kepler's Third Law - The square of the orbital period of a planet is directly proportional to the cube of the semi-major axis of its orbit.

- Kinetic Energy - The energy in moving objects or mass. If it moves, it has kinetic energy.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Latent Heat - The energy absorbed or released by a substance during a constant temperature or phase change from a solid to liquid, liquid to gas or vise versa.

- Law of Conservation of Energy - States that energy cannot be created or destroyed, but may be changed from one form to another.

- Law of Conservation of Mass - States that matter can neither be created or destroyed. You can mix, separate or rearrange, but the total amount of mass remains the same.

- Law of Conservation of Matter - States that the mass of an object or collection of objects never changes over time, even when the matter changes form.

- Law of Conservation of Momentum - States that momentum only moves from one place to another, since it is neither created or destroyed.

- Light - The electromagnetic radiation of a wavelength that is visibal to the human eye. Light travels at a constant speed of about 300,000 kilometers per second.

- Light Year - The distance that light travels in one year, given that light travels at a constant speed of about 300,000 kilometers per second, works out to about 9,461,000,000,000 kilometers (5.879,000,000,000 miles).

- Longitudinal Stress - The stress imposed on the long axis of any shape. It can be either a compressive or tensile stress.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Magnetic Field - Magnetic fields never cross, never start or stop, where the field is strongest lines bunch togeather and can be seen clearly seen in the real world.

- Mass - The amount of matter an object has.

- Mathematical - Applies mathematical ideas to problems in physics or inspired by physics.

- Matter - When you look around, everything you see or may not see in the universe is made up of matter. If it has a mass and takes up space, it is matter.

- Meterology - A study of air polution, analysis and forcasting, atmospheric chemistry, atmospheric dynamics, climatology, global climate, meteorological instruments, and oceanography.

- Moment of Inertia - Measures the resists or change an object has to rotational acceleration about an axis.

- Momentum - The amount of mass in motion of an object.

- Motion - The acceleration, displacement, or velocity of an object relative to a given frame of reference.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Natural Selection - The process by which individuals' inherited needs and abilities are more or less closely matched to resources available in their evironment, giving those with greater fitness a better chance of survival and reproduction.

- Nuclear - Understand the properties of all different forms of nuclear matter.

- Nuclear Fission - The process by which an atomic nucleus splits into two or more large fragments of comparable mass, simuitaneously producing addititional neutrons and vast amounts of energy.

- Nuclear Fusion - The process by which two lighter atomic nuclei combine at extremely high temperatures to form a heavier nucleus and release vast amounts of energy.

- Nuclear Physics - Studies the building blocks and interactions of atomic nuclei.

- Nucleus - The center region of an atom where protons and neutrons are located.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Oceanography - The biological and physical condition of the ocean.

- Omega - Greek for ending or last.

- Optics - The properties and behavior of light and the reaction between energy, light, and matter.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Particle Physics - Understanding the basic forces of nature, like matter and radiation and their interaction.

- Physical Properties - These are the properties that are not mechanical properties, they are relate to the physics of a material such as thermal expansion, boiling point, color, ect.

- Plank Energy - The super-high energy (approximately \(1.22\;x\; 10^{19}\) GeV) at which gravity becomes comparable in strength to the other fundamental forces, and at which the quantum effects of gravity becomes important.

- Plank Length - The fantastically tiny length scale (approximately \(1.6\;x\; 10^{-35}\) meters) at which gravity becomes comparable in strength to the other fundamental forces.

- Plank Temperature - The temperature of the universe at 1 plank time after the big bang, approximately equal to \({1.4\;x\;10^{32} }\; {^\circ C} \).

- Plank Time - The time it would take a proton traveling at the speed of light to cross a distance equal to the plank length.

- Plasma - Plasma is the four phase of matter. It is everywhere in the universe and the most common of all matter. Of all types of matter it is closest to a gas.

- Plasma Physics - The study of plasma.

- Power - The rate of doing work or the rate of using energy per unit time.

- Pulsar - A highly-magnetized rapidly-rotating neutron star that sweeps regular pulses of intense electromagnetic radiation around space like a lighthouse.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Quantum - The study of how everything works at the molecular and smaller levels.

- Quantum Mechanics - Deals with atomic and sub-atomic particles.

- Quantum Physics - Deals with the physical phenomena, where the action is on the order of the Planck constant.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Redshift - The shifting of emitted electromagnetic radiation towards the less energetic red end of the electromagnetic spectrum when a light source is moving away from the observer.

- Relativity - The relationship between energy, matter, space, time, and velocity.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Saturated Air - Air in which equilibrium exists between evaporation and condensation. The relative humidity is 100 percent.

- Saturated Solution - The apparent limit to dissolving a given solid in a specified amount of water at a given temperature.

- Seismology - The study of seismic waves, earthquakes, and the mechanics of soil and rock materials.

- Shear Stress - Tends to deform the material by breaking rather than stretching without changing the volume by restraining the object.

- Solar Mass - The quantity equal to the mass of the sun.

- Solar System - A star and all the planets and other bodies that orbit it.

- Solid-state - Deals with the phisical properties of solids, especially in the electric and magnetic properties of solid crystalline materials like semiconductors.

- Sound and Oscillation - Sound is usally caused by the process in which energy is emitted as particles or waves from a soild vibrating surface or fluid disturbance.

- Space-time - Describes the fabric of reality. A conceptual model combining the three dimensions of space with the fourth dimension of time.

- Special Relativity - Motion warps space and time.

- Specific Heat - The amount of heat required to raise the temperature of a material 1 degree.

- Speed - The rate of change or distance with time. Speed is a scalar quantity having no direction. Speed is not velocity, they do not mean the same thing.

- Speed of Light - Travels at a speed of exactly 299,792,458 meters per second, or about 300,000 kilometers per second, a speed which remains constant irrespective of the speed of the source of the light or of the observer.

- Statistical Mechanics - Studies any physical system that has a large number of degrees of freedom.

- Stefan-Boltzmann Law - Describes the power radiated from a black body, an ideal black surface that absorbs all radiant energy falling on it, in terms of temperature.

- Stiffness - The resistance of the elastic deformation of an object that applies to both compression and tension.

- Sublimation - A physical change of a substance from a solid phase to a gas phase and does not pass through the transitional liquid phase.

- Sun - The closest star to earth and the center of out solar system.

- Supernova - A cataclysmic explosion caused by the collapse of an old massive star which has used up all its fuel.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Temperature - Normally described as the amount of heat or cold, but it is neither heat or cold.

- Thermal Expansion - The increase in length, area or volume due to the increase (in some cased decrease) in temperature.

- Thermodynamics - How heat relates to energy and work.

- Time - A measurement to define a continuous series of events.

- Time Dilation - The slowing of time in a frame of reference moving at nearly the speed of light relatives to an observer.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Uniform Acceleration - When the velocity of a body increases by equal amounts, in equal intervals of time.

- Uniform Speed - When a body travels an equal distance, in equal intervals of time.

- Uniform Velocity - When a body travels along a straight line in a particular direction and covers equal distances, in equal intervals of time.

- Universe - The total sum of all matter and energy that exists.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Velocity - The rate of change or displacement with time.

- Vibration - A back and forth motion that repeats itself.

- Volcanology - The activities and history of volcanos.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Weight - Weight is not mass. Weight is a force on an object accelerated by gravity.

- Work - The overcoming of resistance through space and is the measure of force x distance.

- White Hole - The theoretical time reversal of a black hole, which arises as a valid solution in general relativity.

- Wormhole - A hypothetical tunnel through spacetime that connects widely distant regions, thus providing a kind of short-cut through spacetime.

- A - B - C - D - E - F - G - H - I - J - K - L - M - N - O - P - Q - R - S - T - U - V - W - X - Y

- Young's Modulus - Measures the stiffness of an elastic material. The ratio of the longitudinal stress applied to a body or substance to the resulting longitudinal strain within the elastic limits.

Read more

-

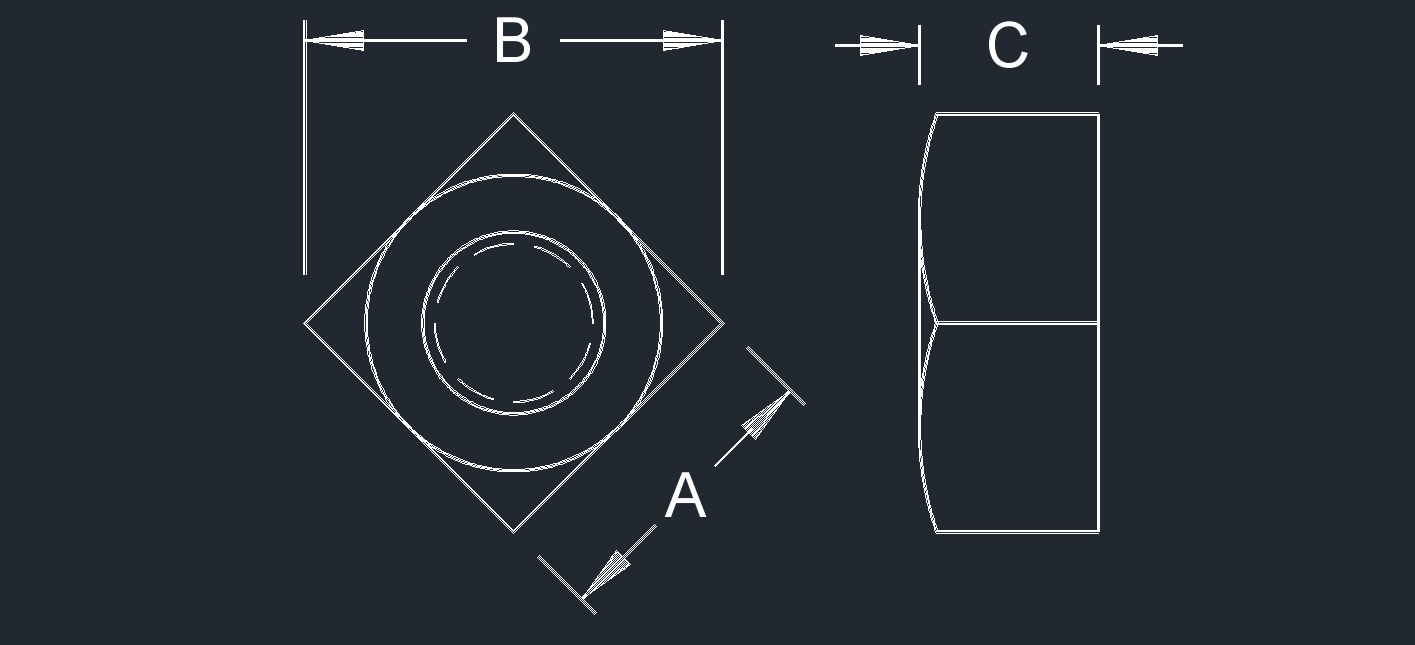

Bolt - Square, ANSI (in)

ASME Standards

Length (L) of a square bolt is measured from underside of head to the end of the bolt.

|

|

|

|

Bolt

Size

|

Body Diameter

D

|

Width Across Flat

A

|

Width Across Corner

B

|

Thickness

C

|

|---|

|

Max

|

Min

|

Basic

|

Max

|

Min

|

Max

|

Min

|

Basic

|

Max

|

Min

|

|---|

|

1/4

|

0.260

|

0.237

|

7/16

|

0.375

|

0.362

|

0.530

|

0.498

|

7/32

|

0.188

|

0.156

|

|

5/16

|

0.324

|

0.298

|

1/2

|

0.500

|

0.484

|

0.707

|

0.665

|

17/64

|

0.220

|

0.186

|

|

3/8

|

0.388

|

0.360

|

5/8

|

0.562

|

0.544

|

0.795

|

0.747

|

21/64

|

0.268

|

0.232

|

|

7/16

|

0.452

|

0.421

|

3/4

|

0.625

|

0.603

|

0.884

|

0.828

|

9/32

|

0.316

|

0.278

|

|

1/2

|

0.515

|

0.482

|

13/16

|

0.750

|

0.725

|

1.061

|

0.995

|

7/16

|

0.348

|

0.308

|

|

5/8

|

0.642

|

0.605

|

1

|

0.938

|

0.906

|

1.326

|

1.244

|

35/64

|

0.444

|

0.400

|

|

3/4

|

0.768

|

0.729

|

1 1/8

|

1.125

|

1.088

|

1.591

|

1.494

|

21/32

|

0.524

|

0.476

|

|

7/8

|

0.895

|

0.852

|

1 5/16

|

1.312

|

1.269

|

1.856

|

1.742

|

49/64

|

0.620

|

0.568

|

|

1

|

1.022

|

0.976

|

1 1/2

|

1.500

|

1.450

|

2.121

|

1.991

|

7/8

|

0.684

|

0.628

|

|

1 1/8

|

1.149

|

1.098

|

1 11/16

|

1.688

|

1.631

|

2.386

|

2.239

|

1

|

0.780

|

0.720

|

|

1 1/4

|

1.277

|

1.223

|

1 7/8

|

1.875

|

1.812

|

2.652

|

2.489

|

1 3/32

|

0.876

|

0.812

|

|

1 3/8

|

1.404

|

1.345

|

2 1/16

|

2.062

|

1.994

|

2.917

|

2.738

|

1 13/64

|

0.940

|

0.872

|

|

1 1/2

|

1.531

|

1.470

|

2 1/4

|

2.250

|

2.175

|

3.182

|

2.986

|

1 5/16

|

1.036

|

0.964

|

Read more

-

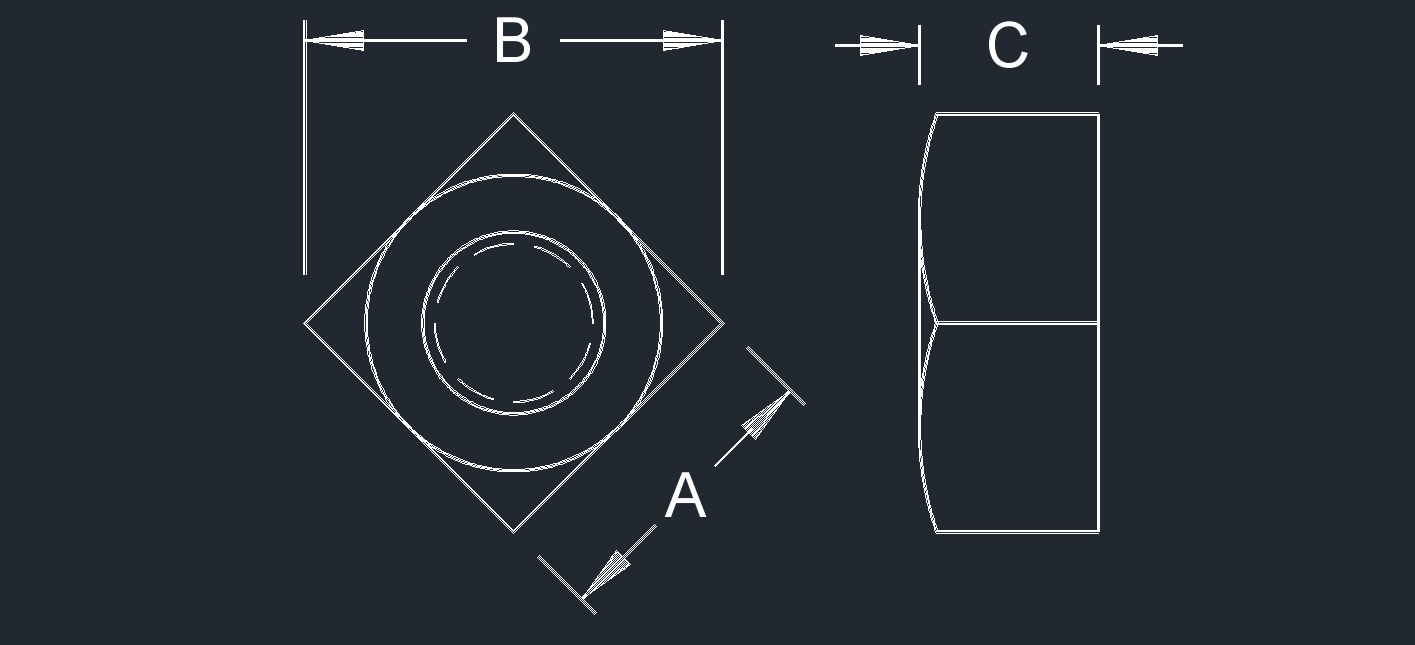

Square Nut (in)

Standard

- ASME Standards

- ASME B18.2.2 - Square and Hex Nuts

Square Nut (in) Datasheet

| Bolt

Size

| Width Across Flat

A

| Width Across Corner

B

| Thickness

C

|

|---|

| Basic | Max | Min | Max | Min | Basic | Max | Min |

|---|

| 1/4 |

7/16 |

0.438 |

0.428 |

0.619 |

0.554 |

7/32 |

0.235 |

0.203 |

| 5/16 |

1/2 |

0.500 |

0.489 |

0.795 |

0.721 |

17/64 |

0.283 |

0.249 |

| 3/8 |

5/8 |

0.625 |

0.606 |

0.884 |

0.802 |

21/64 |

0.346 |

0.310 |

| 1/2 |

13/16 |

0.812 |

0.788 |

1.149 |

1.052 |

7/16 |

0.458 |

0.418 |

| 5/8 |

1 |

1.000 |

0.969 |

1.414 |

1.300 |

35/64 |

0.569 |

0.525 |

| 3/4 |

1 1/8 |

1.125 |

1.088 |

1.591 |

1.464 |

21/32 |

0.680 |

0.632 |

| 7/8 |

1 5/16 |

1.312 |

1.269 |

1.856 |

1.712 |

49/64 |

0.792 |

0.740 |

| 1 |

1 1/2 |

1.500 |

1.450 |

2.121 |

1.961 |

7/8 |

0.903 |

0.847 |

| 1 1/8 |

1 11/16 |

1.688 |

1.631 |

2.386 |

2.209 |

1 |

1.030 |

0.970 |

| 1 1/4 |

1 7/8 |

1.875 |

1.812 |

2.652 |

2.458 |

1 3/32 |

1.126 |

1.062 |

| 1 3/8 |

2 1/16 |

2.062 |

1.994 |

2.917 |

2.708 |

1 13/64 |

1.237 |

1.169 |

| 1 1/2 |

2 1/4 |

2.250 |

2.175 |

3.182 |

2.956 |

1 5/16 |

1.348 |

1.276 |

Read more

Butterfly Valve Advantages and Disadvantages

|

|---|

| Advantages | Disadvantages |

|---|

- Easy to install.

- The installation costs are low.

- Simple structure, small volume and light weight.

- The opening and closing time is short and the flow resistance is small.

- The opening and closing torque is small, because the butterfly plates on both sides of the rotating shaft are basically equal to each other under the action of medium, and the direction of torque is opposite, so it is easier to open and close.

- When the valve seat is fully open, the effective flow area of the valve seat channel is large and the fluid resistance is small.

- The sealing surface materials are generally rubber and plastic, so the low-pressure sealing performance is good.

- It can be used for media with suspended solid particles, and can also be used for powdery and granular media, depending on the strength of the sealing surface.

- It can be applied to the two-way opening and closing and adjustment of ventilation and dust removal pipelines.

- Widely used in pipelines, waterways, light industry, and petrochemical systems.

- Butterfly valves can transfer mud with a little fluid deposit in the outlet of the pipe.

|

- The flow adjustment range is small. When the opening is up to 30%, the flow rate will be nearly 95% or more.

- Due to the limitation of the structure and the sealing material, butterfly valve is not suitable for use in high temperature and pressure piping systems.

- The sealing performance is relatively poor compared to ball valves and globe valves, so it is not used for sealing requirements.

- Prone to cavitation at lower flows.

- When butterfly valves are used, throttling is limited to low pressure drop systems.

- A part of the butterfly disc is always facing the flow, even if it’s completely open.

|